Prosense PPS Manager User manual

2

PRS-UM-PPSM-EN-Rev.03-10.04.2020

WARNING

This user guide must be carefully read by all persons who are or will have the responsibility for

installing, using or servicing this product. This product must be installed, used and serviced in

accordance with the manufacturer's directives. Otherwise it could fail to perform its functions as

designed and persons who rely on this product for their safety could suffer severe personel injury or

death.

Properly installed panel can be used without any problem and covered under Prosense warranty. The

warranties made by Prosense with respect to this product are voided if the product is not installed,

used and serviced in accordance with the instructions in this user manual.

WARNING

Inductive or capacitive loads like motors,ventilation, eg. should not be directly connected to the

panel directly. In such cases, auxiliary external relays should be use to drive these loads.

3

PRS-UM-PPSM-EN-Rev.03-10.04.2020

CONTENTS

1.INTRODUCTION .................................................................................................................................... 4

1.1 Technical Specifications............................................................................................................... 4

1.2 Panel Dimensions .............................................................................................................................. 5

2. INSTALLATION..................................................................................................................................... 5

3. FUNCTIONS AND DETAILS.................................................................................................................... 7

3.1 LCD Screen:........................................................................................................................................ 8

4. MAIN BOARD AND CONNECTIONS...................................................................................................... 9

4.1 Main Board Details:........................................................................................................................... 9

4.2 Backup Battery Connection ............................................................................................................. 10

4.3 Main Power Connection.................................................................................................................. 11

4.4 Detector Connections...................................................................................................................... 11

4.5 PPS Series Detectors Connections................................................................................................... 13

4.5 Relay Outputs .................................................................................................................................. 15

5. FIRST RUN.......................................................................................................................................... 15

5.1 Automatic Test ................................................................................................................................ 16

5.2 LED Test ........................................................................................................................................... 16

6. PROGRAMMING ................................................................................................................................ 16

6.1 Set FAN1 Relay Level: ...................................................................................................................... 16

6.2 Set FAN2 Relay Level: ...................................................................................................................... 17

6.3 Set Alarm Relay Level: ..................................................................................................................... 18

6.4 Set Alarm Activation Type: .............................................................................................................. 18

6.5 Set Gas Type: ................................................................................................................................... 19

6.6 Set Language: .................................................................................................................................. 20

6.7 Scan Detectors:................................................................................................................................ 21

6.8 Show Detector:................................................................................................................................ 21

7. ALARM STATUS.................................................................................................................................. 22

7.1 What to do in case of alarm ............................................................................................................ 22

8. FAULT CODES................................................................................................................................. 23

Declaration ............................................................................................................................................ 24

Warranty Statement.............................................................................................................................. 25

4

PRS-UM-PPSM-EN-Rev.03-10.04.2020

1.INTRODUCTION

Prosense PPS Control Panel is produced specially for carparking area. Prosense PPS control Panel is

able to provide automatic gas concentration reading for gases CO, NO and LPG that mostly exist on

car parking areas. PPS Control Panel permanently transmits the gas concentration measurement

from detectors to the control unit. Before the gas concentration in the atmosphere reaches the LEL

or toxic PPM level, the control panel is able to shut off a gas valve, cut off power and turn on an

alarm via activating relays.

Prosense PPS Control Panel can have up to 4 zone modules that each can monitor up to 32 detectors.

A fully configured PPS Panel can handle managing 128 detectors. PPS Panel can be configured

depending on detectors used in each project with one, two, three or four zone modules.

Prosense PPS Panel has three relays on each zone module those are two level fan relays (F1 and F2)

and one alarm relay. Fan relays are not alarm relays. They will be activated after 60 seconds once the

defined threshold level exceeded and deacticvated after 240 seconds than the alarm status returned

to normal. The PPS Panel has one power module that can provide power to all zone modules. This

power module has also two relays which are fault and alarm. These relays will be activated if any one

of the zone modules generates fault and or alarm status.

Prosense PPS Control panel can manage up to 128 addressable detectors via RS485 serial

communication protocol. PPS Panel has an 2x8 LCD display to adjust measurement and alarm levels.

This LCD screen and menu keys allow user to set correct properties for each detector like gas

concentrations by gas type, measument type, range and alarm levels.

