Progres AGRONIC 2500 User manual

Sections in the manual:

‒ Functional description

‒ Features

‒ Formats, versions, models and options

‒ Technical specifications

‒ Parameters

‒ Input and output coding

‒ Practical examples

‒ Troubleshooting

‒ Technical support

The Communications Parameters section is detailed in

the Communications Manual.

The sections on Programming, Manual Actions and

Query are detailed in the User Manual.

INSTALLER USER MANUAL

AGRÓNIC 2500

Plus Version | V3

Welcome to the Agrónic 2500 manual.

We are pleased to count on your experience and skills to

install the Agrónic 2500.

This document will guide you through the process,

providing details on the programmer’s features and

parameters.

Your experience is essential to teach the customer how to

eectively use the Agrónic 2500.

Remember that there are two versions: basic and Plus,

adapted to the specific needs of each installation.

Thank you for your work!

Index

1 Description of basic functions............................................................................ 4

2 Features ............................................................................................................... 5

3 Formats, versions, models and options........................................................... 11

3.1. Formats.................................................................................................... 11

3.3. Versions.................................................................................................... 11

3.2. Models...................................................................................................... 11

3.4. Options..................................................................................................... 12

4 Technical specifications.................................................................................... 13

5 Parameters ........................................................................................................ 14

5.1. Fertilization.............................................................................................. 14

5.2. Filters........................................................................................................ 18

5.3. General..................................................................................................... 19

5.3.1 Diesel option................................................................................. 20

5.4. Programs.................................................................................................. 22

5.5. Sectors ..................................................................................................... 24

5.6. Determining factors................................................................................. 26

5.6.1 Definitive stop / Temporary stop................................................. 28

5.6.2 Conditional stop........................................................................... 29

5.6.3 Start – Start and Stop................................................................... 30

5.6.4 Warning......................................................................................... 31

5.6.5 Modify irrigation – Modify fertilizer ............................................. 32

5.6.6 End due to rain ............................................................................. 33

5.6.7 Filter pressure gage...................................................................... 34

5.6.8 Diesel pressure gage .................................................................... 35

5.6.9 Stop fertilizer................................................................................ 36

5.7. Sensors..................................................................................................... 37

5.7.1 Digital sensors .............................................................................. 37

5.7.2 Analog sensors ............................................................................. 38

5.7.3 Meter sensors ............................................................................... 40

5.8. Various ..................................................................................................... 41

5.9. Installer .................................................................................................... 42

5.8.1 Erased ........................................................................................... 42

5.8.2 Events ........................................................................................... 42

5.8.3 Access codes................................................................................. 42

5.8.4 Activate options ........................................................................... 42

5.8.5 Various ......................................................................................... 42

5.8.6 Communications.......................................................................... 43

5.8.7 Language ...................................................................................... 43

5.8.8 Update soware........................................................................... 43

5.8.9 Backup copy ................................................................................. 43

5.10. Solar irrigation......................................................................................... 44

6 Input and output coding................................................................................... 45

7 Practical examples............................................................................................ 47

8 Troubleshooting................................................................................................ 48

9 Technical support.............................................................................................. 49

10 Function screen................................................................................................. 52

11 Parameters screen............................................................................................. 53

4User Manual | Agrónic 2500

1 DESCRIPTION OF BASIC FUNCTIONS

The Agrónic 2500 is designed for automating irrigation on small and medium-sized farms

(maximum 30 irrigation sectors) where there is a need to open/close sector and master valves,

fertilizer control and filters.

The farm may have a pressurized water intake or need

a drive pump (electric or motor pump). There may be

an irrigation water meter.

The head can have 12 Vdc power supply (with solar

panel and battery, or battery only) or at 220 Vac (mains

or generator set).

The valves can be 12 Vdc, 24 Vac or latch and can be

close to the head and controlled by microtube or cable,

or at distances of up to 2 km connected to AgroBee-L

radio modules.

In the head, there can be fertilization with a hydraulic

pump injector, electric dosing machines or a venturis

system.

Reading of all types of sensors (analog, digital and

meters) connected to Agrónic and also remotely with

AgroBee-L radio modules.

The Agrónic 2500 has an internet connection, with

mobile telephony or WiFi, to connect to the VEGGA

platform or to the Agrónic APP application and

remotely manage the Agrónic.

For remote management, you can also connect to the

Agrónic PC Windows program. The connection can be

with direct USB to the computer, when it is next to the

unit, by radio modem, for medium distances, or by

Internet, with WiFi or mobile telephony.

All the features of the Agrónic are expanded in the

Plus version. If the Basic version does not meet your

requirements, see the Plus version.

To go from the Basic to the Plus version, just activate

an option from the unit.

5

User Manual | Agrónic 2500

Control up to 30 sectors using 50 irrigation programs.

Each program can activate 1 to 4 irrigation sectors si-

multaneously.

