PROCRAFT 512000 User manual

512000

AC/DC 200AMP INVERTER

PULSE TIG / MMA WELDER

WARNING!

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions listed below may result

in electric shock, re, and/or serious injury.

SAVE THESE INSTRUCTIONS

Keep this manual for the safety warnings and precautions,

assembly, operating, inspection, maintenance and

cleaning procedures. Write the product’s serial number

in the back of the manual (or month and year of purchase

if product has no number). Keep this manual and the

receipt in a safe and dry place for future reference.

OPERATING INSTRUCTIONS

PROCRAFT

Page 2

CONTENTS

Safety warnings ............................................................................................................3

Description of this welder ............................................................................................9

Table of technical Parameters....................................................................................10

Description of the panel function ...............................................................................11

Protection against overheating ................................................................................. 13

Welding with elementary electrodes (MMA method)............................................... 13

Welding with a non-combustible electrode in an inert gas shield (TIG method).... 14

Welding with remote control..................................................................................... 16

Routine maintenance ................................................................................................. 17

Precautions before repairs......................................................................................... 18

Precautions or preventive measures ......................................................................... 19

Troubles may be encountered in welding.................................................................. 19

Trouble shooting ........................................................................................................ 21

Included Standar Accessories....................................................................................23

Page 3

SAVE THIS MANUAL

Keep this manual for the safety

warnings and precautions, assembly,

operating, inspection, maintenance and

cleaning procedures. Write the product’s

serial number in the back of the manual

near the assembly diagram (or month and

year of purchase if product has no

number). Keep this manual and the receipt

in a safe and dry place for future

reference.

IMPROTANT SAFETY INFORMATION

In this manual, on the labeling, and all

other information provided with this

product:

This is the safety alert symbol. It is

used to alert you to potential personal

injury hazards. Obey all safety

messages that follow this symbol to

avoid possible injury or death.

DANGER indicates a hazardous

situation which, if not avoided, will

result in death or serious injury.

WARNING: WARNING indicates a

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: CAUTION, used with

the safety alert symbol, indicates a

hazardous situation which, if not

avoided, could result in minor or

moderate injury.

NOTICE:NOTICE is used to

address practices not related to

personal injury.

SAFETY WARNINGS AND

PRECAUTIONS

WARNING: When using tool, basic safety

precautions should always be followed to

reduce the risk of personal injury and

damage to equipment.

Read all instructions before using this

tool!

Work Area Precautions

1. Keep your work area clean and well

lit. Cluttered benches and dark areas

invite accidents.

2. Do not operate power tools in

explosive atmospheres, such as in

the presence of flammable liquids,

gases, or dust. Power tools create

sparks which may ignite the dust or

fumes.

3. Keep bystanders, children, and

visitors away while operating a

power tool. Distractions can cause

you to lose control. Protect others in

the work area from debris such as

chips and sparks. Provide barriers or

shields as needed.

WARNING!

READANDUNDERSTANDALL

INSTRUCTIONS

Failuretofollowallinstructionslistedbelow

mayresultinelectricshock,fire,and/or

seriousinjury.

SAVETHESEINSTRUCTIONS

Page 4

Electrical Safety

1. Grounded tools must be plugged

into an outlet properly installed and

grounded in accordance with all

codes and ordinances. Never

remove the grounding prong or

modify the plug in any way. Do not

use any adapter plugs. Check with

a qualified electrician if you are in

doubt whether the outlet is properly

grounded. If the tool should

electrically malfunction or break down,

grounding provides a low resistance

path to carry electricity away from the

user.

2. Double insulated tools are

equipped with a polarized plug (one

blade is wider than the other). This

plug will fit in a polarized outlet

only one way. If the plug does not

fit fully in the outlet, reverse the

plug. If it still does not fit, contact a

qualified electrician to install a

polarized outlet. Do not change the

plug in any way. Double insulation

eliminates the need for the three wire

grounded power cord and grounded

power supply system.

3. Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges, and refrigerators. There is

an increased risk of electric shock if

your body is grounded.

4. Do not expose power tools to rain

or wet conditions. Water entering a

power tool will increase the risk of

electric shock.

5. Do not abuse the Power Cord.

Never use the Power Cord to carry

the tool or pull the Plug from an

outlet. Keep the Power Cord away

from heat, oil, sharp edges, or

moving parts. Replace damaged

Power Cords immediately.

Damaged Power Cords increase the

risk of electric shock.

6. When operating a power tool

outside, sue an outdoor extension

cord marker “W-A” or “W”. These

extension cords are rated for outdoor

use, and reduce the risk of electric

shock.

Personal Safety

1. Stay alert. Watch what you are

doing, and use common sense

when operating a power tool. Do

not use a power tool while tired or

under the influence of drugs,

alcohol, or medication. A moment of

inattention while operating power tools

may result in serious personal injury.

2. Dress properly. Do not wear loose

clothing or jewelry. Contain long

hair. Keep your hair, clothing, and

gloves away from moving parts.

