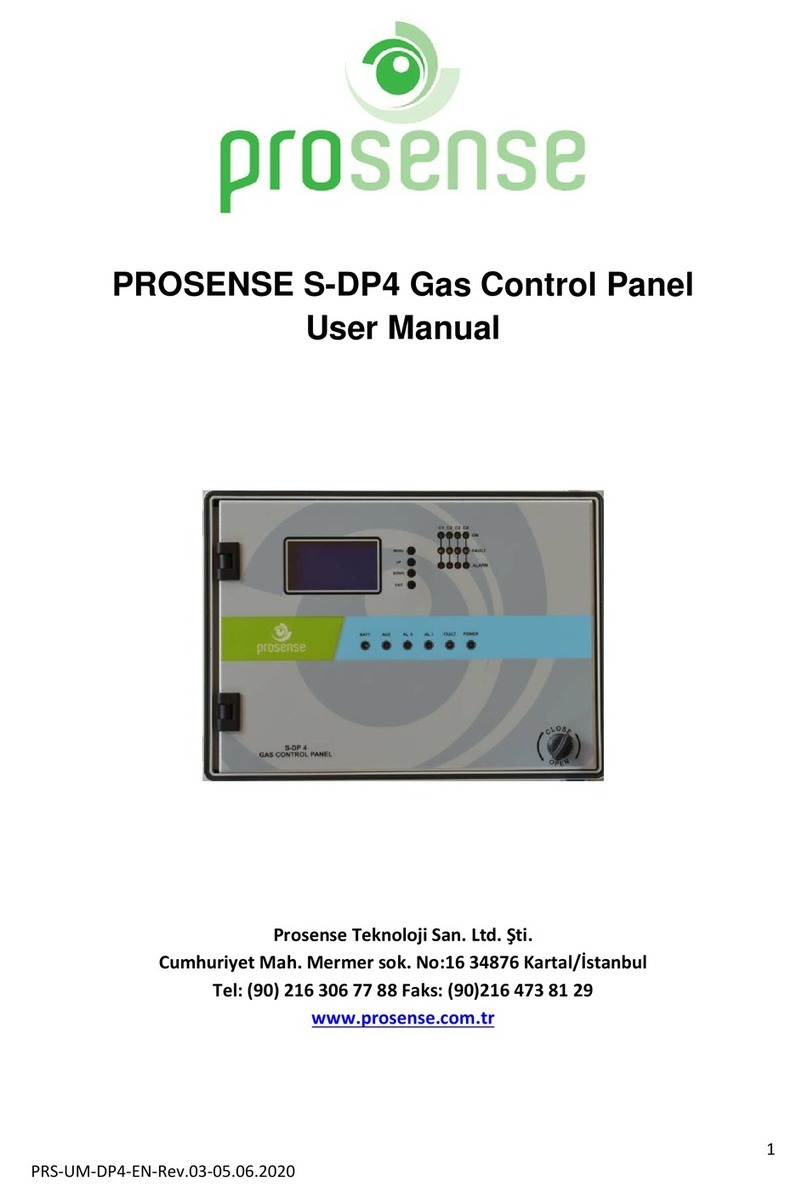

Prosense S-DP32 User manual

2

PRS-UM-DP32-EN-Rev.02-05.2019

WARNING!

READ THIS INSTRUCTION FIRST!

This manual must be carefully read by all persons who have or will have the

responsibility for installing, using or servicing this product.

Like any equipment, this product will perform as designed only if installed,

used and serviced in accordance with the manufacturer’s instructions.

Otherwise, it could fail to perform as designed and persons who rely on this

product for their safety could suffer severe personal injury or death.

The warranties made by Prosense with respect to this product are voided if

the product is not installed, used and serviced in accordance with the

instructions in this user guide. Please protect yourself and other by following

them.

WARNING!

Inductive or capacitive loads like motors, ventilation, e.g. should not be

directly connected to the panel directly. In such cases, auxiliary external

relays should be use to drive these loads.

