Promation Engineering PX1 Series User manual

Installation & Operation

Manual

This IOM is for the following

ProMation Engineering Products:

PX1-24N7+ACDC

PX1-24N7+DC

Division System

CAN/CSA-C22.2 No. 0-10, CSA C22.2 No. 30-M1986, CSA C22.2 No. 25-17, FM

3600, FM 3615, FM 3616

Class I Division 1 Groups C,D T4

Ambient Temperature - 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Class II Division 1 Groups E,F,G T130°C

Ambient Temperature - 30 °C to + 70 °C ( - 22 °F to + 158 °F )

Zone System

CAN/CSA-C22.2 No. 0-10, CAN/CSA-C22.2 No. 60079-0, CAN/CSA-C22.2 No.

60079-1,

CAN/CSA-C22.2 No. 60079-31, UL 60079-0, UL 60079-1, UL 60079-31

Class I, Zone 1, AEx db IIB Gb T4

Class II Zone 21, AEx tb IIIC T130°C

This page intentionally left blank

Contents

2 . . . . . . . . . . . . . . . . . . . Product Specifications

3 . . . . . . . . . . . . . . . . . . . Shipping and Handling

3 . . . . . . . . . . . . . . . . . . . Product Mounting and Setup

3 . . . . . . . . . . . . . . . . . . . Installation Notes

4 . . . . . . . . . . . . . . . . . . . Wiring Diagram

4 . . . . . . . . . . . . . . . . . . . Torque Switches

5 . . . . . . . . . . . . . . . . . . . Layout of Controller

6 . . . . . . . . . . . . . . . . . . . Check End of Travel Settings

6 . . . . . . . . . . . . . . . . . . . Status Indicators

7 . . . . . . . . . . . . . . . . . . . Adjusting the actuator CW position

8 . . . . . . . . . . . . . . . . . . . Adjusting the actuator CCW position

9 . . . . . . . . . . . . . . . . . . . Adjusting the actuator Auxiliary Switches

