Professional Tool Products PWH4000 User manual

PWH4000 1 08/23/06

Copyright © Professional Tool Products, 2006

All rights reserved.

PWH4000

Large Window Shade 10 Welding Helmet

Technical Specification

Viewing Area: 5-1/4" x 4-1/2"

UV/IR Protection: Up To Shade DIN 16 at all times.

Dark State: DIN 10

Helmet Material: High Impact Resistance Nylon

Total Weight: 1.18 Lbs

Some dust created by power sanding, sawing, grinding, drilling, and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and other masonry products, and

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of

work. To reduce your exposure to these chemicals: work in a well ventilated area, and

work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

Auto-darkening welding helmets

are designed to protect the eye

and face from sparks, spatter, and

harmful radiation under normal

welding conditions. Auto-darkening

filter automatically changes from a

light state to a dark state when an

arc is struck, and it returns to the

light state when welding stops.

Auto-darkening welding helmets

are ready for use. Before starting

to weld, adjust the position of the

headband and select the correct

shade number for your application.

Severe personal injury could occur if

the user fails to follow the mentioned

warnings, and/or fails to

follow the operating instructions.

PWH4000 2 08/23/06

PWH4000 Large Window Shade 10 Welding Helmet

•Be sure to read all safety warnings as well as instruction manuals before use of this helmet.

•Never place this helmet on a hot surface.

•This helmet does not provide protection against severe impact hazards, including grinding discs, explosive devices and/or

corrosive liquids. In the presence of these hazards, other protection must be used.

•Do not make modifications to either the filter or the helmet, unless specified in this manual. Do not use replacement

parts other than Matco replacement parts specified in this manual. Any unauthorized parts or modifications will void the

warranty and could expose the user to risk or personal injury.

•Wear ANSI approved safety goggles and ear protection at all times during use of this welding helmet. The lens is

breakable and does not provide complete protection from flying particles.

•Do not use any solvents on screen or helmet components.

•Use between temperature range of -10 degrees C to +55 degrees C (14 degrees F to 131 degrees F).

•Storing temperature of -20 degrees C to +70 degrees C (-4 degrees F to 158 degrees F).

•Do not immerse helmet in water. To clean use a damp soft cloth only.

•Regularly inspect/replace front cover lens if cracks, scratches, or other damage occurs.

•Caution: During welding operation, dust containing chemicals known to cause cancer and birth defects may be produced.

In order to reduce risk, adequate ventilation when welding is necessary and important.

•In order to reduce risk of personal injuries, inspect this helmet frequently and replace worn or damaged parts.

PWH4000 3 08/23/06

PWH4000 Large Window Shade 10 Welding Helmet

Before using the helmet for welding ensure you have read and understand the safety instructions.

Instructions For Use

• The helmet comes fully assembled. Before starting to weld, adjust the helmet to fit the user properly.

• Adjusting The Fit Of The Helmet

The overall circumference of the headband can be made larger or smaller by rotating the knob on the back of

the headband. ( See adjustment "Y" in fig. 1) This can be done while wearing the helmet and allows just the right

tension to be set to keep the helmet firmly on the head without it being too tight.

• If the headband is riding too high or too low on your head, adjust the strap which passes over the top of your

head. To do this, release the end of the band by pushing the locking pin out of the hole in the band. Slide the two

portions of the band to a greater or lesser width as required and push the locking pin through the nearest hole.

(See adjustment "W" in fig. 1)

• Test the fit of the headband by lifting up and closing down the helmet a few times while wearing it. If the

headband moves while tilting, readjust it until it is stable.

• Adjusting Distance Between Helmet And Face

Step 1: Undo the block nut (See"T" in fig. 1) to adjust the distance

between the helmet and your face in the down position.

Step 2: Retighten the block nut when adjustment is complete.

• Adjusting The Viewing Angle Position

Please see fig. 2a and 2b.

fig. 1

"Y"

fig. 2a fig. 2b

"T" "T"

"W"