3

PRS-UM-DP32-EN-Rev.02-05.2019

Contents

Introduction ..........................................................................................................................................4

Technical Specifications .........................................................................................................................5

Panel Dimensions...................................................................................................................................6

Installation .............................................................................................................................................6

Functions................................................................................................................................................9

LCD Screen: ......................................................................................................................................10

Fault Status: .....................................................................................................................................10

Alarm Status: ....................................................................................................................................11

Overrange Status Screen: .................................................................................................................11

Main Board and Connections ...............................................................................................................12

Main Board Details:..........................................................................................................................12

Backup Battery Connection..............................................................................................................13

Main Power Connection...................................................................................................................13

Detectors Connections .....................................................................................................................14

Prosense RS485 Serial Communication Module for Prosense Detectors .........................................15

Relay Outputs...................................................................................................................................16

AUX Relay Output.............................................................................................................................17

First Run ...............................................................................................................................................17

Automatic Test .................................................................................................................................17

Programming........................................................................................................................................18

Single Channel Mode:.......................................................................................................................18

Setup Channel Parameters:..............................................................................................................19

Closing Unused Channels: ................................................................................................................20

Relay Assignment: ............................................................................................................................21

Time Settings:...................................................................................................................................21

What to Do In Case of Alarm ................................................................................................................22

Checking Alarm and Fault Functions ................................................................................................22

Controlling the Alarm Fault Functions..............................................................................................23

Warranty Statement ............................................................................................................................24

4

PRS-UM-DP32-EN-Rev.02-05.2019

Introduction

Prosense S-DP32 Control Panel is able to provide automatic gas concentration reading and

protection against gas explosions. S-DP32 permanently transmits the gas concentration

measurement from detectors to the control unit. Before the gas concentration in the

atmosphere reaches the L.E.L., the control panel is able to shut off a gas valve, cut off power

and turn on an alarm via activating relays when correctly integrated to related control

devices. Prosense S-DP32 Control panel can manage up to 32 explosive-flammable and toxic

gas detectors as well as oxygen detectors with serial loop connection.

Prosense S-DP32 Control panel has two levels of alarm which are adjustable according to the

measuring range and one fault alarm for the detection loop. Individual relays per function

ensure remote controlled output. There are 4 relays on the panel. Two of them used as

alarm relays and configured as ALARM-1 and ALARM-2. There is one FAULT relay and one

AUX relay. The AUX relay can be defined as ALARM-1, ALARM-2 or ALARM-3. ALARM-3 is not

a level based alarm but it is an alarm driven by digital input connected to another external

device.

S-DP32 has 128x64 LCD screen on the front panel to show status of each detector. This LCD

screen and menu keys allow user to set correct properties for each detector like gas

concentrations by gas type, measurement unit, and range and alarm levels.

S-DP32 Gas Control Panel complies to IEC 60079-0:2017 and IEC 60079-29-1:2016 standard

requirements. Please refer to the certification label on the control panel to identify the type

of certification that relates to the product supplied.

Diagram 1:Panel Label

The serial number of the product given with “DP32/???????” numbers.

5

PRS-UM-DP32-EN-Rev.02-05.2019

Technical Specifications

Power Source

220VAC ±10% 50/60 Hz

Power Consumption

27VDC/250mA - 6.75W max. (without connected detectors)

Inputs (Internal)

1 serial input that can communicate to 32 detectors via RS485

Relay outputs

FAULT, ALARM1, ALARM2, AUX

Contact ratings

3A, 24VDC or 3A 120VAC

Display

Graphic LCD (128x64)

LED indicators

FAULT, ALARM1, ALARM2, AUX, BATT, POWER for overall status

Alarm LEDs for each detector

Backup battery

12V 7A/h (Optional)

Operating Temp.

-10 : 60C

0

Humidity

15-95% non condensing

Housing

ABS IP66 (546 X 276 X 186 mm)

Weight

5,75 kg

Main power fuse

2A

Backup battery fuse

2A

Warm-up time

Up to 2 minutes

Delay time

Panel can recognize any special state in 2 minutes

EMC conformity

EN 61326-1 Group-1 Class-A

IEC conformity

IEC 60079-29-1

Program Release

V3.12

Special condition

Do NOT install in hazardous area

Table 1: Technical specifications

6

PRS-UM-DP32-EN-Rev.02-05.2019

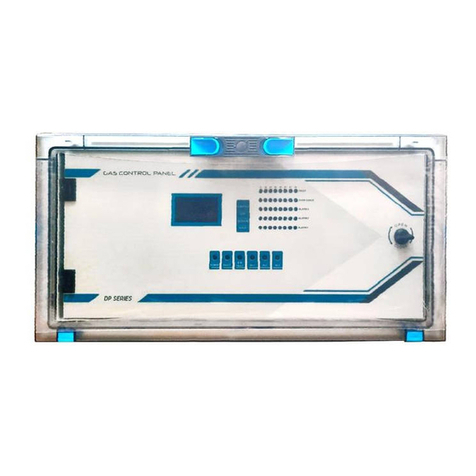

Panel Dimensions

Panel dimensions are explained in Diagram 1:

