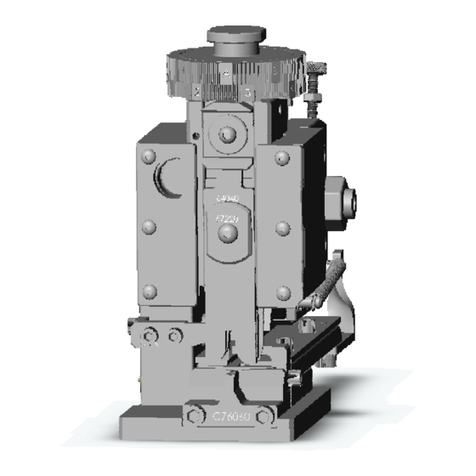

Prometal UNIVERSAL 1000 User manual

Maintenance manual Universal-1000

P R O M E T A L

1

Maintenance manual

UNIVERSAL 1000

Concrete block making

machine

Maintenance manual Universal-1000

P R O M E T A L

2

Contents

Used symbols..............................................................................................................................4

Maintenance manual...................................................................................................................6

-Preface-......................................................................................................................................6

Outline ........................................................................................................................................7

Transport hint .............................................................................................................................8

Safety..........................................................................................................................................9

-Staff safety- ...........................................................................................................................9

-Safety instructions concerning certain operating phases-......................................................9

-Safety regulations for use of concrete product machine- ....................................................10

-Hydraulics- ..........................................................................................................................10

-Oils, greases and other chemical substances-......................................................................11

-Lubrication (preliminary remarks, storage and servicing)- .................................................11

-Industrial safety-..................................................................................................................12

-Checking/cleaning of bearings-...........................................................................................13

-Screwed and electrical connections- ...................................................................................13

-EMergency –OFF-..............................................................................................................14

Maintenance..............................................................................................................................15

-Cleaning- .............................................................................................................................15

-Lubrication- .........................................................................................................................15

-Servicing- ............................................................................................................................15

-Vibration unit- .....................................................................................................................15

-Mould support- ....................................................................................................................16

-Filler box table and hopper- ................................................................................................16

-Filler box drive- ...................................................................................................................17

-Tamper head brake-.............................................................................................................17

-Mould and tamper head mounting- .....................................................................................18

-Hydraulic drive-...................................................................................................................18

-Electrical system- ................................................................................................................18

Maintenance plan......................................................................................................................20

Hydraulic system maintenance.................................................................................................24

-General- ...............................................................................................................................24

Maintenance manual Universal-1000

P R O M E T A L

3

-Checking the oil level-.........................................................................................................28

-Establishing faults in hydraulic system-..............................................................................28

-Maintenance of hydraulic components- ..............................................................................29

-Pressurized fluid-.................................................................................................................29

-Cooler maintenance-............................................................................................................30

-Oil filter maintenance-.........................................................................................................30

Conveyor maintenance .............................................................................................................31

Point of maintenance ............................................................................................................33

Maintenance work.................................................................................................................33

Maintenance interval.............................................................................................................33

Chain conveyor .....................................................................................................................33

Drive shaft.............................................................................................................................33

Lubricating............................................................................................................................33

Weekly (every 50 hours).......................................................................................................33

Drive chain............................................................................................................................33

Transport chain .....................................................................................................................33

Rocker limit switch...............................................................................................................33

Lubrication plan and points ......................................................................................................36

Tamper head maintenance........................................................................................................41

Setting the tamper head: ...........................................................................................................42

Mould maintenance ..................................................................................................................46

Mould change ...........................................................................................................................46

-Important hints for mould changing-...................................................................................48

-Mould changing- .................................................................................................................49

Mould and tamper head mounting on machine frame..............................................................64

Vibrator table maintenance.......................................................................................................65

Vibrators ...................................................................................................................................68

-Tamper Head Vibrators-......................................................................................................68

-Vibrator table vibrators- ......................................................................................................72

-Adjustment Of Vibrators-....................................................................................................73

