Promag STARMIX 60W User guide

PROMAG

le macchine per il gelato

09-2003

STARMIX 60W

STARMIX E60W

STARMIX 60A

STARMIX E60A

STARMIX 120W

STARMIX E120W

USE AND MAINTENANCE

INSTRUCTION MANUAL:

PASTEURIZER

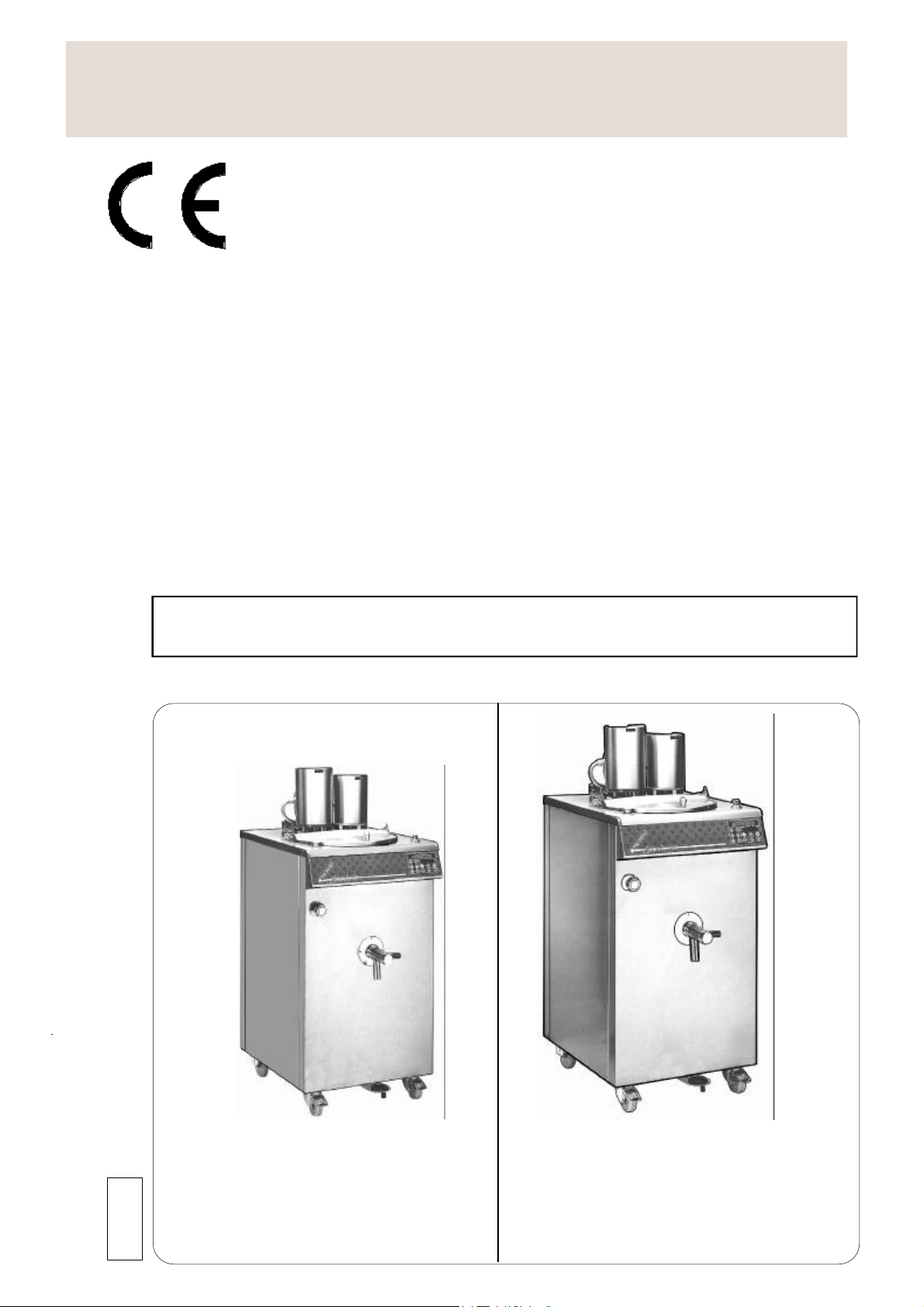

STARMIX 60W

STARMIX E60W STARMIX E120W

STARMIX 120W

USERINSTRUCTIONS

STARMIX60/120IngleseUTILIZZATORE(USER)012

2

PROMAG

STARMIX 60W-E60W-60A -E60A-120W-E120W

GB

The technical data for each machine model is

shown in the enclosed tables and on the data

plate located on the rear side of the machine.

