Audion Elektro D 555 NH User manual

AUDION ELEKTRO ®

ALL-IN-SEALER

D 555 NH

MANUAL

D555 NH ENG Rev06

2

All rights reserved. Nothing from this edition is allowed to be copied and/or made public by means of print, photo copy or any other way

without previous written permission of AUDION L KTRO.

AUDION L KTRO reserves the right to change spareparts and/or specifications without previous notice. Contents of this manual can

also be changed without previous warning.

AUDION L KTRO cannot be hold responsible for eventual damage caused by specifications deviating from the standard model.

Although extreme care has been exercised during writing this manual, AUDION L KTRO will not accept any liability for eventual

errors in this manual and/or for the consequences of (mis)interpretation of the contents.

AUDION L KTRO is not responsible for damage or problems which result from the use of other than the original spareparts.

If this manual has not been supplied with instructions for certain repairs, adjustments and maintenance, you should contact your dealer

of AUDION L KTRO.

3

CONTENTS

1 To unpack the All-in sealer 4

2 Safety instructions 4

3 General description 5

4 Dimensions 5

5 Operation panel 6

6 Installation 7

6 1 Description of workplace 7

6 2 Connecting ALL-IN-SEALER 7

6 2 1 Adjusting height transport belt 7

6 2 2 Connecting to power supply 7

6 3 Adjusting seal temperature/speed 8

6 4 Cool run 8

6 5 Standby 8

6 6 Preparation for use 9

6 7 Emergency stop 9

7 Specifications 9

7 1 Operational specifications 9

7 2 Applocations not allowed 9

8 Maintenance 10

8 1 Maintenance and adjusting ALL-IN-SEALER 11

8 2 Heating elements 12

8 2 1 Adjust heating plates 12

8 2 2 Replace heating elements 12

8 3 PTFE-belts Fout! Bladwijzer niet gedefinieerd.

8 3 1 Adjust PTFE-belts 12

8 3 2 Replace PTFE-belts 13

8 4 V-belts 14

8 4 1 Replace v-belts 14

8 5 Pressure roller 14

8 6 Transport belt 15

8 6 1 Adjust transport belt 15

8 7 Motor Set-up 16

8 8 Correction factor 16

8 9 Reset to factory settings 16

8 10 Print jumpers 17

9 Technical data 17

10 Problems and solutions 17

11 Recommended spare parts 18

12 Discard the All-in 19

13 Conditions of guarantee 19

13 1 Liability 19

13 2 Guarantee 19

14 Electrical circuit Appendix A1

15 Exploded views Appendix B1

4

1 To unpack the All-in sealer

Check during the unpacking of the All-in sealer if all parts mentioned below are present

- ALL-IN-SEALER D 555 NH

- Infeed guide

- Rubber feet (4x)

- Spare PTFE-belt (2x)

- Wrench 10 / 13 to mount rubber feet

- Screw driver to open front cover

- Allan key (2x) gearbox

- Manual

The D 555 NH is mounted on a wooden plate and packed in a carton box The machine should be picked

up, out of the carton box, by two persons Place the D 555NH on a work table Disassamble the wooden

plate and mount the four rubber feet

Check the data on the identification plate of the machine and record the information on the identification

plate (fig 1) in the figure below

The All-in sealer has been packed in a carton box We recommend you to retain the carton box for future

transport

2 Safety instructions

Read the manual carefully before any operation on the All-in!

− Check, before the All-in is put into operation, whether the data on the identification plate corresponds

with the Voltage (V), Power Rating (W) and Frequency (Hz) of the local power supply

− If the All-in is not to be used for a long period of time, disconnect the power cord from the mains

supply

− Remove the power cord from the mains supply before any maintenance takes place on the All-in

Beware of the danger of an electric shock

− Do not use water, abrasives, chemicals or other liquids for cleaning the All-in See Chapter 8

− If in doubt about the correct operation of the All-in, immediately disconnect the power cord and consult

maintenance personnel

− Have repairs done by skilled maintenance personnel only

− Should liquid or an object fall into the All-in, immediately remove the power cord from the mains

supply and have the All-in checked by a skilled person before using it again

− Only use replacements parts provided by Audion Elektro

− Do not use the All-in to seal other materials then recommended by Audion Elektro (see chapter 3)

