Propress PRO580 User manual

PRO580 STEAMER

USER MANUAL

Operating & Safety Instructions

Before using your Propress steamer, please read this manual

thoroughly and retain it for future reference.

1. Operating Safety 2

2. Unpacking Your Propress 4

3. Assembling Your Propress Steamer

and Preparing for Use 5

4. Operating Instructions 8

4.1 Filling Steamer with Water 8

4.2 Switching On 9

4.3 Using Your Steamer 10

4.4 Standby Setting 10

4.5 Safety Filler Cap 10

5. Tips on Use 12

5.1 Steaming Clothing 12

5.2 Full Garment 13

5.3 Wedding Dresses 13

5.4 Curtains & Soft Furnishings 14

5.5 Fabric Limitations 14

6. Care and Maintenance 15

6.2 Cleaning Your Steamer 15

6.3 Descaling Your Steamer 16

7. Storing your Propress When Not In Use 17

8. Propress Troubleshooting Matrix 18

9. Guarantee 21

CONTENTS

1

PRO580 USER MANUAL

OPERATING & SAFETY INSTRUCTIONS

Working safely with your Propress

steamer is only possible when these

operating and safety instructions are

read completely and the contents

herein are understood and followed.

Further copies of these instructions

are available to download on our

website propress.co.uk/customer-care

3

1. OPERATING SAFETY

MAX

4L

disorder increases the risk of an accident.

This appliance can be used by children

aged from 8 years and above and persons

with reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they have been given

supervision or instruction concerning

use of the appliance in a safe way and

understand the hazards involved.

Under no circumstances should the

steamer be left unattended when in

operation. When not in use disconnect

the power supply.

Keep children away from the steamer.

Children should be supervised to ensure

they do not play with the appliance.

Keep the steamer and its cord out of

reach of children less than 8 years of age

when it is energized or cooling down.

Regularly check power cable and plug

when steamer is disconnected from the

power supply.

Do not use the steamer if either power

cable or plug are damaged; contact

an approved service agent for repair.

Do not use the steamer if it has been

dropped, if there are visible signs

of damage or if it is leaking.

rated extension cables can be dangerous

Regularly check hose for damage

or distortion.

or when steamer contains hot water.

Do not unplug the steamer by pulling the

electric cord, always switch off at the

of socket.

and wait for steamer to cool down before

spillage before connecting steamer

to power supply.

when machine is steaming or heating up.

Once a week the steamer should

be cleaned. See section 6. Care

and Maintenance.

Cleaning and user maintenance must

not be carried out by children without

supervision.

clothing being worn.

Persons using the steamer must be

authorised to do so and trained in safe

working procedures. Where necessary,

protective clothing should be worn.

Propress steamers are

electrical steam generating

appliances, therefore

components may get very hot

and could cause burns.

Care should be taken when

using this appliance due to the

emission of steam.

Propress steamers are designed for

vertical pressing of fabric and removal

in any way to alter their operation.

