Operating Instructions

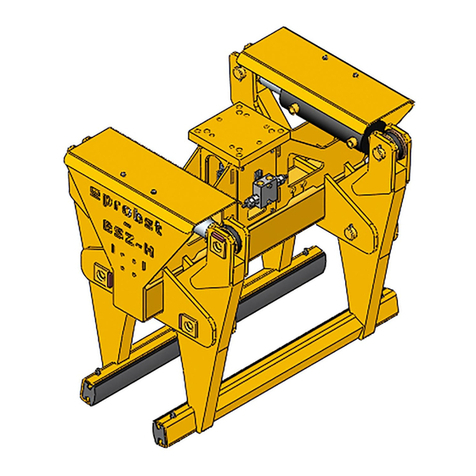

SRZ-M

1Contents

1Contents ................................................................................................................................................................. 2

2EC-Declaration of Conformity ............................................................................................................................... 3

3Safety...................................................................................................................................................................... 4

3.1 Safety symbols................................................................................................................................................4

3.2 Explanation of basic concepts .......................................................................................................................4

3.3 Definition skilled worker / specialist ..............................................................................................................4

3.4 Safety Marking................................................................................................................................................ 5

3.5 Personal safety requirements ........................................................................................................................6

3.1 Protective equipment.....................................................................................................................................6

3.2 Accident prevention .......................................................................................................................................6

3.3 Function Control.............................................................................................................................................6

3.3.1 General .........................................................................................................................................................6

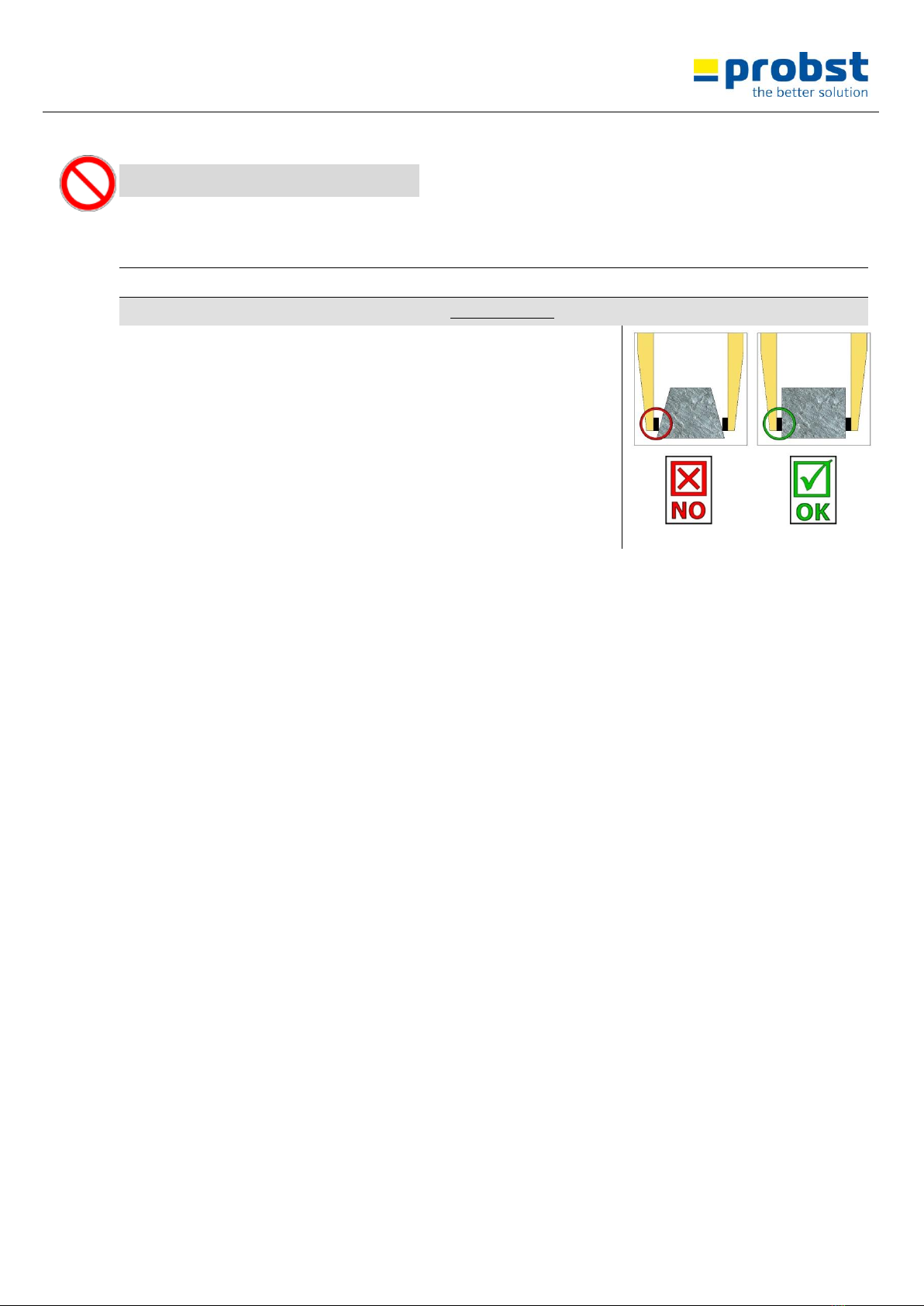

3.4 Safety procedures .......................................................................................................................................... 7

3.4.1 General ......................................................................................................................................................... 7

3.5 Hydraulic excavator and other support frames ............................................................................................ 7

3.6 General ............................................................................................................................................................8

4Authorized use ....................................................................................................................................................... 8

4.1 Survey and construction .............................................................................................................................. 10

4.2 Technical data ............................................................................................................................................... 10

4.3 Installation ..................................................................................................................................................... 11

4.4 Mechanical connection ................................................................................................................................. 11

4.5 Suspension lug............................................................................................................................................... 11

4.5.1 Load hook and chains ................................................................................................................................. 11

5Operation and Adjusting ...................................................................................................................................... 12

5.1 Adjustment gripping range ...........................................................................................................................12

5.2 Adjustment handle ........................................................................................................................................12

5.3 One-man operation .......................................................................................................................................13

5.4 Maintenance and care ...................................................................................................................................14

6Maintenance..........................................................................................................................................................14

6.1 MECHNICAL ...................................................................................................................................................14

6.2 Trouble shooting ...........................................................................................................................................15

6.3 Repairs ...........................................................................................................................................................15

6.4 Safety procedures ........................................................................................................................................ 16

6.1 Hints to the identification plate....................................................................................................................17

6.2 Hints to the renting/leasing of PROBST devices ..........................................................................................17