1.1 Technical Specifications

Power Source

220VAC +/-10%

Power Consumption

27VDC/200mA – 5.4W max. (without connected detectors)

Inputs (Internal)

4 x 32 detectors via RS485 serial input

Relay outputs

Fan1, Fan2, Alarm for each zone

Fault and Alarm for overal status

Contacts rating

3A, 24VDC or 3A 120VAC

Display

Graphic LCD (2x8)

LED indicators

Fan1, Fan2, Alarm

Power/ON, Fault, Alarm LEDs

Backup battery

2 x 12V 7A/h (Optional)

Operating Temp.

0-50C

0

Humidity

15-85% non condensing

Housing

ABS IP66 (366 X 276 X 186 mm)

Weight

5,5 kg

Main power fuse

2A

Backup battery fuse

2A

Table 1 : Technical specifications

5

PRS-UM-PPSM-EN-Rev.03-10.04.2020

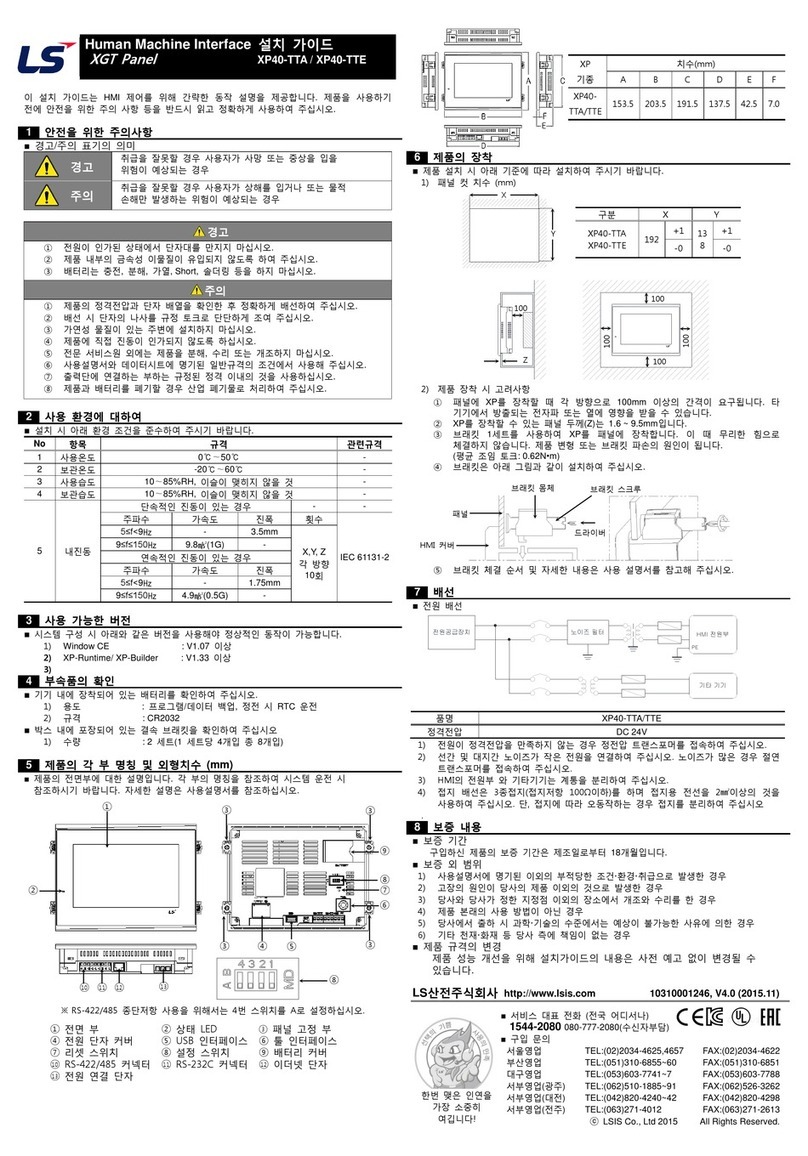

1.2 Panel Dimensions

Panel dimensions are explained in Diagram 1:

Diagram 1: Dimensions (mm)

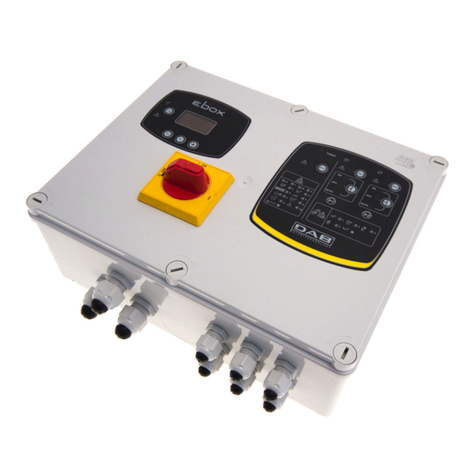

2. INSTALLATION

The PPS Control Panel box should never be placed in an explosive atmosphere and should be readily

accessible. It is necessary to drill holes for cable glands either on the top or bottom of the control

unit, depending on which side the electric cables are running in. Before drilling any holes you can

unscrew and remove the electronic parts to avoid accidentally damaging it. PPS Control panel should

not be placed near by high voltage cables or power cable, coaxial cables or transmitters, welding

stations or frequency regulators.