5

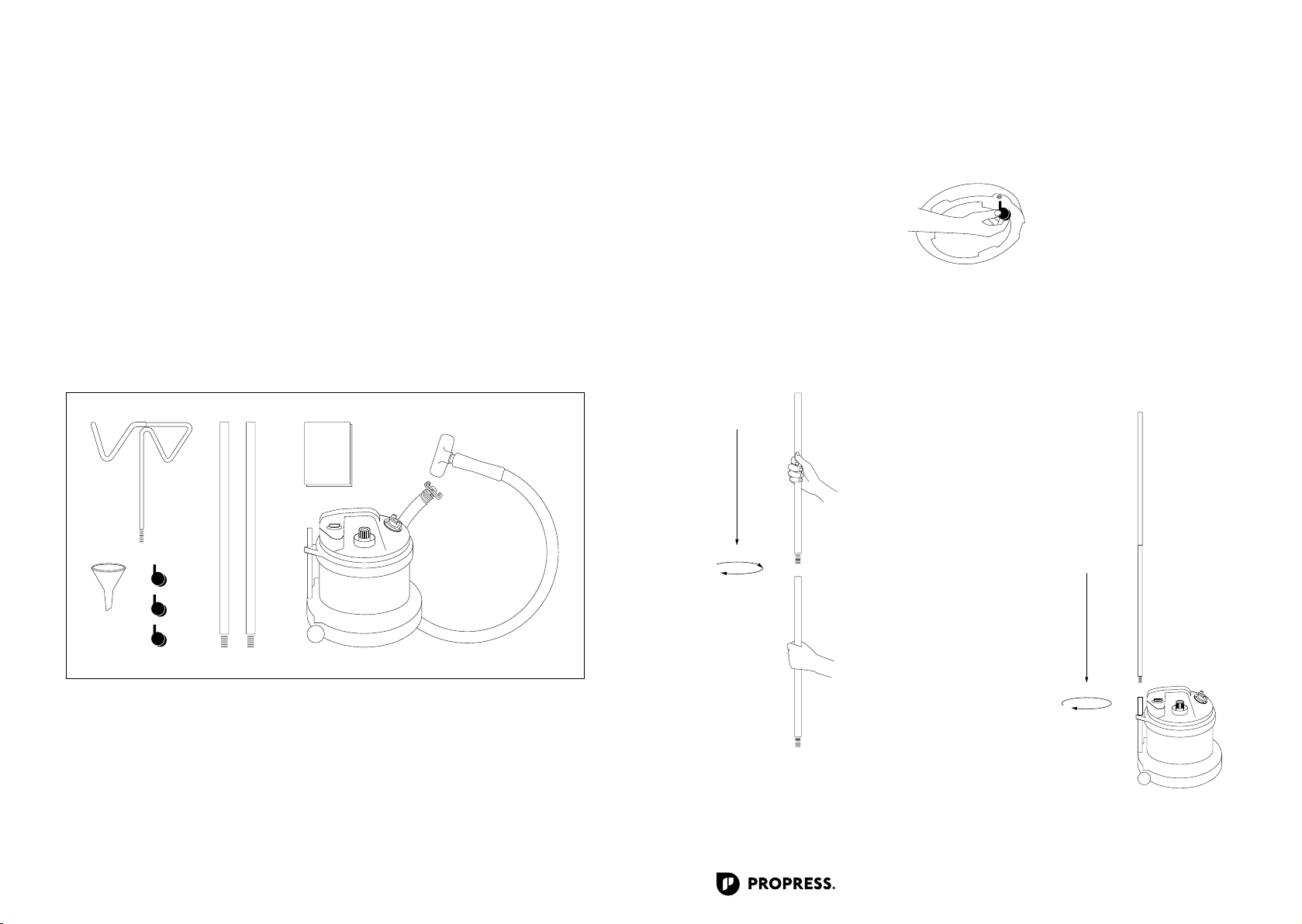

In the box you will nd the following:

• Propress PRO580 Steamer

• 2 part pole set and top hook

• Steam hose with aluminium nozzle and

protective cotton cover/bag

• 3 Castors

• Funnel

• Safe Operating Poster

Before assembling, t

the 3 press-on castors to

locating holes in chassis

base of steamer.