10 . . . . . . . . . . . . . . . . . . Mechanical Data

11 . . . . . . . . . . . . . . . . . . Mechanical Data

12-14 . . . . . . . . . . . . . . . Commissioning

15 . . . . . . . . . . . . . . . . . . AutoCalibration Procedure

IOM Template Master.indd

Page 1 of 17 P2/3 Series HV-TS AdVanced Proportional Control

Table of Contents

2 ................... Product Specifications

3 ................... Hazardous Location Notes

5 ................... Shipping and Handling

5 ................... Product Mounting and Setup

5 ................... Installation Notes

6 ................... Wiring Diagram

7 ................... Check End of Travel Settings

7 ................... Adjusting the actuator CCW and CW positions

8 ................... Adjusting the actuator Auxiliary Switches

9 ................... Mechanical Dimensions

10 .................. Mechanical Data

11 .................. Commissioning

FM_PX1 LV N7 Ver B 072921

Page 1 of 11 P1 HV Series

Field Manual

PX1- Series LV

On/Off/Jog Control

ISO5211 F03/05 8P14

50°F

10°C

75°F

24°C

100°F

38°C

125°F

52°C

150°F

65°C

25%

50%

75%

100%

On/Off/Jog

Proportional

Ambient Temperature

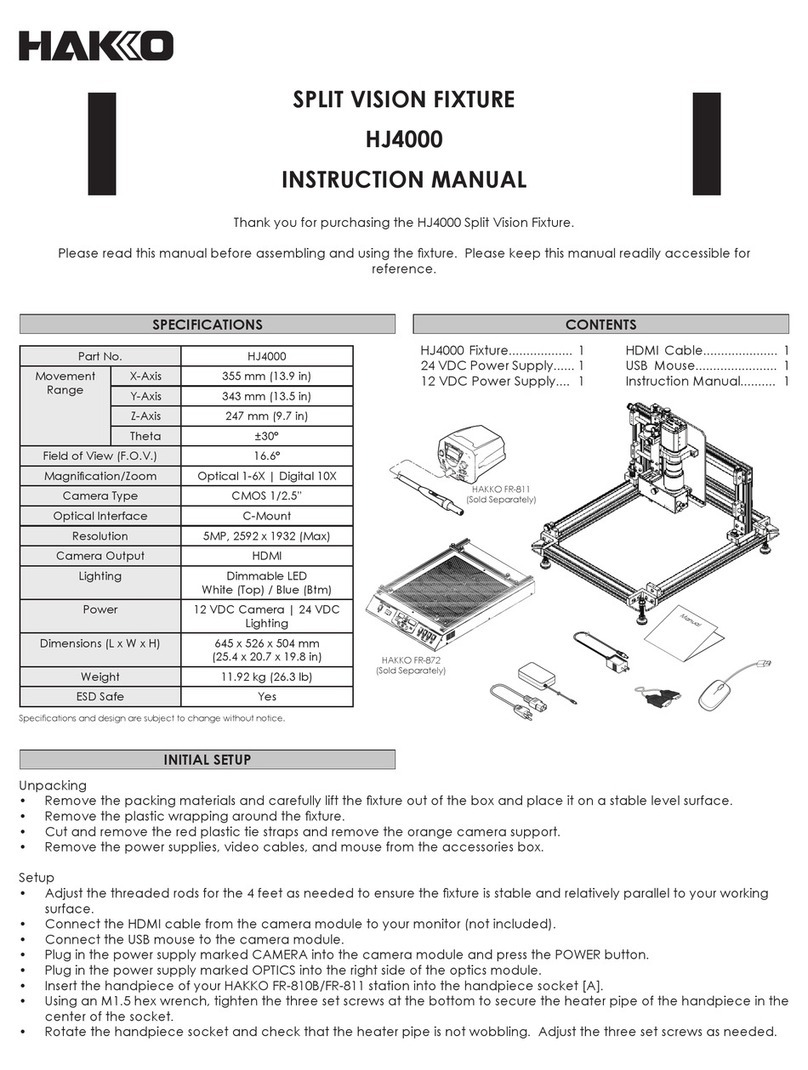

Introduction

The following procedure is to be followed for set-up, calibration, testing and use of the P Series quarter-turn

electric actuators. Each unit is shipped from the factory with initial calibration of cams and switches completed for

0-90 degree operation. However, these are general settings and serve as a starting point for proper calibration

of the actuator in its real-world application. There are no mechanical stops on this model.

Safety

Safety is a basic factor any time you maintain and operate mechanical equipment. Use of proper handling

methods, tools and clothes can help prevent serious accidents -- accidents which can cause injuries to you

or a fellow worker. This manual was created to enable a trained user to install, adjust and troubleshoot your

ProMation P Series actuator.

Only competent and trained personnel should install, maintain and repair ProMation Actuators. Any work related

to this Actuator must be carried out in accordance with this manual and related codes and regulations. Local

workplace health and safety rules should always be followed.

Duty cycle

Duty cycle is the percent of time that an actuator spends running as a fraction of the total time. Duty Cycle is

directly related to heat; overusing an actuator typically results in motor overheating which can permanently

damage it. Overheating also consumes more electricity. Generally speaking, the hotter a motor becomes, the

longer‘rest’itneedstocooldownsoitrunsefficiently.

Actuator Speci cations P1

Torque “lb/Nm 300”lbs/35Nm

Supply Voltage 12vac/dc 24vac/dc

Max Inrush Current 2.0A 2.8/1.8A

Running Current 1.9A 1.6/1.4A

Motor DC Brush Type

Runtime (90°@60Hz/vdc) 15 sec

Runtime (90O@50Hz) 15 sec

Duty Cycle 75%

Motor Starts 1200 per hour

Weight 5lbs/3kg

Mechanical Connections ISO5211 F03/F05 8pt 14mm

Electrical Entry (2) 1/2” NPT

Electrical Terminations 14-18ga

Environmental Rating NEMA 4/4X

Manual Override 8mm Socket Drive

Control On/O/Jog

Actuator Case Material Aluminum Alloy, Powder coated

Motor Protection 230°F/110°C Thermal F* Class

*Totally Enclosed Non-Ventilated Motors

Ambient Temperature

Operating Range

-22°F to +125°F

-30°C to +52°C

Wire Sizing Chart

MAX distance between Actuator

and Supply (feet)

Actuator/

Voltage

P1

12VAC/DC

P1

24VAC/DC

2.0A 1.6A

18 41 103

16 65 162

14 105 262

Wire

Gage

Amps

P1 LV N4

FM_PX1 LV N7 Ver B 072921

Page 2 of 11 P1 HV Series

Product Specications

PX1

, 7, 9

-22°F to +158°F

-30°C to +70°C.

1 General Information

1.1 Safety Instructions

• Installation, maintenance and repair must be performed by trained personnel.

• The handling shall follow the safety and warning instructions contained in this manual.

• The user should read and follow instructions contained in this operation manual. Failure

to do this may result in damages and void warranty. ProMation Engineering is not liable

for damages due to operator negligence or misuse.

• All national, regional and local health and safety codes are to be followed when in

installing and operatring equipment.

• The surface temperature may exceed 60°C (140°F). Please check the surface

temperature before operation, using an appropriate thermometer and protective clothing

before operation.

1.2 Installation Notices

1.2.1 Hazardous Location Information

• DO NOT install in ambient temperatures that exceed 70 °C (158 °F).

• DO NOT, under any circumstances, remove the cover of the actuator while in a

hazardous location when the power is still live inside the actuator. This could cause

ignition of a hazardous atmosphere.

• DO NOT, under any circumstances, use an explosion-proof electric actuator in a

hazardouslocationthatdoesnotmeetthespecicationwhichtheactuatorwas

designed for.

• When removing the actuator, care must be taken not to scratch, scar or deform the

amepathofthecoverorbaseoftheactuator.Thatwillnegatetheprotectionratingof

the enclosure in a hazardous location.

• The explosion proof electric actuator is shipped with matched mating surfaces of the

cover and base. When assembling or dissassembly the cover from the actuator, match

the mating number (QA code) of the top with the bottom. to assure hazardous location

protection.