Loose clothes, jewelry, or long hair

can be caught in moving parts.

3. Avoid accidental staring. Be sure

the Power Switch is off before

plugging in. Carrying power tools

with your finger on the Power Switch,

or plugging in power tools with the

Power Switch on, invites accidents.

4. Remove adjusting keys or

wrenches before turning the power

tool on. A wrench or a key that is left

attached to a rotating part of the power

tool may result in personal injury.

5. Do not overreach. Keep proper

footing and balance at all times.

Proper footing and balance enables

better control of the power tool in

unexpected situations.

6. Use safety equipment. Always wear

Page 5

eye protection. Dust mask, non-skid

safety shoes, hard hat, or hearing

protection must be used for

appropriate conditions.

Tool Use and Care

1. Use clamps (not included) or other

practical ways to secure and

support the workpiece to a stable

platform. Holding the work piece by

hand to against your body is unstable

and may lead to loss of control.

2. Do not force the tool. Use the

correct tool for your application.

The correct tool will do the job better

and safer at the rate for which it is

designed.

3. Do not use the power tool if the

Power Switch does not turn it on or

off. Any tool that cannot be controlled

with the Power Switch is dangerous

and must be replaced.

4. Disconnect the Power Cord Plug

from the power source before

making any adjustments, changing

accessories, or storing the tool.

Such preventive safety measures

reduce the risk of starting the tool

accidentally.

5. Store idle tools out of reach of

children and other untrained

persons. Tools are dangerous in the

hands of untrained users.

6. Maintain tools with care. Keep

cutting tools maintained and clean.

Properly maintained tools are less

likely to bind and are easier to control.

Do not use a damaged tool. Tag

damaged tools “Do not use” until

repaired

7. Check for misalignment or binding

of moving parts, breakage of parts,

and any other condition that may

affect the tool’s operation. If

damaged, have the tool serviced

before using. Many accidents are

caused by poorly maintained tools.

8. Use only accessories that are

recommended by the manufacturer

for your model. Accessories that may

be suitable for one tool may become

hazardous when used on another tool.

Service

1. Tool service must be performed only

by qualified repair personnel. Service

or maintenance performed by

unqualified personnel could result in a

risk of injury.

2. When servicing a tool, use only

identical replacement parts. Use of

unauthorized parts or failure to follow

maintenance instructions may create a

risk of electric shock or injury.

SPECIFIC SAFETY RULES

1. Maintain labels and nameplates on

the tool. These carry important

information. If unreadable or missing,

contact TOOLEX INDUSTRIAL for a

replacement.

2. Always wear the approved safety

impact eye goggles and heavy work

gloves when suing the tool. Using

personal safety devices reduce the

risk for injury. Safety impact eye

goggles and heavy work gloves are

available from Harbor Freight Tools.

3. Maintain a safe working

environment. Keep the work area

well lit. Make sure there is adequate

surrounding workspace. Always keep

the work area free of obstructions,

grease, oil, trash, and other debris. Do

not use a power tool in areas near

flammable chemicals, dusts, and

Page 6

vapors. Do not use this product in a

damp or wet location.

4. Avoid unintentional starting. Make

sure you are prepared to begin work

before turning on the tool.

5. Never leave the tool unattended

when it is plugged into an electrical

outlet. Turn off the tool, and unplug it

from its electrical outlet before leaving.

6. Always unplug the tool from its

electrical outlet before performing

and inspection, maintenance, or

cleaning procedures.

7. Prevent eye injury and burns.

Wearing and using the approved

personal safety clothing and safety

devices reduce the risk for injury.

a. Wear the approved safety impact

eye goggles with a welding helmet

featuring at least a number 10

shade lens rating.

b. Leather leggings, fire resistant

shoes or boots should be worn

when using this product. Do not

wear pants with cuffs, shirts with

open pockets, or any clothing that

can catch and hold molten metal

or sparks.

c. Keep clothing free of grease, oil,

solvents, or any flammable

substances. Wear dry, insulating

gloves and protective clothing.

d. Wear an approved head covering

to protect the head and neck. Use

aprons, cape, sleeves, shoulder

covers, and bibs designed and

approved for welding and cutting

procedures.

e. When welding/cutting overhead or

in confined spaces, wear flame

resistant ear plugs or ear muffs to

keep sparks out of ears.

8. Prevent accidental fires. Remove

any combustible material from the

work area.

a. When possible, move the work to

a location well away from

combustible; protect the

combustibles with a cover made of

fire resistant material.

b. Remove or make safe all

combustible materials for a radius

of 35 feet (10 meters) around the

work area. Use a fire resistant

material to cover or block all open

doorways, windows, cracks, and

other openings.

c. Enclose the work area with

portable fire resistant screens.

