Promag CUOCICREMA Series User manual

PROMAG

lemacchineperilgelato

02 - 2002

USE AND MAINTENANCE

INSTRUCTION MANUAL:

"CUOCICREMA" MACHINE

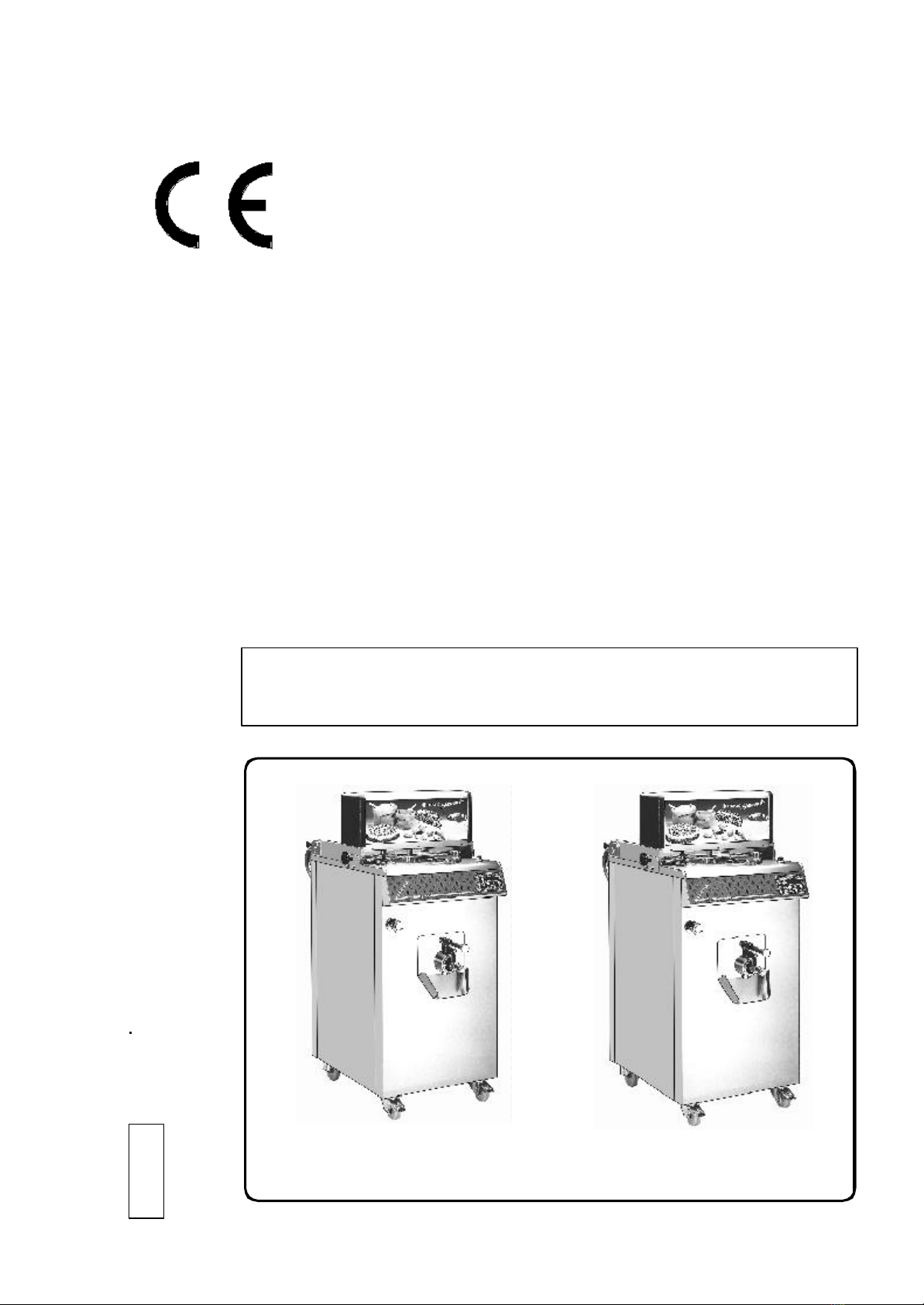

STARCREM 30/1 INV

STARCREM 60/1 INV

with R404A

STARCREM 60/1 INVSTARCREM 30/1 INV

USER INSTRUCTIONS

STARCREM 30/60 IngleseUTILIZZATORE (USER)

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

2

The technical data for each machine model is

shown in the enclosed tables and on the data

plate located on the rear side of the machine.

This data is used as a reference when

performing inspections or checks.

Safemachineoperationisassuredbycorrectlyfollowingthe

instructionsgiveninthismanual.Therefore,wesuggestyoukeepthe

manual in a safe place where it can be readily consulted as required.