• Please read operation manual and wiring diagram carefully before installation.

• Verify that supply voltage is in accordance with the data on nameplate to prevent

electricl component damage caused by incorrect power input.

• Turnpowerobeforeperfominganyinstallation,wiringormaintenanceprocedures.

• There are grounding devices both inside and outside of the actuator. Ground wires

should be connected properly.

• Themetalplugsinconduitentriesarefortransitonly.Forlongtermprotectiont

suitableameproofcableglandandpowercableshouldbewithaminimumwithstand

temperature105 °C (221°F).

• Failure to follow safety instructions may cause serious injury, equipment damage, or

void warranty

• Mount, calibrate, and test actuators only during non-hazardous conditions.

• All electrical connections must be to national, state, and local codes and in

accordancewithhazardouslocationspecicationsforwhichthisactuatoristobe

used.

Hazardous Location Actuators

FM_PX1 LV N7 Ver B 072921

Page 3 of 11 P1 HV Series

Hazardous Location Information (Continued)

• Do not touch any components on the PCB with metal tools or bare hands to avoid functional

failure caused by static electricity discharge.

• Do not parallel wire multiple actuators together without using isolation relay(s).

• Use proper techniques when installing conduit and properly seal the connection. Do not

mount the actuator with conduit entries in such a position that allows condensation to enter

the unit.

• Actuator should be installed in an upright or horizontal position. Do not mount upside down or

below a horizontal position.

• Periodically inspect actuator enclosure to prevent water intrusion and dust accumulation.

• Checkthemarkingandcerticatenumbertoseeifitconformstotheindicatedapplication.

• All the parts of the housing are assembled in the right manner and fastened. USE

FASTENERSWITHYIELDSTRESS≥700MPa.

• KEEP COVER TIGHT WHILE CIRCUITS ARE ALIVE. AFTER DE-ENERGIZING, DELAY

10 MINUTES BEFORE OPENING THE COVER.

• SEAL REQUIRED WITHIN 18 INCHES (450 mm) OF ENCLOSURE (for Divisions only).

• SEAL REQUIRED WITHIN 2 INCHES (50 mm) OF ENCLOSURE (for Zones only).

• The actuator is delivered with two conduit entries plugged by metal plugs. Use cable glands

rated for the corresponding hazardous location designation. The electrical supply cable

must be suitable for power rating and with a temperature rating of greating than 105 °C

(221 °F).

CSA Testing

• Atmospheric pressure : 80 - 106 kPa.

• Ambient temperature: -30 °C to +70 °C (-22 °F to +158 °F).

• Air with normal oxygen content: 21 % (Volume).

FM_PX1 LV N7 Ver B 072921

Page 4 of 11 P1 HV Series

FM_PX1 LV N7 Ver B 072921

Page 5 of 11 P1 HV Series

Shipping and Handling

1. This actuator is shipped in the FULLY CW (position indicator shows “CLOSE”)

position.

2. THIS ACTUATOR MUST HAVE WATER TIGHT HAZARDOUD LOCATION EMT

FITTINGS WITH CONDUIT DRAINAGE INSTALLED AND POWER SUPPLIED

TO UNIT TO KEEP THE HEATER WARM AT THE TIME OF INSTALLATION.

3. Storage: This unit should NOT be stored outside unless it is powered up

and has proper conduit terminations. When NOT powered up, it should be

stored in a clean, dry environment at all times.

4. This actuator has been factory calibrated to operate between 0 degrees and

90 degrees. Most quarter-turn products will not require recalibration of

these settings. If any travel adjustment is necessary, please refer to pages 5

& 6 for instructions.

Product Mounting and Setup

1. Note: This design utilizes NO MECHANICAL stops. It is recommended that you do NOT use the manual override

until the actuator is mounted to a valve or damper that has 90 degree limited travel.

2. Fully CLOSE the valve or damper to which the actuator is to be mounted.

• Keep in mind this actuator rotates CW (as viewed from above the unit) when driving CLOSED.

3. Assemble necessary linkage components and attach the actuator to the driven device.

4. Tighten mounting bolts, making sure actuator is centered on the device drive shaft.

5. Utilize the manual override (8mm hex output drive on bottom of actuator) to check for unobstructed manual operation

from fully CW to fully CCW positions BEFORE applying power to the unit.

Warning: DO NOT operate manual override when power is present. Geartrain damage

and personal injury may occur.

Do not use powered tools to turn the manual override -- it will DAMAGE the gear train or

motor and VOID the warranty.

6. Make the electrical connections per wiring diagram on page 6.

• For operation only four connections are needed. The balance of the connections are used for options and features.

• Terminals A, B & C are an aux switch for the open position (adjustable).

• Terminals A, E & F are an aux switch for the closed position (adjustable).

• Both Switches above share a common terminal “A”. Terminals A-F on the switch card are for the (adjustable) aux

switches. They are dry type Form C rated 3A @ 250vac MAX.

7. Do NOT apply power at this time.

Installation Notes

• There are no mechanical stops on this model.

• These actuators are designed to be used in either a horizontal or upright position. Do NOT mount the assembly with

the actuator top below a horizontal position.

