Instruction Sheet

Hydraulic Crimping 408--8958

LOC B

1of 3

E2010 Tyco Electronics Corporation, Berwyn, PA

All Rights Reserved

TE logo and Tyco Electronics are trademarks.

*Trademark. Other product names, logos, or company names might be trademarks of their respective owners.

TOOLING ASSISTANCE CENTER 1--800--722--1111

PRODUCT INFORMATION 1--800--522--6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.tycoelectronics.com

10 MAR 10 Rev BHead 1752786- 1

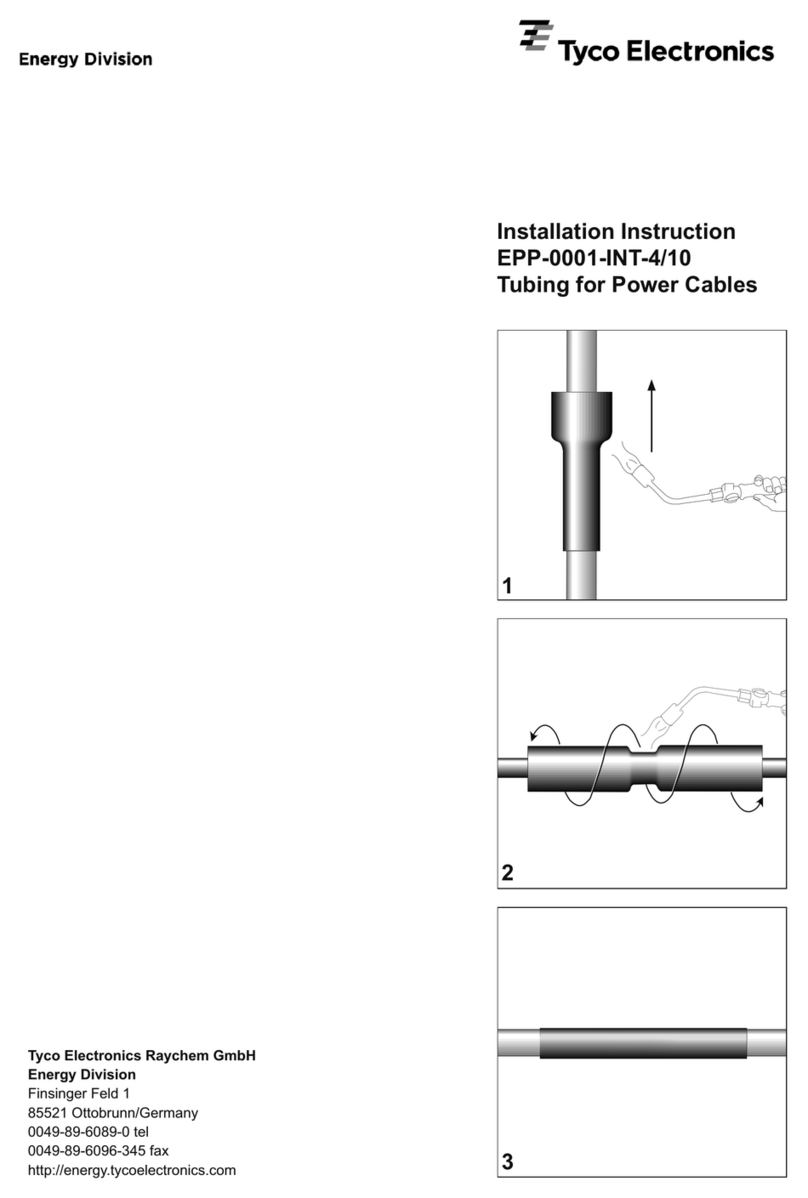

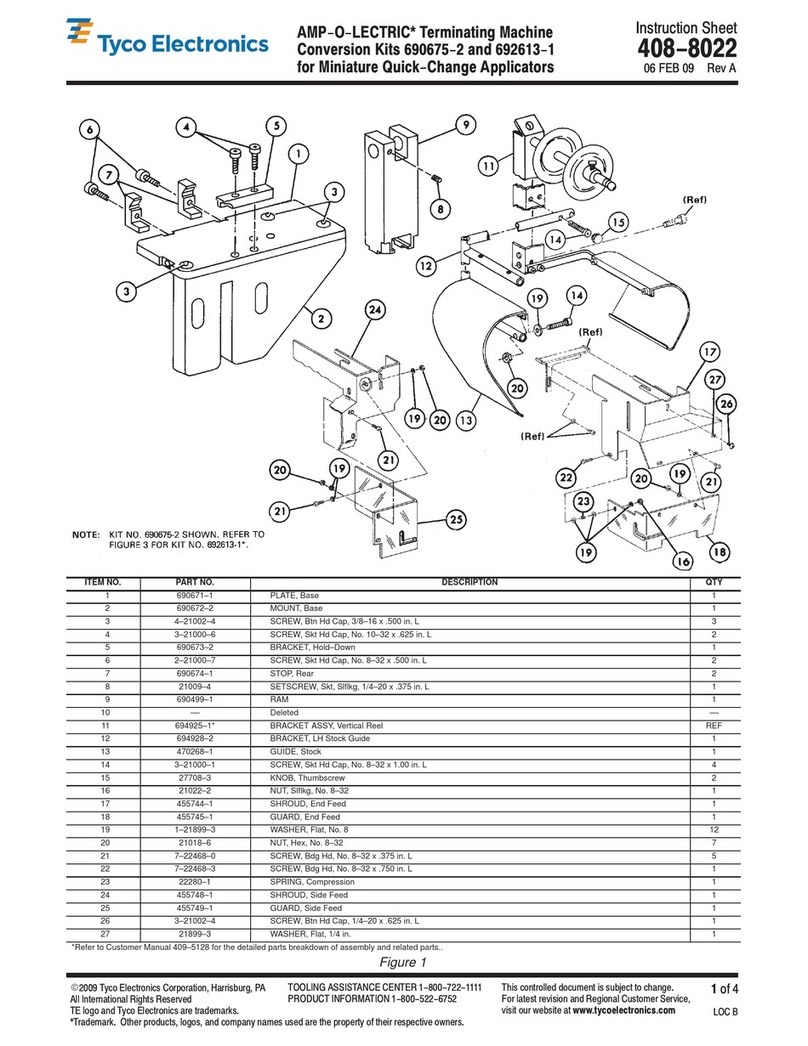

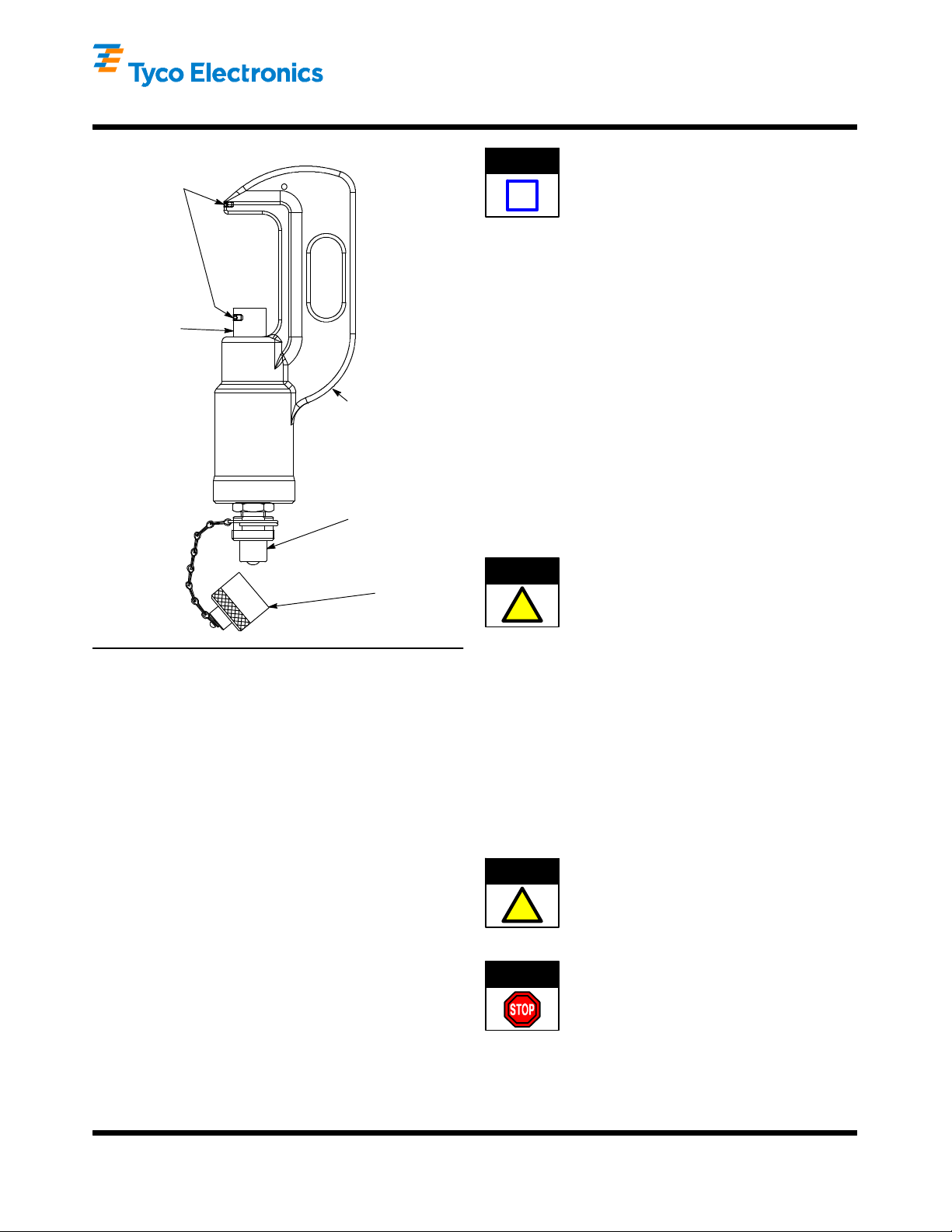

Figure 1

Dust Cap

Quick--Disconnect

Coupling

Crimping

Head

(“C”--Head)

Piston (Fully

Extended)

Lock Screws

1. INTRODUCTION

This instruction sheet provides operation and

maintenance instructions for Hydraulic Crimping Head

1752786--1. See Figure 1.

The crimping head accepts interchangeable die sets

for a variety of terminals and splices for large wire

sizes --4/0 through 1000 MCM range. Refer to the

instructions packaged with the specific die sets for

compatible products, wire ranges, strip dimensions,