The PPS Control Panel box produced based on IP66 standard specifications. Always use the screw

holes to mount it and do not pierce panel from any other side. Always use cable glands to make cable

entries.

The PPS Control Panel has 4 plastic screws on the front of panel. Use a flat screwdriver to loose them

and remove the cover part on the front. Please take care and remove the connectors on the

electronic card while removing the cover. Fix the panel on the wall via using 4 screw holes after

removing the front cover. Reattached the front cover and tighten 4 plastic screws when wall

mounting completed.

6

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Diagram 2: Panel cover plastic screw

To prepare cable entries, remove plastic covers from top or bottom of the panel. Then drill the holes

for cable entry and install cable glands to the holes you made it. Make sure you are using an

adequate IP66 rate cable gland to assure the box ingress protection is not compromised. The panel

box is modular and can be used with different assemblies. Prosense recommends having cable

entries from the lower side. Electronic board is located in the front cover of the panel. The power

supply is located at the back of panel box. The power must be connected to this power supply. If the

installation requires the connection to a backup battery, place the battery to lover right side of the

panel inside.

Diagram 3: Panel body

Plastic screws

Plastic screws

Backup battery connectors and fuse

Wall mounting hole

Power supply

N L G V-V+

Wall mounting hole

Wall mounting hole

Wall mounting hole

Main power entry and fuse

Space for backup

batteries

Power supply LED

Power supply output

adjustment switch

7

PRS-UM-PPSM-EN-Rev.03-10.04.2020

3. FUNCTIONS AND DETAILS

The front panel has the following LEDs for each zone as shown in Diagram 4:

Sign

Meaning

ON

Panel is in operation

FAN1

FAN1 relay status

FAN2

FAN2 relay status

ALARM

ALARM status

FAULT

Fault condition in at least one of the zone module

Table 2 : Front panel signs and meanings

There are four buttons near by LCD screen to perform configuration and display the detector details.

Their functions are given in table (The key assignments may vary depending on the menu page):

Key

Function For Configuration

Function For Display Operation

Enter to panel configuration

OK - Select key

T

Test button

Return back

↑

Go up

Go to next channel

↓

Go down

Go to next channel

Table 3 : Panel buttons and functions

Diagram 4: Front panel signs LCD and LEDs

There is a front plastic cover to protect panel from outer shells, water and dust. To reach to panel

first you need to open plastic cover via pressing both sides of the latches on the front.

8

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Press to open

Diagram 5: Front cover

If panel ordered with keys a key needed to open plastic cover. In order to make panel connection,

you need to open the front cover using the key at right bottom side of front panel. The key works

clockwise and vice versa.

Diagram 6: Front cover with key

Diagram 7: Locker

3.1 LCD Screen:

PPS Panel has 2x8 LCD display on each zone module to show detector address, measurement level

and range as well as detector gas type.

Sign sample

Meaning

CO

Measured gas type

0

Gas level measured by detector

P

Measurement range (PPM)

D01

Detector address

Table 4 : LCD screen details

If there is no detector connected to channel, LCD screen will show fault status on channel (FLT) and

fault LED will be activated. That channel should be closed (deactivated) via using menu steps.