• When installing conduit, use proper techniques for entry into the actuator. Use drip loops to prevent conduit condensate

from entering the actuator.

• Both NPT conduit ports MUST use proper equipment to protect the NEMA 4X integrity of the housing.

• The internal heater is to be used in ALL applications.

• Do NOT install the actuator outdoors or in humid environments unless it is powered up and the heater is functioning.

• Use proper wire size to prevent actuator failure (see chart on page 4 for proper wire sizing).

• All terminals accept 14-18AWG solid/stranded wire.

• Do NOT parallel wire multiple actuators together without utilizing isolation relays! If this is your intention,

please contact ProMation Engineering for a multiple actuator parallel wiring diagram.

The actuator is shipped from the

factory in its fully CW position.

Actuator ships in fully closed position!

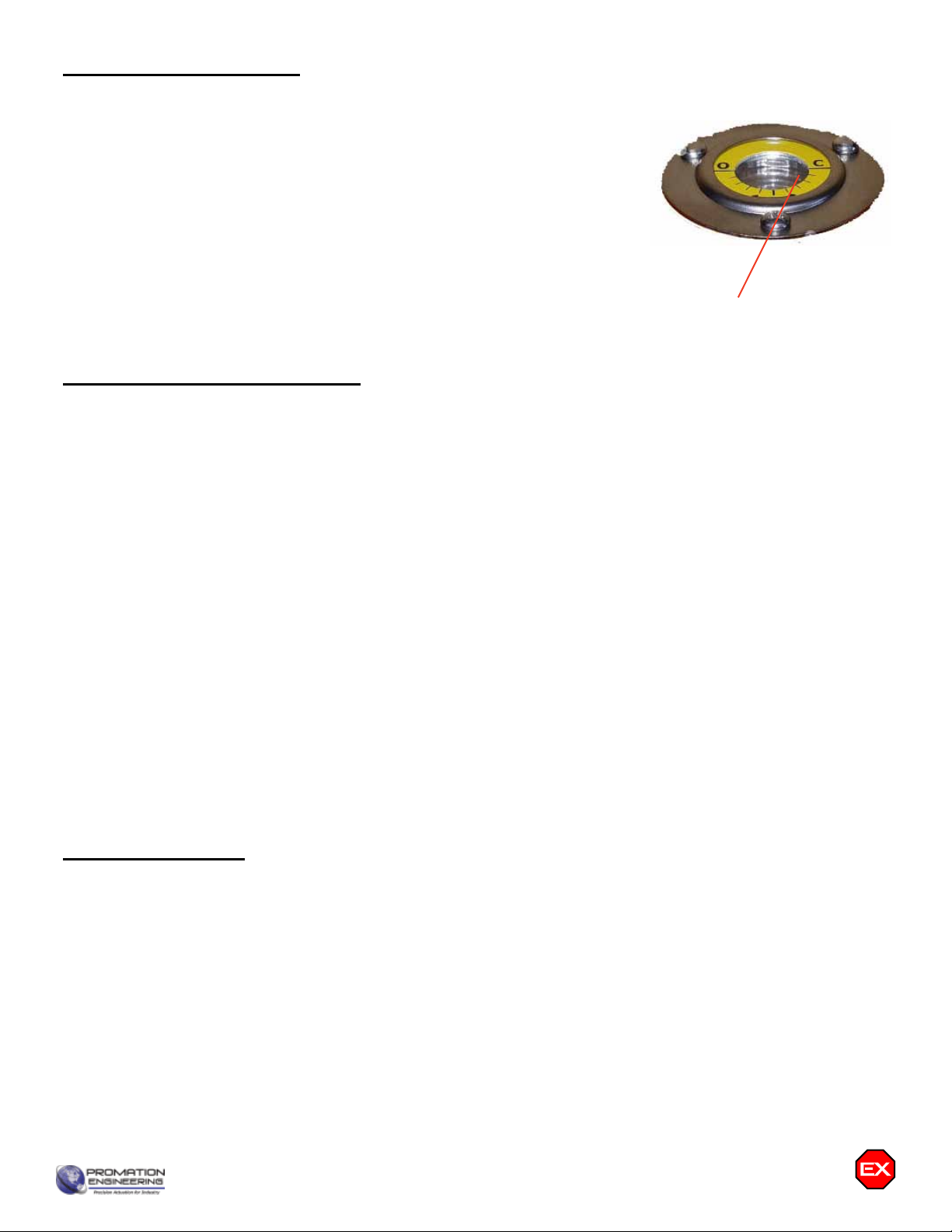

Items within dotted line located inside actuator housing

SW1

SW2

SW3

SW4

Switch Stack

Detail

NOT CLOSED*

CLOSED*

NOT OPEN*

AUX SW COM*

OPEN*

RUN CLOSED

CLOSED PILOT*

RUN OPEN

OPEN PILOT*

HOT/POS (+)

F

E

C

B

A

7

6

5

4

1

* CONNECTIONS

OPTIONAL

FIELD

CONTROL

DEVICE

HEATER

SW1

SW2

SW3

SW4

AUXILIARY

SWITCH

(STANDARD)