Protect combustible walls, ceilings,

floors, etc., from sparks and heat

with fire resistant covers.

d. If working on a metal wall, ceiling,

etc., prevent ignition of

combustibles on the other side by

mobbing the combustibles to a

safe location. If relocation of

combustibles is not possible,

designate someone to serve as a

fire watch, equipped with a fire

extinguisher, during the welding

process and for at least one half

hour after the welding is

completed.

e. Do not weld or cut on materials

having a combustible coating or

combustible internal structure, as

in walls or ceilings, without an

approved method for eliminating

the hazard.

f. Do not dispose of hot slag in

containers holding combustible

materials. Keep a fire extinguisher

nearby and know how to use it.

g. After welding or cutting, make a

thorough examination for evidence

of fire. Be aware that easily visible

smoke or flame may not be

Page 7

present for some time after the fire

has started. Do not weld or cut in

atmospheres containing

h. Dangerously reactive or

flammable gases, vapors, liquids,

and dust.

i. Provide adequate ventilation in

work areas to prevent

accumulation of flammable gases,

vapors, and dust. Do not apply

heat to a container that has held

an unknown substance or a

combustible material whose

contents, when heated, can

produce flammable or explosive

vapors. Clean and purge

containers before applying heat.

Vent closed containers, including

castings, before preheating,

welding, or cutting.

9. Avoid overexposure to fumes and

gases. Always keep your head out of

the fumes. Do not breathe the fumes.

Use enough ventilation or exhaust, or

both, to keep fumes and gases from

your breathing zone and general area.

!Where ventilation is questionable,

have a qualified technician take

an air sampling to determine the

need for corrective measures.

Use mechanical ventilation to

improve air quality. If engineering

controls are not feasible, use an

approved respirator.

!Work in a confined area only if it

is well ventilated, or while

wearing an air-supplied

respirator.

!Follow OSHA guidelines for

Permissible Exposure Limits

(PEL’s) for various fumes and

gases.

!Follow the American Conference

of Governmental Industrial

Hygienists recommendations for

Threshold Limit Values (TLV’s)

for fumes and gases.

!Have a recognized specialist in

Industrial Hygiene or

Environmental Services check

the operation and air quality and

make recommendations for the

specific welding or cutting

situation.

10. Always keep hoses away from

welding/cutting spot. Examine all

hoses and cables for cuts, burns, or

worn areas before each use. If any

damaged areas are found, replace the

hoses or cables immediately.

11. Read and understand all

instructions and safety precautions

as outlined in the manufacturer’s

WARNING

INHALATION HAZARD: Welding and

Plasma Cutting Produce

TOXIC FUMES.

Exposure to welding or cutting exhaust fumes

can increase the risk of developing certain

cancers, such as cancer of the larynx and

lung cancer. Also, some diseases that may be

linked to exposure to welding or plasma

cutting exhaust fumes are:

a. Early onset of Parkinson’s Disease

b. Heart disease

c. Ulcers

d. Damage to the reproductive organs

e. I

nflammation of the small intestine or

stomach

f. Kidney damage

g.

Respiratory diseases such as

emphysema, bronchitis, or pneumonia

Use natural or forced air ventilation and wear

a respirator approved by NIOSH to protect

against the fumes produced to reduce the risk

of developing the above illnesses.

Page 8

Manual for the material you will

weld or cut.

12. Proper cylinder care. Secure

cylinders to a cart, wall, or post, to

prevent them from falling. All cylinders

should be used and stored in an

upright position. Never drop or strike a

cylinder. Do not use cylinders that

have been dented. Cylinder caps

should be used when moving or

storing cylinders. Empty cylinders

should be kept in specified areas and

clearly marked “empty.”

13. Never use oil or grease on any

inlet connector, outlet connector,

or cylinder valves.

14. Use only supplied Torch on this

Inverter Air Plasma Cutter. Using

components from other systems may

cause personal injury and damage

components within.

15. People with pacemakers should

consult their physician(s) before using

this product. Electromagnetic fields in

close proximity to a heart pacemaker

could cause interference to, or failure

of the pacemaker.

16. USE PROPER EXTENSION

CORD.

Make sure your extension cord is in

good condition. When using an

extension cord, be sure to use one

heavy enough to carry the current your

product will draw. An undersized cord

will cause a drop in line voltage

resulting in loss of power and

overheating. We recommend that a

15amp extension cord be used with

the 1.5mm2 cable. The following

Toolex Industrial Extension Leads

would be suitable 594530 10 metre,

594531 20 metre & 594532 30

metre.

Page 9

- 3 -

2. Description of this welder

The welder adopts rectifier designed with advanced inverter technology.

The advent of inverter arc welding machine derives from inverter power theory and devices.

The inverter arc welding power uses high-power device IGBT field-effect transistor to turn

the working frequency of 50/60Hz to high frequency (such as 100KHz or higher). Then voltage

is reduced and current is regulated. A powerful DC power source can be produced by using the

pulse width modulation (PWM)technology. The weight and volume of the main transformer of

the welder are reduced remarkably, and the efficiency is increased by 30%. The advent of

inverter welding machine is regard as a revolution of the welding machine industry.