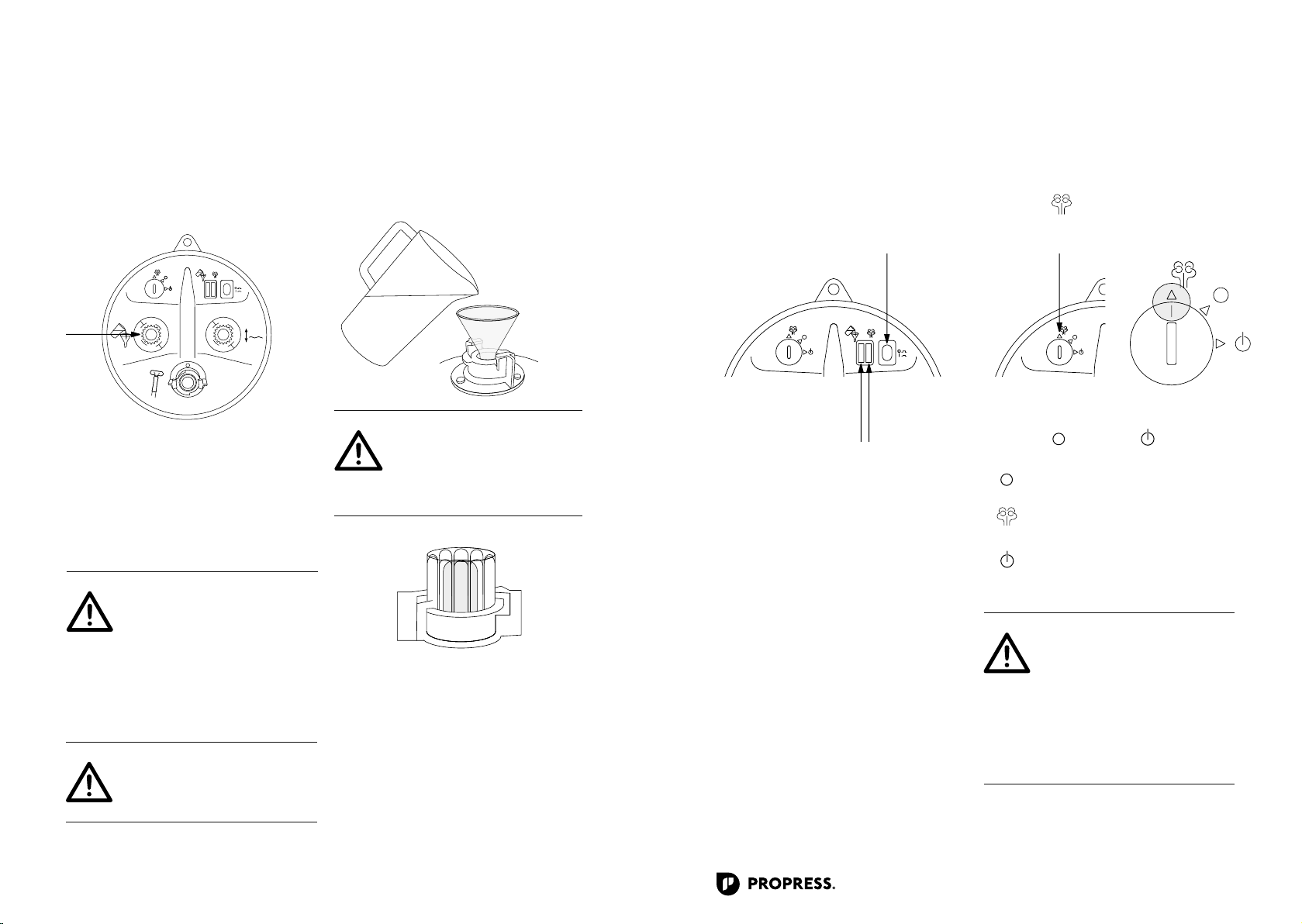

2. UNPACKING YOUR PROPRESS 3. ASSEMBLING YOUR PROPRESS

STEAMER AND PREPARING FOR USE

together and tighten.

2. Screw poles onto base

pole which is attached

to the steamer.

If any of these parts are missing

or damaged, notify your supplier

immediately.

Poster

7

Your Propress steamer is designed to be

used with clean tap water, no additives

in any form should be used as the use

of additives (except Propress Descaler)

will damage your steamer and void the

warranty.

Your steamer is an electrical

appliance and is designed for

indoor use only. It must be

used on level ground, uneven

surfaces can cause damage to

the heating element.

3. ASSEMBLING YOUR PROPRESS STEAMER

AND PREPARING FOR USE (CONTINUED)

3. Screw hook section

into top of poles.

hose outlet coupling by

aligning the ears then

pushing and twisting

the hose end clockwise

on the coupling until it

locks in to position.

5. Place steam nozzle into

hook on top of pole set.

Remove protective cotton

cover/bag from nozzle.

position when not in use.

9

4. OPERATING INSTRUCTIONS

4.1 Filling Steamer with Water 4.2 Switching On

1. Remove the Filler Cap from the

steamer.

and pour in using funnel supplied.

4L

MAX

4L

MAX

4L

MAX

4L

Never remove ller cap

when in operation.

Use only tap water. The addition

of perfume or other agents will

seriously damage your steamer

and void the warranty.

Ret ller cap. Ensure ball

bearing within ller cap is

always free moving before

switching steamer on.

If the red “empty/rell” indicator

light illuminates and the buzzer

sounds when the steamer is

switched on, your steamer is

empty of water. Turn off the

power and rell according to

instructions Filling Steamer

with Water.

1. Plug the steamer into a suitable power

outlet and push down the green on/off

switch that will illuminate to indicate

the steamer is “on”.

light

steam light

2. Turn pointer on control knob to steam

position ( ), amber steam light will

illuminate.

If the control knob is left in the off

position ( ) or standby ( ) position the

water will not be heated.

() Denotes power to the element is

disconnected.

Denotes the element is energised

and steamer will heat and steam.

() Denotes the steamer is in standby

setting keeping water hot.

NOTE: The water in the steamer will

take 10 to 15 minutes to produce steam,

dependent upon the water temperature,

ambient temperature and also the

eciency of your electrical supply.

Do not overll. When the

steamer is full the red

indicator oat will appear

in the sight glass.

If condensation is restricting the view

by twisting anti-clockwise, wipe dry

top of the sight glass, the steamer has

removing the hose and pour out of steam

outlet mopping up any spillage.