-Maintenance Of Vibrators-..................................................................................................75

Maintenance manual Universal-1000

P R O M E T A L

4

Machine-center part..................................................................................................................77

Filler box and agitator maintenance .........................................................................................78

Hopper maintenance.................................................................................................................80

Table plate lifter........................................................................................................................81

-Table plate clamping- ..........................................................................................................81

-Table plate adjusting- ..........................................................................................................81

-Lifter unit for the table plate- ..............................................................................................82

Pneumatic mould clamping

(Option) ....................................................................................................................................82

Maintenance manual Universal-1000

P R O M E T A L

5

Used symbols

This section explains symbols that are used in this manual.

These symbols are used in this manual for warnings to avoid possible dangers for the operator

and damages for the machine. In addition, these symbols indicate ways of safe and easy

operating which will allow efficient use of machine.

Warning!

It is important to follow strictly maintenance manual to avoid possible danger for operators

health. It is necessary to follow work safety instructions strictly!

Caution!

It is important to follow strictly maintenance manual to avoid possible damage for the

machine. It is necessary to follow work safety instructions strictly!

Note

Following instruction will allow easy and safe operating.

Maintenance manual Universal-1000

P R O M E T A L

6

Maintenance manual

-Preface-

- This maintenance manual is designed to make it easier for personnel to familiarize

themselves with the machine/system and to utilize possibilities offered.

–This manual contains important information on reliable, workmanlike and economical

operations of the machine/system. By following this manual carefully will help avoid

accidents, repair costs/downtimes and enhance the reliability/service life of the

machine/system.

- This manual is always to be kept together with the machine/system.

- We recommend careful study of manitenance manual, since we cannot accept any liability

for damage and malfunctions resulting from non-observance.

- This manual is to be read and put to appropriate use by all persons whose job it is to work

with the machine/system, e.g. - In case You encounter any problems or if You have any

question, do not hesitate and contact our technical support.

© All rights reserved, including those of translation into other languages. No part of this

document may be reproduced in any form (by photocopy, microfilm or any other means, nor

transmitted or translated into a machine-readable language) without written permission by:

PROMETAL

NOTE:

All technical details in this manual are subject to change without further notice.

Addresses:

Milosava Vlajica 49

11040 Sopot, Belgrade

Serbia, Europe

Phone:

+381 11 8251 625

+381 11 8251 071

Fax:

+381 11 8250 137

Maintenance manual Universal-1000

P R O M E T A L

7

Outline

- The complete maintenance manual is divided in several sections.

- It contains necessary inspections and maintenance to be done. These sections include:

Maintenance plans (daily, weekly, monthly, half year, yearly maintenance

routines)

Lubrication plans, lubricants ( summary of lubricating points, hydraulic oil and

grease)

Mechanical maintenance (maintenance, lubrication, inspection and adjustment

work)

Hydraulic maintenance (maintenance, inspection and adjustment work)

- If you adhere to these inspections and maintenance, it will considerably extend the life time

of the machine/system. Therefore it must be in Your own interest, to follow this manual

carefully, and maintain machine/system at regular intervals.

- Neglection or non compliance of inspection most likely will result in damaging

machine/system and/or it sub parts and loss of guarantee!

Maintenance manual Universal-1000

P R O M E T A L

8

Transport hint

Do unloading of the machine exclusively with the help of a crane. Avoid absolutely to unload

the machine by means of inclined ramps.

WARNING!

Incorrect lifting or inadequate lifting capacity can result in severe

personal injury or equipment damage. MINIMUM LIFTING

CAPACITY REQUIRED IS INDICATED ON THE LIFTING

LABEL.

Lifting points are provided for use with a shackle and pin type lifting aid. Chains of suitable

length and lifting capacity must be used. Lifting points are designed to position the crane age

point as close to the centre of gravity of the machine as possible, but due to design restrictions

it is not possible to ensure that the frame will remain horizontal while lifting.