Diagram 2: Dimensions (mm)

Installation

The S-DP32 control panel box should never be placed in an explosive atmosphere and should

be readily accessible. It is necessary to drill holes for cable glands either on the top or

bottom of the control unit, depending on which side the electric cables are running in.

Please unscrew and remove the electronic parts before drilling to avoid any accidentally

damaging. S-DP32 control panel should not be placed nearby high voltage cables or power

cable, coaxial cables or transmitters, welding stations or frequency regulators. The S-DP32

panel box produced based on IP66 standard specifications. Always use prepared screw holes

to mount it and do not pierce panel from any other side. Always use suitable cable glands to

make cable entries.

There is a front plastic cover to protect panel from outer shells, water and dust. To reach to

panel first you need to open plastic cover via pressing both sides of the latches on the front.

If panel ordered with keys a key needed to open plastic cover.

Press to open

Diagram 3: Front cover

Lock

7

PRS-UM-DP32-EN-Rev.02-05.2019

If panel ordered with keys a key needed to open plastic cover.

Diagram 4: Front cover with key

In order to make panel connection, you need to open the front cover using the key at right

bottom side of front panel. The key works clockwise and vice versa.

Diagram 5: Locker.

S-DP32 panel has 6 plastic screws keeping panel door in place in front of panel. Use a flat

screwdriver to lose them and remove the panel door assembly. Please take care and remove

the connectors on the electronic card while removing the cover. Fix the panel on to the wall

via using 4 screw holes in each corner after removing the front cover. M4 screws are suitable

to fix the panel body to the wall. Once wall mounting completed reattached the front cover

and tighten 6 plastic screws.

To prepare cable entries, remove plastic cover from top or bottom on the panel. Then drill

the holes for cable entry and install cable glands to the holes you made it. Make sure you are

using an adequate IP66 rate cable gland to assure the box ingress protection is not

compromised. The panel box is modular and can be used with different assemblies. Prosense

recommends having cable entries from the lower side. Electronic board is located in the

front cover of the panel. The power supply is located at the back of panel box. The power

must be connected to this power supply. If the installation requires the connection to a

backup battery, place the battery to lover right side of the panel inside.

8

PRS-UM-DP32-EN-Rev.02-05.2019

Diagram 6: Panel cover plastic screw

Diagram 7: Panel body

Plastic screws

Plastic screws

Backup battery connectors and fuse

Power supply

N L G V-V+

Wall mounting hole

Wall mounting hole

Main power entry and fuse

Space for backup batteries

Power supply LED

Power supply output

adjustment switch

Wall mounting hole

Wall mounting hole

9

PRS-UM-DP32-EN-Rev.02-05.2019

Functions

The front panel has the following indicators as shown in Diagram 4:

Sign

Meaning

BATT

Main Power lost, Battery in operation

AUX

AUX ( assigned as ALARM1, ALARM2 or ALARM3*)

AL1

ALARM1

AL2

ALARM2

FAULT

Fault condition in at least one of the detector

POWER

220 VAC Operate

ON

Operation LED for each detector (8 green LEDs)

FAULT

Fault LED for each detector (8 yellow LEDs)

ALARM

ALARM LED for each detector (8 red LEDs)

Table 2: Front panel signs and meanings

There are four buttons nearby LCD screen to perform configuration and display the detector

details. Their functions are given in table (The key assignments may vary depending on the

menu page):

Key

Function For Configuration

Function For Display Operation

MENU

Enter to panel configuration

OK - Select key

UP

Go to upper menu option during configuration

Go to the single channel details in normal operation

DOWN

Go to lower menu option during configuration

Page change on main screen

EXIT

Undo or exit from menu option

Reset on main screen

Table 3: Panel buttons and functions

Diagram 8: Front panel signs LCD and LEDs

S-DP32 Panel has 32 LEDs numbered from1 to 32 nearby LCD panel. These LEDs will be

activated in case of an alarm to show which detector is raising the alarm. If any of these LEDs

are active it indicates the detector having that address has reached specified threshold level.