Fig 1

5

3 General description

The ALL-IN-SEALER is a stand-alone continuous sealing machine

The width of the bags to be sealed is unlimited The sealing temperature can easily be set The

automatic temperature control keeps the temperature fixed at the same level during operation

The ALL-IN-SEALER is suitable for sealing "ready to hand" bags of Polyethylene (PE), Polypropylene

(PP), thin PVC's and various laminates

The All-in is standard supplied with a touch-panel and a digital display for the temperature and the speed

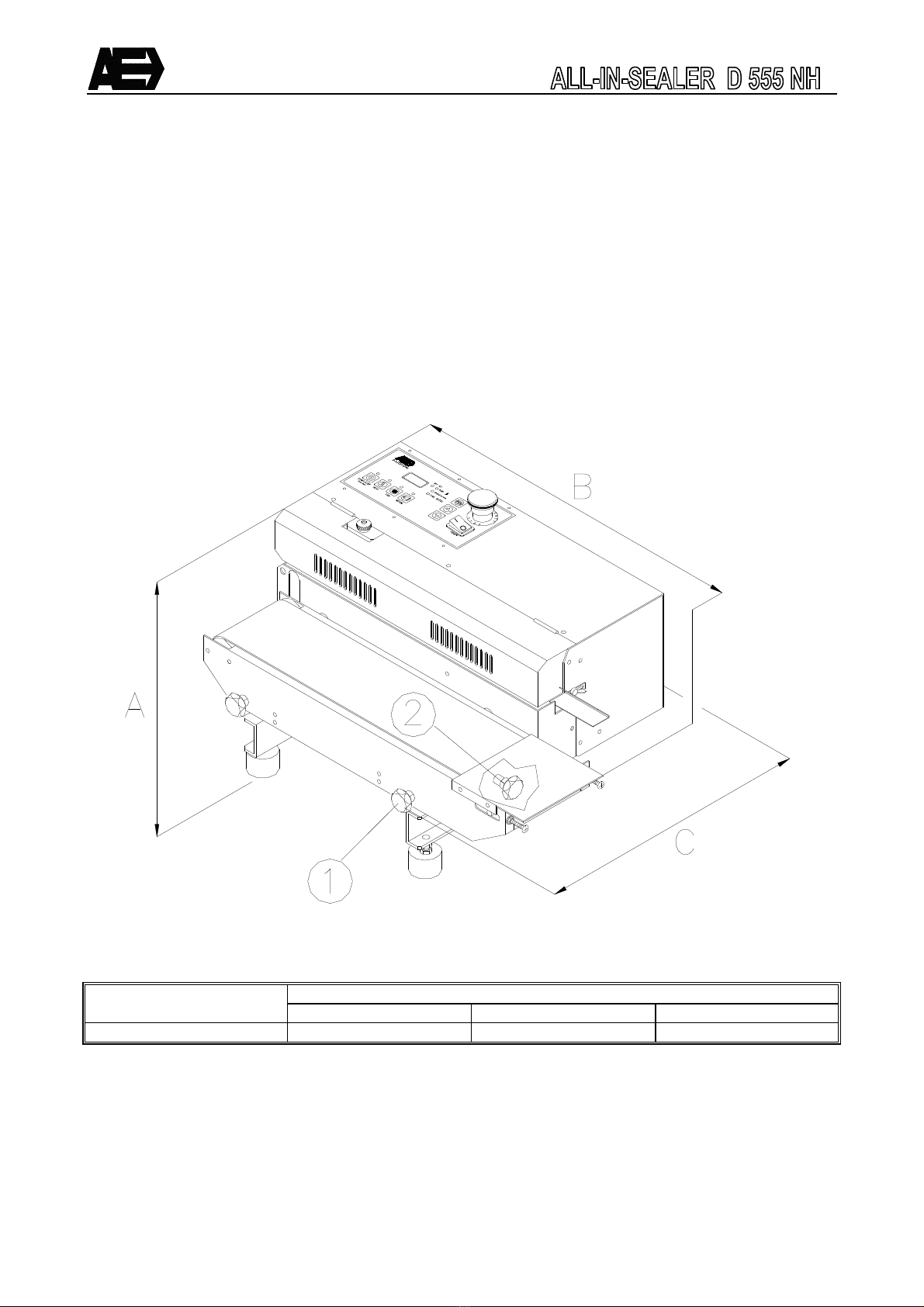

4 imensions

MACHINE Outer dimensions (mm)