Care is therefore needed to avoid personal injury or equipment damage. The correct lifting

arrangement is shown on the label attached to the lifting lug. (See sample below). Please refer

to the specific drawing on the final page of this instruction book for lifting points.

Maintenance manual Universal-1000

P R O M E T A L

9

Safety

-Staff safety-

ATTENTION DANGER

1. It is not allowed for persons to stay within the danger-area of the machine. Even parts

of the machine not moving at the moment could start to move at any time.

2. When servicing and repairing the machine always switch to “0”the main switch on

the cabinet, panel or box. Close the stop-cocks of the hydraulics and put retaining bolt

for tamper head. All main switches must be put to “0”and locked.

3. When doing repair work on the hydraulics with mould raised, the latter must be

secured mechanically against its lowering.

4. No workshop processes and operations are allowed which could be dangerous for

persons and interfere with the safety devices of the machine.

5. All valid accident prevention regulations must be observed.

- It is to be ensured that staff keeps long hair tied back and that they don’t wear loose clothing

or jewelry, including rings, due to the accident risks involved.

- Personal protective equipment is to be used where necessary or stipulated.

- Heed all safety and hazard warning instruction given on the machine/system.

- Make sure all safety and hazard warnings on the machine/system and legible.

- Always avoid any course of action which could jeopardies safety.

- Before switching on/starting up the machine/system, make sure that there is no-one in the

danger area.

- Never climb on parts of the machine.

- Make exclusive use of suitable lifting gear with appropriate loadbearing capacity which is in

proper working order. Never stand under or work beneath suspended loads.

- When performing overhead maintenance employ suitable means to prevent falling.

- Keep all steps, railings, handles, pedestals, platforms and ladders clean and free of dirt, e.g.

snow, ice, oil.

-Always cross transportation track at appropriate points.

-Safety instructions concerning certain operating phases-

- Ensure that the machine/system is in proper working order. Make sure all safety features and

safety-related equipment such as detachable guards, emergency stops and sound absorbers

Maintenance manual Universal-1000

P R O M E T A L

10

have been fitted and are serviceable.

- Check machine/system at least once per shift for visible signs of damage and defects. Any

changes (including changes to operating behavior) are to be reported immediately to those

responsible. If applicable, shut down and secure machine without delay.

- In the event of malfunctions, machine/system is to be shut down immediately and secured.

Have rectified faults without delay.

-Safety regulations for use of concrete product machine-

- Make exclusive use of genuine fuses with prescribed rating. Switch off machine/system if

there are any faults in the power supply.

- The electrical equipment of the machine/system must be checked/inspected at regular

intervals.

- Work on electrical system or parts must be performed by electrician or qualified personnel

under the guidance and supervision of an electrician in line with the appropriate regulations.

- Machine and system components that are under inspection, repair or maintenance must be de

energized where prescribed.

- For parts that are isolated, check for no voltage first.

-Hydraulics-

Warning! Oil drippings and leakages may also develop risks to the

operational safety! The hydraulic system contains high pressure! Remedy the fault

immediately!

- Work on hydraulic facilities may be performed only by qualified personnel.

- All lines, hoses and screw connections are to be regularly checked for leakage and visible

signs of damage. Eliminate any damage immediately. Oil splatter can cause injury and fire.

- Hydraulic stop-cocks

Stop-cocks are located at the machine frame.

Caution!

For all work at and within the machine, the stop-cocks have to be closed. First, switch

off hydraulic pumps.

Maintenance manual Universal-1000

P R O M E T A L

11

Before starting again the hydraulic pumps, first open stop-cocks again.

-Oils, greases and other chemical substances-

- Take precautions when handling hot process materials (danger of burns or scalding).

- The appropriate safety regulations are to be observed when handling oils, grease and other

chemical substances.

-Lubrication (preliminary remarks, storage and servicing)-

- Careful lubrication is a prerequisite for trouble-free operations and prevents costly repairs.

This is particularly true of the proper lubrications of all anti-friction bearings. -

Poor or frequent lubrication will shorten the service life of the anti-friction bearings and result

in failure.