and application procedures.

The crimping head is designed and recommended for

use with the Foot Hydraulic Pump 1583659--1; Hand

Hydraulic Pump 1583661--1; or the Electric Hydraulic

Pump 1804700--1 (110Vac) or 1804700--2 (220 Vac).

Read these instructions and all applicable references

before inserting any die set assemblies and crimping

any terminals or splices.

Dimensions on this sheet are in metric units [with

U.S. customary units in brackets]. Figures and

illustrations are for reference only and are not

drawn to scale.

Reasons for reissue of this instruction sheet are

provided in Section 7, REVISION SUMMARY.

2. DESCRIPTION (Figure 1)

Main components of Hydraulic Crimping Head

1752786--1 include a “C”--head, which houses the

stationary die, a cylinder which contains the head’s

hydraulic chamber, a piston (ram) which holds and

controls the moving die, and a quick--disconnect

coupling (cylinder half) which mates with the coupling

on the hose to release or supply pressure. A dust cap

covers the quick--disconnect coupling.

3. INSTALLATION

3.1. Head Installation

Prior to installing the head, ensure that the pump

and hose being used are working properly, and

are adjusted to and rated at 68948 kPa

[10,000 psi]. An incorrectly adjusted or rated

pump/hose could result in severe tooling

damage, as well as personal injury.

1. Release the hydraulic pressure to the hose.

Disconnect electric power unit from power supply.

2. Remove protective dust caps.

3. Thoroughly clean the coupling on the

pump/hose and the coupling on the crimping head.

4. Mate both quick--disconnect couplings and

tighten the collar of the coupler assembly on the

hose.

Oil flow must be unobstructed between the power

unit and the crimping head. Ensure that all

couplings are fully mated and tightened.

If a crimping head must be removed after the

power unit was in operation, be sure to release

the pressure in the hydraulic system. When using

Hydraulic Power Unit 1804700--[ ],

DISCONNECT THE POWER UNIT FROM THE

POWER SUPPLY. When using Hydraulic Foot

Pump 1583659--1 or Hydraulic Hand Tool

1583661--1, depress the pressure release pedal

to release pressure.

ORIGINAL INSTRUCTIONS

NOTE

i

CAUTION

!

CAUTION

!

DANGER