Inside View Outside View

PWH4000 4 08/23/06

PWH4000 Large Window Shade 10 Welding Helmet

Maintenance

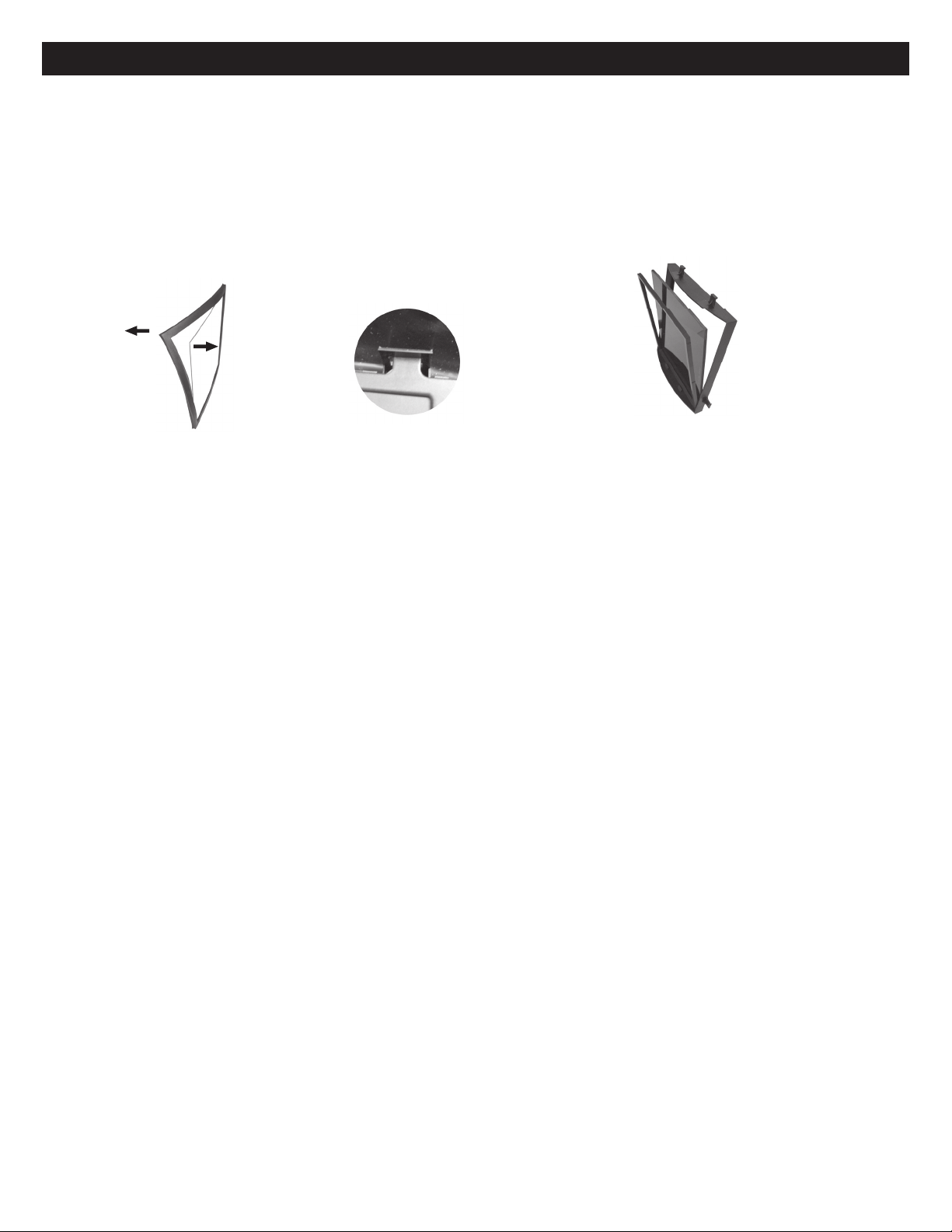

• Replacing Front Lens Plate. (See fig. 4)

Replace the front lens plate if it is damaged (cracked, scratched, soiled or pitted).

• Releasing The Shade Cartridge. (See fig. 5)

• Fitting New Cartridge. (See fig. 6)

• Cleaning

Clean helmet by wiping with a soft cloth. Clean cartridge surfaces regularly. Do not use strong cleaning

solutions. Clean sensors and solar cells with a damp clean cloth and wipe dry with a lint-free cloth.

fig. 5 fig. 4 fig. 6

LIMITED WARRANTY MODEL# PWH4000

Matco warrants these welding helmets for a period of 24 months from original purchase. We will replace any lens assembly only, that is covered under this

warranty, which proves to be defective in material or workmanship during the warranty period.

In order to have your lens assembly replaced, return the lens assembly only (PWH4LENS) to the Matco Authorized Warranty Center listed below, freight

prepaid. Please include your name, address, model number, and evidence of the purchase date, and description of the suspected defect. The lens assembly

will be inspected and if found to be defective in material or workmanship, it will be replaced free of charge and returned to you freight prepaid. This warranty

does not cover damage to the lens assembly; for example, cracked lenses or lenses covered with welding spatter, or damage arising from alteration, abuse,

or misuse, and does not cover any repairs or replacement made by anyone other than Matco or its authorized service center. The foregoing obligation is

Matco’s sole liability under this or any implied warranty and under no circumstances shall we be liable for any incidental or consequential damages.

Note: Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights, which vary from state to state.

Air & Hydraulic Service

315 Hawkins Rd.

Travelers Rest, SC 29690

(866) 496-8423

Please see breakdown and parts list for helmet shell, headgear, lens plates and sweat bands available for purchase separately.

These items are consumable parts not covered under the 2 year warranty.

PWH4000 5 08/23/06

PWH4000 Large Window Shade 10 Welding Helmet

• Parts And Assembly

REF PART

NO. NO. DESCRIPTION QTY.

1 PWH1234-1 Shell (Welding Mask) 1

2 * Rubber Holder 1

3 * Front Lens Plate 1

4 * Rubber Holder 1

5 * Shade 10 Lens 1

6 * Holder 1

7 **+ Block Nut 2

8 **+ Washer 2

9 **+ Angle Adjustable Washer 2

10 **+ Left Limitation Washer 1

11 **+ Screw 2

12 **+ Right Limitation Washer 1

13 + Headgear 1

14 + Sweatband 1

* Available in lens assembly, including #2-6: PWH4LENS

** Available in hardware kit, including #7-12: PWH1234-3

+ Available in headgear set, including #7-14: PWH1234-2

Also Available:

PWH4-3 Set of 5 Replacement Front Lens Plates (ref#3)

PWH1234-4 Set of 10 Replacement Sweat Bands (ref#14)

PWH4LENS

PWH1234-3

PWH1234-2

PWH1234-1

Table of contents

Languages: