This device complies with Part 15 of the FCC .

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

1. General Information

1-A. Model Classification:

WEC 200 - 00

○

1○

2○

3

○

1Model name: WEC (Wiegand Ethernet Controller)

○

2Model number: 200

○

3Type: 00standard

1-B. Accessories

a. WAS-1499 for LAN cable.

b. 5 Pin Wiegand Input (CN2-L35005-T01-G)

c. 10 Pin Output (CN2-L35010-T01-G)

1-C. Key features

Network-enable Wiegand Reader device

The beep mode of BUZZER is adjustable.

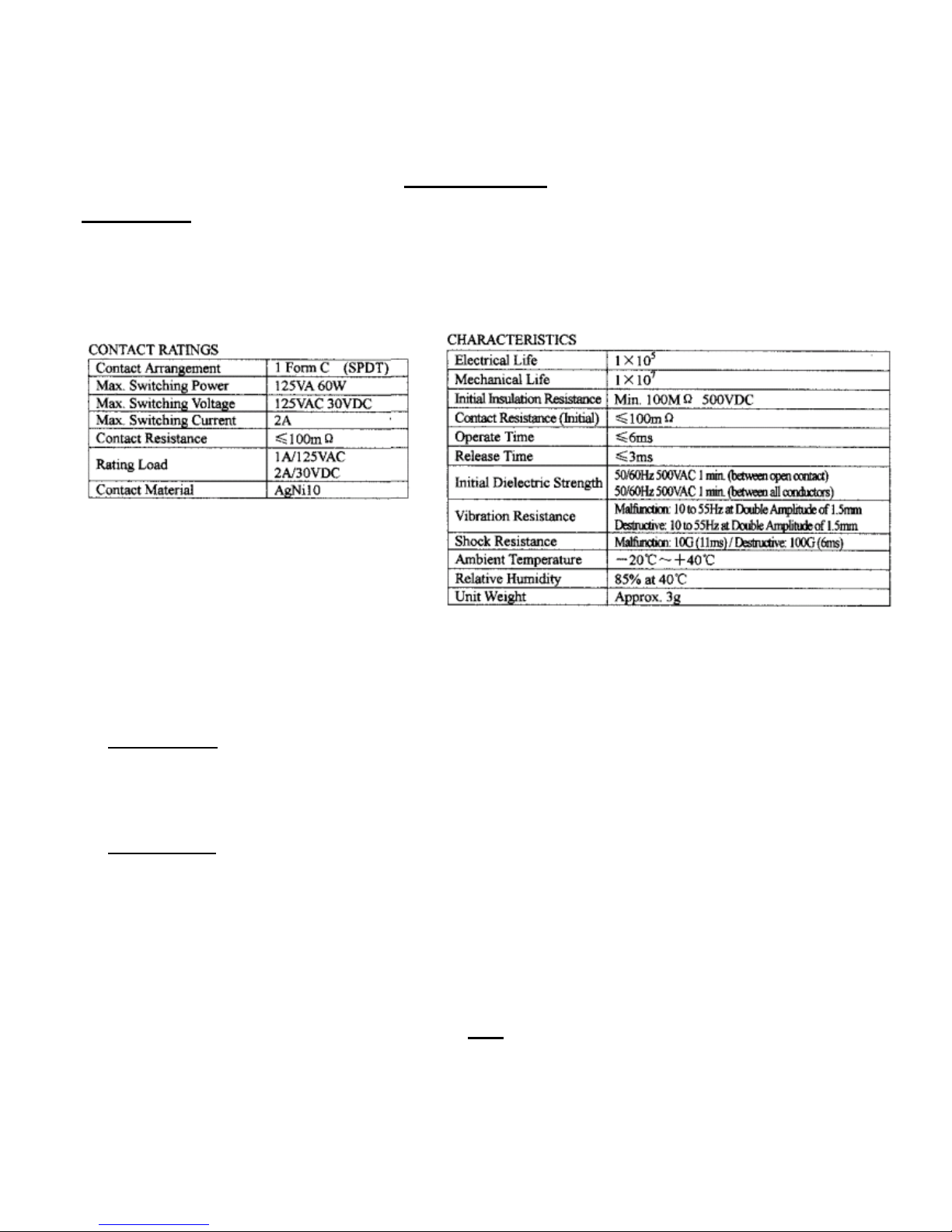

Two relay outputs are set, each relay includes Action (N.O.)/Non Action (N.C.)/Common Contact

Two input contacts are set.

Able to output Wiegand (raw data), or Facility Code (Site Code) and Card Code directly.

If your computer is equipped with one RJ45 port, you are able to connect the 10/100BaseT

Ethernet, and support TCP/IP, UDP with your Wiegand reader through WEC200.

Featuring of unduplicated service code

Able to define the machine ID and name from users’end.

2. Introduction

Points to follow to ensure correct use of the controller

WEC200 applies Ethernet technology to do the communication, which is important respectably

when working on the program applying Ethernet technology. Thanks to WEC200 converter, which is

built-in Ethernet module featuring:

i. The working Ethernet package will transform all Data into Serial Signal.

ii. The Data will be sent to MCU, the internal of WEC200.

Please refer to Chapter 5 for framework and useful tips of WEC200

Please refer to Chapter 6 for the functions of MCU

The package tool named “DS manager”and “Connection wizard”should be attached, which

both equip you rapidly to set a virtual COM port. With connecting to WEC200, you may run the