AUXILIARY

SWITCH

(STANDARD)

3

NEU/NEG (-)

open

close

open aux

close aux

THERMAL SWITCH

DC DRIVE

MOTOR

ALL SWITCHES

SHOWN WITH

ACTUATOR IN

FULL OPEN

POSITION

1

2

3

4

5

6

7

M

FIELD WIRING

(BY OTHERS)

INTERNAL WIRING

(FACTORY)

BLK

P1-24N4+ACDC

A

WD-850-1A101

OP

(-)

CL

OPP

CLP

(+)

408-30042

WHT

BLU

GRY

WHT

RED

Blue PCB

(POS switched)

24 VAC/VDC

HOT/POS

NEU/NEG

-

+

~~

On Board

GND Screw

GND

FM_PX1 LV N7 Ver B 072921

Page 6 of 11 P1 HV Series

On/O/Jog Control

Wiring Diagram

Wire sizing data is provided in the Wire Sizing Data table to assist in the selection

of the proper wire size for ProMation P1 series actuators using various wire

sizes over distance.

Please make sure to reference the correct voltage and do not exceed the

indicated length of the wire run for each model.

Actuator Speci cations P1

Torque “lb/Nm 300”lbs/35Nm

Supply Voltage 24vac 24vdc

Max Inrush Current 3.0A 1.6A

Running Current 2.8A 1.3A

Motor DC Brush Type

Runtime (90°@60Hz/vdc) 15 sec

Runtime (90O@50Hz) 15 sec

Duty Cycle 75% maximum

Motor Starts 1200 per hour

Weight 5lbs/3kg

Mechanical Connections ISO5211 F03/F05 8pt 14mm

Electrical Entry (2) 1/2” NPT

Electrical Terminations 14-18ga

Environmental Rating NEMA 4/4X

Manual Override 8mm Socket Drive

Control Proportional

Actuator Case Material Aluminum Alloy, Powder coated

Motor Protection 230°F/110°C Thermal F* Class

*Totally Enclosed Non-Ventilated Motors

Ambient Temperature

Operating Range

-22°F to +125°F

-30°C to +52°C

P1 LV PN4

MAX distance between

Actuator and Supply (feet)

Actuator/

Voltage

P1

24VAC

P1

24VDC

2.8A 1.3A

18 59 127

16 93 200

14 150 323

Wire

Gage

Amps

Wire Sizing Chart

Internal Actuator

Wiring

Field Wiring

Remove power from this device BEFORE making any End of Travel cam adjustments.