10

PRS-UM-DP32-EN-Rev.02-05.2019

LCD Screen:

LCD screen shows time details and status of each detector connected to channels as shown

in Diagram 8. As The LCD screen can show 6 lines at same time there are up to six pages that

you can move via UP and DOWN buttons:

Diagram 9: LCD screen first page

Note: Date and time information will be unavailable when RS485 module installed.

The meaning of the signs used in LCD screen is given in table 4:

Column

Sign sample

Meaning

1

1>

Channel number

2

DETECTR

Detector name (user can give any name)

3

0 or 0.0

Gas level measured by detector

4

LEL

(LEL, VOL, PPM) measurement unit of

detector

5

A1

ALARM1 is active

5

A2

ALARM2 is active

5

FLT

FAULT status

Table 4: LCD screen details

If there is no detector connected to channel, LCD screen will show it as FLT and fault LED will

be activated. That channel should be closed (deactivated) via using menu steps.

The LCD screen brilliance is adjustable by blue potentiometer shown in Diagram 9.

Fault Status:

Device is in fault state; all related fault text is shown on the display as a text.

The panel reports FAULT status in below cases:

•In case any of the detector connections lost

•In case any of the detector measurement level goes below minimum level

•In case any of the detector goes in to fault state

•In case any panel self-test result reports a fault

•In case panel main power lost and while panel is working with battery power

•In case panel main power supply fails

This status has been detected by panel when an input signal is below 3mA and reported on

LCD screen on related channel with “FLT” symbol. Panel will activate FAULT relay and LED in

case of any fault. Panel also activate fault LED for related channel if the fault status detected

on a detector channel.

11

PRS-UM-DP32-EN-Rev.02-05.2019

Fault relay is energized and set to NC by default. User can monitor power status as it will be

switched in case of total power loss.

Alarm Status:

The Panel will report Alarm status when gas level exceedes defined alarm levels on any of

the detector channel. Panel has two adjustable measurement alarm levels. If any connected

detector measurement reaches the given alarm threshold level, panel will activate related

alarm relay and LED. Alarm-1 relay and LED will be activated in case any of the connected

detector measurement reaches defined Alarm-1 threshold level. Panel will show "AL1"

symbols for the related channel on LCD screen and also activate alarm LED on related

channel. Alarm-2 relay and LED will be activated in case any of the connected detector

measurement reaches defined Alarm-2 threshold level. Panel will show "AL2" symbol for the

related channel on LCD screen and also activate alarm LED on related channel. Alarm-1 and

Alarm-2 relays and LEDs will be both active in case any of the connected detector reports

Alarm-2 status.

Overrange Status Screen:

The panel also report overrange status in case any of the channels reported measurement

higher than measurement range. This status has been detected by panel when an input

signal received from serial line and reported on LCD screen on related channel with

“Range<” symbol and measurement level fixed to 100LEL. The overrange condition is highes

measurement level that panel can understand and overrange level is higher than alarm

levels. The alarm LEDs and relays will be activated before panel reports overrange condition.

Diagram 10: Overrange status display

12

PRS-UM-DP32-EN-Rev.02-05.2019

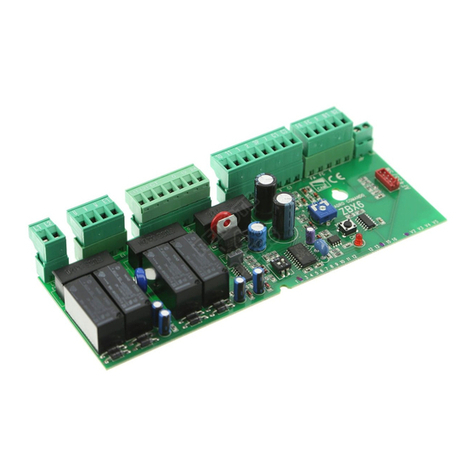

Main Board and Connections

S-DP32 Control panel has one integrated main board. All components and connections are

located on main board.

