Page 1 of 11

PR3215 VOYAGER SHADE AWNING 2 X 2M

FIRST TIME INSTALLATION

• Please read instructions carefully before installation.

• Check the contents of kit. Contact your Prorack dealer if any parts appear to be missing or damaged.

• Clean your roof racks prior to tting the Shade Awning.

• Take care when opening the box with a knife not to slice through the canvas.

• Once your Awning is unpacked, unzip the awning to nd your tting kit.

• Always secure the awning with pegs and guy ropes. Failure to do so may result in injury as well as damage

to the product and your vehicle if the awning is lifted by unexpected wind.

IMPORTANT WARNING!

IT IS CRITICAL THAT ALL PRORACK RACKS AND ACCESSORIES BE PROPERLY AND SECURELY ATTACHED TO YOUR VEHICLE.

IMPROPER ATTACHMENT COULD RESULT IN AN AUTOMOBILE ACCIDENT, AND COULD CAUSE SERIOUS BODILY INJURY OR

DEATH TO YOU OR TO OTHERS. YOU ARE RESPONSIBLE FOR SECURING THE RACKS AND ACCESSORIES TO YOUR CAR,

CHECKING THE ATTACHMENTS PRIOR TO USE, AND PERIODICALLY INSPECTING THE PRODUCTS FOR ADJUSTMENT, WEAR,

AND DAMAGE. THEREFORE, YOU MUST READ AND UNDERSTAND ALL OF THE INSTRUCTIONS AND CAUTIONS SUPPLIED WITH

YOUR PRORACK PRODUCT PRIOR TO INSTALLATION OR USE. IF YOU DO NOT UNDERSTAND ALL OF THE INSTRUCTIONS AND

CAUTIONS, OR IF YOU HAVE NO MECHANICAL EXPERIENCE AND ARE NOT THOROUGHLY FAMILIAR WITH THE INSTALLATION

PROCEDURES, YOU SHOULD HAVE THE PRODUCT INSTALLED BY A PROFESSIONAL INSTALLER SUCH AS A ROOF RACK

SPECIALIST.