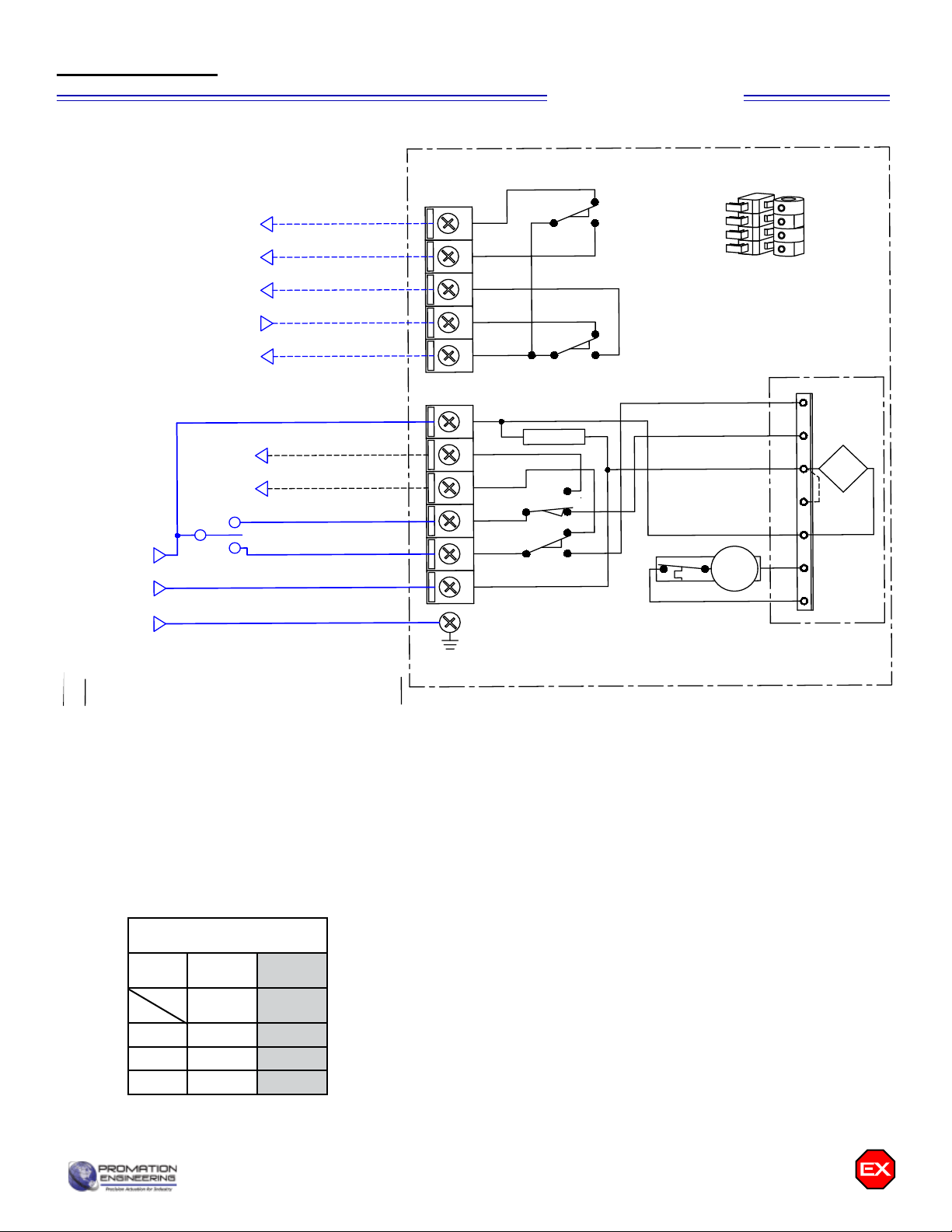

Cam 1 Adjustment

1. The lower cam is Cam 1, the CCW end-of-travel adjustment. Once the actuator

is at its required CCW position, with POWER OFF, use a 2.5mm hex key to

free up the cam set screw. Once it is free, rotate the hex key to the LEFT 10-15

degrees to reset the switch roller arm. Then snug the set screw up against the

camshaft (CW) until slight pressure is felt. Then SLOWLY rotate the hex key

pushing the cam to the RIGHT until you hear the “click” on the bottom switch

indicating that correct adjustment has been achieved. Tighten the cam.

2. Apply power to the actuator and drive CW at least 15-20 degrees. Then drive

the actuator CCW until the cam stops the electrical travel. Check to be sure this

is the correct CCW position you require. Repeat step 1 if further adjustment

is needed.

3. If using the Auxiliary Switches, adjust Cam 3 per instructions on page 6.

Cam 2 Adjustment

1. The second cam is Cam 2, the CW end of travel adjustment. Once the actuator

is at its required CW position with POWER OFF, use a 2.5mm hex key to free

up the cam set screw. Once it is free, rotate the hex key to the RIGHT 10-15

degrees to reset the switch roller arm. Then snug the set screw up against the

camshaft (CW) until slight pressure is felt. Then SLOWLY rotate the hex key to

the LEFT until you hear the “click” on the second switch indicating that correct

adjustment has been achieved. Tighten the cam set screw.

2. Apply power to the actuator and drive CCW at least 15-20 degrees. Then drive

the actuator CW until the cam stops the electrical travel. Check to be sure this

is the correct CW position you require. Repeat step 1 if further adjustment is

needed. Remove power from the actuator.

3. If using the Auxiliary Switches, adjust Cam 4 per instructions on page 6.

Cam 1

Cam 2

NC

NO

COM

LESS

CLOSED

CLOSED

LIMIT SWITCH

FURTHER

CLOSED

FURTHER

OPEN

OPEN

LIMIT SWITCH

LESS

OPEN

NC

NO

COM

NC

NO

COM

NC

NO

COM

LESS

CW

CW

LIMIT SWITCH

FURTHER

CW

FURTHER

CCW

CCW

LIMIT SWITCH

LESS

CCW

OLD

NEW

NC

NO

COM

LESS

CLOSED

CLOSED

LIMIT SWITCH

FURTHER

CLOSED

FURTHER

OPEN

OPEN

LIMIT SWITCH

LESS

OPEN

NC

NO

COM

NC

NO

COM

NC

NO

COM

LESS

CW

CW

LIMIT SWITCH

FURTHER

CW

FURTHER

CCW

CCW

LIMIT SWITCH

LESS

CCW

OLD

NEW

The actuators are tested, calibrated and shipped in the Full CW position and End of Travel cams are set at 90 degrees

from each other.

A. Set the control device (valve or damper) to the closed position.

B. Mount the actuator to the device to be controlled (valve or damper).

C. Insure that the CW End of Travel cam trips the CW End of Travel switch at the correct CW point.

C.1. If the switch does not change state at the correct CW position, adjust CAM 2 per instructions below.

D. Manually move (see Manual Override on page 6) the actuator so the valve or damper is in the fully CCW position.

E. Insure that the CCW End of Travel cam trips the CCW End of Travel switch at the correct CCW point.

E.1. If the switch does not change state at the correct CCW position, adjust CAM 1 per instructions below.

FM_PX1 LV N7 Ver B 072921

Page 7 of 11 P1 HV Series

Check End of Travel Settings

Adjusting the actuator CCW and CW positions (Cam adjustment)

Remove power from this device BEFORE making any End of Travel cam adjustments.