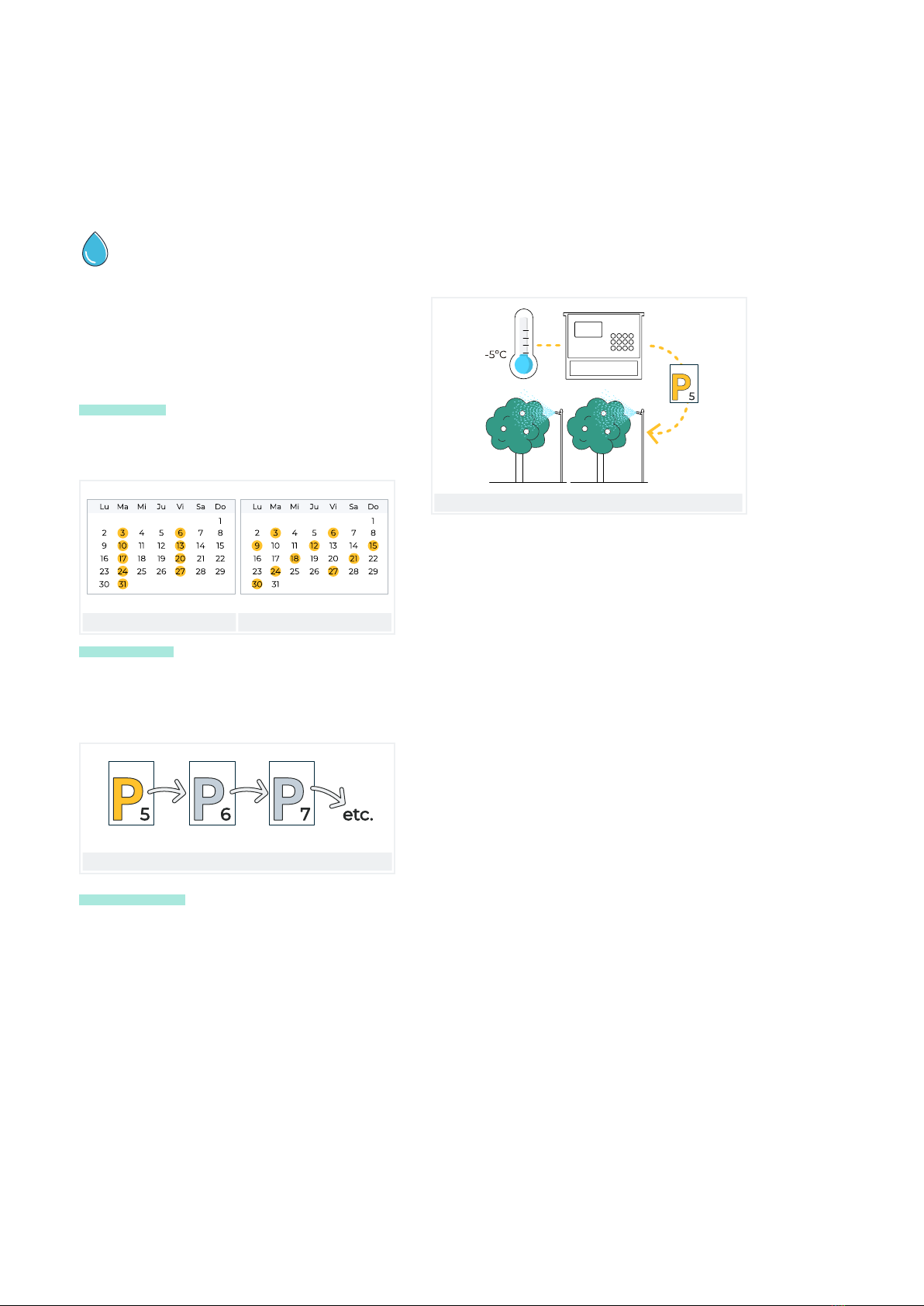

There are three ways to start a program:

Schedule start: at a specific time choosing the days

of the week or repeat the irrigation every few days

(frequency of days).

Days of the week Every 3 days

Sequential start: when another program has finished.

It is used to irrigate several sector groups one aer

another. The first program in the sequence must be

schedule start or conditional.

P6 sequential of P5 and P7 sequential of P6, etc.

Conditional start: when a determining factor is

activated.

The determining factor is related to any type of sensor

and can activate the program, for example, when

the temperature rises, when a buoy is deactivated

or when a flow rate drops below a certain level. An

active schedule and a safe schedule can be configured

between starts.

Conditional start due to frost

Once the program has started, there is an option to

repeat the irrigation every certain amount of time.

At the start, the amount of irrigation can be modified

using the determining factors. For example, increase

irrigation by % if there is a lot of radiation, decrease ir-

rigation by % if there is a lot of moisture in the soil, etc.

Irrigation units can be in time, hh:mm, mm:ss or

hh:mm/ha; or in volume, m3 or m3/ha (m3 per hectare).

A record is made of the irrigation time and volume for

each sector and in total.

When the program is active, irrigation can be stopped,

permanently or temporarily, using a determining

factor. For example, stopping when it is very windy,

stopping while the well level is low, stopping when the

flow in a sector is too high (broken pipe), etc.

2 FEATURES

The Agrónic 2500 is a controller for controlling irrigation, fertilization, pumping and filter cleaning.

It detects malfunctions and creates a chronological record of the events. Fully configurable, with

multiple possibilities for use, communication and expansion.

IRRIGATION

6User Manual | Agrónic 2500

Description of basic functions

PUMPING

It has 2 general irrigation outputs, or pumps.

One of the pumps can be a motor pump or generator

set. Each sector is assigned with the pumps associated

to it.

The pumps are activated together with the sector.

There are time delays to separate the pump from the

sector activation, during activation as well as stop, to

avoid water hammer.

Configurable from 0 to 4 fertilizers in separate tanks.

Separates pre- and post-irrigation values in each

program.

Fertilization units in time (hh:mm or mm:ss) or in

volume (L or L/ha).

Configured to use mixers, with pre-mixing and inter-

mittent or continuous mixing.

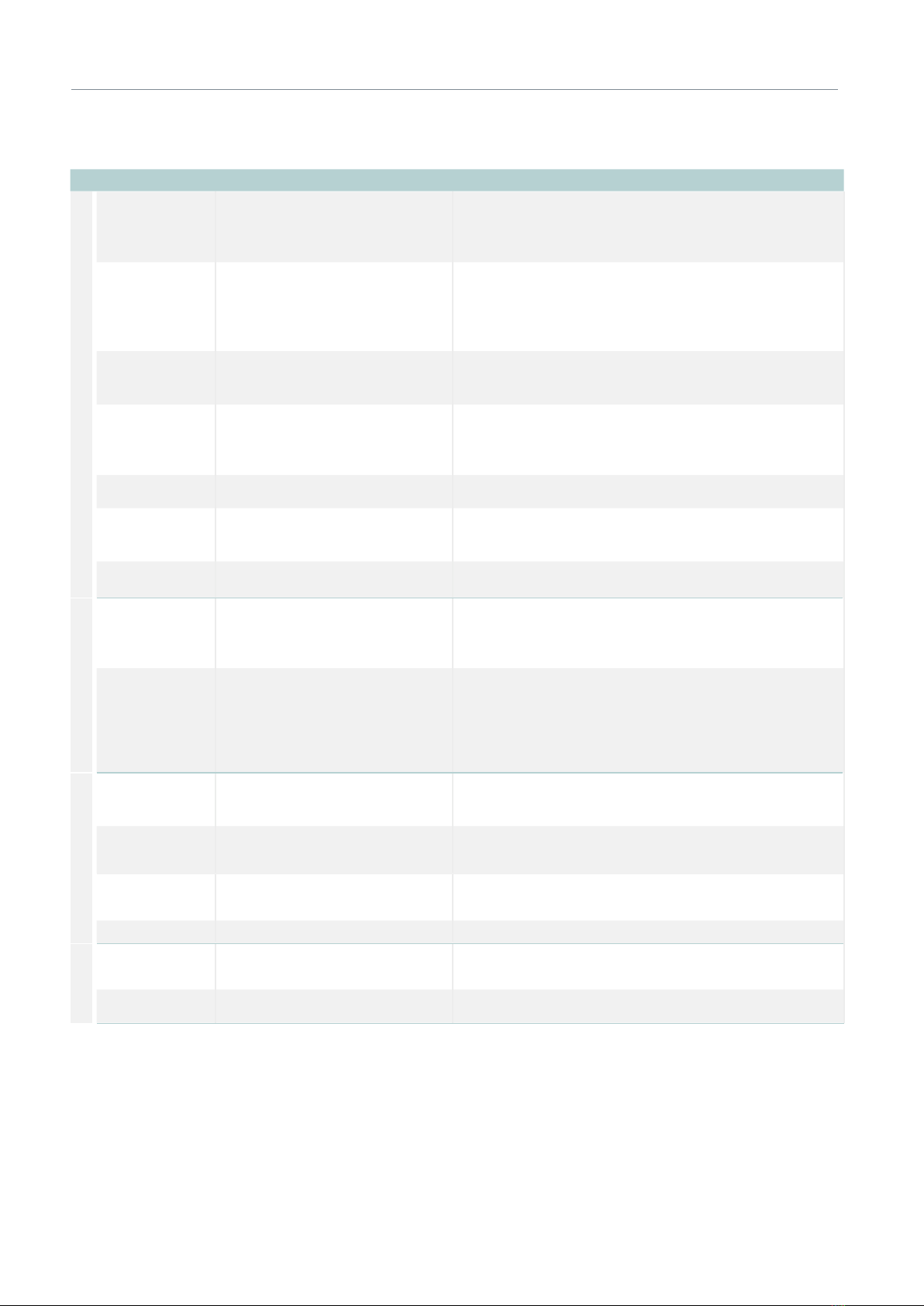

Fertilizers can be applied in three dierent ways:

in series: one type of fertilizer aer another from a

single injector

Series fertilization

IRRIGATION

FERTILIZER 1

20 L

30 L

12 L

FERTILIZER 2

FERTILIZER 3

Parallel: various fertilizers simultaneously with one

injector per type.

