Sivu 5 / 15

2. INTENDED USE

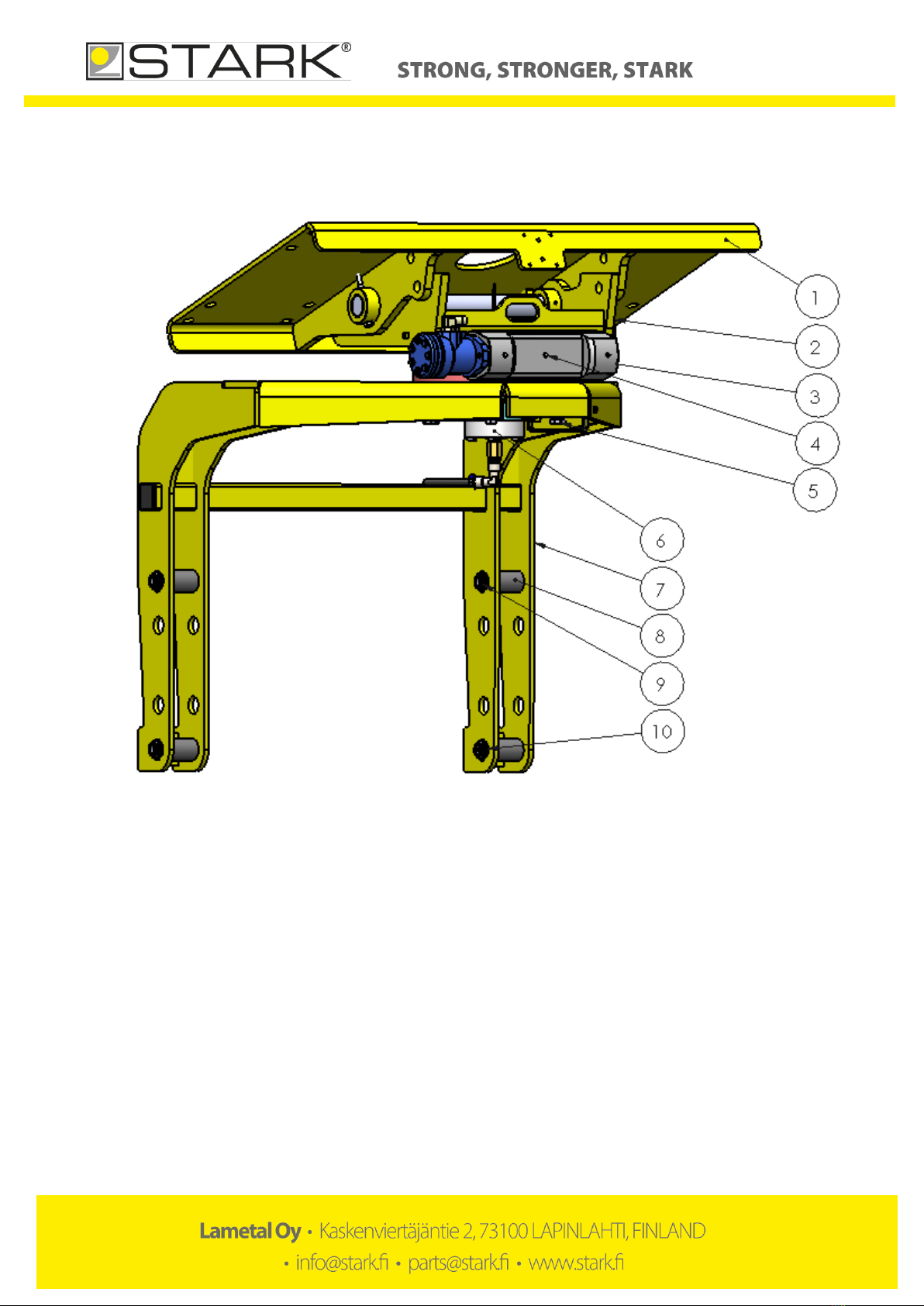

STARK RF900- Rotating Device is designed and intended to be used as an attachment on STARK Bucket Sweepers for

rotating the machine. Rotating device enables turning the Bucket Sweeper rearwards while driving forward. Rotating

device also enables sweeping near of edge rocks. RF 900 Rotating device is suitable for KAH 1600/ST, 1800/ST,

2000/ST and 2510/ST- models. Rotating device enables unlimited turning of the bucket sweeper.

3. SAFETY INSTRUCTIONS

Familiarise yourself with the attachment before taking it in use. The attachment should be operated only by proficient

users.