A B C

ALL-IN-SEALER D 555 NH

270 610 460

Fig 2

6

5 Operation panel

The operation panel contains:

1 POWER Main switch, turns the power on/off

2 Emergency stop Stops machine immediately in case of emergency

3 START/STOP Button to start/stop the machine If the machine will be stopped and the actual

temperature is above the 80°C The machine will cooldown till 80°C in the cool run

mode After the cool run mode the machine automatically switches off to the standby

mode

4 HEAT Turns the heater on/off

5 FAN Turns the fan on/off

6 MOTOR Turns the motor on/off

7 Leds These leds indicate an active function

8 Display The display shows the temperature/speed/sync factor/cool run/errors

9 Leds During the adjustment these leds indicate which adjustment is active

10 PROG Button to pass the temp/speed/sync adjustments

After 30 seconds from the last button pressure, the program returns automatically to

the actual temperature

11 Down Button to decrease the adjusted value

12 Up Button to increase the adjusted value

Fig 3

7

6 Installation

6.1 Description of workplace

Install the ALL-IN-SEALER in a ventilated, well illuminated space Ensure that the ALL-IN-SEALER is not

exposed to direct sunlight, extreme temperatures, damp, dust or sand The ALL-IN-SEALER is not allowed

to be exposed to mechanical shocks or vibrations

6.2 Connecting ALL-IN-SEALER

Before connecting the ALL-IN-SEALER, be sure that the power is off, the main switch (fig 3 pos 1)

must be at position O (OFF)

6.2.1 Adjusting height transport belt

Adjust the height of the conveyor in relation to the seal unit The bag must be sealed at the half of the

product height

− Loosen the two knobs (fig 2 pos 1)

− Adjust the height of the transport belt by raising or lowering it manually

− If the transport belt is at the correct height, and the transport belt is horizontal, tighten the two knobs

to secure the transport belt

6.2.2 Connecting to power supply

Connect the power cord into the power supply The main socket must have an ground connection

and must be max fused at 16 Ampere

8

6.3 A justing seal temperature/spee

Use the PROG-button to change the adjustments The leds indicates which adjustment is selected After 30

seconds from the last button pressure, the program returns automatically to the actual seal temperature

To find the ideal sealing temperature and speed Make a couple of trial seals with different adjustments The

settings for a good seal are a combination between sealing temperature (TEMP) and on the other side the

operation speed (SPEED)

Adjust the next parameters:

− The sealing temperature to 100°C

− The operation speed “speed” to 50

Follow the next steps to adjust the seal temperature and the operation speed:

− Press on PROG

− Led TEMP/SET illuminates and the display shows the actual adjusted temperature

− Press on UP/DOWN to raise or lower the adjusted temperature

− Press on PROG

− Led SPEED/SET illuminates and the display shows the actual adjusted operation speed

− Press on UP/DOWN to raise or lower the adjusted operation speed

− Press the PROG-button again to return to the actual temperature

The led of the seal temperature TEMP/ACT flashes if the temperature deviation is more than 5 degrees from

the adjusted value

Make a couple of bags Re-adjust if the bags are not sealed properly

− The seals are not tight The sealing temperature is too low and the operation speed too high

− The seals looks melted The sealing temperature is too high and the operation speed too low

6.4 Cool run

Turn off the machine with the START/STOP-button The machine will cool down to 80°C in the cool run

mode After the cool run mode the machine automatically switches off to the standby mode During the cool

run mode the motor and fan turn on and the heater turns off automatically The cool run protects the PTFE-

belts against burning That will increase the life cycle of the belts Below 80°C the cool run turns off the

machine immediately to the standby mode

The START/STOP led flashes during the cool run The display shows intermittent “c-r” and the actual

temperature

6.5 Stan by

Turn the machine off with the cool run After the cool run mode the machine automatically switches off to the

standby mode The display shows “- - -“ and all functions are shut down Press a button to turn the machine

on again If the All-in is not to be used for a long period of time, use the main switch (POWER) to turn off the

machine In this way the current is shut down

9

6.6 Preparation for use

After the All-in is connected to the power and properly checked The machine can be put into operation

− Reset the emergency stop

− Set the main switch (POWER) to on (1)

− Adjust the seal temperature (TEMP)

− Adjust the operation speed (SPEED)