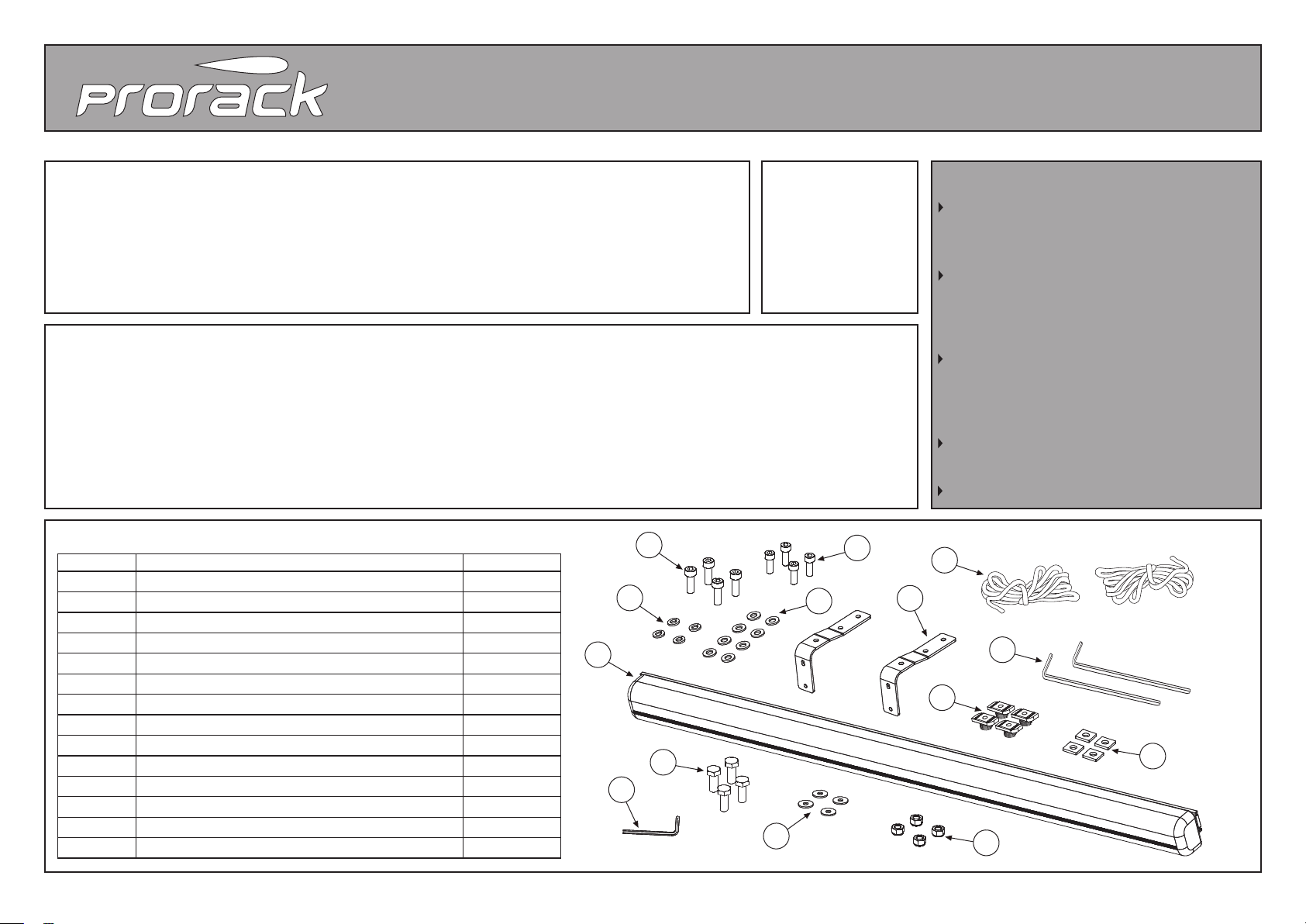

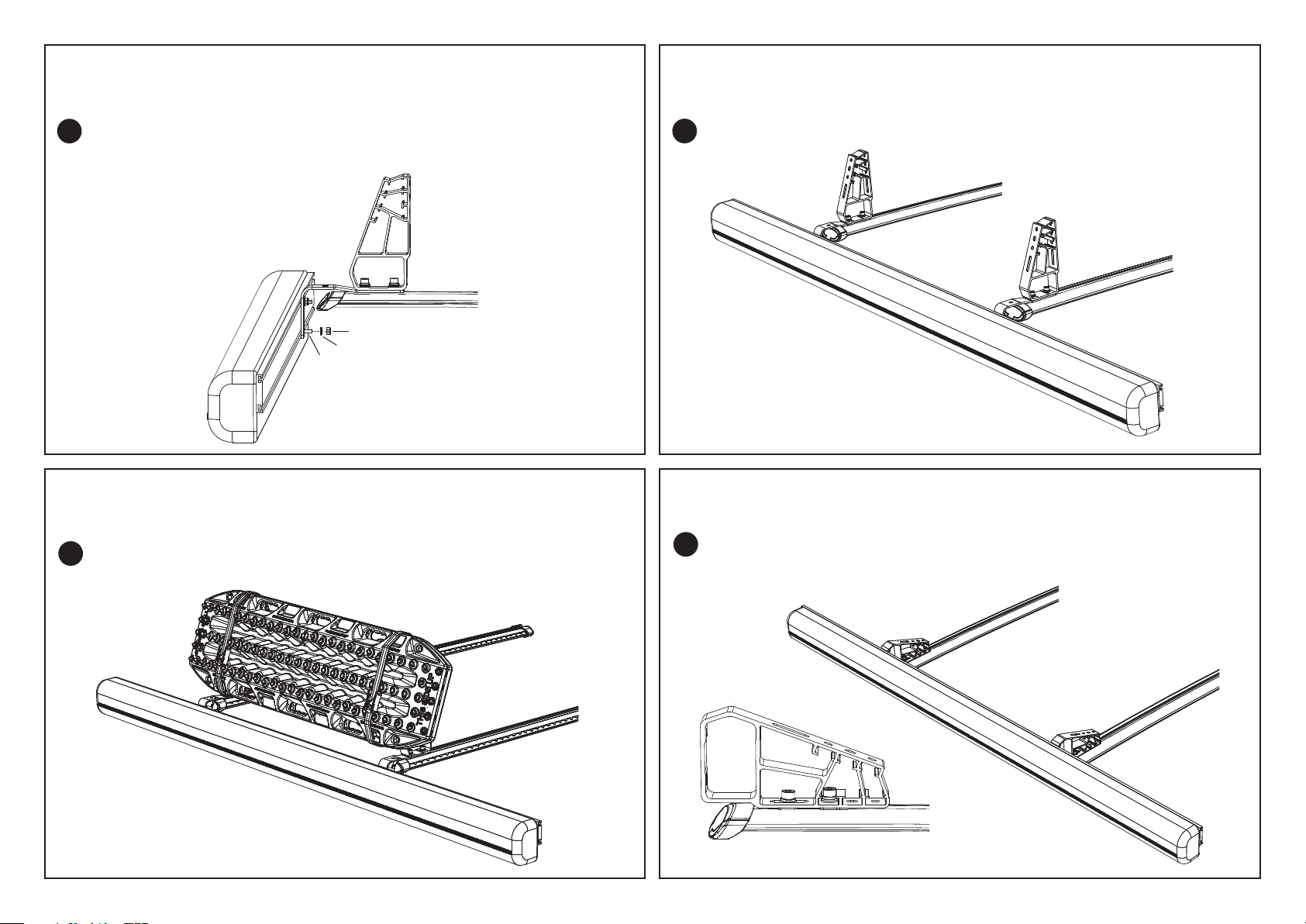

KIT CONTENTS

Item # Component Qty

1 Shade Awning 2 x 2m 1

2 Awning Bracket 2

3 Pegs 2

4 Guy Rope 2

5 M8 Spring Nut 4

6M8 T-Nut 4

7M8 Washer 8

8M8 Spring Washer 4

9 M8 Socket Head Capscrew 25mm 4

10 M8 Socket Head Capscrew 20mm 4

11 M6 Hex Bolt 4

12 M6 Washer 4

13 M6 Nylock Nut 4

14 6mm Allen Key 1

09-13-577 Rev 1

TOOLS REQUIRED

• Tape measure

• 10mm Spanner

• Torque Wrench

(optional)