Before connecting hydraulics to the device, please check:

-there is no one between the attachment and base machine

-the base machine is turned off and the parking brake is on

When connecting the attachment to base machine, please pay attention:

-that the locking pins and cotter pins are fine

-there is no pressure in the hydraulics system

-that the hydraulic hoses are intact

-when connecting the hydraulics avoid skin contact with hydraulic fluid

-do not pull from the hose, only from the hydraulic fitting

While operating, please pay attention:

-safe and appropriate speed

-other traffic, people and animals

-danger zones and visual obstacles

-device should not be used when someone is in the danger zone

-be careful around children

-use flashing light while operating the machine

-do not go under the device

While servicing the device, the base machine’s hydraulics must be switched off, the base machine turned off and the

parking brake put on. The device must be lowered on supports if going under the device is required. Never go under the

device if it is not supported.

Daily maintenance:

-check the overall condition of structures, make repairs if needed

-check the condition of hydraulic hoses and couplings, change if damaged

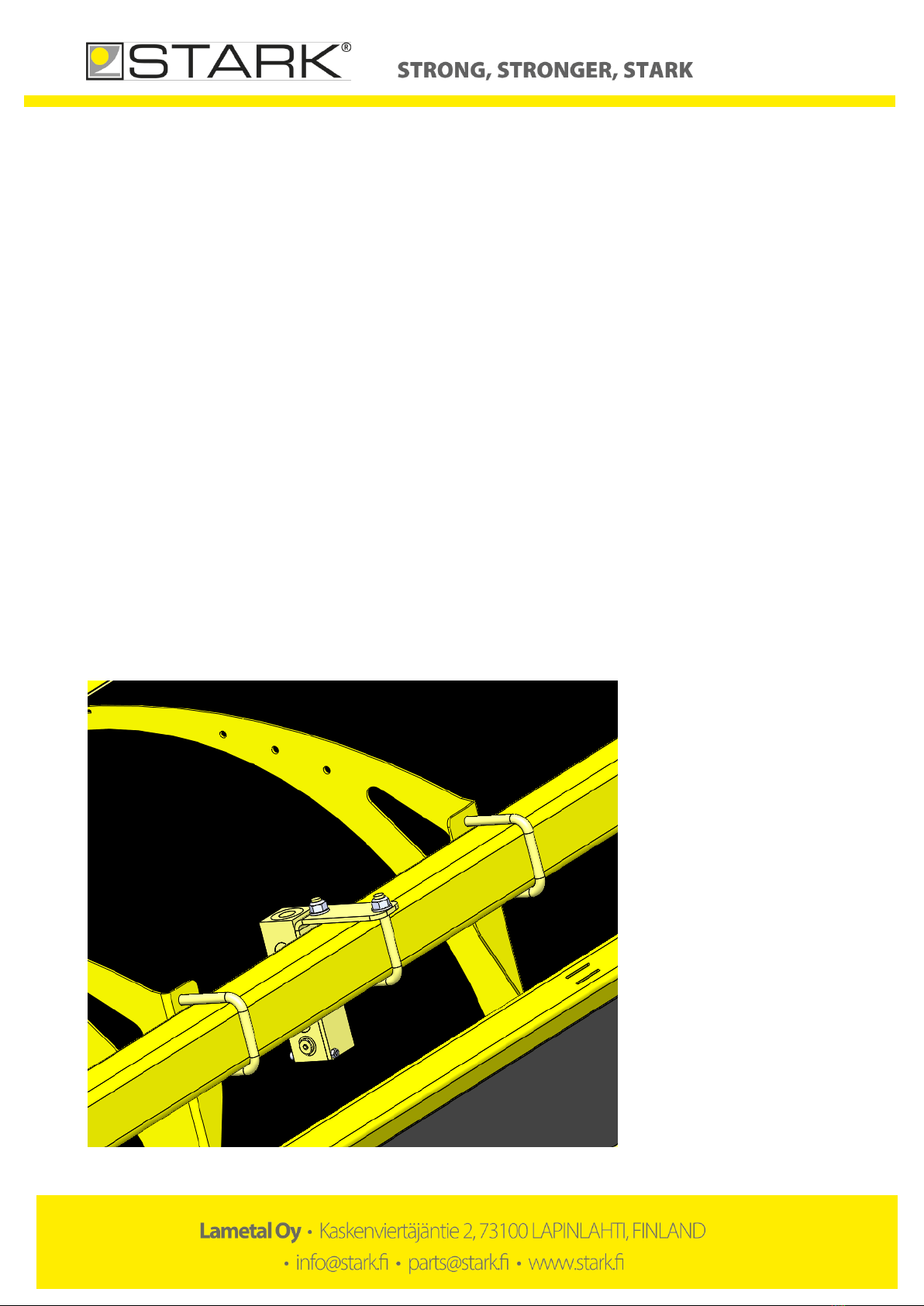

Maintenance every 50 hours:

-lubricate the lubrication points (locations are given in product specific section)

-check the tightness of the bolts and nuts

Check the tightness of hydraulic connectors, bolts and nuts after first eight hours of use!

If the device is left unused for a long time, it needs to be cleaned well and lubricated before storage.