− Turn on the MOTOR, FAN, and HEATER if necessary

− Press START/STOP to turn on the machine

− Let the machine heat up The led TEMP/ACT stops flashing if the machine is at the set temperature

Turn off the All-in normally with the cool run If the All-in is not used for a longer period of time, set the main

switch (POWER) off and disconnect the power cord from the mains supply

6.7 Emergency stop

In case of emergency the emergency stop (fig 4) can be

activated This causes the power supply to be shut off and the

machine to stop

The emergency stop should only be used for emergencies and

not for a temporary switch off or stop of the machine

The emergency stop is operated by means of pushing the red

button (fig 4) on top of the machine After each use of the

emergency stop it should be resetted by turning the red button in

the direction of the arrow

After resetting the emergency stop, press the START/STOP-

button and the machine starts running again

7 Specifications

7.1 Operational specifications

− Operation speed : max 10 meter per minute

− Ambient temperature : +5ø +40ø Celsius

− Humidity : 30% 95% rel (without condensation)

− Fastening, fixing : The ALL-IN-SEALER is standing on 4 rubber feet

− Explosion safety : Not to be used in explosive surroundings

− Extraction, ventilation : To be used in ventilated spaces

7.2 Applocations not allowe

− Packing in medical, sterile environment

− Use in an explosive surrounding

− Packing of poisonous, corrosive, irritating substances

− Packing of explosive materials

− Packing of (dangerous) dusty products

Fig 4

10

8 Maintenance

The ALL-IN-SEALER is a relatively simple machine which needs very little maintenance There are a few

repairs which could be carried out by yourself For other repairs please contact your dealer or Audion

Elektro

− Always dissonnect the sealer from the main power supply in case of maintenance or repairs

− Wait till the machine has cooled down before any maintenance or repairs are carried out

− Before switching off the cooling ventilator and the motor the ALL-IN-SEALER must cool down or at

least 10 minutes!

− Only use spare parts supplied by Audion Elektro

The maintenance schedule below is for normal use In case of intensive use or under extreme

circumstances maintenance should be executed more frequently

Daily maintenance:

PTFE-belts Check if the PTFE-belts are clean If necessary, clean them

with a wet cloth

Heating plates Check if the plates are clean If necessary, clean them with a

wet cloth

Weekly maintenance:

Driving mechanism Check condition of driving mechanism and rotating parts If

needed, lubricate them

V-belts Check condition (rupture) and tension

Conveyor belt Check condition (rupture) and tension

Cleaning Clean the All-In-Sealer with a wet cloth and soft soap

11

8.1 Maintenance an a justing ALL-IN-SEALER

In order to be able to carry out maintenance or to replace spareparts easily you should:

− Disconnect the ALL-IN-SEALE from the power supply

− Loosen the two knobs under the transport belt, and move the transport belt as far as possible from the

ALL-IN-SEALER

− See fig 5 - Remove the back cover (1)

- Open the upper front cover (2)

- Remove the lower front cover (3)

Take care! The heating plates can still be hot Before switching off the cooling ventilator and the

motor, the machine must cool down for at least 10 minutes!!

When all activities have been done, remount the rear cover and the protection covers

DO NOT OPERATE THE MACHINE IF THE PROTECTION COVERS HAVE NOT BEEN MOUNTED

Fig 5

12

8.2 Heating elements

The heating elements are mounted in the heating plates In order to obtain a good seal correct adjustment of

the heating plates is essential Adjustment of the heating plates depends on the material properties

8.2.1 Adjust heating plates

If very thick films need to be sealed, it may be necessary to

adjust the distance between the two heating and cooling

elements If this is the case, then:

− Carry out the activities as described in § 8 1

− Turn the 4 nuts (fig 6 pos 2) clockwise a few times to

raise the elements Counter clockwise to lower the

elements

− Close all covers

8.2.2 Replace heating elements

− Remove the back cover

− Open the upper front cover

− Loosen the 3 screws (fig 6 pos 1) to remove the complete moutingplate

− Disconnect the wiring of the heating elements

− Loosen the cup (fig 6 pos 3) to replace the heating element (fig 6 pos 4)

− Connect the wiring and place the mounting plate

− Mount all covers

8.3 PTFE-belts

The PTFE-belts prevent contact of the product to be sealed with the heating plates The PTFE-belts should

never be folded as otherwise the folded part of the bands becomes a weak point during use