Parallel fertilization

FERTILIZER 1

IRRIGATION

FERTILIZER 2

FERTILIZER 3

20 L

30 L

12 L

Uniform: applies and distributes the each type of fertil-

izer uniformly between pre- and post-irrigation.

Uniform fertilization

IRRIGATION

FERTILIZER 1

20 L

30 L

12 L

FERTILIZER 2

FERTILIZER 3

In volume fertilization, detect no pulses or leak. The

proportional distribution of each pulse made by the

meter is recorded into the totals and history according

to the planned flows in sectors being fertilized at the

same time. Parallel fertilization.

FERTILIZATION

7

Description of basic functions

User Manual | Agrónic 2500

FILTER CLEANING

Configured for 0 to 9 filters, with selectable cleaning

times. Programmable pause between filters.

Washing sequence may be started by the pressure dif-

ferential and/or according to the time or volume of the

water circulation.

Whether or not the irrigation sectors and fertilizers are

stopped while the filters are being cleaned is configu-

rable.

Control over malfunctions due to continuous cleanings.

Configurable general filter output.

DETERMINING FACTORS

The unit has a total or 30 completely configurable

determining factors to trigger actions that take into

account certain determining factors or values from

digital or analog sensors and meters.

There is a wide variety of actions possible, such as the

ability to make definitive, temporary or determined

stops that are applied to specific programs or all of

them, start and/or stop irrigation, send a warning,

adjust irrigation or fertilizer units when starting an ir-

rigation program according to an instantaneous value

from a sensor or the value recorded from a previous

irrigation, etc. Each determining factor can also be

configured to create a malfunction or send an SMS

message and an SMS message to another machine.

To give a few examples, it can be used to terminate ir-

rigation due to a broken pipe, postpone irrigation due

to the lack of water level or excessive wind, modify the

volume of each irrigation as to the value of the water

content in the soil or the solar radiation the plant

received since its previous irrigation or the evapotrans-

piration, terminate irrigation if a certain amount of

rain has fallen since the previous irrigation, or send a

warning to the owner for an attempted the, etc.

Information about

Digital sensors

Analog sensors

Meter sensors

Flow error

Communication

Programs

Types of determining factors.

Definitive stop

Temporary stop

Conditional stop

Start

Start / Stop

Warning

DETERMINING FACTORS

Modifying irrigation

Modifying fertilizer

End due to rain

Filter pressure gage

Diesel pressure gage

Stop fertilizer

8User Manual | Agrónic 2500

Description of basic functions

PIVOT CONTROL

Remote management of up to 4 circular and linear

pivots. Its features are:

• position reading by GPS.

• Speed and direction control.

• Deactivation of the jet and the wing according to

position.

• Control of diesel pumps or solar irrigation.

• Control of physical guards in sector pivots.

• Manual action such as start, stop, dry passes, etc.

• Sectorization and configuration of up to 8 irrigable

areas by pivot.

• Programming by time or by passes.

• Modify precipitation rate by area.

• Information on alarms, misalignment, slip and

pivot position.

Modify irrigation depending on the sensors (climate,

plant, soil).

Remote management through Agrónic APP, VEGGA

and Agrónic PC.

SOLAR IRRIGATION

Uses solar power to irrigate. It drives pumps using

solar panels connected to a solar radiation sensor and

a frequency drive.

It combines solar power and power from the electrical

grid or diesel pump in hybrid installations to ensure

irrigation on cloudy days or outside of sunlight hours.

Solar irrigation also allows irrigation at dierent

pressures, prioritizing sectors with higher pressure.

MANUAL

Through manual commands, the unit can:

• start, stop or place a program out of service

• Suspend a program for a few hours

• Leave the unit out of service or on general stop

• Start or stop filter cleaning

• Modify the time and date on the unit

• Terminate alarms and malfunctions

• Set the sectors to manual, stop or automatic

• Modify virtual sensors

• Activate outputs

• Erase totals

• Place the determining factors out of service

9

Description of basic functions

User Manual | Agrónic 2500

EXTERNAL MODULES

SDI12 UNITS

With the AgroBee-L Link option, the unit links with

AgroBee-L radio modules, expanding the possibilities

and the use of new features.

The dierent modules in the range activate valves and

other irrigation elements, as well as read digital and

analog sensors and meters.

The SDI-12 is a communications bus that enables

the units that use this bus to communicate with the

Agrónic. Currently, soil moisture sensors from the

The AgroBee-L radio modules work with LoRa radio

modulation, which operates in the free bands of 868

MHz / 433 MHz / 915 MHz, obtaining coverage radii of

up to 2500 m between two points (depending on the

orography).

Meter Group, AquaCheck and Decagon brands can be

connected.

READINGS

The unit stores all totals in memory that cannot be

erased and, optionally, the events history and records

with the anomalies of the previous days.

• General totals and totals by sector for irrigation

and fertilization units in time and volume starting

from an initial date.

• Anomalies with time and date of the incident and

related instructions.

• Detailed records of every event occurring in the

unit.

• Separate history per irrigation sector with the units

in time and the irrigation and fertilizer volumes

applied everyday.

• History of every analog sensor with average values,

with maximum and minimums in 10-minute

fractions.

• History of every meter sensor with the irrigation

or fertilization values plus leaks in 10-minute

fractions.

10 User Manual | Agrónic 2500

Description of basic functions

SUMMARY OF PLUS VERSION FEATURES

SUMMARY OF BASIC VERSION FEATURES

Head

Pumping

2 general pumps or valves, pump 1 can be a generator set or motor

pump

Solar pumping together with generator set or network

Filters 9 filters in a single group

Fertilization

4 fertilizers

Type: series or parallel (uniform or not)

Units: hh:mm, mm’ss’’, Liters, Liters/ha

Irrigation

Sectors 30

Maximum 27 in the base, the rest in AgroBee or AgroBee-L

Programs

50 programs

From 1 to 4 sectors per program

Start type: schedule, sequential and determining factor

Units: hh:mm, mm’ss’’, hh:mm/ha m3, m3/ha

5 determining factors

Solar irrigation 10 determining factors

Sensors

Digital

20 sensors

Start cleaning / Temporary malfunction / Definitive malfunction

Conditional stop / Program start / Alarm

Analog 40 sensors

Meters 10 sensors

Irrigation meter / Fertilizer meters 1 to 4

Determining factors 30 determining factors

Pivots

4 pivots

Areas (by pivot) 8 Irrigation areas

8 exterior areas (wing and/or jet)

External modules AgroBee 16 modules

AgroBee-L 20 modules

SDI-12 8 units

Davis station 1 Weather station

Head

Pumping 2 general pumps or valves, pump 1 can be a generator set or motor

pump

Filters 9 filters in a single group

Fertilization

4 fertilizers

Type: series or parallel

Units: hh:mm, Liters

Irrigation

Sectors 30

Maximum 27 in the base, the rest in AgroBee or AgroBee-L

Programs

50 programs

From 1 to 4 sectors per program

Start type: hourly, sequential and by input

Units: hh:mm, m3

Sensors (inputs)

Digital

6 sensors

Start cleaning / Temporary malfunction / Definitive malfunction

Conditional stop / Program start / Alarm

Meters 5 sensors

Irrigation meter / Fertilizer meters 1 to 4

External modules AgroBee-L 20 modules

11

User Manual | Agrónic 2500

3 FORMATS, VERSIONS, MODELS AND OPTIONS

Box format

Built-in format in Agrónic 2509 and 2518 (9 and 18

outputs)

Built-in format in Agrónic 2527 (27 outputs)

Formats

Basic version

Plus version For analog sensor management,

This version is required.

