ProMeister PT5229 User manual

No. 1 2 3 4 5 6 7 8 9 10

Description Pressure

Plate

Installing

Back-Up

Ring

Removal

Back-Up

Ring

Spindle

Installing

Centering

Bushing

Removal

Centering

Bushing

Screw

M8x35L

Forcing

Bolt

Spindle

Nut

VW T 5

Sleeve

Qty1111112511

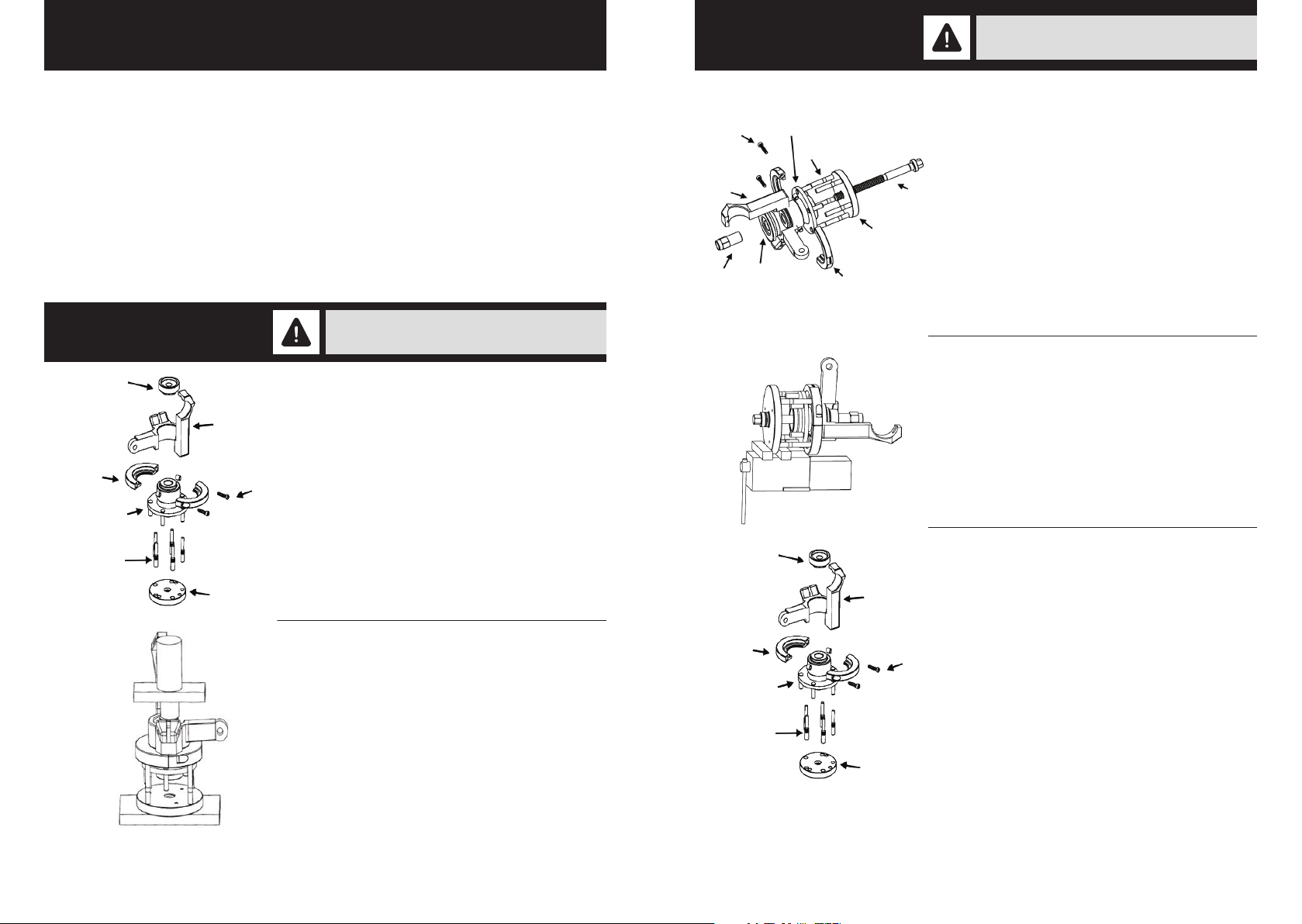

Wheel hub installation with the help of a workshop press

Installation of wheel bearing on wheel hub with threaded

spindle (4) and spindle nut (9)

Fig 6

• Before pressing down the bearing with the plunge, please

make sure that all parts are aligned and centered. Then

press down the bearing with regulated pressure on the

wheel hubs with an internal diameter of 68mm.

• First, insert the installation centering bushing (5) with

the diameter 68mm pointing towards the bore hole of

the wheel hub. Then slide the wheel bearing over the

installation centering bushing (5)

• Place and press the bushing sleeve with regulated pressure.