Manufacturer

This plate is an exact

copy of that located on

the rear side of the

machine, for this reason

the manual forms an

integral part of the

machine and must be

kept together with it.

PROMAG

Via Benaco 4

20098 San Giuliano Milanese

Milano Italy

Tel. 02 - 98296.1

Telefax 02 - 98.80.232

Bar code

A = air condensation

W = water condensation

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

3

USER INSTRUCTIONS

A

pag.

pag.

77/89pag.

INSTRUCTIONS FOR USER

B

INSTRUCTIONS FOR TECHNICIAN-INSTALLER61/76

7/60

SPARE PARTS

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

4

INTRODUCTION

This manual gives all assembly, operating and

maintenance instructions required for assuring

excellent operating results and a long machine

service life.

Before starting to use the machine,

read these instructions and follow them

very carefully.

Please do not hesitate to contact us for

any assistance you may require.

Failure to abide by the norms included in this

manual will invalidate the guarantee.

If the machine is sold or otherwise put into another

person's possession,ensure that the manual

accompanies the machine therefore allowing the

new owner to correctly follow the operating

procedures and abide by the relative precautions.

The present "CUOCICREMA" machine,

is a multi-functional machine, destined exclusively

for pastry products (cream cooking) and ice cream

making (preparation and/or pasteurization of ice

cream mixture).

Do not utilize the "CUOCICREMA" for any other use

other than that described above.

A similar use shall be considered improper.

This machine is designed to be used by adults.

Keep children away from the machine;

they should not be allowed to play with it.

Any attempt to modify this machine will not only

invalidate the guarantee but is also extremely

dangerous.

In order to assure efficient, correct machine

operation carefully follow the manufacturer's

instructions and only allow professionally qualified

personnel to perform any necessary maintenance.

Never try to repair the machine yourselves,

as any attempt to make repairs by incompetent

persons will not only be dangerous but may also

cause serious injuries.

In the case of a malfunction, contact the distributor

from whom the machine was bought.

They can give you the address of the Authorized

Service Centre closest to you.

Only use original spare parts for any necessary

replacements.

If you decide to no longer use the machine,

we advise you to cut the electrical cord so that it

cannot be used (after disconnecting the plug from

the power socket).

In addition:

- Under no circumstances should the refrigerant

gas or compressor oil be allowed to escape and

thus contaminate the environment.

- See that the machine is disassembled and that

the parts are disposed of in accordance with the

national regulations in force.

This machine contains H.C.F.C. gas which could be

harmful to the environment in the case of incorrect

maintenance operations or disassembly.

Therefore, any such operations must be done in

accordance with the national regulations in force,

and must only be performed by authorized

maintenance personnel.

PROMAG reserves the right to make any and all

modifications reemed necessary in order to keep

the machine updated - technically or otherwise -

as well as to allow it to meet the requirements of

certain individual countries.

For any additional information or technical help you

may require, please contact your authorized service

centre.

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

5

USER INSTRUCTIONS

The operating instructions form an integral part of the machine. - The machine user must not perform any of the operations

described in parts B and C; these must only be carried out by a qualified technician. - The user is therefore informed that if he

attempts to do so he will compromise the safety and health standards with which the machine is designed and built.

I) La ditta PROMAG, con la firma del suo delegato alla sicurezza del prodotto, dichiara sotto la propria esclusiva responsabilità

che la macchina:

2) The company PROMAG hereby declares under its own sole responsibility, through the signature of its product safety manager, that

the machine:

3) La société PROMAG, parla signature de son délégué à fa sécurité du produit, déclare sous sa propre et exclusive responsabilité

que la machine:

4) Die Firma PROMAG erklärt unter ihrer ausschließlichen Verantwortung mit der Unterschrift ihres Beauftragten für die Produkt-

Sicherheit, daß die Maschine:

5) Het bedrijf PROMAG verklaart hierbij uitsluitend op eigen verantwoordelijkheid, door middel van de handtekening van zijn

manager produktveiligheid, dat de machine:

6) La empresa PROMAG, mediante la firma de su encargado para la seguridad del producto, declara bajo su propia y exclusiva

responsabilidad que la máquina:

7) A firma PROMAG, com a assinatura do seu delegado para a segurança do produto, declara sob a própria e exclusiva

responsabilidade que a máquina:

8) Firmaet PROMAG erklærer hermed, gennem den produktsikkerhedsansvarliges underskrft og under eget ansvar, at maskinen:

9) Yhtiö PROMAG vakuuttaa täten tuoteturvallisuudesta vastaavansa allekirjoittamana ja omalla vastuullaan, että kone:

10) Härmed intygar företaget PROMAG, genom underskrift av sin produktsäkerhetsansvarige och på eget ansvar, att maskinen:

11) Firmaet PROMAG erklærer herved, ved den produktsikkerhetsansvarliges underskrift og under sitt eneansvar, at maskinen:

STARCREM 30/60 Matr..................