It is activated by code.

Versions Observations

The Agrónic 2500 has two formats:

• box format With plastic box and transparent door

to hang on the wall.

• Built-in format With metal box to be built-in on a

cabinet or desk.

The Agrónic 2500 has two versions, the Basic version

and the Plus version, which also has uniform fertil-

ization, more determining factors, analog sensors,

records, history, descriptive text in each element, more

than one irrigation meter, total per meter and, for ir-

rigation programs, operating by frequency of days, by

3.1. FORMATS

3.3. VERSIONS

Power

• Single 12 Vdc power supply model. It can be served

with an external power supply from 220 Vac to 12

Vdc (included with the 220/24 option).

Valve type:

• valves at 12 Vdc.

• Valves at 24 Vac. It can be served with an external

power supply from 220 Vac to 24 Vac (included with

the 220/24 option).

• Latch valves. Selectable 2- or 3-wire.

Number of outputs:

• models with 9, 18 and 27 outputs.

3.2. MODELS

Agrónic 2509 220/24 Vac Includes 220/12 Vdc 2 A power supply and 220/24 Vac 50 VA transformer

Agrónic 2509 12 Vdc

Agrónic 2509 latch 2-wire Includes solar regulator

Agrónic 2509 latch 3-wire Includes solar regulator and diode box

Agrónic 2509 12 Vdc dual voltage Includes 220/24 Vac 50 VA transformer and diesel pump control option

Agrónic 2509 12 Vdc with battery charger The Plus version and GPRS modem option are required

Agrónic 2518 220/24 Vac Includes 220/12 Vdc 2 A power supply and 220/24 Vac 50 VA transformer

Agrónic 2518 12 Vdc

Agrónic 2518 latch 2-wire Includes solar regulator

Agrónic 2518 latch 3-wire Includes solar regulator and diode box

Agrónic 2518 12 Vdc dual voltage Includes 220/24 V 50 VA transformer and diesel pump control option.

Agrónic 2518 12 Vdc with battery charger The Plus version and GPRS modem option are required

Agrónic 2527 220/24 Vac Includes 220/12 Vdc 2 A power supply and 220/24 Vac 50 VA transformer

Agrónic 2527 12 Vdc

Agrónic 2527 latch 2-wire Includes solar regulator

Agrónic 2527 latch 3-wire Includes solar regulator and diode box

Agrónic 2527 12 Vdc dual voltage Includes 220/24 Vac 50 VA transformer and diesel pump control option

Agrónic 2527 12 Vdc with battery charger The Plus version and GPRS modem option are required

9 Outputs18 Outputs

Models Observations

27 Outputs

activations, by schedule and active period.

12 User Manual | Agrónic 2500

Formats, versions, models and options | Options

3.4. OPTIONS

Remote management communicationRadio control

Sensor control

Cloud

“Web platform”

(Agrónic APP +

VEGGA)

License to connect the unit to the

cloud.

The GPRS or WiFi modem option are required.

To use the Agrónic APP or VEGGA, the unit must be registered in

the cloud and an annual fee paid.

It is activated by code.

Cloud + PC

“Agrónic PC

program”

(Agrónic PC +

Agrónic APP +

VEGGA)

GPRS and WiFi – License to connect up

to 3 PCs/Servers or to the cloud.

USB, RS485 and Radiolink – License to

connect 1 PC/Server.

The GPRS, WiFi, USB, RS485 or Radiolink modem option are

required.

To use the Agrónic APP or VEGGA, the unit must be registered in

the cloud and an annual fee paid.

It is activated by code.

Modem link / SMS

messages

Option to connect with Agrónic PC,

Agrónic APP and VEGGA via GPRS, and/

or receive SMS messages from the unit.

Includes GPRS modem with deactivated Movistar M2M SIM card.

Includes 5dBi quad-band antenna and 3 meters of cable.

Not compatible with the WiFi Link option.

WiFi link Option to connect with Agrónic PC,

Agrónic APP and VEGGA via WiFi router.

Not compatible with the GPRS Modem Link / SMS Messages

option.

Includes 7dBi directive antenna with six meters of cable and 3dBi

omni-directional antenna.

USB link Option to connect with Agrónic PC

via cable. Includes three meters of cable.

433 MHz radio link Option to connect with Agrónic PC

via radio.

An Agrónic Radiomodem 433 MHz must be connected to the PC

with the Agrónic PC program.

See Agrónic Radiomodem 433 MHz in the Accessories section.

RS 485 link for PC Serial port to connect with Agrónic PC

with RS485 Link box.

A 220/12 V 2 A power supply and an RS485 + USB link box are

required.

AgroBee-L Link

868 MHz / 915

MHz / 433MHz

Option to connect with external

AgroBee-L modules (Lora technology).

Only valid for units with version 3. Includes coordinator, omni-

directional antenna with 10 meters of cable, optionally 15 meters

of cable (check price). The Plus version must be activated in order

to activate general and read analog sensors.

AgroBee-L link

868 MHz / 915

MHz / 433MHz +

modem

Option to connect with external

AgroBee-L modules (Lora technology)

with GPRS modem included on the

same board.

Only valid for units with version 3. Includes deactivated

Movistar M2M SIM card and 5dBi quad-band antenna with 3

meters of cable for the GPRS modem. For the AgroBee-L modem,

coordinator, omni-directional antenna with 10 meters of cable,

optionally 15 meters of cable (check price). The Plus version must

be activated in order to activate general and read analog sensors.

RS 485 Modbus

link

Serial port to connect to Davis Vantage

Pro 2 weather station.

Only valid for units with version 3.

The “SDI-12 expansion and 4 analog inputs” option and the

“Gateway for Davis Vantage Pro” complement are required.

2 Analog inputs

Connector for 2 analog inputs.

For voltage and current measurement

(V/mA). The Plus version must be activated on the computer.

SDI-12 expansion

and 4 analog

inputs

Board to incorporate 8 sensors with

SDI-12 protocol + 4 analog 4-20 mA

sensors.

Only valid for units with version 3 and Plus version activated.

See Sensor section to see compatible SDI-12 models.

5 digital inputs Connector for 5 digital inputs. Only for relay models (not compatible with latch units).

Pivot control

Option to control position, movement

direction, speed, start, stop, etc. up to

a maximum of 4 pivots.

The Plus version must be activated on the computer.

It is activated by code.