10 11

4.3 Using Your Steamer

NOTE: Ensure the area you are steaming in is well ventilated.

Once steam is emitting from the nozzle, allow the hose and nozzle

to get hot for approximately 30 seconds before using the steamer.

This reduces any condensation build-up.

any excess condensation before use and repeat periodically when

steaming garments.

4.4 Standby Setting

To use standby, once you have steam coming from nozzle, switch

control knob to standby mode, in standby the amber light will illuminate

intermittently. Standby mode ( ) will maintain water temperature just

below boiling point (occasional puffs of steam may appear from nozzle).

From standby, steam will be regenerated in seconds when control knob

is switched back to steam position. The steamer may be left in standby

mode for as long as required.

NOTE: When steamer has been left in standby mode, condensation

can occur in the steam nozzle, after switching back to steam

allow nozzle to heat and shake nozzle before use to remove any

condensation (see 4.3 Using Your Steamer)

4.5 Safety Filler Cap

this occurs turn off immediately to ensure no damage is caused to

• The steamer needs rinsing out and descaling to remove build up of

sediment or limescale

• The steamer hose is blocked, kinked or restricted

4. OPERATING INSTRUCTIONS (CONTINUED)

assembly when not in use.

steamer using the green on/off switch and disconnect

the power supply.

Do not kink or restrict the hose, as this may

cause an ejection of water and irreparable

damage to hose.

Use extreme caution when removing the ller cap.

Severe risk of burns from steam.

Never use fabric freshening sprays near your steamer. If the

body of your steamer comes into contact with this type of

spray it can cause severe damage to your steamer and will

void your warranty.

Never leave hose assembly on the oor as this

will cause a trip and burn hazard to the user

and others and could damage the hose.

When steamer runs out of water an alarm buzzer will sound and the red

cap. Then follow instructions – 4.1 Filling Steamer with Water.

for further steaming.