8.3.1 Adjust P FE-belts

Note : Do not adjust the heating plates too tight to prevent unnecessary wear of the PTFE-belts

See § 8 2 1

The PTFE-belts are being tensioned by springs, which means that these belts do not need separate

adjustments

Fig 6

13

8.3.2 Replace P FE-belts

Burnt or worn PTFE-belts can be replaced easily:

− Carry out the activities as described in § 8 2 1

− Remove the V-belts as described in § 8 4 1

− Raise the heating and cooling plates by rotating the handles above the plates clockwise (fig 6 pos 5)

− Push the PTFE pulley on the righthand-side to the left until you hear a click The pulley is now locked

− Place the new PTFE belt over the pulley's

− Press the screw above or below (depending on what pulley you are working on) the guide block to

unlock the pulley

− Lower the heating and cooling plate

− Close the covers as described in § 8 1

14

8.4 V-belts

There are 2 V-belts in the ALL-IN-SEALER They are located at the lefthand-side of the machine

8.4.1 Replace v-belts

− Carry out the activities as described in § 8 2 1

− Loosen the nut (fig 7 pos 1) and slide the shaft (pos 2) to the

right

− Replace the v-belt

− Tension the v-belt by sliding the shaft (pos 2) to the left, and

fasten the nut

− Close all covers

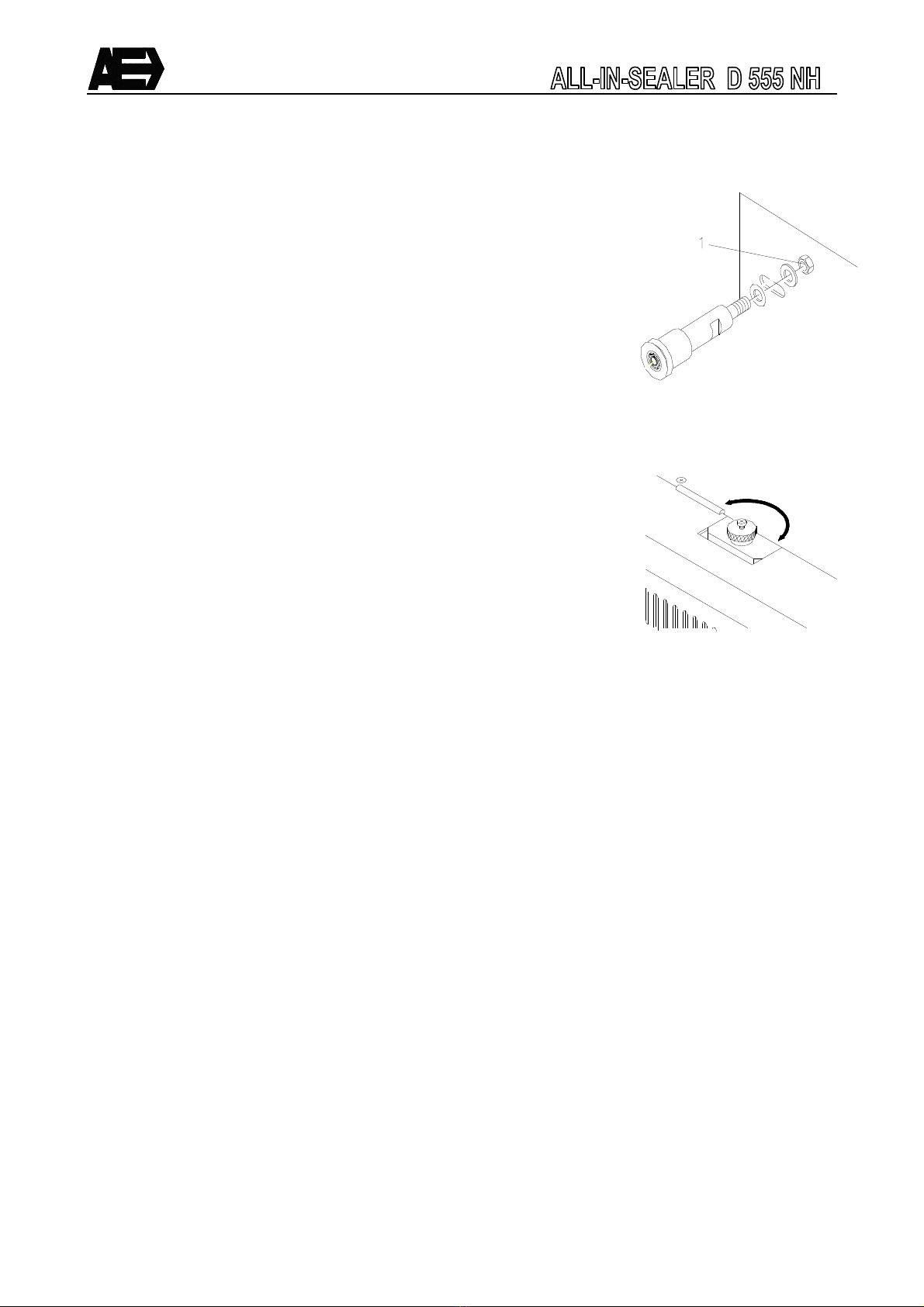

8.5 Pressure roller

The pressure roller applies an extra pressure onto the cooled seal

The pressure roller can be replaced by a code roller

In case the pressure roller is not needed, it can be disabled

By turning the ring (fig 8 pos 1) clockwise the pressure roller is lifted

upwards

Fig 8

Fig 7

15

Fig 9

8.6 Transport belt

The transport belt supports and transports the packing to be sealed The transport belt prevents the packing

from hanging on the seal

Make sure that:

− The distance between the transport belt and the sealunit is correct (half of the thickness of the