1) preparatore e pastorizzatore di prodotti per pasticceria e gelateria, è conforme ai requisiti essenziali previsti dalle Direttive CEE

89/392, 91/368, 89/336, 73/23 e 93/68.

2) preparing and pasteurizing machine for pastry and ice cream products, complies with the essential requirements indicated in

EEC directive 89/392, 91/368, 89/336, 73/23 and 93/68.

3) machine pour la prèparation et la pasteurisation de produits pour pâtisserie et glacerie, est conforme aux conditions requises

essentielles prévues par les directives CEE 89/392, 91/368, 89/336, 73/23 et 93/68.

4) Maschine für die Vorbereitung und Pasteurisierung von Konditorei- und Speiseeisprodukten, den grundlegenden, von den

EWG-Richtlinien 89/392, 91/368, 89/336, 73/23 und 93/68 gestellten Anforderungen genügt.

5) machine voor het bereiden en pasteuriseeren van producten voor gebak en consumptieijs, voldoet aan de essentiële

voorwaarden vervat in de EEG-Richtlijnen 89/392, 91/368, 89/336, 73/23 en 93/68.

6) preparador y pasteurizador de productos para pastelería y helados, es conforme a los requisitos esenciales prevístos por las

Directivas CEE 89/392, 91/368, 89/336, 73/23y 93/68.

7) Preparador e pastorizador de produtos para confeitaria e sorveteria, é feita conforme os resuisitos principais previstos pelas

Normas CEE 89/392, 91/368, 89/336, 73/23 e 93/68.

8) maskine til tilberedning og pasteurisering af konditorkager og is-produkter overensstemmer med de væsentligste krav anført i

EU direktiv 89/392, 91/368, 89/336, 73/23 og 93/68.

9) konditoria-ja jäätelötuotteiden valmistus-ja pastörointikone noudattaa EU direktiiveissä 89/392, 91/368, 89/336, 73/23 ja 93/68

ilmaistuja olennaisia vaatimuksia.

10) för tillagning samt pastörisering av bakverk och glassprodukter uppfyller de väsentliga kraven i EU-direktiv 89/392, 91/368, 89/

336, 73/23 och 93/68.

11) maskin for tilberedning og pasteurisering av deig-og iskremprodukter er i samsvar med de vesentligste krav angitt i EU-

direktiv 89/392, 91/368, 89/336, 73/23 og 93/68.

This manual is made

up of three parts: Part B:

instructions and information for

the Technician - the Shipper

the Installer - the Maintenance Man the Repair Man

Part C:

electrical diagrams

and spare parts

Part A:

instructions and information for

the User and

the Technician-Installer

Copy of the conformity declaration found with the machine

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

6

INFORMATIONFORTHEUSERANDTECHNICIAN-INSTALLER

HELPFUL ADVICE

When manufacturing your products only use

the very best ingredients, in order to fully

satisfy even your most demanding customers.

Obtain all basic ingredients from well-established

firms that have a proven reliability.

When making your products follow the

instructions very carefully and do not try

to change the recipe in any way.

Always keep the machine spotlessly clean.

For all necessary repair work always contact one of PROMAG's assigned maintenance

firms.

If any of the operating, cleaning or maintenance instructions given in this manual are not

carefully followed, and an accident occurs, PROMAG cannot be held responsible.

General Information

Thank you for having chosen this machine.

Please read the instructions in this manual

carefully; they will assure long machine

service life.

We can guarantee that only the very best

materials have been used for this machine,

that it has been very carefully tested,

and that we are always ready to serve and

assist you in the best possible way.

IMPORTANT PRECAUTIONS

When the machine is being installed,

make sure that a disconnecting switch is

installed on the power supply line by a qualified

technician.

Always ensure that the plug is disconnected

from the mains before putting your hands inside

the machine or before performing cleaning or

maintenance operations.

(Contact a qualified technician whenever

maintenance is required).

Never clean the machine using a water jet

under pressure.

Always ensure that the plug is disconnected

from the mains before removing the housing,

side panels or any other protection in order to

carry out any operation within the inner part

of the machine.

(Such operations must only be performed by a

qualified technician)

Thanking you once again, we wish you all the best.