Diesel pump

control

Option for automatic start of a motor

pump or generator set. It is activated by code.

Options Description Observations

Other

13

User Manual | Agrónic 2500

Voltage 12 Vdc +15% -10%

Frequency --

Power consumption Less than 12.5 W (0.3 W standby)

Fuse Input Thermal (PTC) 1.1 Amp. at 25°C, auto-resettable

General power supply

Voltage From 12 to 24 Vdc or Vac (maximum 30 V)

Fuse Input “R+” Thermal (PTC) 3.0 Amp. at 25°C, auto-resettable

Output power source

Memory No maintenance, 10 years for parameters and programs in FRAM memory and FLASH memory

records

Clock 48 hours without power

Memory and clock safeguard

Digital

Number 9, extendable to 18 and 27.

Type By relay contact, with 24 VAC potential (external transformer).

Limits 30 Vac / 30 Vdc, 1 Ampere, 50-60 Hz, CAT ll (per output)

All outputs have double isolation in respect to the power output.

Outputs

Temperature -5°C to 45°C

Humidity < 85%

Altitude 2000 m

Pollution Grade 2

Environment

Box model From 1.0 kg to 1.6 kg

Built-in model From 1.1 kg to 1.5 kg

Weight

This symbol indicates that electronic devices should not be disposed of along with household waste at the end of their

useful life. The product must be taken to the corresponding collection point for electric and electronic unit recycling and

correctly processed pursuant to Spanish legislation.

Digital sensors Number 6, expandable (option) to 11 on non-Latch models.

Type Coupling options, operate at 12 or 24 V

Analog

(option)

Number 2

Type 4-20 mA, 0-20 V. (on demand, with galvanized separation)

Number 4

Type 4-20 mA

Inputs

Complies with Directive 89/336/EEC for Electromagnetic Compatibility and Low Voltage Directive

73/23/EEC for Product Safety Compliance. Compliance with the following specifications was

demonstrated as indicated in the European Community Oicial Gazette.

Statement of compliance

4 TECHNICAL SPECIFICATIONS

Protective ground

terminal Antenna Ground terminal Double isolation

Symbols that may appear on the product

14 User Manual | Agrónic 2500

5.1. FERTILIZATION

5 PARAMETERS

To access the menu, press ‘Function’ on the keypad,

select 4. Parameters, ‘Enter’.

FUNCTION

1. PROGRAMS

2. MANUAL

3. READINGS

4. PARAMETERS

5. PIVOTS

It is divided into twelve sections. To enter one of them,

just press the corresponding index number or move to

the selection with the arrow keys and then press ‘Enter’.

PARAMETERS

1. Fertilization

2. Filters

3. General

4. Programs

5. Sectors

6. Communications

7. Determining factors

8. Sensors

9. Various

10. Installer

11. Solar irrigation

12. Pivot

If a menu has more than 5 lines, the ‘↓’ symbol will be

displayed to indicate that they do not fit on the screen, so

press the index number or move the ‘↓’ key to access them.

An example of how to interpret the questions and how

to modify the possible values to configure is explained:

Example

Type of fert. (series | parallel) YES FRI

• Indicates that there are several options to

modify.

N. of fertilizers (0 ... 4)

• Underlined value or number: indicates the

default value that is configured in the con-

troller.

Fertilizer general (yes | no) YES

• Indicates the option to respond with ‘yes’ or

‘no’.

Example of interpretation

N. of fertilizers: 0

Fertilizer general: no

Type of fert.: series

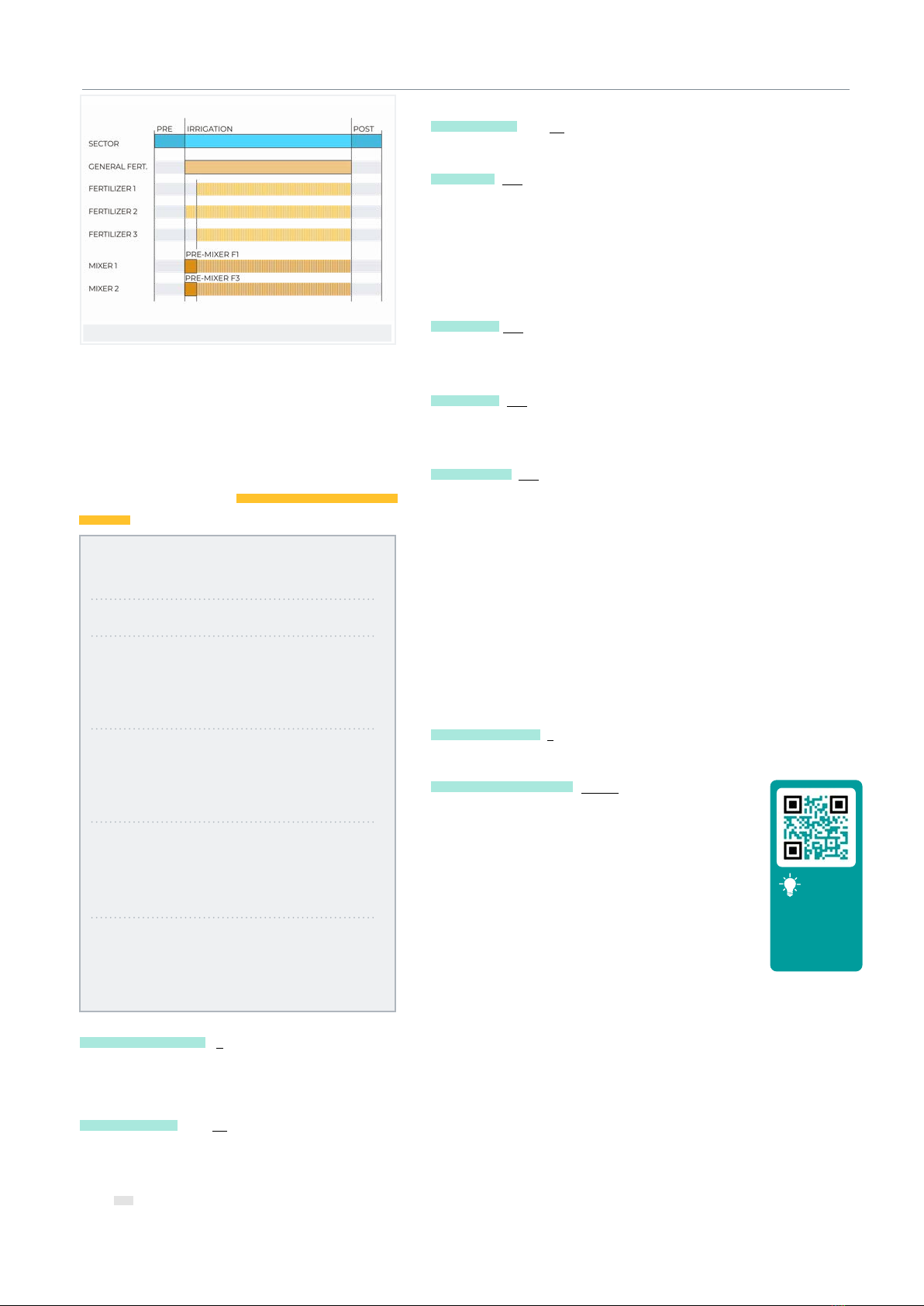

The Agrónic 2500 can work up to four fertilizers.