12 13

5. TIPS ON USE

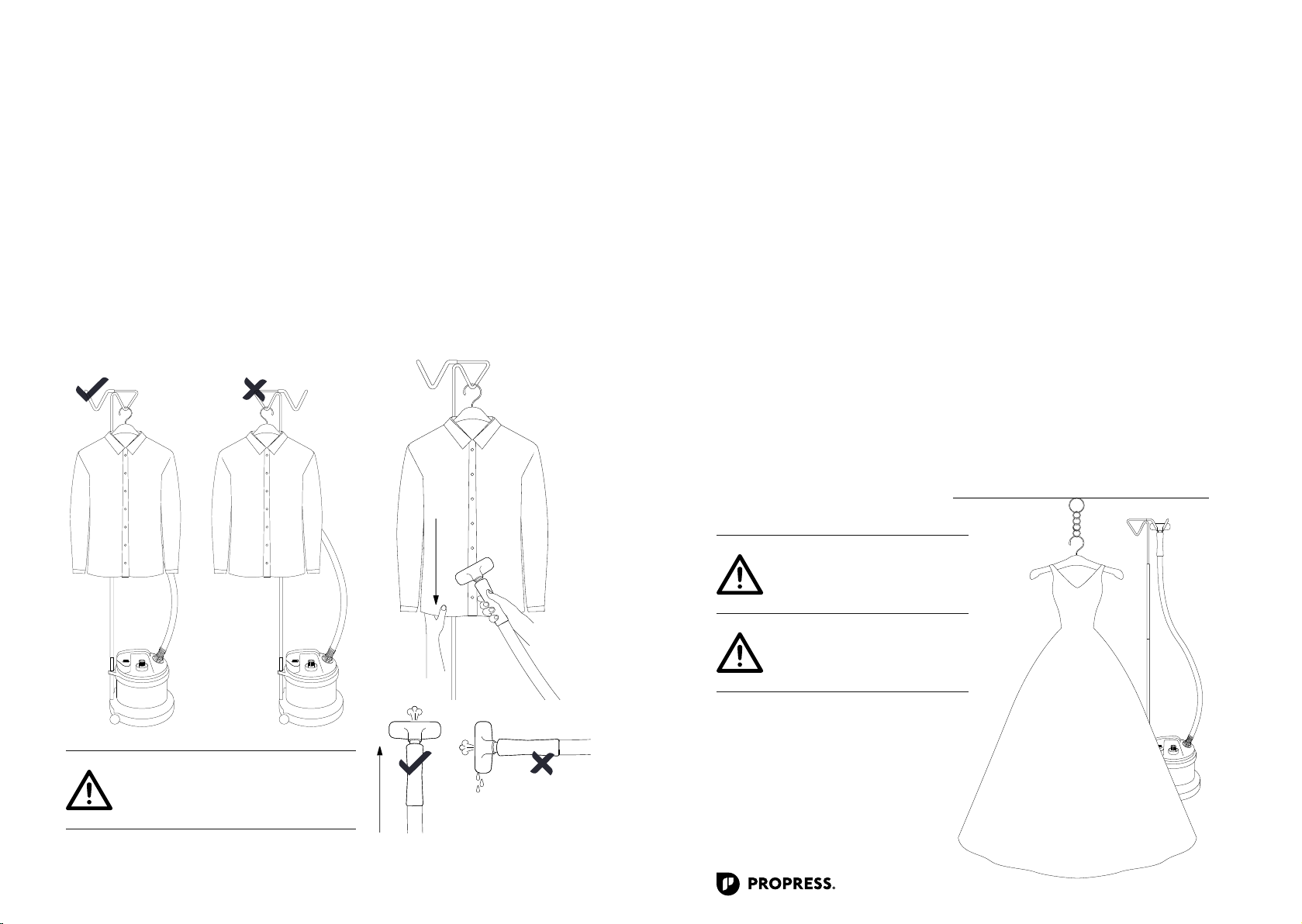

5.1 Steaming Clothing

Garments can either be steamed on a hanger, rail, mannequin

or hung from the hook on the pole assembly.

NOTE: Ensure that the pole hook is over the steamer when hanging

garments on it. This maintains the stability of the machine.

Run nozzle over the fabric while holding it taut with your free hand, taking

care not to steam near your hand in the process.

If steaming at a low level regularly lift hose up so condensation can be

allowed to run back into the steamer.

5.2 Full Garments

Full garments, such as dresses and skirts can be steamed from the

inside by touching the nozzle on to material and steaming outwards.

Caution is required as steam can build up inside the garment and get

extremely hot. Steaming from the inside reduces the possibility of

adding creases and opens up gathers; bringing dresses back to life.