Locker

9

PRS-UM-PPSM-EN-Rev.03-10.04.2020

4. MAIN BOARD AND CONNECTIONS

4.1 Main Board Details:

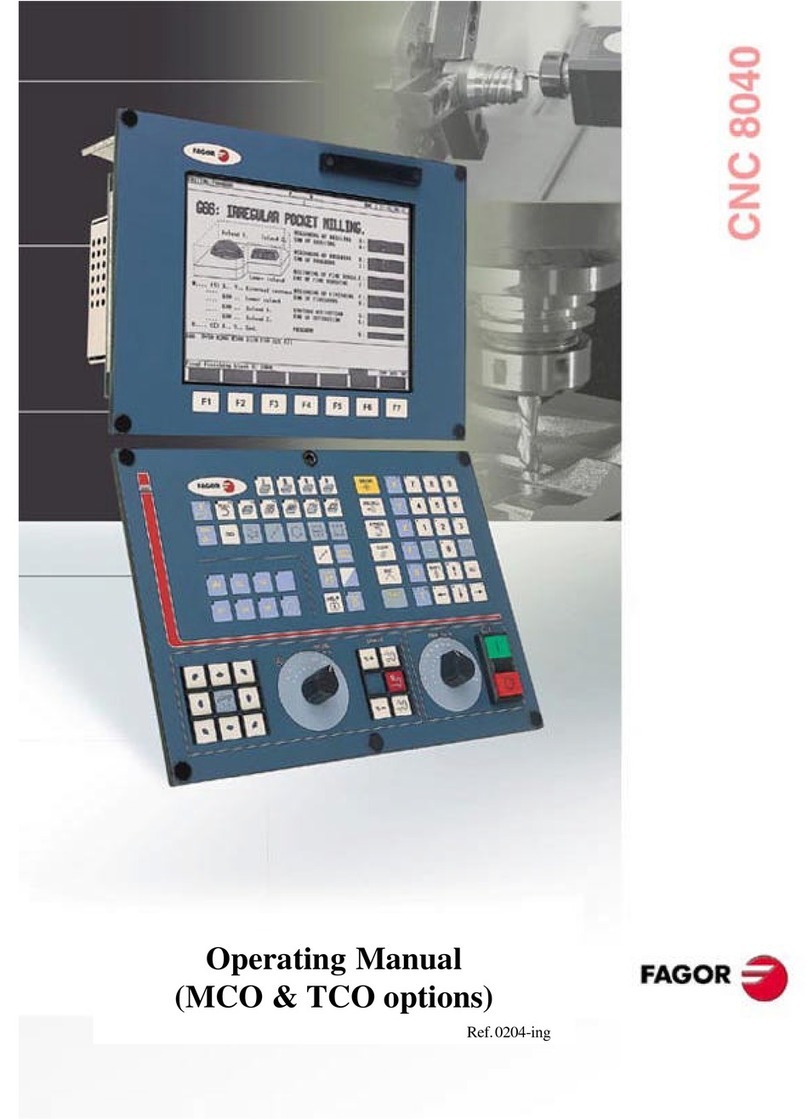

PPS Control panel has one power module and main power connection from power supply to control

panel made on this board. This board provides power to zone modules.

Diagram 8: Control panel main board

As shown in the picture, power module has its own fuse. Power module equipped with two relay

modules as fault and alarm. Fault relay will be activated when any of the detector goes in to fault

status and alarm relay will be activated when any of the zone modules raise the alarm status.

Each zone module works independantly with the detectors connected to them. The connection made

by the V+, V-, A and B ports on zone module. Each zone module has three relays which are Alarm,

Fan 1 and Fan 2.

Connections to Zone modules

Fuse

Main power input

Backup

battery input

Fault relay

output

Alarm relay

output

10

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Diagram 9: Control panel zone module board

4.2 Backup Battery Connection

To contiue operation in case of main power failure two backup batteries (12V 7Ah) must be serially

connected to the system. Take extra care to use correct poles while connecting the batteries. The

cables or main board can be damaged in case of mixing pins or making short circuits. Backup

batteries must be connected as shown in Diagram 10 below.

Diagram 10: Backup battery connection

Panel battery input

V+

V-

V+

V-

Battery 1/ 12V 7Ah

Battery 2/ 12V 7Ah

V-

V+

V+ A B V-

Detector connections

Alarm FAN2 FAN1

Relay outputs

11

PRS-UM-PPSM-EN-Rev.03-10.04.2020

4.3 Main Power Connection

Connection must be made three-wire 1.5mm2cross section cable to the main supply terminal entries

and fixed by using cable fastener on the terminal. Make sure all the detectors connected properly

before applying the power.

Name

Usage

L

Phase

Gnd

Ground

N

Neutral

Table 5 : Main power connection details

4.4 Detector Connections

Each PPS panel zone module can manage up to 32 PPS series detectors via RS485 serial conneciton.