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

7

USER INSTRUCTIONS

Environmental conditions

Machine description

Number of users and type of work

Productive cycle

Operating modes

Precautions

Safety devices

Machine use

Description of external components

Correct use of product dispensing cock

Scraping blades

Description of internal components

Dangerous points on the machine

Protection measures for dangerous machine areas

Risks information

Recommendations on prevention measures to be adopted

Installation/Use of machine

Machine preparation

Operation

Program check

Inverter manual operation

Inverter semiautomatic operation

Cycle A Pastry cream

Cycle B High temperature pasteurization for ice cream mix

Cycle C Low temperature pasteurization for ice cream mix

Cycle D solidification of plain chocolate

Cycle G Bavarian cream

Cycle H Fruit jam

Cycle I Cooling

Cycle L Manual Cooking

Cycle M - N Personalized

Significance of programmable parameters

Stop modes

Black out

Anomalies

Operations to be performed after use

Dismantling

Technical characteristics

Dimensions

Programming table inverter Starcrem 30/1 INV

Tabella programmazione inverter Starcrem 60/1 INV

8

9

10

10

10

11

12/14

15

16/19

20/21

22

23

24/25

26

26/27

27/28

29

29

30/31

32

33

33/34

34/35

36/37

38/39

40

41

42

43

44

45

46/52

53

53

54

55

56

57

58/59

60

60

A 1

A 2

A 3

A 4

A 5

A 6

A 7

A 8

A 9

A 10

A 11

A 12

A 13/A 14

A 15

A 16

A 17

A 18/A19

A 20

A 21

A 22

A 23

A 24

A 25

A 26

A 27

A 28

A 29

A 30

A 31

A 32

A 33

A 34/45

A 46

A 47

A 48

A 49

A 50

A 51

A 52

A 53

A 54

A

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

page

INSTRUCTIONS FOR THE USER AND THE TECHNICIAN-INSTALLER

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

8

A 1.1

MACHINE OPERATING NOISE LEVELS

A 1 -ENVIRONMENTAL CONDITIONS

The machine must not be kept in a room where the

temperature can drop below 0° C.

The machine is not designed for installation in

atmospheres where there is a risk of explosion.

The acoustical pressure level produced by the

machine is shown on the enclosed technical

diagram.

Measurements were made throughout the operating

cycle using a class 1 instrument held

at the point where the user stands in relation to the

machine (as indicated in the sketch).

Level of continuous acoustical pressure measured

with a ponderation "A" filter.

STARCREM 30 - STARCREM 60

dB (A) 61 ÷ 65

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

9

USER INSTRUCTIONS

A2-MACHINEDESCRIPTION

Significanceoftrade-marknames

STARCREM 30 =30litres

STARCREM 60 =60litres

Function:

MULTIFUNCTIONALMACHINETOBEUSEDEXCLUSIVELYFORPASTRY

PRODUCTS (CREAM COOKING) AND ICE CREAM MAKING

(PREPARATIONAND/ORPASTEURIZATION OFICECREAM MIXES,

MAINTENANCEAND/ORMATURINGOFICECREAMMIXES).

For technical data of machines, see enclosures.

Machine components

Themachineiscompletewithamainframewithastainless

steel structure, the base of which is provided with four

wheels, one at each corner.

The frame is parallelpipedal, containing the cylinder,

electric box and cooling system.

Thecylinderismountedvertically,disposingofacooling

systemonexternalsurface(containingrefrigeratinggas),

a heating system (containing water) and a deep basin

(containingwater),inwhichresistances arelocated,and

wherebyheatingiscarriedoutwith"bain-marie"method,

a particular characteristic of Promag.

The low speed and high speed mixer shafts are

immersed in the cylinder. They are connected to

respectivemotors,thelatterbeingassembledontomotor

bearings.

The main cooling system elements comprise: a

compressor, a condenser, a thermostatic valve and a

compressor pressure switch.

Thecylinderdiposesofanoutletwhichislocatedonthe

front side of the machine. This opening may be closed

withacock,providedwithapistonwithtwoO-ringseals.

Above closes outlet at the level of container edge. This

solution guarantees a perfect hygiene, as the mix

contained in the cylinder has no chance of stagnating in

the stub pipe.

The outlet diameter may also be reduced for the

discharge of extremely liquid mixes.

Twohalf-lidsarelocatedattheupperpartofthecylinder,

served by two magnetic safety microswitches.

On opening any one of the two lids, all machine

operationswillbeinterruptedand "OPEN" willappear

on the display.

As already mentioned, the motors are mounted on

motor bearings.

Above are served by a magnetic safety microswitch.

On lifting the motor bearings, all operations of the

machine are interrupted and "OPEN" will appear on

the display.

The manual cock commanding the small washing

shower unit is located on the upper left front side of

the machine.

The small shower unit is situated on the bottom of the

cylinder in the right-hand corner.

Acontrolpanel,facinginwards,islocatedontheupper

front side of the machine, where an electronic card

may be found.