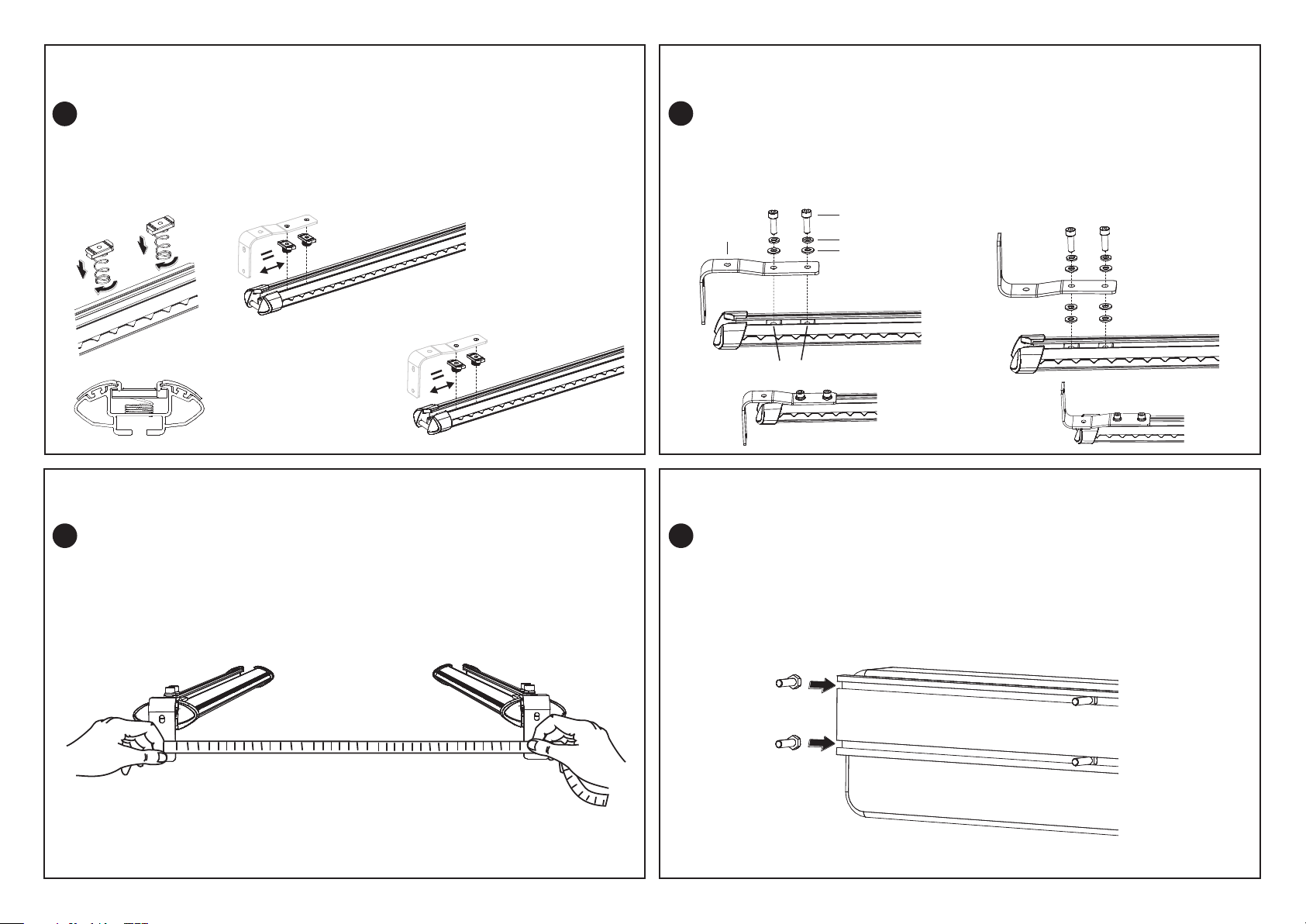

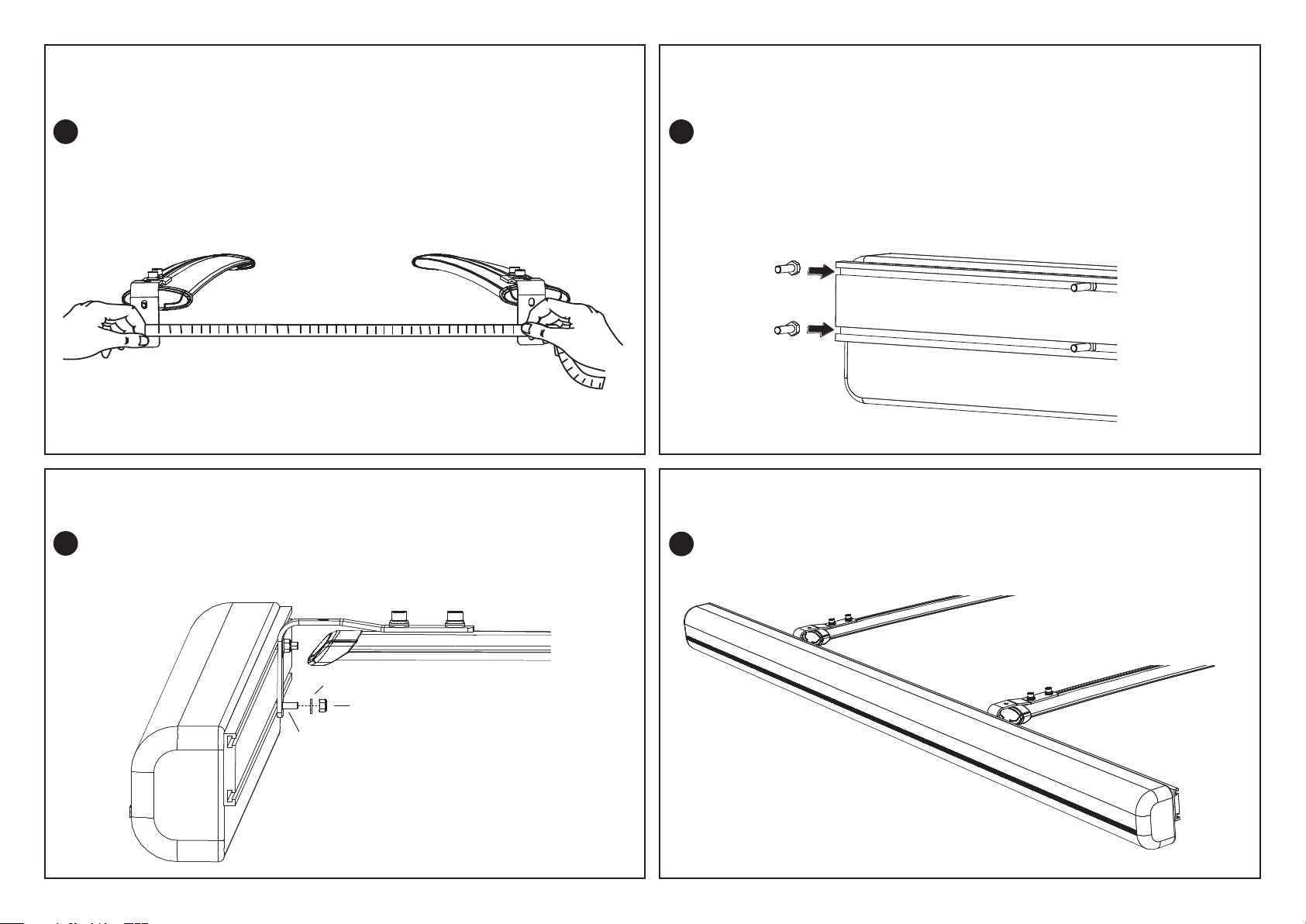

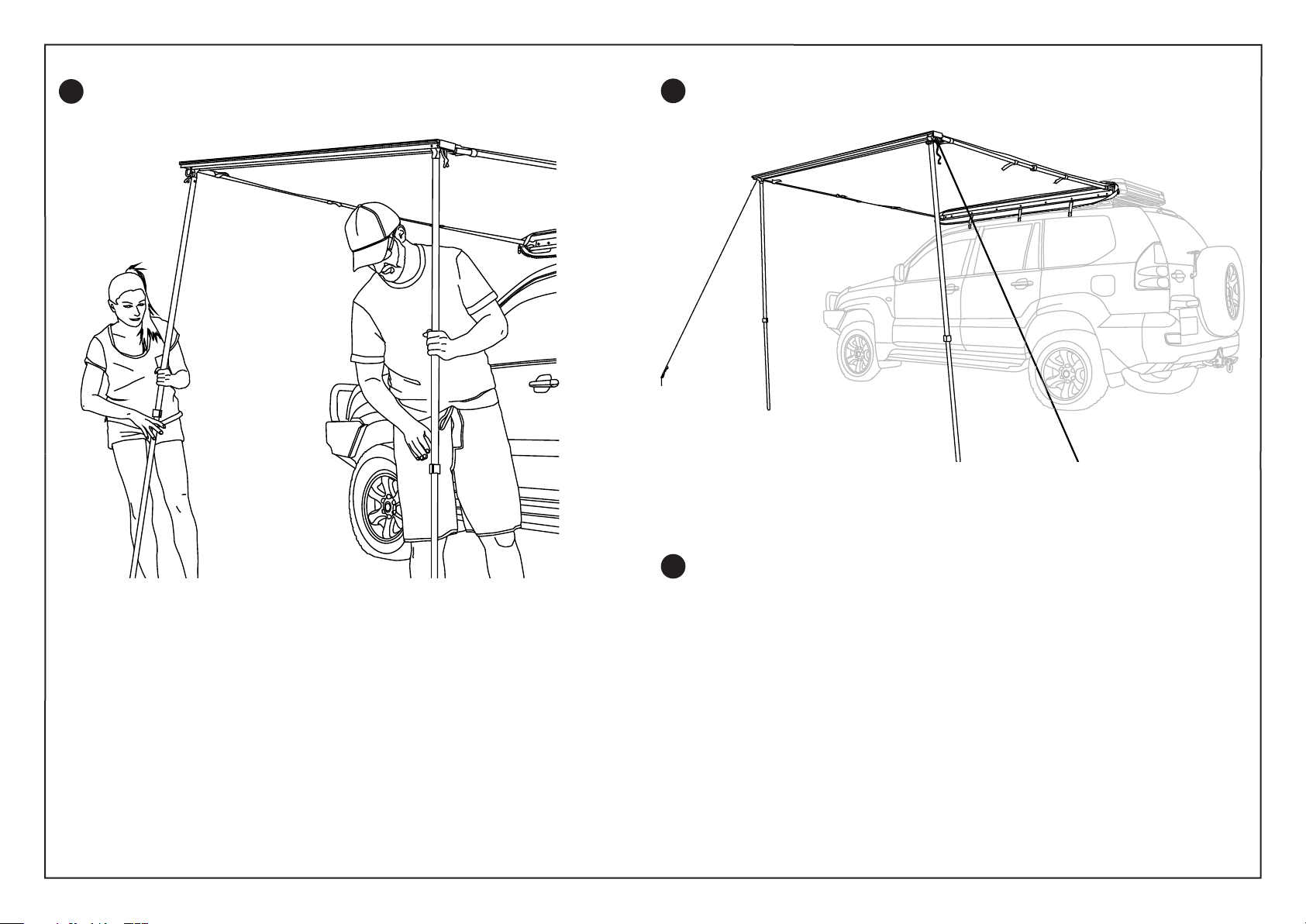

Installing Shade Awning direct to Prorack HD,

Tradesman and other Heavy Duty Crossbars