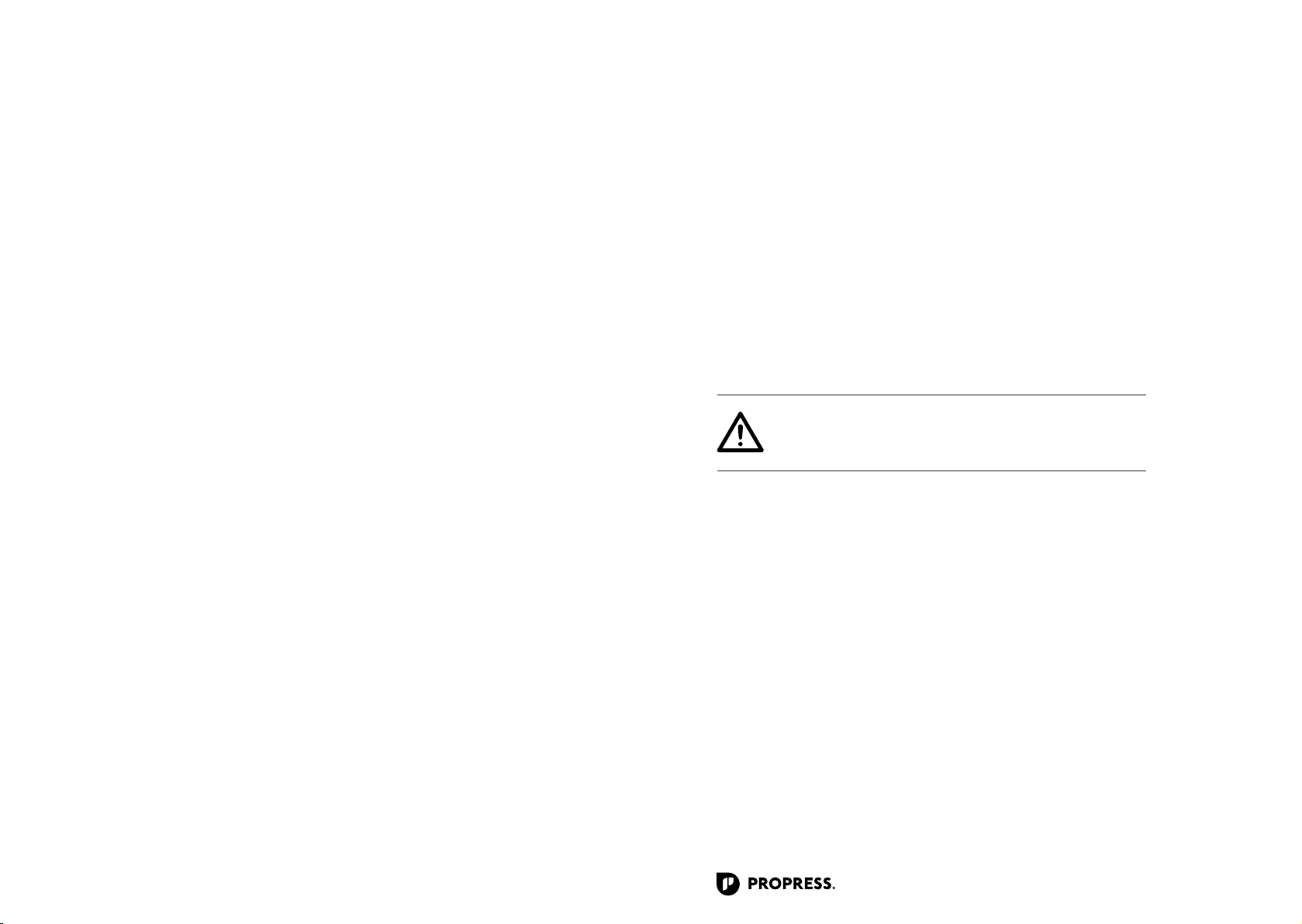

5.3 Wedding Dresses

Wedding dresses should not be hung on the pole set as their weight

can make the steamer unstable and topple over. They are best steamed

hanging from a rail or, ideally, using a plastic chain attached to a hook in

the ceiling. This allows the dress to be hung at different heights on the

chain so the lower parts of the dress and the train can be steamed with

ease. Steam the dress in sections, starting with the underskirt.

creases and to shape collars.

If steaming at a low level, regularly lift hose up so condensation can be

allowed to run back into the steamer.

If steamer nozzle is used with holes

in vertical line, this can cause water

droplets to drip from the holes.

Never steam clothes whilst

they are being worn by a

person.

Use extreme caution when

operating the appliance.

Steam can burn.

14 15

5.4 Curtains & Soft Furnishings

Steam curtains from the face side.

If curtains are interlined, it may be necessary to steam lining as well.

If using optional Drapery Kit, it will be necessary to change to standard

drapers hose when working at heights of less than 2m, otherwise

a large amount of condensation will build up in the hose and cause

reduced performance.

When steaming, periodically lift the hose so excess condensation can

run back into the boiler.

Ideal for use on bed valances, chair covers, banqueting table cloths

and removing pressure marks on carpets.

creases.

5.5 Fabric Limitations

• Seersucker

• Silk taffeta

If in doubt, test on a small inconspicuous area or steam from reverse

side of fabric.

Extreme caution should be used with man-made pile fabrics to

avoid shading – keep nozzle at least 10cm away from face or reverse,

allowing steam to penetrate and use Propress velvet brush to maintain

the pile.

Cotton and silk velvet can be steamed by lightly running the nozzle

over the pile. In the event of a condensation spot on fabric, gently rub

the back of the nozzle over the area. It should dry without leaving a

water mark.

5. TIPS ON USE (CONTINUED) 6. CARE AND MAINTENANCE

To ensure a long and trouble free life of your steamer it is essential that

of sediment and limescale. Descale regularly to ensure no unnecessary

on the heating element if not maintained properly; this will cause reduced

performance, irreparable damage to the element and void your warranty.

6.2 Cleaning your Steamer

Disconnect from the power supply.

Remove steam hose and pole assembly.

Steamer must be disconnected from the power supply.

The water in the steamer must be allowed to cool to a

temperature which will not cause injury before emptying.

NOTE: The steamer should be emptied through the steam outlet (not the

ller inlet) into a ground level drain where possible to avoid raising the

steamer up and emptying into a sink.

Start by emptying any residue water from the steamer.

fresh water and empty again, repeat procedure until the water runs clear.

Clean the outside of the steamer with a damp cloth. Do not use any

detergents or polish.

It is recommended the steamer be descaled using a non-aggressive descaler

at least every 2 months. Descaling frequency is dependent upon usage and

water hardness.

For details on suitable descalers, please contact Propress. We recommend

the use of Propress Descaler which can be purchased by calling Propress on

020 8417 0660 or visiting propress.co.uk.

16 17

6.3 Descaling your Steamer

Before descaling, carry out 6.2 Cleaning your Steamer to remove as

much loose sediment as possible.

follow directions.