This product is a dual-purpose machine composed of DC pulse argon arc welder and AC

argon arc welder, whose most important feature is a machine with multiple purposes, you can

achieve the welding for a various metal by a various ways without having to change machines.

DC pulse argon arc welding can achieve high-quality welding for the plate, various metals,

different thickness and double-sided forming process. AC argon arc welding adopts double-time

inverter techniques and a pure square wave output, making a feature of a good arc stiffness, heat

concentration, strong reverse cleaning capability, wide cleaning range and so on, to ensure the

welder good welding characteristics, suitable for welding aluminum and aluminum alloy

products.

We welcome friends from all walks of life to use the products and present valuable

suggestions to us. We’ll devote ourselves to providing customers with perfect products and

services.

Warning!

This equipment is mainly used in the industrial sector. In an indoor environment it may

produce radio jamming and operators should adopt adequate preventive measures.

Page 10

- 4 -

3. Table of technical Parameters

model

parameters 512000

Power voltage(V)1 PhaseAC240V±15%

Frequency (HZ)50

Rated input current (A)

TIG 25..7

MMA 34.9

Rated output voltage (V)

TIG 18

MMA 27.2

Rated output current(A)

TIG 200

MMA 180

No-load voltage(V)67

Arcing way HF

Pre-flow(S)0.1-1

Current descending time(S)1-10

Post flow time(S)1-15

Duty cycle (%)60

No-load loss(W)40

Efficiency (%) 80

Power factor 0.73

Insulation grade F

Housing protection grade IP21

weight(kg)25.3

Overall dimension(mm)548×252×534

Page 11

- 5 -

4. Description of the panel function

1 Abnormal indicator 14 pre flow knob

2 Remote control indictor 15 base current

3 current display 16 pulse frequency

4 TIG/MMA control switch 17 pulse duty

5 AC/DC control switch 18 post flow

6 AC frequency knob 19 pulse control switch

7 AC balance knob 20 TIG welding torch interface

8 2T/4T control switch 21 STICK welding interface

9 end amps knob 22 TIG welding torch switch/Remote

control socket

10 down slope knob 23 ground cable connector

11 welding current 24 Power supply input

12 up slope knob 25 Power switch

13 start current 26 Gas Inlet interface

Page 12

- 6 -

Start current - current appearing in the circuit after pressing the button in the grip handle. The higher

the initial current, the easier it is to ignite the arc. However, when welding thin sheets, too high an

initial current can lead to the burning of the sheet. In some welding modes, the current does not

increase in order to heat the welded element.

End current - current used in some welding modes, when the arc is not extinguished immediately

after the welding current sinking. It allows filling the crater and the end of the weld.

Base current - current responsible for maintaining the welding process, lower value of the current

pulse. It makes it easier to control the amount of heat entering the material. The adjustment of the

base current is only possible when the switch (19) is in the (central) position.

Pulse frequency - frequency with which the value of the current pulse between the welding current

and the base current changes. Pulse frequency adjustment is possible with the knob (16) in two ranges

- low 0.5 - 10 Hz with the switch (19) in the (upper) position and high 10 - 200 Hz with the switch

(19) in the (central) position. Setting the switch (19) to (lower) will result in welding without a pulse.

Pulse width - duration of the pulse, allows you to adjust the depth of the penetration. The increase in

width increases the penetration depth, the reduction reduces the amount of heat entering the material,

reducing the risk of burning thinner sheets or smaller elements.

Lower pulse width values should be used for higher currents. For example, a width of 30% should be

used for currents greater than 200A. The larger pulse width should be used for small currents, for

example, a width greater than 50% should be used for currents below 100A.

Gas pre-flow time - time from pressing a button in the grip handle until the arc is ignited. It should

normally be longer than 0.5 s to provide shielding gas to the nozzle tip outlet to cover the welding

start point and the tungsten electrode. In the case of a longer gas line from the cylinder, the pre-run

time should be longer.

Time of gas post-flow - time from extinction of the arc to closing the gas valve to shield the

solidifying weld pool from air and to cool the tungsten electrode. Too short time of outflow may

result in oxidation of the weld. When welding in AC TIG mode (AC), this time should be longer

Current rise time - time of welding current rise from the start current to the set welding current

value.

Time of current descent - time of welding current dropping from the value set to zero or the value of

the crater current.

AC current frequency - a function useful when welding aluminum. The higher the frequency, the

better the weld quality, the better the arc focus

AC Current Balance - The ratio of the duration of the positive to negative phase. The reduction of

the balance results in the introduction of more heat into the material, resulting in a narrower weld and

deeper penetration, and at the same time reduces the heat load of the tungsten electrode. Increasing

the balance results in the introduction of less heat into the material, resulting in better cleaning, a

broad joint and a shallower penetration, however, it significantly weighs the tungsten electrode.