- Lubrications itself and other associated operations are to be performed with the

machines/system stopped.

- Lubricants, such as oil and grease, are to be kept in clean, closed containers (cans, drums,

tins) to prevent the ingress of dust and moisture and to reduce oxidation effect of the air level

to minimum. Storage location should be dry and cool.

- The lubricant fill in a bearing gradually losses it’s lubrication capacity in the course of its

service life as a result of mechanical loading, ageing and increasing contamination. Grease

fills must be therefore topped up or replaced from time to time and oil fills constantly filtered

in addition to replacing the oil at specific intervals.

Maintenance manual Universal-1000

P R O M E T A L

12

-Safety regulations for use of concrete product machine-

-Industrial safety-

When or in the area of the mould or tamper head, always secure

tamper head so it cannot come down and switch off pump of

main hydraulic system when carrying out work in the machine.

Holes are provided in the two locking rods for fixing the tamper

head in the upper position. The tamper head is raised above these

holes and the locking pins are inserted in same. After that tamper

head is lowered until it makes contact with the pins. This

procedure stops tamper head from dropping.

- As a general rule, adjustment work should never perform with the machine running. The

sole exception to the above is speed regulation in the hydraulic system by way of the throttle-

type check valves under the directional control valves and adjustment of the pressure

limiting/pressure reduction valve. These valves are installed in the system in such a manner

that they are outside the hazard zone. However, increased care is to be taken when performing

such task.

- When cleaning hoppers, main hydraulic system is to be turned off.

- Wear safety helmet on entering machine pit.

- Caution: Even if the pump is switched off, pipes can be pressurized if the cylinders are

perpendicular and the plunger rods loaded but still not fully retracted or extended. For

example, this is the case of mould, tamper head, hopper outlets and height adjustment.

- In the events of faults, always switch system component(s) concerned to manual and shut

down all hydraulic facilities.

- Switch cabinets are not to be opened until main switch had been turned off.

- Hydraulic system is to be turned off and de-pressured before working on them. Vessels and

pipes are to be drained.

- Never crawl under raised, non-secured filling units. If it is necessary to perform work

beneath such units, secure beforehand with height adjusters.

- Never reach into components that are operating.

Maintenance manual Universal-1000

P R O M E T A L

13

-Checking/cleaning of bearings-

- Anti-friction bearings must be checked and cleaned from

time to time with the inspection intervals being governed

by the operating conditions. If it’s possible to monitor

condition of the bearings during the operation by listening

to running noise, measuring the bearing temperature or

checking the lubricant, it is generally sufficient to

thoroughly check and clean the bearings (races, cages and

rolling elements) and all other parts of the mounting in the

course of general machine inspection or repair. However,

more frequent checks are needed if bearings are subjected to heavy loading.

- After cleaning every component

with suitable cleaning agent, bearings must be thoroughly dried and then immediately

protected against corrosion by oiling or greasing them. This part is especially important for

the machine that remains shut down for a lengthy period of time.

-Screwed and electrical connections-

- After 20-30 hours screws and bolts have to be checked whether they are tight or not.

- Self-locking nuts are to be used only once.

- The machine components have to withstand high loads and stress during production due to

mechanical forces and vibrations. Especially the tight fit of the screwed connections on safety

related components must be checked regularly.

- Check regularly the tight fit of the electrical connections.

ATTENTION!

After 20 - 30 working hours

screws and bolts have to be

checked wether they are tight or

not!

Read this manual carefully!

Maintenance manual Universal-1000

P R O M E T A L

14

-EMergency –OFF-

Strike Button: The unit is equipped with Emergency-off strike buttons (with lock). Upon

actuating the emergency-off switches, the complete control voltage is disconnected.

Hint! Reconnecting of control voltage is possible only by switching on the key switch,

after unlocking the emergency switch.

Key Switch: The key switch “Control Voltage On”is located on the control panel or on the

end wall of the control cabinet. With this the control voltage is switched on. With switch

“Control Voltage Off”is switched off.