This data is used as a reference when

performing inspections or checks.

Safe machine operation is assured by correctly following the

instructions given in this manual. Therefore, we suggest you keep the

manual in a safe place where it can be readily consulted as required.

Manufacturer

This plate is an exact

copy of that located on

the rear side of the

machine, for this reason

the manual forms an

integral part of the

machine and must be

kept together with it.

PROMAG

Via Benaco 4

20098 San Giuliano Milanese

Milano Italy

Tel. 02 - 98296.1

Telefax 02 - 98.80.232

Bar code

A = air condensation

W = water condensation

3

PROMAG STARMIX 60W-E60W-60A -E60A-120W-E120W

GB

A

B

C

page 7 / 41

43 / 60

page

61 / 64

page

65 / 73

page

INSTRUCTIONSFORUSER

INSTRUCTIONSFORTECHNICIAN-INSTALLER

ELECTRICALDIAGRAMS

SPAREPARTS

4

PROMAG

STARMIX 60W-E60W-60A -E60A-120W-E120W

GB

INTRODUCTION

This manual gives all assembly, operating and

maintenance instructions required for assuring

excellent operating results and a long machine

service life.

Before starting to use the machine,

read these instructions and follow them

very carefully.

Please do not hesitate to contact us for

any assistance you may require.

Failure to abide by the norms included in this

manual will invalidate the guarantee.

If the machine is sold or otherwise put

into another person's possession, ensure that the

manual accompanies the machine, therefore

allowing the new owner to correctly follow the

operating procedures and abide by the relative

precautions.

This machine is destined exclusively for the

pasteurization, maintenance and maturation of ice

cream mixtures.

Do not use this machine for any other use other

than that described above.

A similar use shall be considered improper.

This machine is designed to be used by adults.

Keep children away from the machine:

they should not be allowed to play with it.

Any attempt to modify this machine will not

only invalidate the guarantee but it will also be

extremely dangerous.

In order to assure efficient, correct machine

operation, carefully follow the manufacturer's

instructions and only allow professionally qualified

personnel to perform any necessary maintenance.

Never try to repair the machine yourselves, as any

attempt to make repairs by non-competent

persons will not only be dangerous but may also

cause serious injuries.

In the case of a malfunction, contact the distributor

from whom the machine was bought. He can give

you the address of the Authorized Service Centre

closest to you.

Only use original spare parts for any necessary

replacements.

If you decide to no longer use the machine, we

advise you to cut the electrical cord so that it

cannot be used (after disconnecting the plug from

the power socket).

In addition:

- In no circumstances should the refrigerant

gas or compressor oil be allowed to escape and

thus contaminate the environment.

- See that the machine is disassembled and that

the parts are disposed of in accordance with the

national regulations in force.

This machine contains H.C.F.C. gas which could be

harmful to the environment in the case of incorrect

maintenance operations or disassembly.

Therefore, any such operations must be done in

accordance with the national regulations in force,

and must only be performed by authorized

maintenance personnel.

PROMAG reserves the right to make any and all

modifications it deems necessary in order to keep

the machine updated - technically or otherwise - as

well as to allow it to meet the requirements of

certain individual countries.

For any additional information or technical help you

may require, please contact your authorized

service centre.