Page 13

- 7 -

2T / 4T - modes of source operation control. In the 2T time, pressing the TIG torch button starts

welding, releasing the welding end button. In the 4T, pressing and releasing the button starts welding,

to finish it, press and release the button again. Four-stroke is mainly used when making long welds, as

it does not require holding the button on the handle during operation at all times.

5. Protection against overheating

The power source is equipped with a thermal, automatic overload switch. When the temperature of

the welding machine is too high, the protection will disconnect the welding current and the diode

signaling overheating will light (1). After the temperature has dropped, the breaker will be

automatically reset.

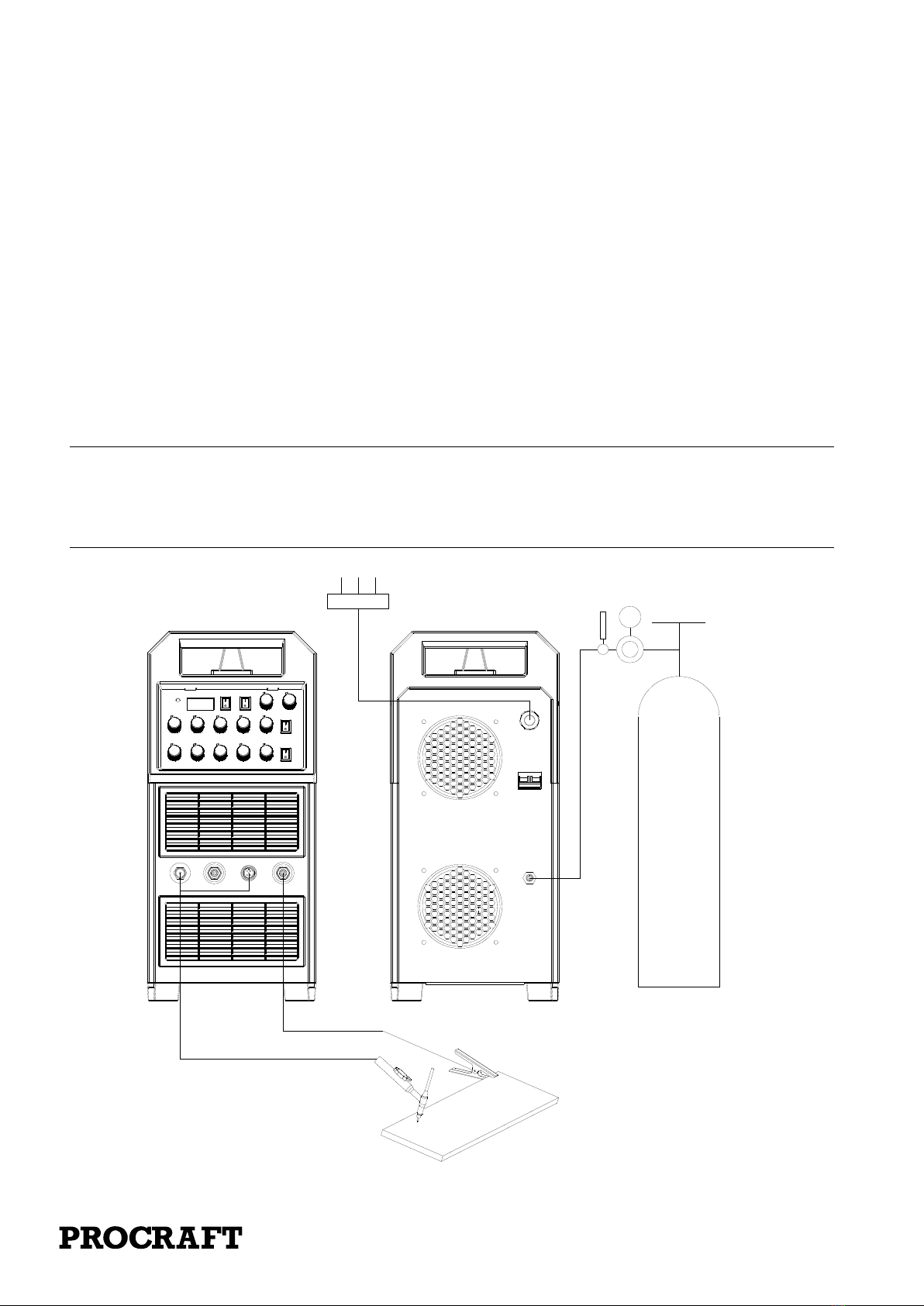

6. Welding with elementary electrodes (MMA methode)

6.1 Preparation of the device for work

Electrode holder

Earthclamp

Workpiece

Page 14

- 8 -

If the device is stored or transported in low temperatures, the device should be brought to the right

temperature before starting work !!!

The ends of the welding cables should be connected to the sockets (21) and (23) on the front panel, so

that the polarity of the electrode is on the electrode holder. The polarity of the welding cable

connection depends on the type of electrode used and is given on the electrode packaging. The clamp

of the return pipe should be securely attached to the welded material. Connect the device plug to the

115V/230V 60Hz mains socket. Switch on the device using the switch (25) on the back of the

welding machine.