Go to Step 1

Installing Shade Awning direct to Prorack S-Wing

and International T-Slot Crossbars

Go to Step 7

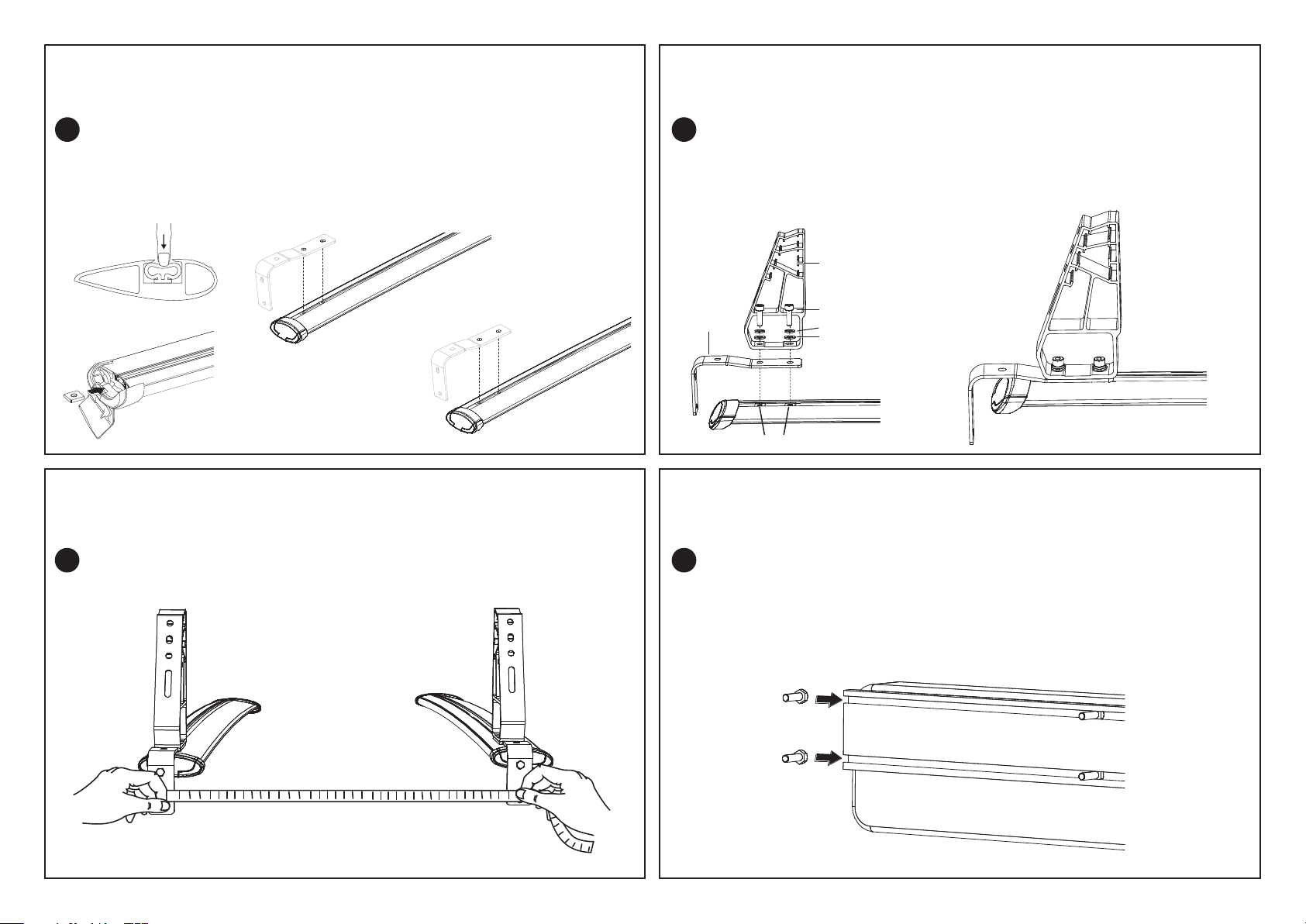

Installation of Shade Awning plus Recovery Tracks