Control buttons are accessible on control panel.

Theelectricbox,asdescribedabove,isalsoincluded

inside the frame and is positioned on the rear side of

same.

Water connections for cooling system are present on

the rear side of the machine, in addition to those for

drinking water for small shower unit.

Electric feed cables are also present.

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

10

A3 -NUMBER OF USERS AND TYPE OF WORK

The machine is designed to be used by one

operator only, in charge of loading product to be

processed, setting productive cycle and

subsequent recovery of product through cock.

A 4 -PRODUCTIVECYCLE

The user opens the front half-lid (34) and pours the

product into the cylinder, closing same.

He starts up productive cycle, after having set

appropriate parameters with buttons (36).

He unloads product by using special cock (37).

A5 -OPERATING MODES

The machine is designed for a single type of

continuous operation, on pressing heating or

maintenance buttons.

Machine stops automatically.

Machine is also designed for manual operation on

pressing buttons for low speed stirring, intermittent

low speed stirring, high speed stirring.

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

11

USER INSTRUCTIONS

A6-PRECAUTIONS

(For the user only)

It is forbidden and very dangerous for user to carry out any intervention which should

be done by a TECHNICIAN/INSTALLER.

Removal of protective coverings and access to internal parts of machine, in addition to all internal

maintenance operations, repairs, installation, transport and unpacking must be

carried out by qualified personnel.

Danger points

Themachinehascertain dangerpointsandareaswhere

accidents may occur if the following precautions are not

observed.

-Itisforbiddenandverydangeroustoapproachmachine

cylinder when same is turned on or in motion.

- It is forbidden and very dangerous to carry out

anyrepairsonsystem,whethermechanicalorelectrical,

when the machine is functioning.

Refer to enclosures for electric and water systems.

- It is forbidden to use the machine without operatorís

supervision.

- It is forbidden and very dangerous to come too near

and/ortouchwithany part ofthebodyand/orany type of

objecttheshaftbars:lowspeedandhigh speed mixers

project from cylinder covers

until reaching motor bearings.

For the same reason do not approach relative motors

from rear side of motor casing.

-Itis forbiddenandverydangerous tointroduceparts of

the body or any type of object into the product outlet.

- It is dangerous to touch machine ON/OFF wall switch

with wet hands.

- It is strictly forbidden to open electric box.

- It is forbidden and very dangerous to approach

the machine with magnetic materials, as they

would interfere with magnetic safety microswitches

located under the two cylinder half-lids and under the

right shoulders of the motor bearings

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

12

21

A7-SAFETYDEVICES

A 7.1

Three magnetic microswitches are mounted onto the

STARCREM machines (19) (20) (21).

Microswitch (19) is located on the front left-hand side

under the cylinder.

Microswitch (20) is located on the rear right-hand

side under the cylinder.

Microswitch (21) is located on the rear left-hand side

under the cylinder.

Their purpose is to block any machine operation

should the front half-lid [(microswitch (19)], motor

bearings [(microswitch (20)], rear half-lid

[(microswitch (21)], be opened or lifted with the

machine in operation.

7

19 Front left-hand microswitch

21 Rear left-hand microswitch

22 Blocking device for motor bearings

20 Rear right-hand microswitch

20 36

22

19

A 7.2

There is a machine stop button (7) located on the

control panel at the front of the machine which, when

pressed, stops any machine operation.

A 7.3

- 12 Volt control panel.