Main Board Details:

S-DP32 Control panel has all connections on main board.

Diagram 11: Control panel main board

As shown in the picture, there is a 3V battery on the panel electronic board to keep data and

time information. It may operate during the normal lifetime of the control panel. It should

be replaced when it is run off.

There are five sockets on the main board to install optional relay modules. Each relay

module has 8 relay on it and each relay controlled by one detector. It is also possible to take

an independent output from each relay (each detector). The relay module install location

should be used as follows:

1. Zone (1. Bölge): Alarm relay for detectors 1-8

2. Zone (2. Bölge): Alarm relay for detectors 9-16

3. Zone (3. Bölge): Alarm relay for detectors 17-24

4. Zone (4. Bölge): Alarm relay for detectors 24-32

5. Zone (5. Bölge): Not in use

LCD brightness adjustment potentiometer

Relay module mounting holes

Main power

input

Backup

battery input

Clock battery

Digital input

Relays and relay outputs

Buzzer

Relay test buttons

RS485 input

Power output

for detectors

13

PRS-UM-DP32-EN-Rev.02-05.2019

There are 4 cube relays on main board and relay outputs can be taken from the terminals on

the bottom of relays. The relays are used for Fault, Alarm 1, Alarm 2 and Aux outputs. There

are test buttons at the top of each relay that can help to generate artificial alarms for testing

purposes.

S-DP32 Panel has a buzzer on the main board to generate sound alarms. A digital input port

provided on main board that should be 24VDC. To activate this input the AUX relay must be

defined as Alarm-3 to work with digital input. Otherwise it does not provide any output.

Not: The electronic board may become hot when the panel is in alarm status for a long time.

