Wiring Box of theA1-Hybrid Series Inverter

Transformer

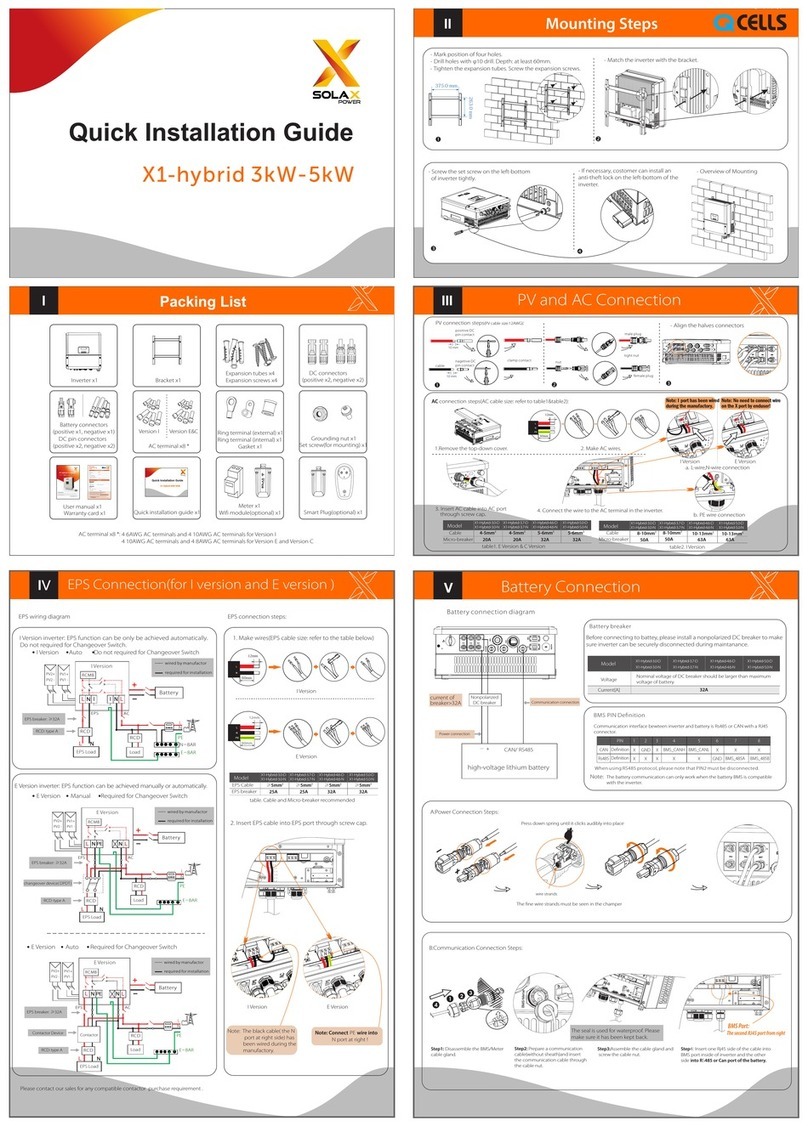

Grounding Connection (Mandatory)

- User must earth the inverter to the home ground busbar.

- It is recommended that all devices in the system should be earthed to the home ground busbar, such as battery, loads, autotransformer, etc.

VIII

Start Inverter

Preperation for Communication Connection

Remove the Communication Board

- Remove the 2 cover screws, then remove the board.