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

13

USER INSTRUCTIONS

A 7.5

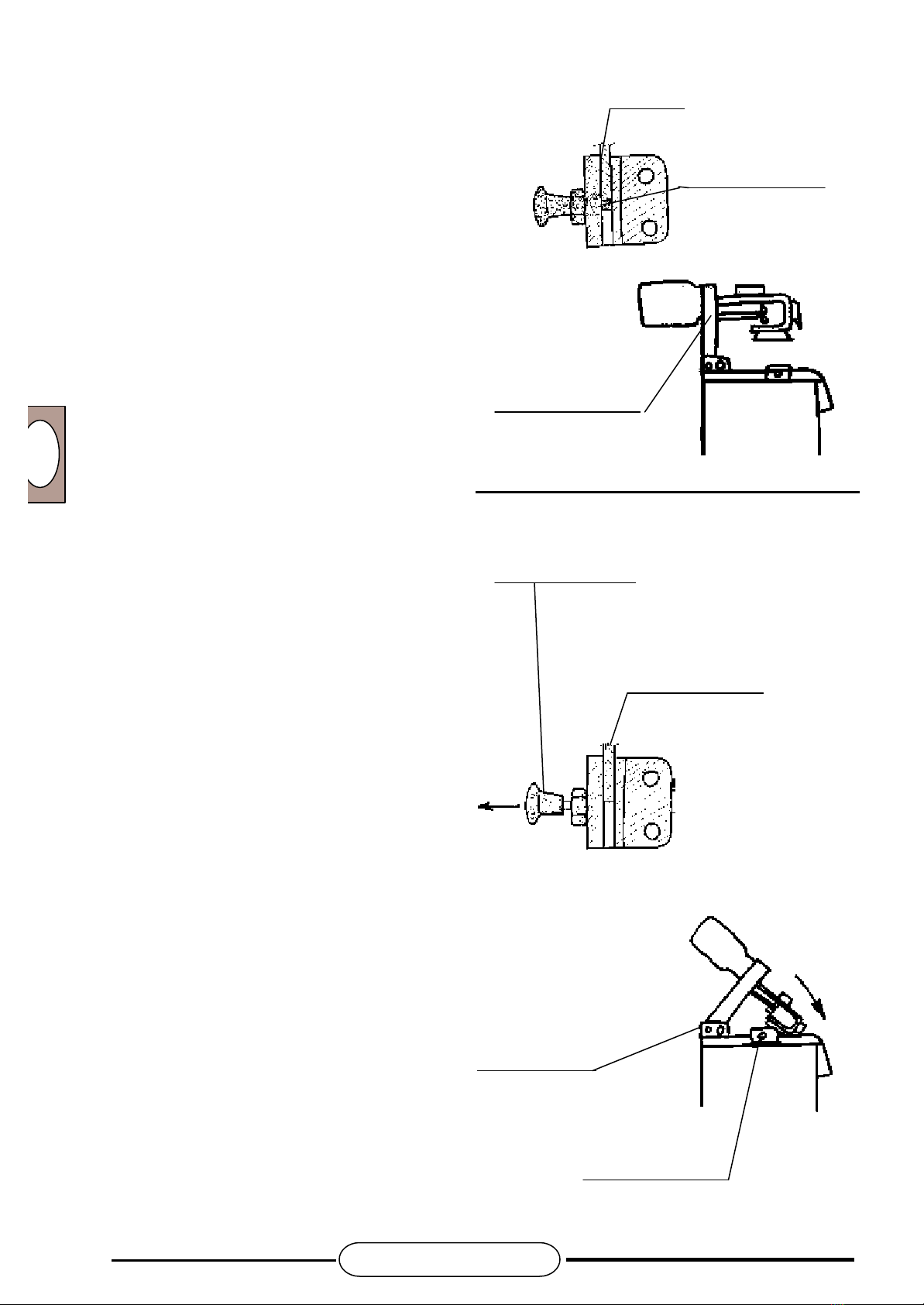

The STARCREM machines also have a safety device

to block the motor bearings (22).

The purpose of this is to prevent motor bearings falling

onto cylinder plane, should the latter be lifted for either

cleaning of mixer shafts or for any other reason.

A 7.5a

Normal position of motor bearings with machine in

operation. The motor bearing leans on cylinder plane

and disconnected blocking device.

A 7.5b

Turnover phase of motor bearings.

The motor bearing may be lifted subsequent to

unscrewing of closing handwheel screws.

Perform above operation with extreme care, so that

motor bearing does not fall on cylinder plane,

subsequently hitting operator and causing serious

damage.

Until motor bearing is not in a vertical position, the

relative safety blocking device will not be activated;

therefore, as already mentioned, it is the operatorís

responsibility to take precautions, utilizing the

necessary measures to prevent risks of crushing,

entangling, or cutting with regard to persons, animals

or objects.