V+, V-(GND), A and B ports must be connected via using four-wire cable. Detector connections supply

12-24VDC power to detector and read the output signal of detector from A and B ports. Thus

connections should be made correctly with extra care to do not mix ports and not cause any damage

on the detectors. Detector power connection should be done with 1.5mm2cross section cable. The

total distance between control panel and detectors should not exceed 800m. Detector connections

should be made with 4 core cable wire that 2 for power and 2 for RS485 and pin definitions are as

follows:

V+

output

+24VDC (Only for panel and detectors, do not use for any other device)

A

input

RS485 port A

B

input

RS485 port B

V-

Output

-VDC (GND)

Table 6 : Connection pin definitions

The wiring for detectors utilized with RS485 board should be done by using connection cable EIA

RS485 2 core wires with section 0.22 / 0.35 mm2 and shielded. Nominal capacity between the wires

< 50pF/m and nominal impedance 120 Ohms.

The V+, V- ports and A,B ports are located on same socket in PPS panel zone module. These ports are

formed together on Prosense PPS series detectors on detector main board. The connections should

be done with care to do not mix power and RS485 ports. All detectors will be connected through one

cable via hopping one detector to another till the last detector on the line.

12

PRS-UM-PPSM-EN-Rev.03-10.04.2020

The connection schema given in Diagram 11:

Diagram 11: Panel to detector connections

There should be one master device and up to 32 slave devices in RS485 communication. The master

is DP32 control panel and detectors will be the slave devices:

Diagram 12: RS485 communication

Each detector connected to same PPS panel should have unique address. Detectors having same

address would not be recognised by control panel. PPS panel can communicate up to 32 detectors. In

case less then 32 detectors connected, control panel would not show non-existent detectors. Unused

detectors should be deactivated on channel settings menu steps.

The last detector at the RS485 serial line should have the end of line resistor to enable the total

communication line. Otherwise control panel may not communicate to all, some or none of the

detectors. The end of line resistor controlled by end of line pins located on Prosense PPS series

detectors and can be enabled via putting the jumper on end of line pins. Details are given in section

4.5.