Carrier Mounting Brackets (PR3207) on Prorack

HD, Tradesman and other Heavy Duty Crossbars

Go to Step 13

Installation of Shade Awning plus Recovery Tracks

Carrier Mounting Brackets (PR3207) on Prorack

S-Wing and International T-Slot Crossbars

Go to Step 21

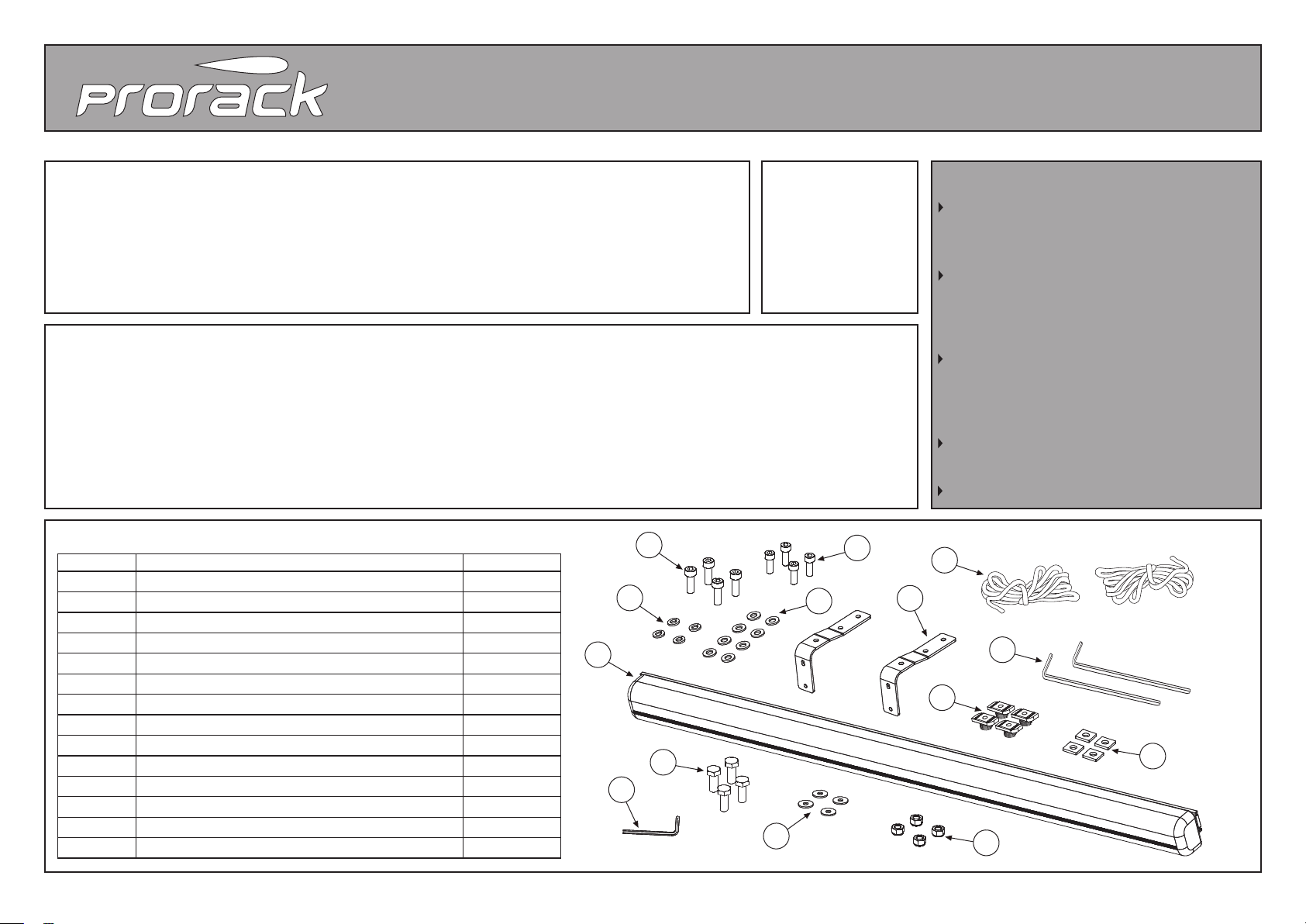

Set-up and Pack-up of Shade Awning

Go to page 9

1

2

3

4

5

6

7

8

11

12 13

910

14