Dissolve/dilute descaler in warm water, or as directed by the

manufacturer, ensuring the correct water volume to descaler ratio is

followed. Pour the diluted descaler solution into the steamer.

for a minimum of 3 hours. For best results leave to descale overnight.

completely clear.

Failure to maintain your steamer will void its warranty.

NOTE: the water in the steam generator must be allowed to cool to a

temperature which will not cause injury before emptying.

In addition to mandatory electrical tests, regularly check the condition

of the steamer's plug, cable and cable restraint for damage. If any

approved service agent for repair. Ensure all warning labels are legible.

6. CARE AND MAINTENANCE (CONTINUED)

When descaler is left in the steamer, clearly label your

steamer so no one attempts to use it.

7. STORING YOUR PROPRESS WHEN

NOT IN USE

The steamer should be emptied of water and cleaned. The electrical

cable should be coiled and steamer stored in a dry location.

If the steamer is not to be used for an extended period of time it is

recommended that the steamer is descaled before storage.

18 19

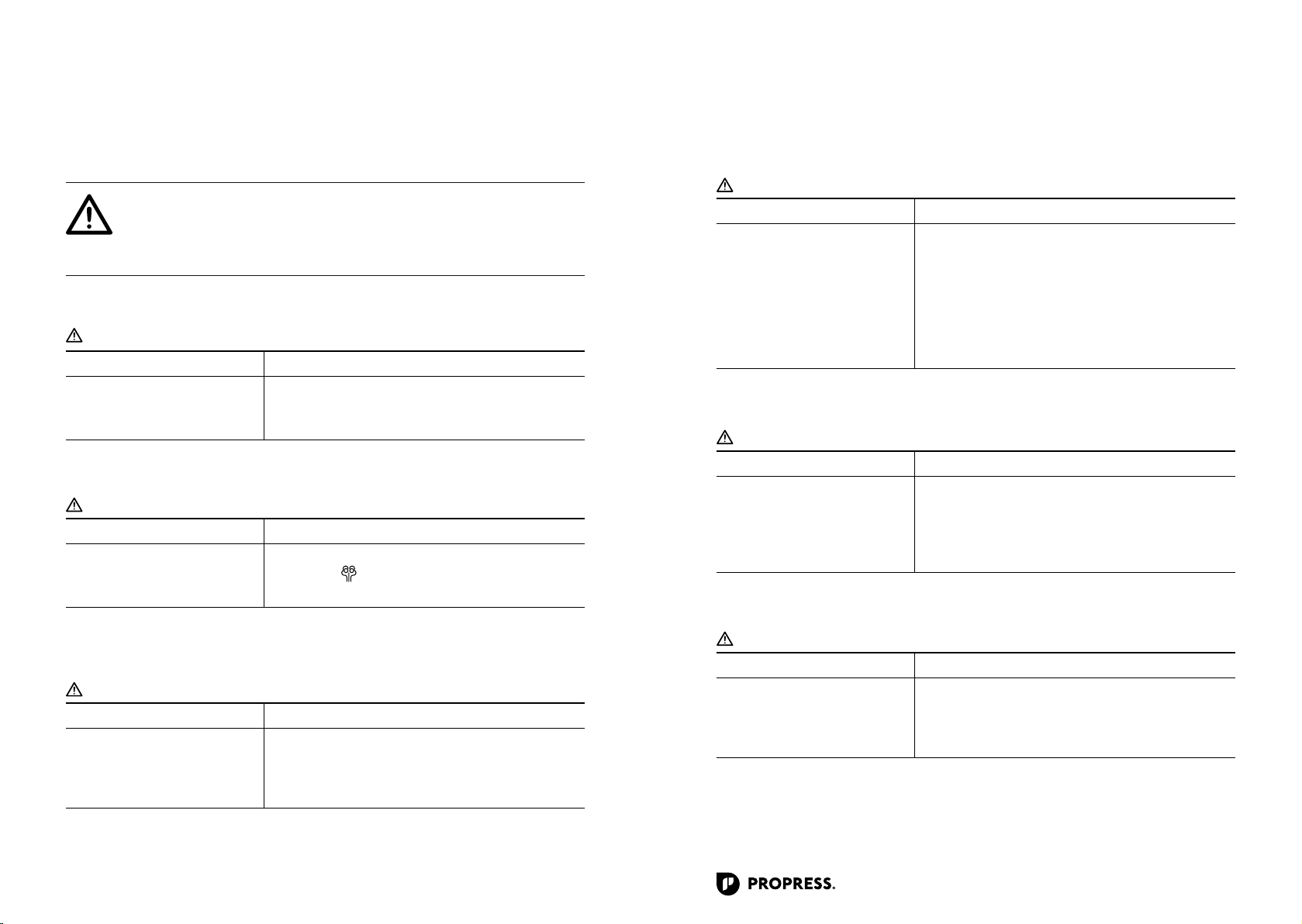

NO LIGHTS COME ON AND STEAMER DOES NOT HEAT UP

Probable Cause Solution

Steamer is not switched on, fuse

in plug has failed or power outlet

is not working/switched off.