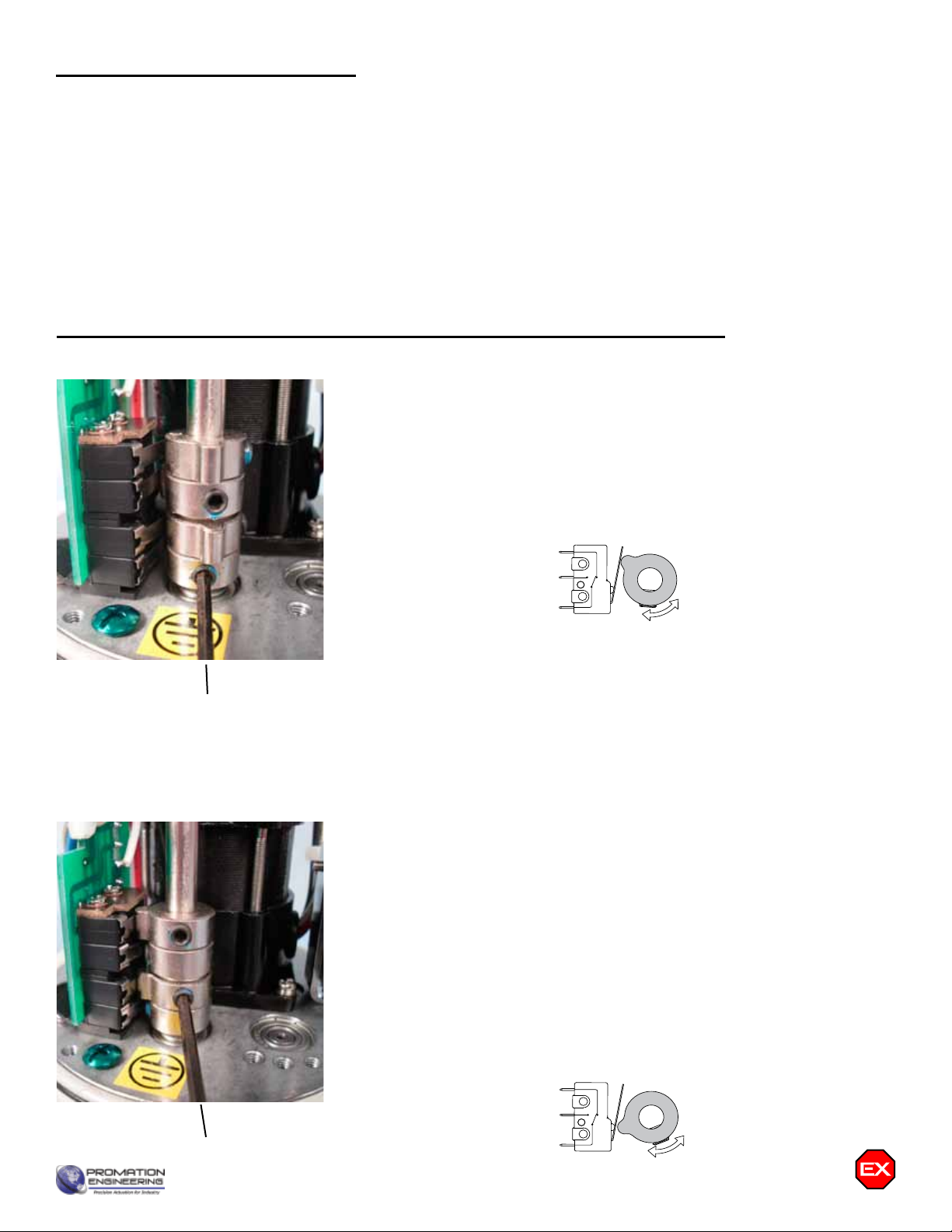

Cam 3 Adjustment

1. The third cam is Cam 3, the CCW auxiliary switch adjustment. Drive the

actuator to its CCW position. Then use a 2.5mm hex key to free up the cam

set screw. Once it is free, rotate the hex key to the LEFT 10-15 degrees to

reset the switch roller arm. Then snug the set screw up against the camshaft

(CW) until slight pressure is felt. Then SLOWLY rotate the hex key and cam

to the RIGHT until you hear the “click” on the third switch. Continue to rotate

the cam between 3 and 5 degrees to the RIGHT to make sure the auxiliary

cam switch changes state before the actuator reaches its end of travel

electrically. Tighten the cam set screw.

Cam 4 Adjustment

1. The fourth cam is Cam 4, the CW auxiliary switch adjustment. Drive the

actuator to its CW position. Then use a 2.5mm hex key to free up the cam

set screw. Once it is free, rotate the hex key to the RIGHT 10-15 degrees to

reset the switch roller arm. Then snug the set screw up against the camshaft

(CW) until slight pressure is felt. Then SLOWLY rotate the hex key to the

LEFT until you hear the “click” on the fourth switch. Continue to rotate the

cam between 3 and 5 degrees to the LEFT to make sure the auxiliary

cam switch changes state before the actuator reaches its end of travel

electrically. Tighten the cam set screw.

Cam 3

Cam 4

Warning: DO NOT operate manual

override when power is present. Geartrain

damage and personal injury may occur.

Do not use powered tools to turn the

manual override -- it will DAMAGE the gear

train or motor and VOID the warranty.