packing that is to be sealed

− The transport belt does not run against anything

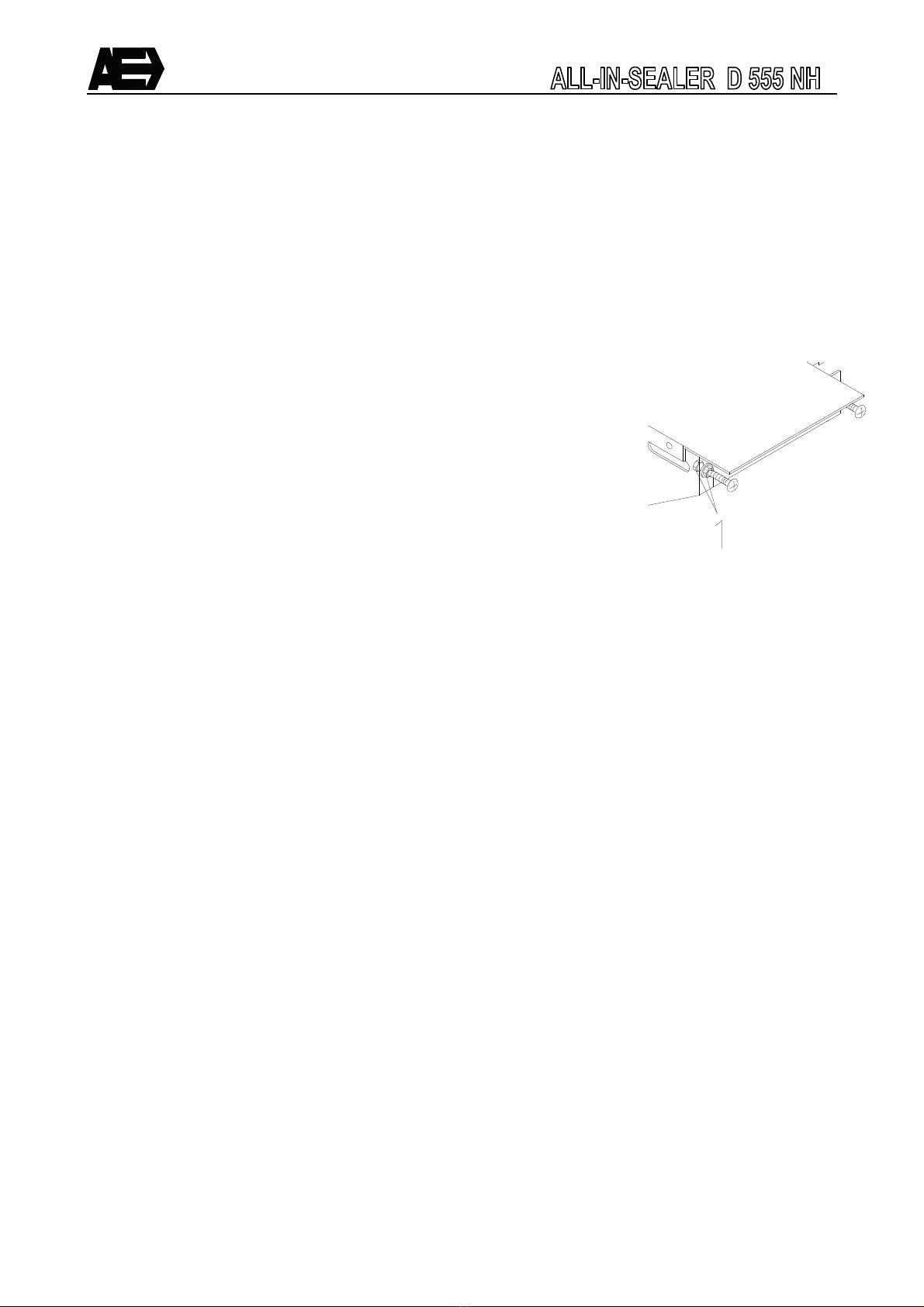

8.6.1 Adjust transport belt

Adjust the transport belt if:

− the belt touches the sides

− the tension on the belt is too high or too low

Note: Loosen the 4 locknuts (fig 9 pos 1) before adjusting the tension

Only adjust the tension when the belt is running slowly

The tension can be adjusted by rotating the front or rear locknut (fig 9

pos 1):

− Clockwise tension belt

− Counter clockwise release belt

If the transport belt touches one side of the frame;

− Tension the belt on the side it is touching

− Release the belt on the other side

If the transport belt has been incorrectly tensioned;

− Tension the belt equally by adjusting both sides

16

8.7 Motor Set-up

The machine has an automatic motor set-up function This motor set-up function must be carried out when a

motor is replaced During this set-up the motor will run at full speed for a few seconds Be aware that the

machine can run safely for a few seconds

To perform a motor set-up follow the next steps:

− Select the ‘SPEED’ mode with the ‘PROG’ button

− Press the ‘PROG’ button for 5 seconds till ‘SP1’ appears in the display

− Start the set-up routine by pressing the ‘PROG’ button The motor will run at maximum speed for a

few seconds

− End the function by pressing the ‘PROG’ button for 5 seconds till the SPEED settings appear on the

display

8.8 Correction factor

The machine has correction factors to adjust the motor if necessary This factor (%) will affect the motor

output If set at e g 90 the motor will run slower and set at e g 110 the motor will run faster

To perform a motor set-up follow the next steps:

− Select the ‘SPEED’ mode with the ‘PROG’ button