Blocking

device Cylinder plane

Motor bearing

Hinge pin

Closing handwheel

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

14

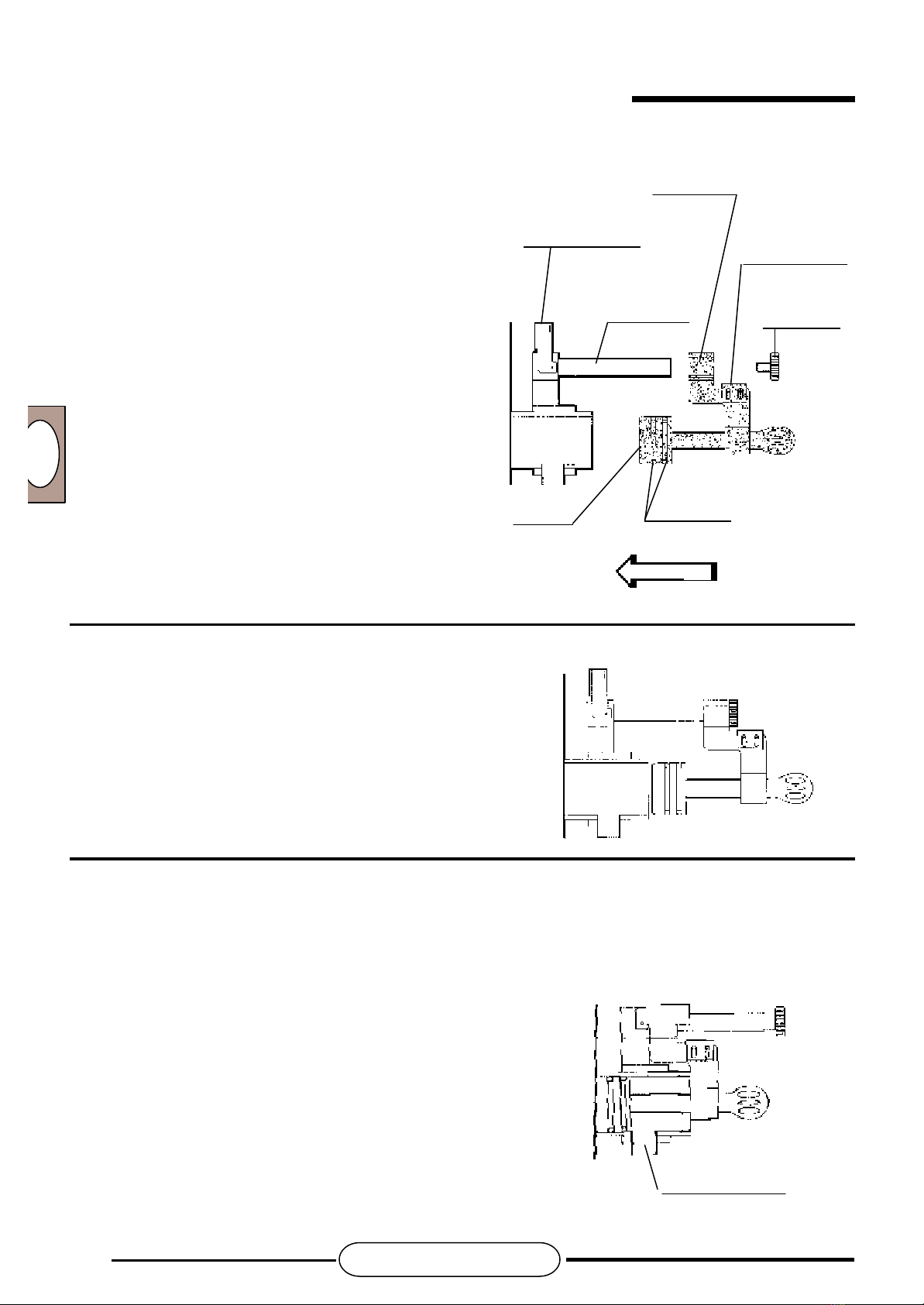

A. 7.5c

Motor bearing entirely upturned: motor bearing has

been completely lifted, therefore now in vertical

position. Only in this position will the blocking

security device be activated, causing the block pip

to protrude.

In this manner, the motor bearing cannot fall onto the

cylinder plane and cleaning and washing operations

may be safely performed.

However, it is always necessary to check that above

device is functioning properly, together with wear of

same.

Should any deterioration be detected, please

contact authorized technical service.

A. 7.5e

Closing of motor bearing on cylinder plane.

In order to carry out this operation, it is necessary to

unblock security device.

With the right hand, firmly maintain motor bearing in

vertical position; contemporarily pull the security

device knob towards the left with the left hand.

Slightly lower motor bearing, until block pip grazes

over left shoulder of motor bearing. In this position,

safety block may no longer be activated.

Firmly grip motor bearing with both hands,

subsequently lowering same onto cylinder plane.

Carry out this operation extremely carefully, avoiding

that motor bearing falls abruptly onto cylinder plane,

subsequently hitting operator and causing serious

damage.

When closing motor bearing, it is operatorís

responsibility to be careful, taking necessary

precautions to prevent risks of crushing, entangling

and cutting with respect to persons, animals or

things.

When the motor bearing is on the cylinder plane,

block it with two closing handwheels.

Motor bearing left

shoulder

Blocking pip

Motor bearing in

vertical position

Hinge pin

Motor bearing left

shoulder

Closing handwheel

Safety device knob

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

15

USER INSTRUCTIONS

A 8 - MACHINE USE

Use according to norms.

STARCREM machines are expressly designed to

cook cream, being multifunctional and only

destined for pastry products (cream cooking), ice

cream making (preparation and/or pasteurization of

ice cream mixes), maintenance and/or maturing of

ice cream mixes.