The Plus version has three types of application: series,

parallel and parallel with uniform distribution.

Series fertilization

(one behind the other)

To install and prepare the unit for operation, enter the ‘Parameters’ section and adapt them to

the needs of each installation.

Parallel fertilization

(all at the same time)

Video tutorial

available for

this section

An example of how to interpret the questions and how

to modify the possible values to configure is explained:

Watch video

15

Parameters | Fertilization

User Manual | Agrónic 2500

Parallel fertilization uniform distribution

It works in units of time or volume and has an indepen-

dent pre/post irrigation for each program.

For each fertilizer, there may be a mixer that stirs the

fertilizer tanks before and during irrigation.

The outputs where the fertilization elements can be

connected are assigned in ‘Function - 4. Parameters - 3.

Generals’.

FERTILIZATION PARAMETERS

No. fertilizers: 4

General fertilizer: yes

F1 mixer: no

F2 mixer: yes

F3 mixer: yes

F4 mixer: no

Pre-mixing: 015”

Mixing start: 030”

Mixing stop: 120 ”

End cleaning: 030”

F1 Meter: 01

F2 Meter: 02

F3 Meter: 03

F4 Meter: 04

Flow rate F1: 000.00 m3/h

Flow rate F2: 000.00 m3/h

Flow rate F3: 000.00 m3/h

Flow rate F4: 000.00 m3/h

Number of fertilizers (0 ... 4): enter in the unit the

number of fertilizers installed in the irrigation network.

Leave the value at 0 if there are none.

Fertilizer general (yes | no): is an output normally used

to connect the injector in series application and is only

activated when one of the fertilizers activates.

Enter yes if it is going to be used.

Fertilizer mixer (yes | no): each fertilizer can be assigned

a separate mixer. Indicate which fertilizers have a mixer.

Pre-mixing (000 ... 999”): time that the fertilizer will be

stirred before starting fertilization. Pre-mixing comes

in before the program starts. If it is less than 10 minutes

since the last irrigation, do not start the pre-mixing.

Mixing during fertilization can be continuous or with

pauses.

Mixing start(000 ... 999”): mixing time before a pause. If

continuous mixing is desired, set the mixing pause to 0

and any time here.

Mixing stop (000 ... 999”): time that the mixing will be

stopped aer a startning time. If continuous mixing is

desired, set this time to 0.

Final cleaning (000 ... 999”): when fertilization ends, the

general and fertilizer cleaning outputs are activated

during this time. If the fertilization is in series, it cleans

at the termination of each fertilizer. If it is in parallel,

when the last one ends.

Fertilizer meters

If fertilizer by volume, the meters must be assigned.

When fertilizer is parallel or uniform, a meter must be

assigned to each fertilizer; if it is series, the same meter

can be assigned to all fertilizers.

Meter F1, F2, F3, F4 (0 ... 10): meter sensor number asso-

ciated with the fertilizer.

Flow rate F1, F2, F3, F4 (000.00 ... 655.35): maximum

planned injection flow rate for these fertilizers. The

planned flow rate is used for uniform fertilization.

Uniform fertilization

With uniform fertilization, the fertilizer is distributed,

injecting small doses, throughout the irrigation. This

achieves better nutrient absorption, more homoge-

neous growth, drainage losses and sedimentation in

pipes.

It is applied using simple Venturi-type hydraulic

systems, reducing installation costs and can be done

in time and volume.

See further

information

about uniform

fertilization

See

instruction

16 User Manual | Agrónic 2500

Parameters | Fertilization

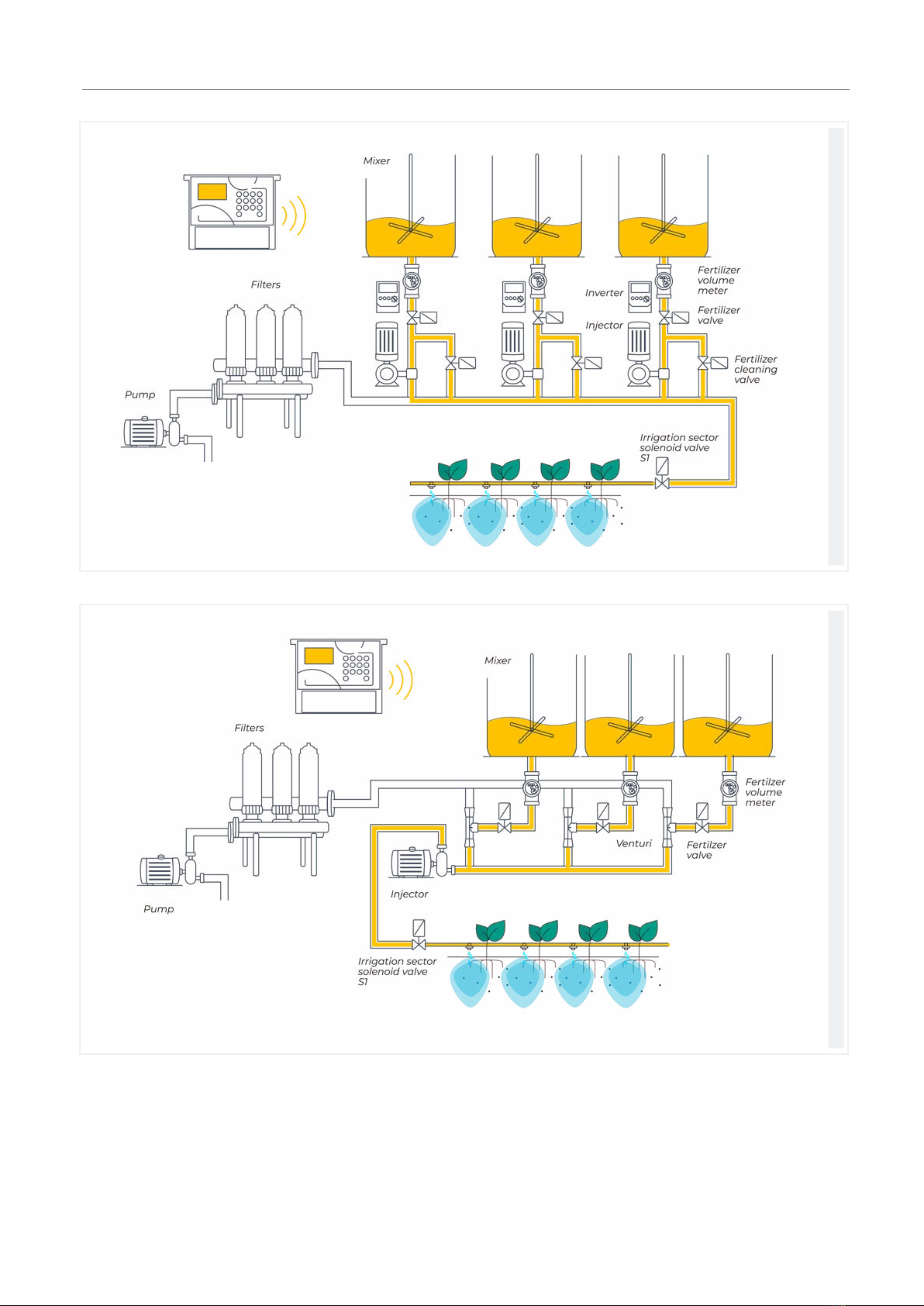

Series fertilizationParallel fertilization

17

Parameters | Fertilization

User Manual | Agrónic 2500

Uniform fertilizationUniform fertilization with Venturis

18 User Manual | Agrónic 2500

Parameters | Filters

The Agrónic can control the filter cleaning. Cleaning

can be started manually or automatically. It starts au-

tomatically by a dierential pressure gage or by a time

or volume of water having passed through the filters. It

will only start automatically if the general one assigned

to the filters is activated. In other words, when there

is a program irrigating. It can be started manually

whenever desired from ‘Function - 2. Manual - 4. Filters’.