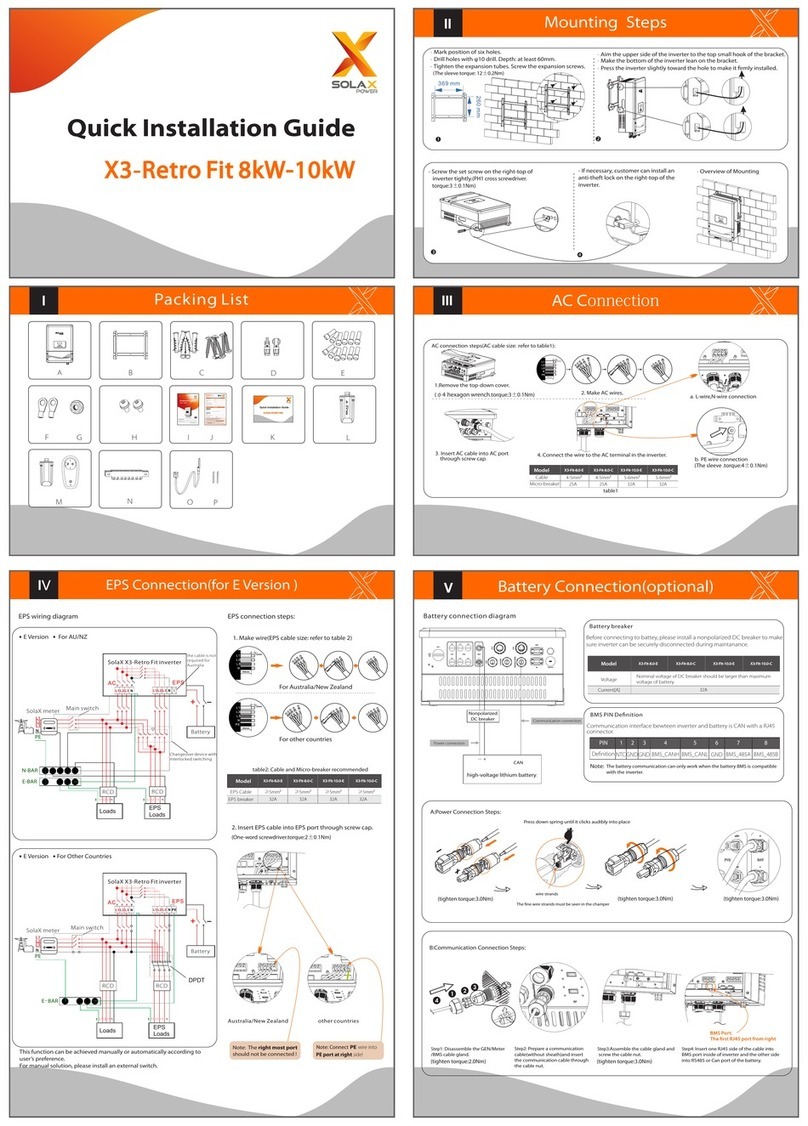

Conduit Installation and Wiring Routing

- For this installation, refer to Section III.

- It is recommended that all communication cables should be connected

through two conduits from right hand side on the bottom of the inverter.

Communication Board Introduction

- Note in this quick installation guide, only Meter connection (Section IX), BMS connection

(Section VI) and Monitoring connection (Section XI) will be introduced in detail.

For other communication connections, refer to the Inverter User Manual.

Communication Board

Inside the Wiring Box

X

Meter Connection

- Meter connections can be divided into two parts: One is the communication connection between the meter and the inverter, and another one is the electrical cable connection between the

meter and the grid.

Communication Connection Between the Meter and the Inverter (Inverter Side)

Communication Connection Between the Meter and the Inverter (Meter Side)

- For this operation, refer to the diagram below.

Electrical Cable Connection between the Meter and the Grid

- For electrical cable installation, refer to the diagram below.

- To assist in understanding the relationship between the meter and the HYB system, a system diagram is shown below. A sub-meter is as the example show in this diagram.

For actual installation of the sub-meter, refer to specic Meter User Manual.

Characteristic Impedance: 100 to 120 ohms

Mutual capacitance: <30pF/ft (<12.5pF/ft is preferable )

Note: One shielded twisted pair, plus an additional wire for a common reference

IX

X

XIII

XII

Inverter Power On

Step 1: Turn on both the DC switch and the AC circuit breakers.

Step 2: Turn on the DC switch at the bottom of the inverter.

Step 3: Inverter will start up automatically when the PV panels generate enough power or when the battery is discharging.

LCD Display Setting

Upon rst startup, ve items need to be set in the LCD display as shown below.

0 W

>

This function allows the inverter to control energy exported to the grid.

There is a user value and a factory value. The factory value is a default which can’t be changed

by the user. The user value setting made by installer must be less than the factory value.

Step 1: Plug Pocket Wi-Fi / Pocket LAN into “Wi-Fi” port at the bottom of the inverter.

Step 2: Build the connection between the inverter and router.

Step 3: Create a user account online (Refer to the relevant User Manual for more details).

Pocket Wi-Fi / Pocket LAN / Pocket 4G Connection

The A1-Hybrid inverter can transmit inverter data to the monitoring website via an external monitoring data collector.

There are three types of monitoring data collectors, including Pocket Wi-Fi, Pocket LAN, and Pocket 4G.

XI

Max. 12 lbf-in

Required TorquePermitted Wire Size

8AWG,120V,194℉/90℃ for A1 Hybrid-6.0/7.0-US

6AWG,120V,194℉/90℃ for A1 Hybrid-7.6/8.6-US

Required Torque

Part

Max. 13.8 lbf-in

Max. 13.8 lbf-in

Removing Communication Board Cover Screw

Removing Conduit Fitting

Monitoring Installation

Cloud

Router

ØPocket LAN Connection Diagram

ØCellular Communication Module Connection Diagram

Cloud

Router

Cloud

WiFi Plus Connection Diagram

Ø

5. Check that the battery is connected.

4. Check that the meter is connected.

3. Check that all DC wirings and AC wirings are completed.

2. Check that the inverter is fixed safely on the wall.

1. Check that the main switch is in the “OFF” position. 8. Check that the PV arrays are connected.

10. Check that the loads and critical loads are connected, and that the critical loads rating is within the required rating range.