Maintenance manual Universal-1000

P R O M E T A L

15

Maintenance

-Cleaning-

Cleaning at the end of production is essential prerequisite for proper functioning of the

machine.

It is appropriate to start with filler boxes and hoppers by knocking off residual concrete. After

this, open hopper outlets to enable the loose concrete to drop into filler boxes with which the

concrete is moved into mould and removed from the machine together with the pallet.

Tamper head brushes are likewise to be cleaned.

Special care needs to be taken when cleaning mould. Especially if mould is of complex design

(e.g. hollow block mould), which is more difficult, but also more important. Old solid

concrete on the tamper head and mould, and above all on the tamper head plates, on the

bottom of the mould and between the webs promotes wear and the finished products are then

often no longer true to size and shape. Blowing out with compressed air has proven to be and

effective means of general cleaning. Then loose concrete falls into machines pit, from where

it is easy to be removed.

Rubber buffers, rubber profile strips, rubber discs and bronze parts should not be allowed to

come into contact with oil, grease or other media which have an adverse effect on them, as

this would shorten service life.

-Lubrication-

The number of lubrication points on the machine has been kept to the minimum. Types of

lubricants to be used are given in our lubricant table. The points concerned are listed in a

separate lubrication chart outlining the lubrication intervals.

-Servicing-

By its very nature, a heavy-duty vibration machine is subject to considerable loading and

there is bound to be component wear. Design measures and the use of appropriate materials

help to offset this factor. It is then up to customers to do the same by keeping the machine in

good condition and performing systematic service work. The information given in the

following is designed to provide assistance with the above. It is important to have good

cooperation between the machine operators and the maintenance staff (mechanics and

electricians). A brief production stoppage to tighten a loose screw is better and cheaper than

waiting until the screw drops out and causes major damage.

-Vibration unit-

Check tightness of all screws on vibration unit as these are subject to particularly severe

stress. Renew damaged rubber buffers. The scraper plates bolted to the vibration table needs

to be renewed if severely worn. Renew damaged rubber universal joints at articulated shafts.

The brake shoes of the vibrator brakes must move freely to enable them to lift rapidly off the

brake disc after braking. Renew worn brake pads in good time, so as to prevent subsequent

damage to braking discs/motors. Renew worn brake discs. To check the vibrator bearings, the

Maintenance manual Universal-1000

P R O M E T A L

16

unbalance weights should be pushed by hand and must then oscillate. If this is not the case,

then it is most likely the sign of imminent bearing damage.

-Mould support-

Check condition of rubber profiles and bronze strips in mould holders, particularly on mould

replacement. Secure loose parts and renew damaged ones. Renew damaged or worn bushings.

-Filler box table and hopper-

Check tightness of bronze wear strips on end faces of filler-box tables. Secure loose strips;

renew if damaged or severely worn. Check scraper plates of filler-box tables and replace if

necessary.

Check functioning of hopper outlets. Renew worn bolts and bronze bushings in mount. If

level indicators are fitted, check cables for damage and renew if necessary.

Maintenance manual Universal-1000

P R O M E T A L

17

-Filler box drive-

Check proper functioning of scraper. Adjust scrapers on both filler boxes. Check top-mounted

shaking grate; it must move freely back and forth. Replace worn and seized bushings. Tamper

head cleaning brush on front of filler box must be adjusted in line with wear. Renew self-

aligning plain bearings and shafts. Renew damaged or worn rubber bushings. Make sure that

filler box walls are not too worn; if they are, rework or replace filler box. Check rollers for

bearing damage.

-Tamper head brake-

Renew damaged rubber buffers between tamper head frame and tamper head carrier. Make

sure that there is no residual concrete left in the tamper head carrier. Renew damaged/worn

bushings. If top vibrators are fitted, check their attachment to the tamper head carrier. Cables

to top vibrators are to be examined for damage. If leakage occurs at the cylinders of the

tamper head brake, the seals are to be renewed. Check linkage and plates for damage. Replace

Maintenance manual Universal-1000

P R O M E T A L

18

return springs for brake shoes if these are severely worn. Brake shoes must move freely to

permit rapid release of the tamper head.