5

PROMAG STARMIX 60W-E60W-60A -E60A-120W-E120W

GB

This manual is made

up of three parts: Part B:

instructions and information for

the Technician - the Shipper

the Installer - the Maintenance Man the Repair Man

Part C:

electrical diagrams

and spare parts

Part A:

instructions and information for

the User and

the Technician-Installer

I)LadittaPROMAG,conlafirmadelsuodelegatoallasicurezzadelprodotto,dichiarasottolapropriaesclusivaresponsabilitàchelamacchina:

2) The company PROMAG hereby declares under its own sole responsibility, through the signature of its product safety mana-

ger, that the machine:

3) La société PROMAG, parla signature de son délégué à fa sécurité du produit, déclare sous sa propre et exclusive

responsabilité que la machine:

4) Die Firma PROMAG erklärt unter ihrer ausschließlichen Verantwortung mit der Unterschrift ihres Beauftragten für die

Produkt-Sicherheit, daß die Maschine:

5) Het bedrijf PROMAG verklaart hierbij uitsluitend op eigen verantwoordelijkheid, door middel van de handtekening van zijn

manager produktveiligheid, dat de machine:

6) La empresa PROMAG, mediante la firma de su encargado para la seguridad del producto, declara bajo su propia y exclusiva

responsabilidad que la máquina:

7) A firma PROMAG, com a assinatura do seu delegado para a segurança do produto, declara sob a própria e exclusiva

responsabilidade que a máquina:

8) Firmaet PROMAG erklærer hermed, gennem den produktsikkerhedsansvarliges underskrft og under eget ansvar,

at maskinen:

9) Yhtiö PROMAG vakuuttaa täten tuoteturvallisuudesta vastaavansa allekirjoittamana ja omalla vastuullaan, että kone:

10) Härmed intygar företaget PROMAG, genom underskrift av sin produktsäkerhetsansvarige och på eget ansvar, att maskinen:

11) Firmaet PROMAG erklærer herved, ved den produktsikkerhetsansvarliges underskrift og under sitt eneansvar, at maskinen:

STARMIX60/120 Matr..................

1) pastorizzatore di miscela per gelato, è conforme ai requisiti essenziali previsti dalle Direttive CEE 89/392,

91/368, 89/336, 73/23 e 93/68.

2) mix pasteurizing machine for ice cream, complies with the essential requirements indicated in EEC directive 89/392, 91/368,

89/336, 73/23 and 93/68.

3) machine pour la pasteurisation de mélange pour glace, est conforme aux conditions requises essentielles prévues par les

directives CEE 89/392, 91/368, 89/336, 73/23 et 93/68.

4) Pasteurisierautomat für Speiseeismisschungen, den grundlegenden, von den EWG-Richtlinien 89/392, 91/368, 89/336,

73/23 und 93/68 gestellten Anforderungen genügt.

5) machine voor het pasteuriseeren van mengsels voor consumptieijs, voldoet aan de essentiële voorwaarden vervat in de

EEG-Richtlijnen 89/392, 91/368, 89/336, 73/23 en 93/68.

6) pasteurizador de mezcla para helado, es conforme a los requisitos esenciales prevístos por las Directivas CEE 89/392,

91/368, 89/336, 73/23y 93/68.

7) Pastorizador de mistura para sorvete, é feita conforme os resuisitos principais previstos pelas Normas CEE 89/392, 91/368,

89/336, 73/23 e 93/68.

8) maskine til pasteurisering af mix till is overensstemmer med de væsentligste krav anført i EU direktiv 89/392, 91/368, 89/336,

73/23 og 93/68.

9) jäätelön sekoituksen pastörointikone noudattaa EU direktiiveissä 89/392, 91/368, 89/336, 73/23 ja 93/68 ilmaistuja olennaisia

vaatimuksia.

10) för mixning och pastörisering av glass uppfyller de väsentliga kraven i EU-direktiv 89/392, 91/368, 89/336, 73/23 och 93/68.

11) pasteuriserende blandemaskin for iskrem er i samsvar med de vesentligste krav angitt i EU-direktiv 89/392, 91/368, 89/336,

73/23 og 93/68.

The operating instructions form an integral part of the machine. - The machine user must not perform any of the operations

described in parts B and C; these must only be carried out by a qualified technician. - The user is therefore informed that if he

attempts to do so he will compromise the safety and health standards with which the machine is designed and built.

Copy of the conformity declaration found with the machine

This manual suits for next models

5

Table of contents

Other Promag Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use