FILTER PARAMETERS

No. of filters 3

Initial wait: 000”

Time of activation

by filter: 045”

Pause between filters: 04”

Units between cleanings

Volume: 0000 m3

Time: 0000 ‘

General of filters: no

Relation with P1: yes

Relation with P2: no

Max. number of continuous

cleanings: 0

Stop of sectors: no

Number of filters (0 ... 9): number of filters.

Initial wait (000 ... 999”): the waiting time between ac-

tivating the filter general and starting cleaning the first

filter.

Activation time per filter (000 ... 999”): time that the

water will pass through each filter to perform cleaning.

Pause between filters (00 ... 99”): waiting time between

closing the cleaning of one filter and activating the

next one.

5.2. FILTERS

Units between cleanings (0000 ... 9999): the irrigation

time or volume that must pass through the filters for

automatic cleaning to begin. Time in minutes and

volume in m3.

Filter general (yes | no): indicate ‘yes’ to activate an

output during the entire filter washing process.

Relation with P1, P2 (yes | no): it indicates the pump

from which the water that passes through the filters

comes from. It is used to count units between cleanings

and to start the cleaning.

Maximum number of consecutive cleanings (0 ... 9): if

cleaning is started by the dierential pressure gage

and is always activated, it will do the cleanings config-

ured here at most. It then goes into malfunction and

will not continue cleanings until it is manually recon-

figured. At 0, it never goes into malfunction. To restart

cleaning go to ‘Function - 2. Manual - 4. Filters’.

Stop sectors (yes | no): if cleaning takes place during

irrigation, select whether or not to postpone the irri-

gation while it does so. It is used when sectors must be

closed during cleaning to maintain pressure.

• Yes: programs that have sectors related to the

pump that use cleaning are postponed. When the

cleaning is finished, the programs continue where

they were.

• No: the programs remain active during cleaning

and the irrigation sectors are not closed.

Video tutorial

available for

this section

Watch video

19

Parameters | General

User Manual | Agrónic 2500

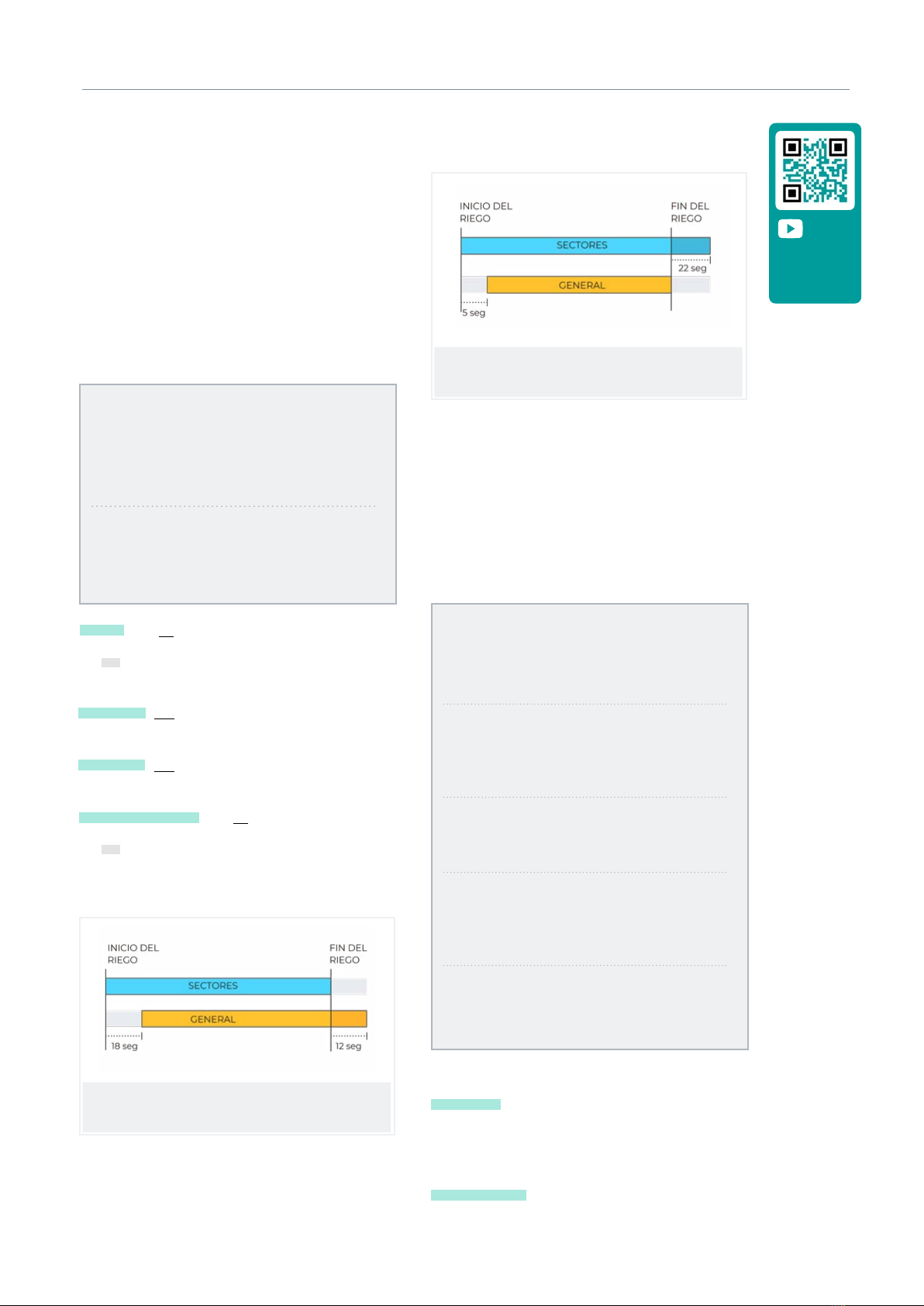

5.3. GENERAL

The pump, fertilizers, filter and diesel outputs are con-

figured in this section.

The outputs can be from the base of the Agrónic 2500, a

recommended option and from external modules such

as the AgroBee-L, an option not recommended due to

the activation and deactivation delays they may have.

Pumps

Output connected to the drive pumps or general valves.

GENERAL PARAMETERS

Pump 1: yes

Temp. start: 018”

Temp. stop: 012”

Stopping the sectors: no

Pump 2: yes

Temp. start: 005”

Temp. stop: 022”

Stopping sectors: yes

Pump 1 (yes | no):

• Yes: i f pump 1 output is to be used. An output must

be assigned to the pump.