− Press the ‘MOTOR’ and ‘PROG’ button simultaneous for 5 seconds till ‘CF1’ appears in the display

− Set the CF1 setting with the ‘UP’ or ‘DOWN’ button

− End the function by pressing the ‘PROG’ button for 5 seconds till the SPEED settings appear on the

display

8.9 Reset to factory settings

The machine has a function to reset all settings to the original factory settings

Note that if you reset the machine all settings prior made will be lost

To perform a reset follow the next steps:

− Switch the main power OFF

− Keep the ‘START/STOP’ button pressed, while the main power is switched ON, until ‘rES’ appears in

the display

− Perform a motor set-up (see 8 7)

− Adjust the correction factor if necessary (see 8 8)

17

8.10 Print jumpers

There are two jumpers on the back of the PCB These two jumpers will adjust:

Jumper 1: Voltage 240V-50Hz / 115V-60Hz

Jumper 2: No application

The display shows the current jumper adjustment Turn the All-in on by the main switch (POWER) The first

two seconds, the display shows the software version and the jumper configuration

Code in display Jumper 1 Jumper 2

J 1 2 50Hz No application

J - 2 60Hz No application

J 1 - 50Hz No application

J - - 60Hz No application

The jumpers of the PCB are placed on the right side in the middle

The standard values are ON and 50Hz if the jumpers are removed

9 Technical data

ALL-IN-SEALER D 555 NH

Dimensions

Weight

Sealwidth

Power rating

Voltage

Frequency

Noise

See §4

29 kg

10 mm

550 Watt

230 V

50 Hz

≤ 70 dB(A)

10 Problems and solutions

Problem Cause Solution

The All-in sealer does not work - Main switch is at “0”

- The plug is not properly in the

main power supply

- Emergency stop has been

activated

- Internal interruption

- Set the main switch to “1”