• Place the pressure plate (1) onto the opened vice jaws,

then place the wheel hub on the vice as shown in the

illustration.

• On the wheel hub, an Installing Back-up ring (2) has to be

inserted on the side of the wheel hub as far as it will go.

• Use the box wrench to turn the spindle nut until the wheel

bearing onto the wheel hub.

Fig 7

Fig 8

Wheel

Hub

Bearing

7

8

4

1

2

5

9

1

2

3

4

5

6

7

8

8

9

10

User Guide

Wheel Hub Bearing Puller Set

Produced in Taiwan for

Bileko Car Parts AB

P.O. Box 542

S-645 25 Strängnäs, Sweden

Tel: +46 771 72 00 00

www.promeister.com Art. Nr: PT5229 RVNR-02

Application

Please secure the separate parts properly!

Please lubricate the threaded spindle before each use!

Application

• Please make to carefully read these operating instructions and fully understands all information given before it is

used.

• These user guide contains important information that is necessary for a safe and trouble-free operation of your

Wheel Hub Tool Set.

• For the effectivity of the Wheel Hub Tool Set, as its intended use, it is essential that all the safety and other

information in these operating instructions are adhered to.

• For this reason, always keep his user guide together with your Wheel Hub Tool Set.

• This tool has been designed exclusively for specific applications. We emphasize that any modification to the tool

and/or use on an application not detailed to its intentions are strictly prohibited.

• We are not liable for any injuries to person(s) or damage to property originating from improper application,

misuse of the tool or a disregard of the safety instructions.

• Furthermore, the general safety regulations and the regulations for the prevention of accidents valid for the

application area of this tool must be observed and respected.

• Always keep the tool clean and the user guide together with the tool set at all times.

• All safety equipment must always be within reach and should be checked regularly.

Wheel hub removal with the help of a workshop press

Fig 2

• Remove the wheel bearing and wheel hub out of the spring

strut.

• Insert the 5 forcing bolts (8) into the locating hole of the

pressure plate (1).

• Insert both halves of the removal back-up ring (3) sideways

between the wheel bearing and the wheel hub. Then screw

them together with the 2 cylinder screws (7) M8x35.

• Put the bearing unit onto the forcing bolts (8) in a way that

the forcing bolts (8) pass through the threaded holes of the

wheel hub against the removal back-up ring (3).

• Lay the wheel bearing with the wheel hub and the

installed tools onto the press table with the pressure plate

downwards.

• Insert the removal centering bushing (6) into the wheel

bearing.

• Adjust the wheel bearing with the tools installed so that the

press head’s pressure is applied right onto the center of the

removal centering bushing (6).

• Operate the workshop press until the wheel hub is

separated from the bearing.

• After removing the wheel hub, remove the attached parts.

Please secure the separate parts properly!

Please lubricate the threaded spindle before each use!

Wheel hub removal with the help of spindle (4) and

spindle nut (9)

Wheel hub removal with the help of spindle (4) and

spindle nut (9) with clamp

Wheel hub installation with the help of a workshop press

Fig 4

• Remove the wheel bearing with the wheel hub out of the

spring strut.

• Insert both halves of the removal back-up ring (3) sideways

between the wheel bearing and the wheel hub and screw

them together with the 2 cylinder screws (7) M8x35.

• Put the threaded spindle (4) and the pressure plate (1)

with 5 forcing bolts (8) inserted onto the wheel bearing/

wheel hub in a way that the forcing bolts (8) pass through

the threaded holes of the wheel hub, against the removal

back-up ring (3).

• Slide the removal centering bushing (6) over the spindle up

to the wheel bearing’s front end.

• Screw the spindle nut (9) onto the spindle.

• Clamp the wheel bearing unit with the wheel hub and the

connected tools into a Machinist’s vice.

• Once the required connection has been reached, it is

necessary to retain the spindle nut (9) with a screw driving

tool (e.g. box wrench) until the wheel hub is separated

from the bearing.

• After the wheel hub removal, then remove the attached

parts.

• Lay the pressure plate (1) onto the press table.

• Place the wheel hub onto the Pressure plate (1) as shown in

the illustration. With an internal diameter of 94mm on the

wheel hub which the installation back-up ring (2) has to be

inserted on the side of the bearing as far as it will go.

• Place both parts with the bore hole downwards onto the

wheel hub. The installation centering bushing (5) centers in

the bore hole of the wheel hub.

• Afterwards, slip the pressure sleeve top-down over the

installation centering bushing (5).

Fig 1 6

3

8

1

7

Wheel

Hub

Bearing

Fig 3

7

8

963

1

4

Bearing

Wheel

Hub

Fig 5 5

2

8

1

7

Wheel

Hub

Bearing

Safety Precaution Application

Please secure the separate parts properly!

Please lubricate the threaded spindle before each use!

Other ProMeister Tools manuals