6. Check that all grounded busbars are connected.

11. Check that the generator is connected (if needed).

12. Check that the manual bypass breaker (mechanical interlock) is connected and the original state should be connected

with inverter side (if needed).

9. Check that the autotransformer is connected.

7. Check that the RSD controller is connected.

+ _+_+_+_+_

PV 1

PV 2

PV 3

PV 4

BAT

LOAD

RESERVE

L1 N L2 L1 N L2

GRID

L1 N L2

L1 N L2

Transformer

Meter Port

EPO Port

BMS

Por t

LAN

Por t

Wi-Fi/

4G Port

RPSD Port

Wi-FiInternetRouter

Wi-Fi

Gateway Cloud

WAN

Ground Busbar

PV Ar ray #1

PV Ar ray #2

PV Ar ray #3

PV Ar ray #4

RSD Mo dules

RSD Mo dules

RSD Mo dules

RSD Mo dules

PV 1+

PV 1 -

PV 2+

PV 2 -

PV 3+

PV 3 -

PV 4+

PV 4 -

RPS D CT

GROUND Busbar

Ground

Electrode

Conductor

(Ground Rod)

Battery

+

-

RPS D

Con tro lle r

N.C. N.O.

GROUND Busbar

Ground

Electrode

Conductor

(Ground Rod)

Loads

L2

CT 1

N

L1

CT 2

Neutral-Ground Bond

N L1 L2 NL1 L2

AC Backup-to

Critical Loads

NL1 L2

Auto

transformer

+

-

+

-

+

-

+

-

Wi-Fi Module or

4G Module

Emergency Stop

Switch

Signal

LEGEND

EPO Cable

LAN Cable

BMS Cable

Meter Cable

CT Cable

AC

LEGEND

HOT L1

HOT L2

Neutral

Ground

BATTERY

LEGEND

PV

LEGEND

Positive

Negative

Ground

Positive

Negative

Ground

+

-

+

-

RPSD Cable

Step 1 : Find the 3-pin female terminal block in the accessories package.

Step 2 : Choose the wires (22-24AWG), and remove 0.2in/5mm of the insulation from the end of the wire.

Step 3 : Insert the stripped wires into the female terminal block and ensure that all conductor strands are captured in the terminal.

Step 4 : Compress the female terminal head by using a slot screwdriver.

Step 5 : Plug the female terminal block into the corresponding male terminal block on the communication board tightly.

Step 3

Step 4

Conduit

0.2in/5mm

Wirings

Step 2

B-

3-pin

Step 1

A+

GND

Meter

Communication Board

Step 5 Overview

B-

A+

GND

B-

A+

G

Mode Select

> self use <

Work Mode

4. Set Work Mode

There are five Work Modes to choose from:

The battery will be charged forcibly in the setting time, allowing it to choose whether to charge from the

grid or not. The battery will stop discharging to keep higher capacity when the grid is on. Only when the

grid is down and PV energy is not sufficient will the battery start to discharge to keep the essential loads

working normally.

This work mode applies to areas that suffer from regular blackouts.

Self Use

(default)

Time of Use

Back Up Mode

The PV-generated power will first be used to supply the local loads, then to charge the battery. The

redundant power will be exported to the grid.

When there is no PV supplied, the battery will first discharge for local loads, then the grid will supply power

when the battery capacity is reached.

Charging and discharging can be set flexibly, allowing the user to select whether to charge from the grid

or not.

Parameter Comment

The priority of the inverter output power is in this order:

Feeding to the grid Supplying the load Charging the battery.

This work mode applies to areas with high feed-in tariffs.

Feed in Priority

> Mute

No

EPS system

5. Set EPS System

Inverter can work in EPS mode.

EPS System parameters can be set as below.

You can choose to mute the warning of a system that has entered into EPS mode.

“No” - there will be a buzzing sound (this is the default value). if the buzzing sound is loud, it

means that the EPS System output is overloaded.

“Yes” - shut down the warning function.

“Frequency” - can only be set to 60Hz.

> Mute

No

EPS system

6. Set Function Type

IUsers can set the type of inverter, Hybrid or AC Coupled. This option can only be set if the

inverter is . A1 Hybrid

If choose the AC Coupled, then have to restart the inverter, this function will take effect. And if you

re-select the Hybrid, you will also have to restart the inverter.

In this mode, battery discharges during two discharge window to limit demand charge (if enabled)

(Similar to Time of Use mode but on Demand Mode the system will allow grid consumption up to a

threshold limit defined by the user (default 2kW).)

Demand Mode

614.00401.03

Terminal Required TorquePermitted Wire Size

Meter

Type

3-pin Terminal Block

2.3 Ibf-in

22-24AWG

2.Set the safety standard

1.Set date time

3.Set export control