6.2 Setting of welding parameters

The welding method switch (4) must be set to the MMA position. Turn the knob (11) to set the

desired welding current.

6.3 Arc initiation

Arc initiation during welding with the coated electrode consists in touching the electrode to the

welded material, short rubbing and detachment. In the case of arc initiation with electrodes, the

lagging of which forms a nonconductive slag after setting, it is necessary to pre-clean the top of the

electrode by repeated impact against a hard surface until metallic contact with the welded material.

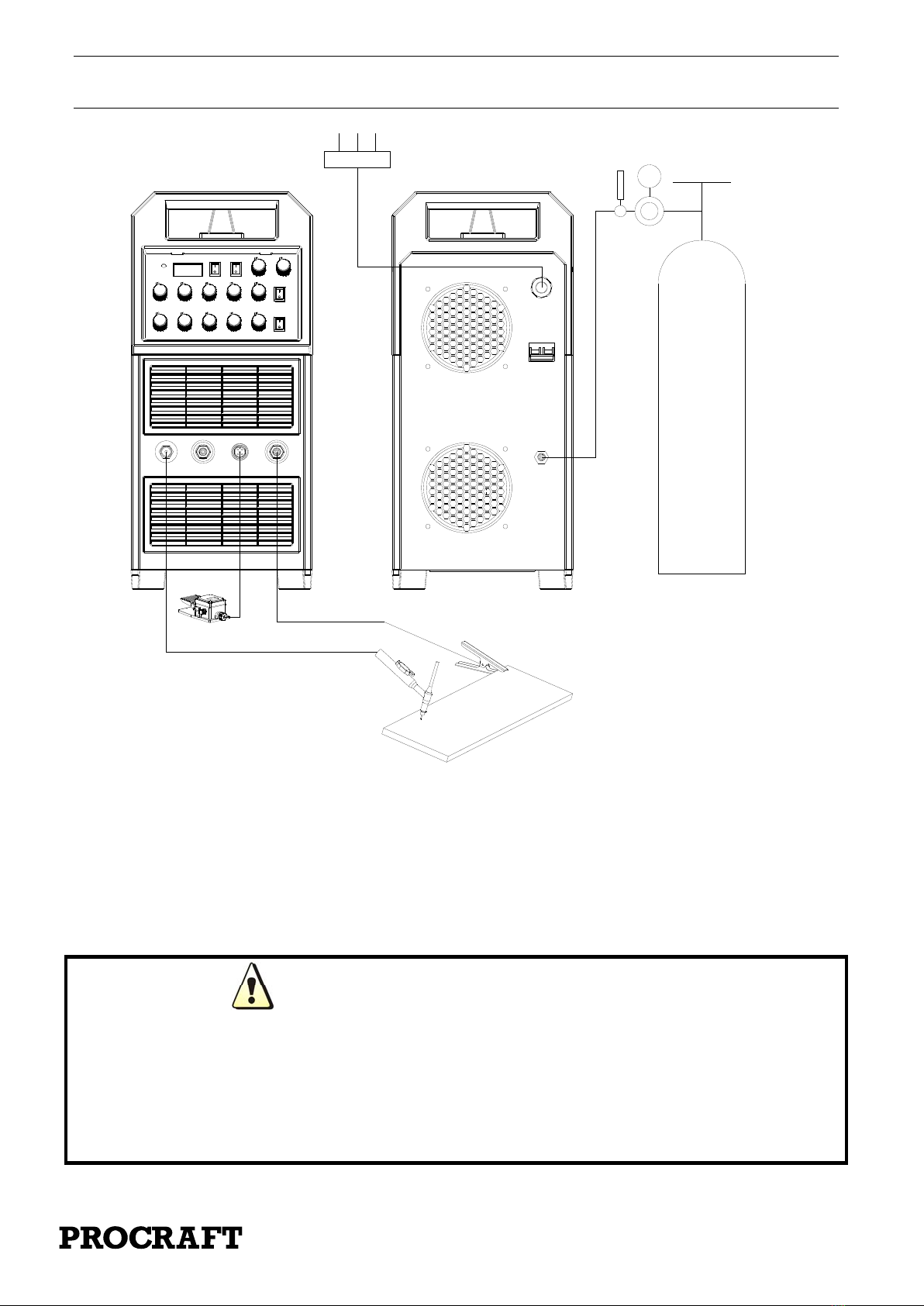

7. Welding with a non-combustible electrode in an inert gas shield (TIG

mothode)

groundclamp

workpiece

TIG weldingtorch

Gas

cylinder

Ar meter

Page 15

- 9 -

7.1. Connection of shielding gas

Secure the cylinder against tipping over. Unscrew the cylinder valve for a moment to remove any

contamination. Install the regulator on the cylinder. Connect the reducer hose to the welder by fitting

one end of the hose to the reducer connector and the other at the inlet connector (26) on the back of

the welding machine. Tighten the hose with the hose clamp. Open the cylinder and regulator valve.