Manual Override

FM_PX1 LV N7 Ver B 072921

Page 8 of 11 P1 HV Series

Adjusting the actuator Auxiliary Switches

FM_PX1 LV N7 Ver B 072921

Page 9 of 11 P1 HV Series

Drawn By

Finish

Promation Engineering Inc.

16138 Flight Path Drive

Brooksville, Fl 34604

Phone: 352-544-8436

Fax: 352-544-8439

This Document is the property of ProMation Engineering,

Inc. Distribution of this document without the written

consent of the owner is Strictly forbidden.

Failure to comply will incur a liability for Damages.

Checked By

1/7/2020

Rev.

A

NO SCALE Sheet Number: 1

Material

ProMation Engineering, Inc.

DJG

PMR

1/6/2020

PX1 F0305 8P14 DimData.idw

Created:

Last Checked:

Part No.

Dwg. Name

Dimensional Data for PX1 On/Off Actuators

Engineering Change Notice

Change Date Description Name

01 06 19 New Document from P1 F05 Dim Data DJG

REV

A

B

C

D

E

F

Dimensional Tolerances (Unless Otherwise Noted):

X ±2.5mm [X.X ±.1]

X.X ±.3mm [X.XX ±.01"]

X.XX ±.13mm [X.XXX ±.005"]

ALL TOLERANCE FEATURES IN mm

1

1

2

2

A A

B B

14.00 -.13

.00

+mm

0.551 -0.005

0.000

+in

14.00 -.13

.00

+mm

0.551 -0.005

0.000

+in

15.00 mm

0.591 in

Depth

Drive Coupling Fabrication Data

14.00 mm

0.551 in

Square

36 mm

1.4 in

BHC

50 mm

2.0 in

BHC

F03/05 ISO Flange

(4) M5x0.8

8mm

0.3"

(4) M6x1

10mm

0.4"

8 mm

0.3 in

132 mm

5.2 in

8 mm

0.3 in

120 mm

4.7 in

168 mm

6.6 in

Add min 122mm

[4.8"] to allow

for cover

removal

25 mm

1.0 in

122 mm

4.8 in

132 mm

5.2 in

(2) 1/2" NPT

EMT Entry

Shipped w/ Caps

Mechanical Data P1 Series Dimensional Data

PX1 Series Dimensional Data

P1 Series Exploded View

(P1-120N4 unit is shown)

Position indicator

viewport

Easily distinguishable

yellow/red position

indicator

Heavy Duty

Drive Motor

Easily accessible

switch stack

Adjustable End of

Travel cams

(2) 1/2” EMT Ports

Switch Card

Anti-Condensation

Heater

Aluminum Casting

NEMA 4X Protection

Aluminum Casting

NEMA 4X Protection

NEMA 4X Cover Seal

Switch Logic Map and Switch/

Cam Arrangement

Switch sequencing data is provided in the table

below to show the change-of-state points during

the rotation of the actuator from CCW to CW

and back again. The red bar shows when that

terminal makes with its respective common.

Switches 1 and 2 are set at the factory and should

NOT be changed. The INCLUDED auxiliary

switches SW3 & SW4 are for terminals 7 thru 12

and those set points may be modied if need be.

SW3 CCW AUX

(Factory Set - Adj)

SW4 CW AUX

(Factory Set - Adj)

Used by

Controller

F

E

C

B

A

-5o0o

CW CCW

85o

5o90o95o

}

}

Common Switch Terminal

Open

Not Closed

Closed

Not Open

}

FM_PX1 LV N7 Ver B 072921

Page 10 of 11 P1 HV Series

Mechanical Data

This procedure will assume that the actuator is installed correctly both mechanically and electrically with correct power.

1. Apply the correct supply power to the actuator.

• NOTE - Power is measured at terminals marked 1 & 7 on the actuator.

1.A NORMAL OPERATION

I. Power applied to terminals marked 1 & 3 will cause the actuator to run CCW.

II. Power applied to terminals marked 1 & 4 will cause the actuator to run CW.

2. Test Full CW and CCW Positions

2.A Apply power to terminals marked 1 & 3

I. The actuator will drive to the full CCW position (as viewed from ABOVE the actuator).

II. If this is NOT the correct stop position, refer to Adjusting the actuator CCW position instructions for CAM 1 on

Page 5 in this document.

2.B Apply power to terminals marked 1 & 4

I. The actuator will drive to the full CW position (as viewed from ABOVE the actuator).

II. If this is NOT the correct stop position, refer to Adjusting the actuator CW position instructions for CAM 2 on

Page 5 in this document.

FM_PX1 LV N7 Ver B 072921

Page 11 of 11 P1 HV Series

Commissioning

This manual suits for next models

2

Table of contents

Other Promation Engineering Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Fein

Fein GRIT GI 75 manual

Eaton

Eaton SL4-PIB Series Instruction leaflet

PCB Piezotronics

PCB Piezotronics IMI SENSORS 691M157 Installation and operating manual

Scheppach

Scheppach combi 6 Original instructions

Pfannenberg

Pfannenberg PWS Series Installation, operation and service manual

SIAM

SIAM SIDDOS-automat 3M Operation manual