Check steamer is switched on, plug into another

power outlet, if steamer still not working try changing

fuse in plug.

If steamer is still not working call your dealer to arrange service.

LIGHTS COME ON AND STEAMING INTERMITTENTLY

Probable Cause Solution

Control knob is set to position

other than steam.

Check pointer on control knob is pointing at the

steam icon ( ) and 'clicked' into position.

Check hose not kinked. Check cord set not damaged.

Steam is only produced when arrow is pointing at steam icon. If cord is damaged do not

use steamer and call your dealer to arrange service.

DIRTY WATER COMING OUT OF FILLER CAP

Probable Cause Solution

Steamer needs cleaning out

or descaling.

as directed in 6.2 Cleaning your Steamer. If steamer

has not been descaled recently, descale as directed

in 6.3 Descaling your Steamer.

Failure to regularly clean the boiler and descale regularly will result in damage to the element.

WATER AND STEAM COMING FROM FILLER CAP

Probable Cause Solution

or the hose is kinked or damaged.

Steamer nozzle being used at low

level causing condensation to

form in the hose.

poles and hose and empty excess water through

damage. Restrictions in the hose will cause safety

hose so condensation can run back into the steamer.

BUZZING WHEN STEAMER IS NOT EMPTY

Probable Cause Solution

Thermal sensor is damaged or

element heavily scaled.

boiler as directed in 6.2 Cleaning your Steamer.

6.3 Descaling your Steamer. If this does not correct

problem call your dealer to arrange service.

We recommend the use of Propress Descaler which is available from your local dealer.

BURNING SMELL WHEN WATER LEVEL RUNS LOW

Probable Cause Solution

Element is scaled and surrounded

by sediment.

boiler as directed in 6.2 Cleaning your Steamer.

6.3 Descaling your Steamer.

Keeping your steamer clean will extend the life of the element.

Your Propress steamer operates at high temperatures and produces steam

which can burn – use extreme caution. Troubleshooting should only be

carried out by a competent person. Always allow steamer to cool down

before commencing trouble shooting.

8. PROPRESS TROUBLESHOOTING

MATRIX

20 21

NOZZLE HANDLE VERY HOT WHEN IN USE

Probable Cause Solution

Loose securing screw in handle. Using appropriate screwdriver, check that screw

in handle is tight.

If screw continually turns you will need to order a new hose set.

EXCESS WATER FROM STEAM NOZZLE

Probable Cause Solution

heat up fully before use, or nozzle

is being used with holes lined up

in vertical orientation. Screw in

handle loose.

fabric see 4.3 Using your Steamer and also see

5. Tips on Use. Check that screw in hose handle

is tight.

Refer to full user manual for further details.

8. PROPRESS TROUBLESHOOTING MATRIX

9. GUARANTEE

regulations (proof of purchase by invoice or delivery note required).

The guarantee covers the repair or replacement (at the discretion of

Propress Ltd) of your machine or part of your machine if it is found to be

defective due to faulty materials or workmanship within the guarantee

period. This includes all parts and labour required to get the machine

working properly again without charge.

This guarantee excludes the use for hire purposes.

with instructions and user maintenance and damage from incorrect

power supply is excluded from the guarantee.

Damage caused by scale build up, impact, use of additives, dirty water

and fabric freshening sprays is excluded from the guarantee.

In case of complaint, please send the machine dismantled, empty of

water and clearly marked with your details and nature of your complaint,

to your dealer.

22 23

CLEANING RECORD

DESCALING RECORD

24

If you have any questions or comments relating to your Propress,

please contact the Propress Customer Care Team.

Record your PROPRESS Steamer serial number and purchase date here for

future reference.

Your Propress PRO580 is covered by a 12 month Propress Guarantee.

Model No.: PROPRESS PRO580

4 Litre

UK & Europe

Propress Steamers

Unit 3 The Pavilions,

2 East Road,

London SW19 1UW

TUV-025731-EA

Other manuals for PRO580

2

Table of contents

Other Propress Kitchen Appliance manuals