7.2. Preparation of the device for work

If the device is stored or transported in low temperatures, the device should be brought to the right

temperature before starting work !!!

The TIG torch gas connector should be connected to the socket (20) and dinse plug should be

connected to the socket (21), the control plug of the torch should be carefully screwed to the control

socket (22), The gas pipe from the reducer should be led and secured to the gas connector (26) on the

back of the device. Connect the positive pole of the source with the material being welded using a

cable with a clamp. Connect the device plug to the 115/230V 60Hz mains socket. Switch on the

device using the switch (25) on the back of the welding machine.

7.3. Setting of welding parameters

7.3.1 Selecting the type of welding current

Set the welding current type with the switch (5). If you are going to use DC power, the switch should

be in the DC position and the AC should be AC.

7.3.2 Setting the welding current

The welding method switch (4) must be set to the TIG position. Turn the knob (13) to set the desired

start current value, turn the knob (12), the current rise time, the knob (11) the welding current value,

the knob (10) time of current descent, and the knob (9) the end current. In the case of alternating

current (AC) welding, the arc ignition is possible at a current of at least 20A.

7.3.3 Setting pulse parameters

Use the switch (19) to select the pulse rate range or non-pulse operation. In the case of pulse welding

with a knob (15) set the desired value of the base current, the knob (16) the pulse frequency, and the

knob (17) the duration of the current pulse

7.3.4 Setting of AC parameters

Turn the knob (7) to adjust the current balance. Turn the knob (6) to set the desired current frequency.

7.3.5 Setting gas flow parameters

Set the pre-flow time with the knob (14). Set the gas post-flow time using the knob (18).

7.3.6. Selecting the source control mode

Source control can be done in two-stroke or four-stroke mode. Select the source control mode using

the switch (8)

7.4. Arc initiation and welding process

The TIG 225 AC / DC pulse devices are equipped with an ionizer that allows contactless arc ignition.

To ignite the arc in the two-stroke mode, the electrode should be brought closer to the welded

material for a distance of 2 millimeters and press the button in the torch holder to activate the ionizer.

After correct arc initiation, carry out the welding with the button pressed. Releasing the button on the

handle causes the start of the current dropping phase and the end of the welding process.

In order to ignite the arc in the four-stroke mode, the electrode should be brought closer to the

material for 2 millimeters and press the button on the torch handle to activate the ionizer. After

correct arc ignition, the button can be released and the welding can be carried out with the button

released. To stop welding, press and release the button on the handle again.

Page 16

- 10 -

8. Welding with remote control

When the pedal switch is used to control, connect the 7-core aviation plug with the 7 socket.

The remote control green indictor(2) will be on, it is automatically recognized when you plug in,

adjust the knob(11) “Welding current”, it can set the maximum current when you press the foot

pedal to the maximum, the current display(3) will show the setting current. The digital display

shows the actual welding current when using foot pedal to control the welding.

WARNING !!

- During the welding of alternating current (AC) with low current values, the formation of oxides

on the surface of the tungsten electrode occurs. This can cause problems with arc ignition. In this

case, the electrode should be rubbed against the material being welded or otherwise mechanically

cleaned of the tip of the electrode from the oxide layer.

- Do not operate the button more than 2 mm from the welded material.

ground clamp

workpiece

TIGweldingtorch

Gas

cylinder

Ar meter

Page 17

- 11 -

- Do not touch the electrode while holding the button on the handle. The high voltage of the

ionizer and the unloaded voltage then occurring at the electrode can cause electric shock

9、Routine maintenance

Warning:

All the maintenance and repair jobs must be carried out when the power is cut-off

completely. Make sure the power plug is disconnected before opening the shell.

1Dust should be removed with dry and clean compressed air regularly. If the welder is used in a

heavily polluted environment with dense smoke and polluted air, dust must be removed from the

welder each month.

2The pressure of compressed air should be reasonable so that damage is not done to small elements

in the welder.

3Regularly check the connection of electric circuit in the welder and make sure circuit be

connected properly and joint is secured (especially inserted joint or element). If the cases of

rusting or loosening are found, the rust layer or oxidized film should be removed with abrasive

paper and then the joint should be connected again and tightened firmly.

4Entry of water or steam into the interior of the welder should be avoided. If this condition occurs,

the welder should undergo drying treatment. Then the welder is measured for insulation by a

megohm-meter (including the area between connecting points and the areas between the

connecting points and shell). Welding can go on only when evidence shows no abnormality.

5If the welder is not to be used for a long time, it should be replaced in the original package and

kept in a dry environment.

Page 18

- 12 -

10、Precautions before repairs

Warning

A haphazard experiment and imprudent repair may lead to expansion of fault area,

making formal repair more difficult. The exposed part of the welder in energization carries high voltage

that may lead to hazards and any direct or indirect touch with it will result in electric shock accident. In serious case

death may occur

If in the warranty period the user carries out an erroneous examination and repair of any fault in

the welding and cutting power without permission, the free maintenance warranty offered by the

supplier will be invalidated.