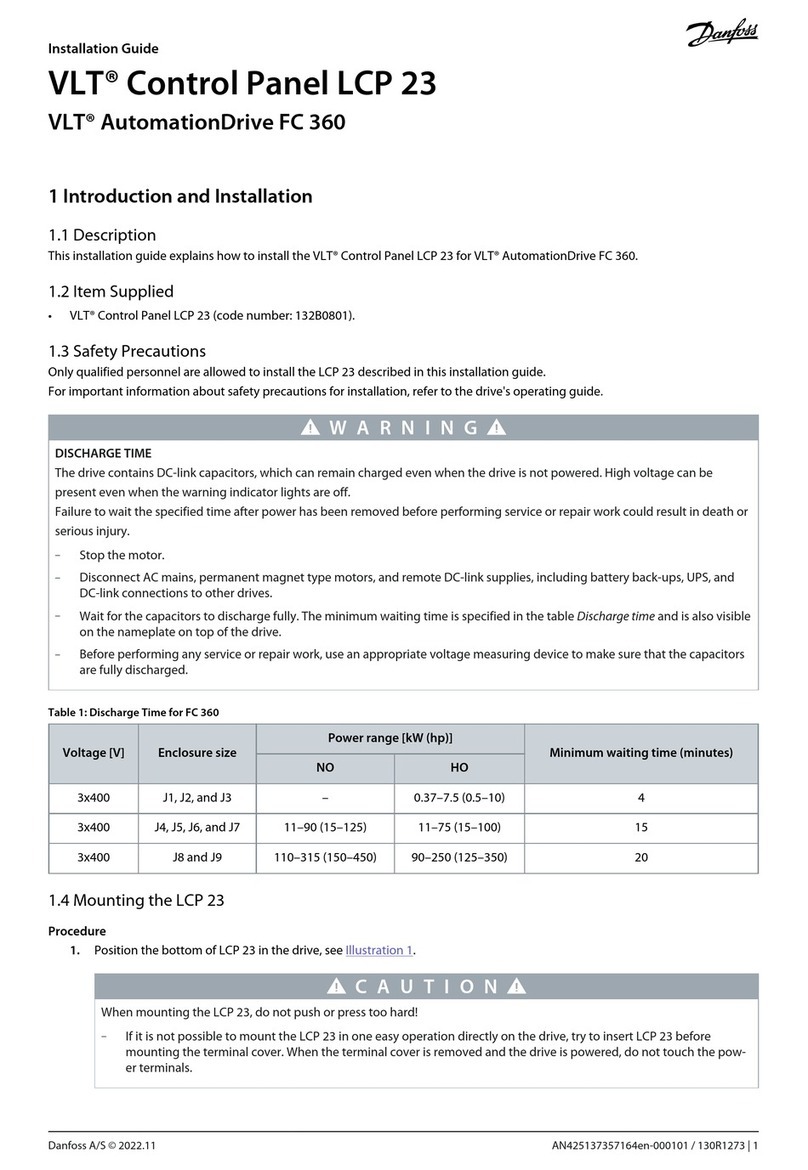

Backup Battery Connection

To continue operation in case of main power failure two backup batteries (12V 7Ah) must be

serially connected to the system. Take extra care to connect the batteries with correct poles.

The cables or main board can be damaged in case of mixing pins or making short circuits.

Backup batteries must be connected as shown below.

Diagram 12: Backup battery connection

Main Power Connection

Connection must be made three-wire 1.5mm2cross section cable to the main supply

terminal entries and fixed by using cable fastener on the terminal. Make sure all the

detectors connected properly before applying the power.

Name

Type

Usage

L

input

Phase

Gnd

input

Ground

N

input

Neutral

V+

output

+24VDC (Only for panel and detectors, do not use for any other device)

V-

output

-VDC

Table 5: Main power connection details

Panel battery input

V+

V-

V+

V-

Battery 1/ 12V 7Ah

Battery 2/ 12V 7Ah

V-

V+

14

PRS-UM-DP32-EN-Rev.02-05.2019

Detectors Connections

S-DP32 Panel can be connected and monitor 32 detectors with RS485 serial connection. V+,

V-(GND), A and B ports must be connected via using four-wire cable. Detector connections

supply 27VDC power to detector and read the output signal of detector from A and B ports.

Thus connections should be made correctly to do not cause any damage on the detectors.

Detector power connection should be done with 1.5mm2cross section cable. The total

distance between control panel and detectors should not exceed 800 meters. Detector

connections should be made with 4 core cable wire that 2 for power and 2 for RS485 and pin

definitions are as follows:

V+

output

+24VDC (Only for panel and detectors, do not use for any other device)

V-

output

-VDC

A

input

RS485 port A

B

input

RS485 port B

Table 6: Connection pin definitions

The wiring for detectors utilized with RS485 board should be done by using connection cable

EIA RS485 2 core wires with section 0.22 / 0.35 mm2 and shielded. Nominal capacity

between the wires should be < 50pF/m and nominal impedance should be 120 Ohms.

The V+, V- ports and A, B ports are located different sockets in S-DP32 main board. These

ports are formed in same or different sockets on Prosense detector address modules. The

connections should be done with care to do not mix power and RS485 ports. All detectors

will be connected through one cable via hopping one detector to another till the last

detector on the line. The connection schema is given in Diagram 11:

Diagram 13: Panel to detector connections

There should be one master device and up to 32 slave devices in RS485 communication. The

master is S-DP32 control panel and detectors will be the slave devices:

B AV- V+

A

B

V+

V-

Panel

S-S-

B A V- V+

V+

V-

A

B

Detector 1

Detector 2

Max 32

Detector

15

PRS-UM-DP32-EN-Rev.02-05.2019

Diagram 14: RS485 communication

Each detector connected to same S-DP32 panel should have unique address. Detectors

having same address would not be recognised by control panel. S-DP32 panel can

communicate up to 32 detectors. In case less than 32 detectors connected, control panel

would not show non-existent detectors. Unused detectors should be deactivated on channel

settings menu steps.

The last detector at the RS485 serial line should have the end of line resistor to enable the

total communication line. Otherwise control panel may not communicate to all, some or

none of the detectors. The end of line resistor controlled by end of line pins located on

address module of Prosense detectors and can be enabled via putting the jumper on end of

line pins.

Detector connections supply 24VDC power to detector and read the output signal from

RS485 serial ports. Thus connections should be made correctly to do not cause any damage

on the detectors. Cable diameter should be selected correctly via taking care about voltage

drop due to cable internal resistance. Thus the cable diameter should be increased while

distance increase between the panel and detectors. The applications show that connection

made with 1.5mm2cross section cable works fine in general.