-Mould and tamper head mounting-

The hard chromium-plated columns are to be checked for damage and can be turned if

necessary (from bottom to top). Whether or not the gunmetal bearing shells need replacing

can be seen during production. In this case, there will be a gap between column and bearing

such that the tamper head can oscillate even in its upper position. Scraper rings are likewise to

be changed on replacing bearings.Check tightness of bronze wear strips on end faces of filler-

box tables. Secure loose strips; renew if damaged or severely worn. Check scraper plates of

filler-box tables and replace if necessary.

Check functioning of hopper outlets. Renew worn bolts and bronze bushings in mount. If

level indicators are fitted, check cables for damage and renew if necessary.

-Hydraulic drive-

Perform first filter change after installation/commissioning, however at the latest if the gauge

on the housing cover is in the yellow zone. This likewise applies to subsequent operation.

Eliminate any leaks. The plunger rod gaskets are to be renewed in the event of leakage at the

plunger rods of the hydraulic cylinders. Tighten loose pipe clamps, as otherwise switching

impact in the hydraulic system could overload the pipe unions and cause them to brake off.

Always keep oil cooler away from dust. It is appropriate to clean it at frequent intervals with

compressed air so as to maintain the cooling capacity. The best temperature range for

hydraulic oil is approximately 40°C - 65°C. The temperature of the hydraulic oil should never

bebelow 15°C or above 70°C, as pump damage could occur outside this range.

-Electrical system-

Make sure the electrical system has been de-energized before working on it. Switch off main

switch. Work on the electrical system is only to be performed by a qualified electrician.

Practice has shown that it is difficult to keep switch cabinets completely free from dust.

Electrical devices and switching contacts thus become dusty. It is appropriate to blow out the

electrical devices and switchgear at regular intervals with clean, dry air. Contact cleaning

spray is a good solution if devices are heavily contaminated. It is beneficial to retighten the

terminal studs during the initial period. This likewise applies to those at contactors, including

terminals which are not being used. Loose screws can drop out and cause damage. Clean

cooling fins and cooling-air slots on electric motors on a regular basis. Never use fuses with a

higher rating than those stated.

Maintenance manual Universal-1000

P R O M E T A L

19

Maintenance manual Universal-1000

P R O M E T A L

20

Maintenance plan

Every mould change

Daily

Weekly

Vibrator table

Monthly

Half yearly

Yearly

Maintenance at every mould change

Part

Point of maintenance

Maintenance activity

Hydraulic tamper head clamping

Clamping surfaces, push rods

Checking, cleaning

Mould clamping

Rubber buffers

Cleaning

Vibrator table

Impact bars

Checking distance and parallelism

Charging frame

Guide rails

Cleaning

Daily maintenance (based on a 1-shift-operation)

Part

Point of maintenance

Maintenance activity

Mould guide/clamping

Area of the mould guide

Clean from remaining concrete

Mould guide/clamping

Supporting screws

Check and clean

Filler box/agitator cart

Inside

Clean from remaining concrete

Filler box/agitator cart

Wheel/wheel path

Check and clean

Agitator

Check condition and clean

Filler box

Stripper frame, strings

Check and clean

Table plate

Check condition and clean

Concrete hopper

Concrete hopper, hopper flaps

Check condition and clean

Hydraulic unit

Inspection glasses

Check oil level

Hydraulic unit

Pressure gage

Check system pressure for main function

Hydraulic unit

Electronic pressure sensor

Check accumulator pressure

Also take care of following:

-Lubricate mould and tamper head guide bearings

-Clean machine pit

-Check entire vibration unit for loose parts or worn brakes: push against unbalanced

weights to check for bearing damage

-Drain service unit and fill lubricator with oil if needed

Table of contents