Use for any other purpose will not conform to the

norms.

The manufacturer is not responsible for any

damages deriving from improper use.

Any risks will be borne by user.

Manufacturerís safety, operational and maintenance

regulations must be observed.

The norms in force regarding accident prevention

and other acknowledged technical safety

regulations must also be observed.

Only properly trained and qualified personnel may

use, maintain or repair the machine.

The machine is mainly manufactured in stainless

steel AISI 304, together with plastic material as for

the food industry.

Any arbitrary modifications made to the machine will

exonerate manufacturer from any eventual damages

deriving therefrom.

The machine may only be used with original

accessories and spare parts made by the

manufacturer.

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

16

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS (front view)

49) Motor bearing

blocking device

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS

(top view without motor casing)

48) Rotating front wheels

34) Front half-lid

38) Motor casing

35) Rear half-lid

43) Shower cock

37) Product outlet cock

44) Slide

39) Motor bearing

41) Closing handwheel 36) Control panel

42) Small shower

40) Hinge

45) Outlet for

dense products

46) Outlet for

liquid products

47) Fixed rear wheels

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

17

USER INSTRUCTIONS

14) Start-up led for cooling and

maintenance cycle

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS (Control panel )

10)Emergency

stop button

12) Program button

1) Start button for cooking

cycle

13) Start-up led for

cooking cycle

2) Start button for cooling and

maintenance cycle

15) ON-OFF low speed motor led

3)Low speed motor

ON-OFF button

7)High speed motor

ON-OFF button

4)Low speed intermittent

motor manual start-up

button

8)Bell setting button

5)Button for parameter

reduction

9) Reset

button

16) Manual start-up led for low

speed intermittent motor

17) High speed motor ON-OFF led

6)Button for

parameter

increase

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

18

Setscrew

Cock security lock

A 9 -DESCRIPTION OF EXTERNAL COMPONENTS PRODUCT OUTLET COCK

Piston guide rod

Piston bearing

Outlet lock for liquid mixes

Knob

Bush

Cylinder

OR Seal

Piston guide rod bearing

Outlet for dense mixes

Piston rod

Outlet for liquid mixes

PROMAG STARCREM 30/1 INV - STARCREM 60/1 INV

GB

19

USER INSTRUCTIONS

In order to avoid mineral deposits in the tubes and condenser, caused by water hardness, it is

recommended to install a water softener.

27) Wall ON/OFF switch

29) Air extraction fan

30) Drinkable water

inlet for small

washing shower

A 9 -DESCRIPTION OF EXTERNAL COMPONENTS (rear view)

25) Electric cable

for high speed

mixer motor

26) Electric cable

for low speed

mixer motor

28) Electric cable

31) Cooling system

water inlet 32) Water outlet

PROMAG

STARCREM 30/1 INV - STARCREM 60/1 INV

GB

USER INSTRUCTIONS

20

A 10 - CORRECT USE OF PRODUCT DISPENSING COCK

Guide rod

Piston ORseals

Liquidmixoutlet

lock

Pistonbush

Setscrew

Cocksafetylock

In order to use the product dispensing cock correctly,

the following must be carried out:

begin productive cycle after having carried out cleaning

operations indicated in specific paragraph.

However, remember that mechanical parts in contact with

food must be perfectly sterilized, whilst those in motion

or sliding must be subsequently lubricated,

using advised products or similar.

A - Check that guide rod, piston bush and 2 OR

seals are duly lubricated. Push piston guide rod bearing

against slide.

Tighten the dowel on the right-hand side with

special setscrew wrench.

B- Place cock safety lock in vertical position.

C- Place liquid mix outlet lock in downward position.

D- Assemble piston group onto guide rod with piston bush.

Centering of bush with rod should be carried out carefully,

thereby avoiding any damage to bush during introduction,

wearing out external edges of same.

E- Screw setscrew until contact is made with guide rod.

A 10.2

Cock disassembly

Repeat previous operations in opposite sense.

Assembled cock

A 10.3

Cock closing

A -Push the piston group towards the dense mix outlet.

The movement direction must be perpendicular to outlet.

IN NO WAY MUST GUIDE ROD OR PISTON GROUP BE FORCED

IN DIFFERENT DIRECTION, as disalignment of guide could be

caused, with consequential erroneous centering of piston in outlet.

B - Introduce piston into the outlet with a smooth movement, avoiding

that any metallic parts of the two components come into contact with

one another. Push piston until reaching stop.

C- Lower the cock safety lock.

D- This will guarantee closing position, also in the presence of strong

mixing vibrations in the cylinder towards outside. Workingsurface

This manual suits for next models

2

Table of contents

Other Promag Commercial Food Equipment manuals