(fig 3 pos 1)

- Insert the plug properly into

the main power supply

- Unlock the emergency stop

¤ 6 7

- Contact your dealer or

Audion Elektro B V

The All-in makes a bad seal - Temperature has not been

set well

- Set the temperature ¤ 6 3

Fig 10

18

- Speed has not been set well

- Heating plates and/or PTFE-

belts are dirty

- Seal is not well cooled

- PTFE-belts are worn

- Adjust the speed ¤ 6 3

- Clean the heating plates

and/or PTFE-belts

- Switch on the cooling

- Replace the PTFE-belts

Cooling does not work - The fan is turned off

- Internal interruption

- Switch on the fan

- Contact your dealer or

Audion Elektro B V

Error codes in display E1

E2

E3

- Wrong frequency 50/60Hz

- Loose wire to PT100

- Short circuit in PT100

- Check the frequency and

adjust the jumper

- Check wiring and connections

to the PT100

- Replace PT100

Conveyor does not work - Speed is at 0

- Internal interruption

- Adjust the speed ¤ 6 3

- Contact your dealer or

Audion Elektro B V

11 Recommended spare parts

A TICLE NUMBE

NAME

PE MACHINE

305-02002 V-belt 2

129-02003 PTFE belt 2

129-03000 Heating element 2

FUSE PCB

NAME

PE MACHINE

052026 Fuse F1 125mAT 1

160-1343125 Fuse F2 10AT 1

052010 Fuse F3 2AT 1

160-1343127 fuse F4 500mAT 1

19

12 iscard the All-in

In accordance with the directive 2002/96/CE, the logo below indicates that the equipment concerned is not

to be disposed of as ordinary waste at the end of its useable life

The equipment is to be delivered to a suitable depot that will dispose of the equipment in a proper way in

accordance with the legislation on this subject, or to the supplier of new equipment in case of replacement

The owner of the equipment is responsible for proper disposal of the equipment

For further information we advise you to contact your local waste facility

Appropriate disposal of Waste of Electric and Electronic Equipment prevents unnecessary pollution

of the environment and negative influence on general health.

13 Conditions of guarantee

13.1 Liability

1 We exclude any liability as far as it has not been arranged by law

2 Our liability will never exceed the amount of order

3 Subject to the general valid regulations of the law, we are not obliged to any compensation of

damage of which kind ever, directly or indirectly, under which company damage, to movables and

immovables or to persons, both to the opposite party as to third persons

4 In no way we are liable for damage arisen from or caused by the supplied or by the

unsuitability of this for the purpose for which the opposite party has purchased the

machine

13.2 Guarantee

1 With due observance of the restrictions stated hereafter, we allow 12 months of guarantee to the

products supplied by us This guarantee is restricted to the occurring manufacture errors and does

not imply interruptions caused by any form of wear spare parts subject to use

2 To spare parts or enclosures obtained from third persons we do not give longer guarantee than this

third supplier does

3 Guarantee expires if the opposite party and/or third parties associated make improper use of the

supplied

4 Guarantee also expires if the opposite party and/or third parties associated execute activities and/or

modifications to the supplied

5 In case we replace spare parts to fulfill our guarantee engagement, the spare parts replaced

become property of AUDION ELEKTRO B V

6 In case the opposite party does not come up completely, partially or does not come up in time to the

obligations arisen from the closed engagement between the parties, we are not obliged to guarantee

as long as the situation continues

Appendix A1

14 Electrical circuit

Table of contents

Other Audion Elektro Food Saver manuals

Audion Elektro

Audion Elektro Sealmaster Magneta 421 MGI User manual

Audion Elektro

Audion Elektro 255 PR User manual

Audion Elektro

Audion Elektro SEALBOY SB 236 User manual

Audion Elektro

Audion Elektro D 555 NVT User manual

Audion Elektro

Audion Elektro Sealmaster MAGNETA MG 321 User manual

Audion Elektro

Audion Elektro MAGNETA MGMI 421 User manual

Audion Elektro

Audion Elektro SUPER CELLO 300 SC User manual

Audion Elektro

Audion Elektro Futura Portable 150 B User manual

Audion Elektro

Audion Elektro SEALBOY SB 321 User manual

Audion Elektro

Audion Elektro Sealmaster Magneta 421 MGI User manual