Prosense RS485 Serial Communication Module for Prosense Detectors

Prosense produce a communication module to enable RS485 Modbus serial

communication. The board has 4 ports thus the detector connection should be made by 4

wire that 2 for power and 2 for RS485. The total length of the connection line should not

exceed 800 meters.

The wiring for detectors utilized with RS485 board should be done by using connection

cable EIA RS485 2 core wires with section 0.22 / 0.35 mm2 and shielded. Nominal capacity

between the wires should be < 50pF/m and nominal impedance 120 Ohms.

Detectors will be wired in daisy chain (bus) mode. We recommend not using star mode

connection due to negative impact of interference. Each detector should have unique

address number in the chain. The detectors with same address would not be recognised by

control panel. The address of detector can be adjusted via using DIP-Switch set on the

board or using the detector menu depending of the detector model:

16

PRS-UM-DP32-EN-Rev.02-05.2019

Diagram 15: RS485 Modbus serial communication address and switch position

The last detector in the chain should have 120 Ohms RS485 termination resistor. The resistor

is already implemented on the board by default but not activated. User should activate the

termination resistor via using the termination pin once the installation completed.

Important: Only the last detector on the serial bus should have end of line pin.

For more details please check detector user manuals.

Relay Outputs

S-DP32 panel has four relay outputs which are ALARM1, ALARM2, FAULT and AUX. Relay

connection ports are located right under the relays. Alarm relays are operating in latched

mode. Hence the panel will wait user intervention to clear alarm status even conditions

returned to normal. User should reset status via pressing Exit button to acknowledge any

alarm. The active relays can also be monitored via related LEDs on the panel. Relay details

and activation rules are given below:

ALARM1: This relay will be activated when any of the detectors in the system will exceed the

programmed Alarm-1 level threshold. If there is oxygen detector used in the system,

ALARM1 is also used as the low oxygen level alarm.

ALARM2: This relay will be activated when any of the detectors in the system will exceed the

programmed Alarm-2 threshold level. If there is oxygen detector used in the system,

ALARM2 is also used as the high oxygen level alarm.

FAULT: This relay will be activated when any of the detectors in fault status or any panel self

test function fails. The Fault LED will be activated when line power lost and system runs with

17

PRS-UM-DP32-EN-Rev.02-05.2019

battery power. The Fault relay is energised and it is possible to get an alarm when control

panel totally lost the power

If needed user can obtain independent alarm and fault outputs from each detector via using

optional relay module. Relay modules should be installed reserved zone sockets explained

earlier. The relays are configured as NO (normally open) by default at factory. The relay

configurations can be adjusted via putting jumpers under each relay. Relay will not provide

output while jumpers are omitted or not installed. Relay connections pins are:

NC : Normally closed contact pin (Select by jumper under relay)

NO : Normally open pin (Select by jumper under relay)

COM : Common pin

Note: Relays should not be connected to high current or 220V AC loads. The relay outputs

should be used as control signal and external relays should be used to drive such devices as

relay on main board cannot handle high load.

AUX Relay Output

Aux relay can be programmed from the main menu on the panel to match to ALARM1,

ALARM2 or ALARM3. When ALARM1 is selected, AUX relay will operate simultaneously with

ALARM1 relay of the system. When ALARM2 is selected, AUX relay will be active when

ALARM2 relay activated. When ALARM3 is selected, AUX relay will be active by the digital

input on the panel. In case of any alarm signal received from external device it will be shown

in 9th line on LCD as digital alarm.

First Run

Panel manufacturer (Prosense) and model (S-DP32) will be seen on LCD screen following the

power-up. All LEDs on the panel and sounder device will be activated for 3 seconds. The user

can recognize any malfunctioning LED on panel at this period. The Fault relay and LED will be

activated during the warm-up period. The panel will start searching channels one by one and

activate the channel power and fault LEDs. This operation may take two minutes. During this

period, system will operate in standby mode until the detectors are warmed up.

Instantaneous alarms will be turned off during the warm-up period.

Panel will list recognized detectors on LCD screen with their current status information.

Automatic Test

S-DP32 gas control panel simultaneously monitor all detectors connected to it. Panel should

have power LED and connected detector Channel ON LEDs during normal operation. S-DP32

panel also runs internal component tests at the warm-up time and every 8 hours. The FAULT

relay and LED will be activated in case any problem. Alarm and fault status can be monitored

on the screen and via checking related detector LEDs.