Temp. start (000 ... 250”): time delay in activating the

pump when starting an irrigation.

Temp. stop (000 ... 250”): time that the pump stop is

extended when stopping irrigation.

Stopping the sectors (yes | no):

• Yes: for the pump to stop when irrigation is finished

and for the sectors to remain open for a few more

seconds.

Start timing: 018

Stop timing: 012

Stop in the sectors: no

Start timing: 005

Stop timing: 022

Stop in sectors: yes

Outputs

At the base of the Agrónic 2500, there can be up to 27

digital outputs, identified as R1 to R27, to connect the

general outputs. It is recommended to start with the

unit’s last outputs and reserve the first ones for the

sectors.

GENERAL PARAMETERS

Assign outputs:

Pump 1: 00018

Pump 2: 00017

F1: 00015

F2: 00014

F3: 00013

F4: 00012

Fertilizer:

Pump: 00016

Cleaning: 00020

A1: 00000

A2: 00011

A3: 00000

A4: 00000

L1: 00010

L3: 00007

GL: 00000

Pumps

P1 and P2 : outputs connected to pumps or general

valves.

Fertilizers

F1, F2, F3, F4 : outputs connected to the fertilizer

injectors.

Video tutorial

available for

this section

Watch video

20 User Manual | Agrónic 2500

Parameters | Filters

MF: output connected to the pump or general fertilizer.

A1, A2, A3, A4: outputs connected to the mixers.

LF: output connected to the fertilizer cleaning valve.

Filter cleaning.

Before assigning the outputs, configure how many

filters there are in the installation. This is assigned in

‘Function - 4. Parameters - 2. Filters’.

L1: output assigned to the first filter.

Lx: output assigned to the last filter.

GL: output connected to the general filter cleaning

valve.

The outputs that occupy the filters between the first

and last are assigned automatically. If there is only one

filter, the last one is not asked.

Example

An installation with 4 filters, in which the assigned

outputs would be: l1 output 10, L2 output 9, L3

output 8 and L4 output 7.

The output number coding can be found in section ‘6

Input and output coding’ of this manual.

5.3.1 Diesel option

This option is used to start, stop and monitor diesel

pumps for malfunctions.

Operation

The diesel pump is related to pump 1. It starts when a

sector that uses pump 1 opens and stops when the last

sector that uses pump 1 closes.

First the sector is opened, the contact and preheating

output of the diesel pump is activated. When preheat-

ing is finished, the start output activates. If the pressure

gage input is activated, the diesel pump has already

started and irrigation begins. If it is not activated aer

the boot time, wait 30” and attempt another boot. If

the diesel pump cannot be started in 4 attempts, the

stop output is activated, it enters ‘Malfunction’ and

makes a record. The pump will attempt to start again

at the next irrigation start.

When irrigation is finished, it closes the sectors and

the pump, carrying out the water hammer timings and

once the end of pump time has transpired, it activates

the stop.

‘Consult - 1. General’ shows the status of the diesel

pump.

These screens only appear if the Diesel Option is

activated.

Pressure gage

A pressure gage is used to detect that the pump is

startning. Its purpose is twofold: to detect start-up

when attempting to start and, once finished, to detect

insuicient oil pressure. In the Agrónic Basic version,

the pressure gage must be connected to digital input 6

(D6). This input cannot be used for any other function.

If you have a generator on which there is no need to

control the pressure gage input, set the start and stop

times to 0.

GENERAL PARAMETERS

Preheating: 08”

Start-up: 04”

Stop: 060”

Pump input: 085”

Pump end: 0120”

Assign outputs:

ar Pa Co Pr

18 17 16 15

Preheating (00 ... 99”): time that the preheating output

(Pr) is activated before starting the diesel pump.

Start (00 ... 99”): time that the start output (Ar) is

activated to start the diesel pump.

Other manuals for AGRONIC 2500

3

Table of contents

Other Progres Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Monosem

Monosem MECA V4 Assembly, Adjustment and Maintenance Instructions

sitrex

sitrex BR 2030/6 Operator's manual

Clarke

Clarke STRONG-ARM CST6 Assembly & user instructions

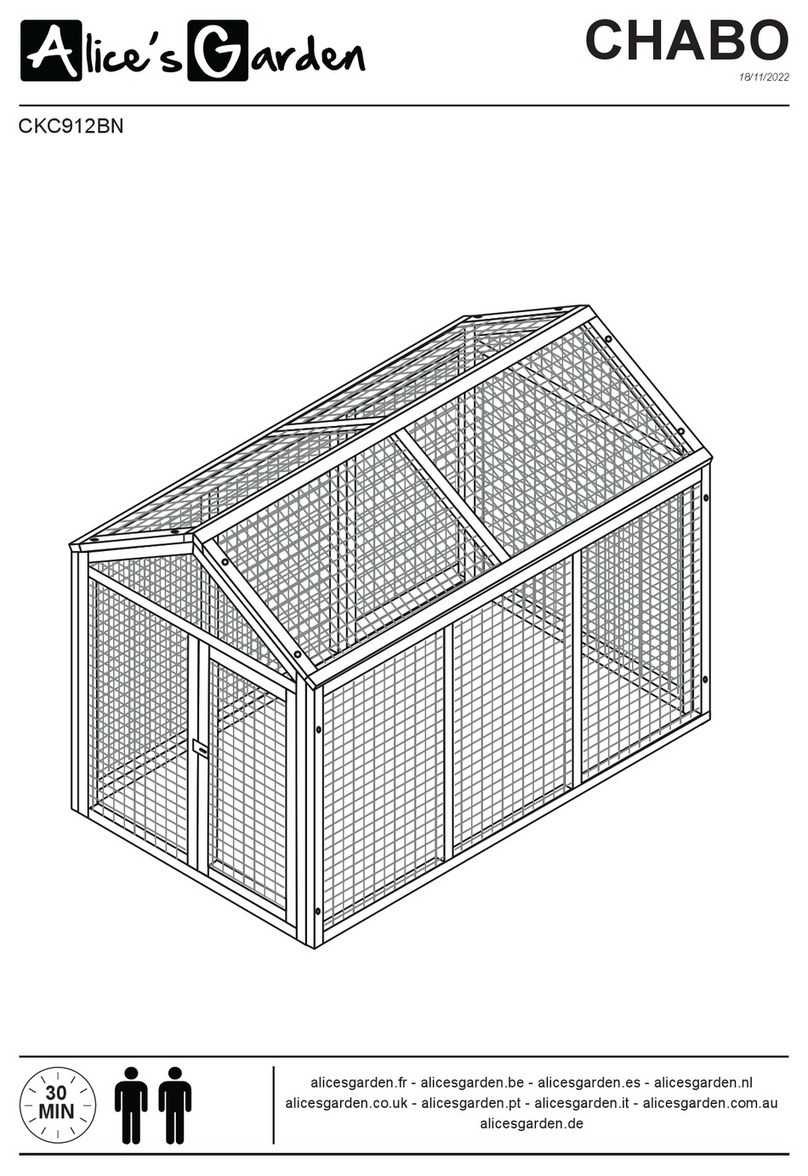

Alice's Garden

Alice's Garden CHABO CKC912BN manual

Land Pride

Land Pride CB1072 Operator's manual

Raven

Raven AutoBoom installation manual