TABLE OF CONTENTS

1. SAFETY ................................................................................................................... 1

1.1 SAFETY RECOMMENDATIONS ............................................................................... 1

1.2 PERSONALSAFETY .................................................................................................... 2

1.3 FOOD SAFETY ............................................................................................................ 3

2. INSTALLATION..................................................................................................... 4

2.1 UNPACKING ..................................................................................................................4

2.2 MOVINGTHE MACHINE ........................................................................................... 4

2.3 MACHINE

SPECIFICATI

ONS ..................................................................................... 5

2.4 ENVIRONMENT REQUIREMENTS .......................................................................... 5

2.5 CHECK OIL LEVEL ..................................................................................................... 6

2.6 POWER CONNECTION ............................................................................................... 6

2.7 VACUUM PUMPROTATION ...................................................................................... 6

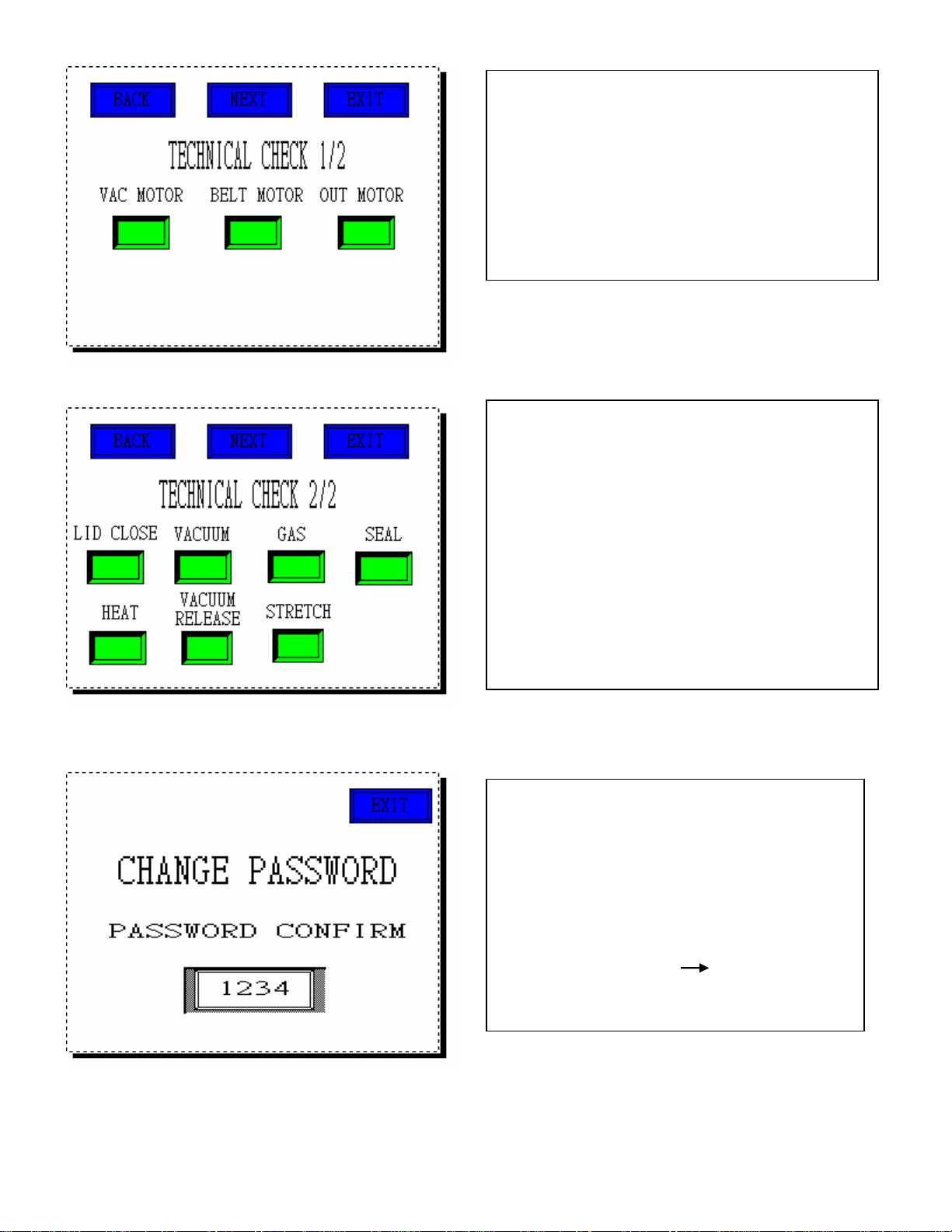

3. OPERATION PARAMETERS ..........................................................................7-16

4. MAINTENANCE .................................................................................................... 17

4.1 BASIC MAINTENANCE ............................................................................................. 17

4.1.1 DAILYVISUAL INSPECTION ......................................................................... 17

4.1.2 DAILY CLEANING ............................................................................................. 18

4.2 VACUUM PUMPMAINTENANCE ............................................................................. 18

4.3 SEALBAR MAINTENANCE ....................................................................................... 18

4.4 VACUUM VALVE MAINTENANCE ......................................................................... 19

4.4.1 VENT VALVE GREASING PROCEDURE ...................................................... 19

4.4.2 VACUUM VALVE GREASING PROCEDURE ................................................ 19-20

4.5 MAINTENANCE INTERVALCHART ....................................................................... 21

5. TROUBLESHOOTING ........................................................................................ 22

5.1 OPTIONAL DEVICE ..................................................................................................... 22

5.2 25 PIN D TYPE TERMINALWIRING CONNECTION INSTRUCTIONS ............ 23

5.3 PNEUMATIC DIAGRAM ............................................................................................. 24

5.4 ELECTRICALDIAGRAM ........................................................................................... 25-26

6. FABRICATION ..................................................................................................... 27

6.1 BODY DIAGRAM ........................................................................................................ 28-34

6.2 WORKING BED (BOTTOM) ....................................................................................... 35-37

6.3 SEALING BAR/ CUSHION BAR CONFIGURATIONS ........................................... 38

6.3.1 CUSHION BAR (FB)............................................................................................. 38-39

6.3.2 CUSHION BAR (FBPK)....................................................................................... 40-42

6.3.3 SEALING BAR (FBTBPK)................................................................................... 43-45

6.4 CHAMBER LID,TOPDIAGRAM ................................................................................ 46-47

6.5 SEALING BAR CONFIGUATIONS,TOP ................................................................. 48

6.5.1 SEALING BAR (FB).............................................................................................. 48-50

6.5.2 SEALING BAR (PK)............................................................................................. 49-51

6.6 BELT CONVEYOR........................................................................................................ 51-53

6.7 WATER COOLING........................................................................................................ 54-56

6.8 OPERATOR BOX........................................................................................................... 59-60

6.9 ELECTRICAL BOXES.................................................................................................. 61