18

PRS-UM-DP32-EN-Rev.02-05.2019

Programming

The panel is already programmed and ready for using when shipped. User should adjust the

alarm settings via changing alarm levels for each channel depending on the detectors

installed. Each channel parameters should be adjusted regarding related detector

measurement unit and range. These adjustments can be done via using the keys nearby LCD.

Each detector can also be named in the menu. The menu steps are given in Diagram 11.

Diagram 16: Menu structure

S-DP32 control panel keeps data and time information to record alarm events in the internal

log space. The alarm logs menu is not available when panel uses RS485 module to

communicate to Prosense Panel Monitor software.

To activate configuration menu, press and hold the MENU button for a second. You can

navigate between the menu items via using the UP and DOWN keys. Press MENU key again

to enter submenu. You can EXIT from submenu or menu by pressing the EXIT button.

1. Channel setting

2. Time / Language settings

3. Relay assignment

4. Alarm logs

Single Channel Mode:

To see each detector status in detail, press UP button on the main menu. Screen will switch

in to single channel mode. Then it will display detector status, instant reading value, alarm

status and detector name:

If there is any fault or alarm it will be displayed right bottom corner of screen:

1- Channel setting

2- Time/Language settings

3- Relay assignment

4- Alarm logs

1. Detectr.

2. Detectr.

3. Detectr.

4. Detectr.

MENU

1-Detector Setting

Aux > Alarm2

Alarm > automatic

hour. min. sec day/

month/ year

4-Alarm logs

2-Time Setting

3-Relay Assign

1>D4 F3 23/06 15:55

2>D3 A1 23/06 12:12

Main menu screen

19

PRS-UM-DP32-EN-Rev.02-05.2019

You can switch between channels via using UP or DOWN buttons. Also you can directly reach

alarm logs screen via pressing MENU button in single channel mode. Logs keep alarm and

fault details with their date and time for last 24 hours. You might use UP and DOWN buttons

to see all records. Press EXIT button to return main menu. Screen will automatically exit from

the single channel menu to main menu after 2 minutes if there is no user action.

Setup Channel Parameters:

To adjust channel parameter follow below steps.

1- Press Menu button for 2 seconds. The screen will display menu options:

2- Select Channel setting via pressing the MENU button. Screen will list channels:

3- Move desired Channel from the list via using UP and DOWN buttons and press MENU

button to select channel. A new menu will display with below options:

4- S-DP32 panel automatically recognize the measurement unit and range while

communicating the detector. Therefore these settings cannot be changed by user. To adjust

alarm level settings select "Level Settings" option. Screen will display default alarm level

settings:

20

PRS-UM-DP32-EN-Rev.02-05.2019

5- When press MENU button a cursor will be located under Alarm1 level. You can adjust

alarm level via using UP and DOWN buttons.

6- Then press EXIT button to release the cursor.

7- Then you can move Alarm2 via using UP or DOWN buttons.

8- Press MENU button again to activate cursor and adjust level using UP and DOWN buttons.

9- Once all completed press exit button to return the previous screen.

Alarm1 level would not be increased higher than Alarm2 level. So if you want to increase

alarm levels it would be easier to adjust first Alarm2 level then adjust Alarm1 level.

10- Once all completed press EXIT button to return main menu.

Closing Unused Channels:

In case a detector will temporarily off due to any reason, panel will raise fault status as it

cannot communicate to the detector. If user knows the reason and want to deactivate this

fault status simply close the channel as it is an unused channel. Otherwise unused channels

and control panel will stay in fault status. To deactivate unused channel go to the Channel

Settings menu via pressing the MENU button. Then move related channel via using UP and

DOWN buttons and select channel with MENU button. You will see the below detailed

settings menu:

The second step on this menu pointing the actual status of the channel. “Open” means

channel is active. To close this channel move to the option 2 on screen via UP and DOWN

buttons then press MENU button to change status. It will be deactivated and shown like

below:

Once the temporarily outage has been resolved user should follow same steps and open the

channel. S-DP32 panel will start communicating to the detector without power-off/power-on

the control panel.

Table of contents

Other Prosense Control Panel manuals