11、Precautions or preventive measures

1、Environment

1)Welding operation should be carried out in a relatively dry environment with air humidity usually

less than 90%.

2)Ambient temperature should be kept between -10C ~40C.

3)Welding in the sun or rain should be avoided and water or rainwater should never be seeped into

the welder interior.

4)Welding in the dusty area or under a corrosive gas environment should be avoided.

5)Gas protection welding operation in an environment with strong air flow should be avoided.

2、Essentials for safety

In this welder over-voltage, over-current and overheat protection circuits have been installed

beforehand. When the grid voltage, output current and machine temperature surpass the set

standards, the machine will stop automatically. But excessive use (for example, when the voltage

is too high) can still lead to the breakdown of the welder. So you have to pay attention to the

following items:

1)Good ventilation!

This machine is a small type welder. In operation a high working current flows in and natural

ventilation is unable to meet the welder’s requirement for cooling. So a fan is fitted to effectively

cool the welder to keep it work smoothly.

Operators should make sure that the vent is not covered or plugged, the distance of the welder

from its surrounding objects is not less than 0.3 m and good ventilation is kept all the time. All

Page 19

- 13 -

these are very important for better operation of the welder and longer service life of the welder.

2)No overload!

Operators should bear in mind that maximum permissible load current (relative to the selected

load duration factor) be observed at any time and welding current should never surpass the

maximum permissible load current.

Over-current will shorten the service life of the welder remarkably and even burn it down.

3)No over-voltage!

Power voltage is shown in the main performance parameter table. In general, the voltage

auto-compensation circuit in the welder will ensure the welding current remain within the

permissible range. If power voltage surpasses the permissible value, the welder will be broken

down. Operators should fully know this and adopt corresponding preventive measures.

4)Behind each welder there is a grounding screw with the grounding mark. Before operation the shell

of the welder should be grounded reliably by a cable wire with a sectional area bigger than 6mm2

so as to release static electricity or prevent any accident due to leakage.

5)If the welding machine exceeds the standard load duration factor in operation, it may probably go

into a protective state suddenly and stop work, which indicates it has exceeded the standard load

duration factor. Excessive heating triggers the temperature control switch and makes the welding

machine stop operation. Under such circumstances you needn’t turn off the power so that the

cooling fan may work continuously for cooling. When the temperature drops to the standard

range, welding may be restarted.

12、Troubles may be encountered in welding

Phenomena enumerated here may have something to do with the parts, gas, environmental factors

and power supply you use and efforts should be made in improving the environment to avoid

occurrence of such cases.

A、Black welding spot

——This shows the welding spot is oxidized without being protected effectively and you can

make the following inspection :

1. Make sure that the valve of argon cylinder has been opened with sufficient pressure. As a rule, if

the pressure within the cylinder is lower than 0.5MPa, then it is necessary to refill the cylinder.

2. Check if the argon flow-meter is turned on with sufficient flow. You can select different flow rates

in light of varying welding current, but too small flow may lead to inadequate gas stiffness and

thus failure to cover all the welded spots. We suggest argon flow should never be lower than

3l/min no matter how weak the current will be.

3. The easiest way to check gas delivery is to touch the nozzle of welding torch to see whether the

Page 20

- 14 -

gas passage of the welding torch is blocked.

4. Poor sealing of gas passage or lower gas purity will also give rise to welding quality trouble.

5. Strong air flow in the environment may also lead to deterioration of welding quality.

B、Difficulty in arc starting with easy arc breaking:

1. Make sure that the tungsten electrode in use is of good quality as discharge ability of inferior

tungsten electrode may fail the requirement;

2. Tungsten electrode without sharpening treatment is also unable to start arc and leads to unstable

arc.

C、Output current can’t reach the rated value:

Deviation of power voltage from the rated value will lead to unconformity of output current value

with the set value. When power voltage is lower than the rated value, maximum output current of the

welder may also be lower than the rated value.

D、Unstable current in the operation of the welder:

This may be attributed to the following factors:

1. Change in grid voltage;

2. Interference from the power grid or other power equipments.

E、:Severely burn of the tungsten needle

The duty cycle is adjusted too large, causing emission from the workpiece to the tungsten electron for

too long, resulting in severe heat of the tungsten needles.

F、The oxide film can’t be torn when welding aluminum:

1. the welding gear is selected wrong.

2. The duty cycle is adjusted too small;

3. The secondary inverter has field pipe damage.

G、The abnormal pilot lamp is on:

1、The light is on when the welder work abnormally, please turn off the power switch and then

reboot the machine, it can continue to use if it return to normal,

2、If the light is on repeatedly, please refer to the professional or the manufacturer for repair.

Table of contents

Other PROCRAFT Welding System manuals