V1.0

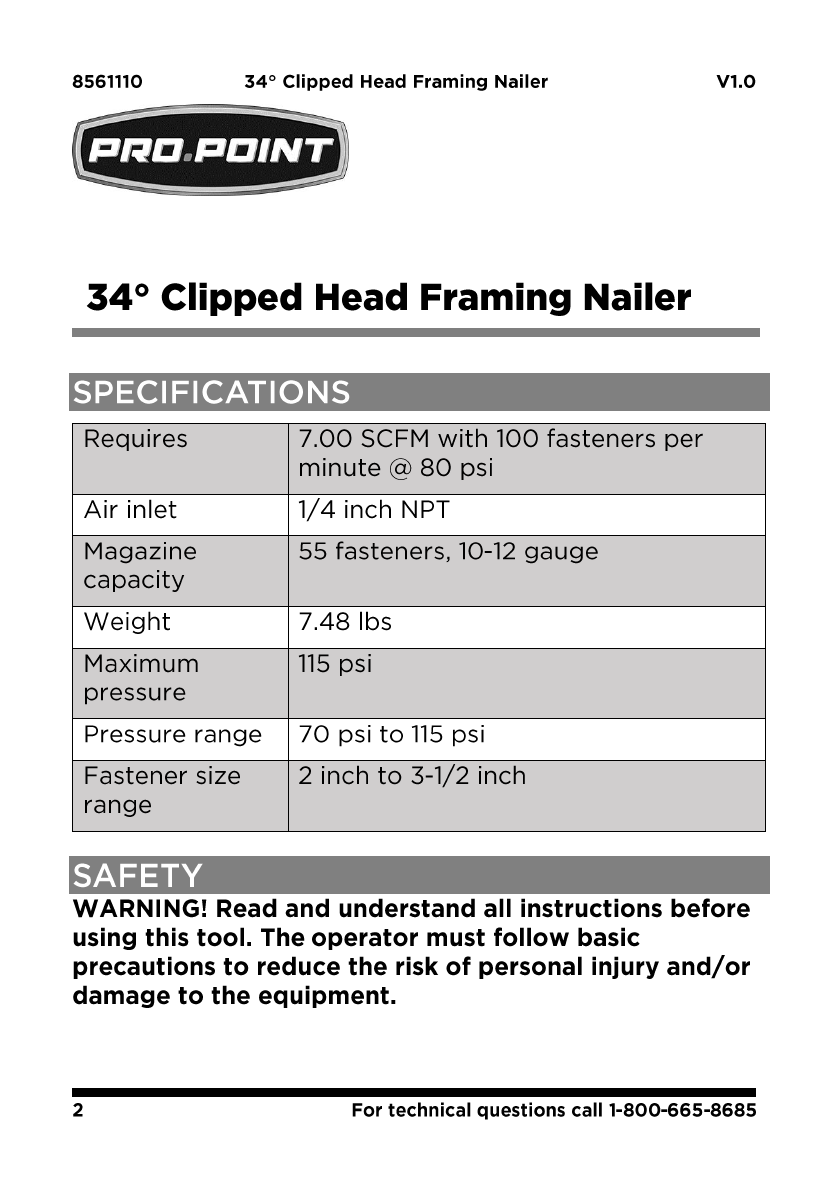

34°

Clipped Head Framing Nailer 8561110

USE

AND

CARE

OF

THE

TOOL

WARNING: Disconnect the tool from the air source

before making adjustments, doing tool maintenance,

clearing jams, touching the safety yoke, leaving work

area, or unloading the tool. Such precautionary

measures reduce the risk

of

injury

to

persons.

1.

Know

this

tool.

Read

manual

carefully,

learn its

applications

and

limitations,

as

well

as

the

specific

potential

hazards

related

to

this

tool.

2.

Use

only

fasteners

that

are

recommended

for

your

models.

Do

not

use

the

wrong

fasteners

or

load

the

fasteners

incorrectly.

3.

Use

only

accessories

that

are

identified

by

the

manufacturer

for

the

specific

tool

model.

Use

of

unauthorized

parts

or

failure

to

follow

maintenance

instructions

may

create

a

risk

of

injury.

4. Use

only

those

fasteners

recommended

for

use

with

this

tool.

Fasteners

not

identified

for

use

with

this

tool

by

the

tool

manufacturer

are

able

to

result

in a

risk

of

injury

to

persons

or

tool

damage

when

used

in

this

tool.

5.

Check

for

misalignment

or

binding

of

moving

parts,

breakage

of

parts,

and

any

other

condition

that

may

affect

the

tool's

operation.

If

damaged,

have

the

tool

serviced

before

using.

Many

accidents

are

caused

by

poorly

maintained

tools.

6.

Maintain

tools

with

care.

Keep

tool

clean. A

properly

maintained

tool,

reduces

the

risk

of

binding

and

is

easier

to

control.

7.

Store

tools

out

of

the

reach

of

children

and

other

untrained

people.

Tools

are

dangerous

in

the

hands

of

untrained

users.

Visit www.princessauto.com for more information 7