Detector 1

Detector 2

V-

B

A

V+

PPS

Panel

Max 32

Detector

V+ A B V-

V+ A B V-

V-

B

A

V+

13

PRS-UM-PPSM-EN-Rev.03-10.04.2020

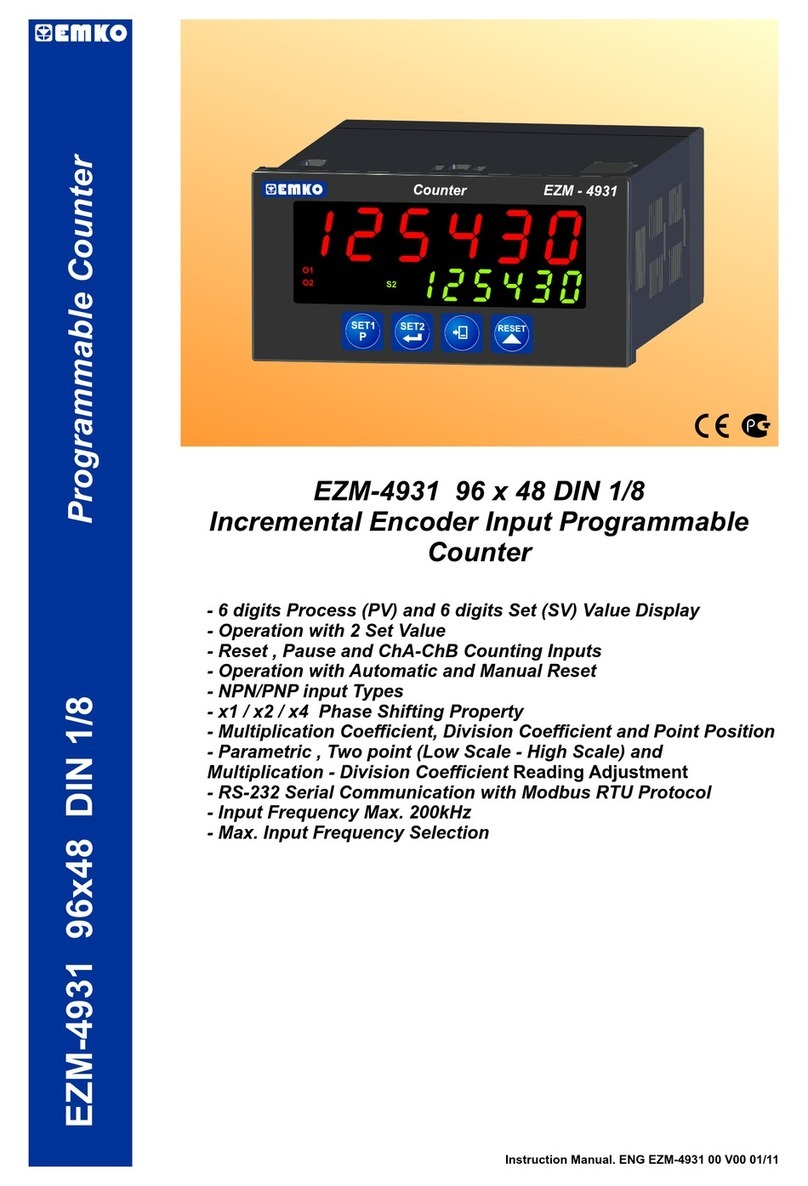

4.5 PPS Series Detectors Connections

Prosense PPS series detectors has onboard RS485 Modbus serial communication module. The

board has 4 ports thus the detector connection should be made by 4 wire that 2 for power and 2

for RS485. The total lenght of the connection line should not exceed 1000 meters.

Diagram 13: PPS series detector board

The wiring for detectors utilized with RS485 board should be done by using connection cable EIA

RS485 2 core wires with section 0.22 / 0.35 mm2 and shielded. Nominal capacity between the wires

< 50pF/m and nominal impedance 120 Ohms.

Detectors will be wired in daisy chain (bus) mode. We recommend not to use star mode connection

due to negative impact of interference. Each detector should have uniqe address number in the

chain. The detectors would not be recognised by control panel if same address given to them. The

address of detector can be adjusted via using DIP-Switch set on the board:

DIP Switch to set detector address

V+ A BV-

Detector connection pins

14

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Diagram 14: RS485 Modbus serial communication address and switch position

The last detector in the chain should have 120 Ohms RS485 termination resistor. The resistor is

already implemented on the board by default but not activated. User should activate the

termination resistor via using the termination pin once the installation completed:

Diagram 15: RS485 Modbus serial communication module end of line jumper

Important : Only the last detector on the serial bus should have end of line pin.

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1 2 3 4 5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

29

25

26

27

30

31

32

28

End of Line jumper enabled

15

PRS-UM-PPSM-EN-Rev.03-10.04.2020

4.5 Relay Outputs

PPS panel has two relays which are fault and alarm on main power module.

Fault: This relay will be activated when any of the zone modules in the system raise fault status.

Alarm: This relay will be activated when any of the zone modules in the system will exceed the

programmed alarm level.

Each zone module has three relays which are Alarm, Fan1 and Fan2. Their activation mechanism as

follows:

Alarm: This relay will be activated when the defined gaz level threshold exceed depending of the

activity type defined for related zone.

Fan 1: This relay will be activated after 30 seconds when any of the detectors will exceed the

programmed F1 level in related zone. This relay will be deactivated after 240 seconds when the

status returned to normal.

Fan 2: This relay will be activated after 30 seconds when any of the detectors will exceed the

programmed F2 level in related zone. This relay will be deactivated afte 240 seconds when the status

returned to normal.

The relays are configured as NO (Normally Open) by default at factory. The relay configurations

cannot be adjusted to NC (Normally Closed)

Important: Relays should not be connected to high current or 220V AC loads. The relay outputs

should be used as control signal and external relays should be used to drive such devices as relay on

main board cannot handle high load.

5. FIRST RUN

After power applied to PPS panel it will start illuminating the On LED. The LCD display shpw

“Sacnning Detector” at same time while panel tries to initialize the detectors connected to it:

Scanning will take at least 2 minutes. After two minutes each zone module installed on teh PPS panel

will report the number of detectors they recognized:

If all detectors working fine then LCD display will show the status of detectors: at first line the

number of detectors and average gas measurement level, at the bottom the detector address which

is measuring the highest gas level and the measurement level.

Scanning

Detector

Detector

01

CO:000P

D21:000P

16

PRS-UM-PPSM-EN-Rev.03-10.04.2020

In case an error the fault LED will be activated together with fault relay at same time. Fault details

can be seen via pressing up and down buttons. The fault codes and details given in section XXX.

5.1 Automatic Test

Prosense PPS Manager simultaneously monitor all detectors connected to it. The FAULT relay and

LED will be activated in case any problem. Alarm and fault status can be monitored on the screen.

5.2 LED Test

Prosense PPS Manager has special function to test LEDs on front panel at any time. Press T button to

initiate test operation. Panel will activate all LEDs for moment and turn off all of them except on LED

as it is always blinking.

6. PROGRAMMING

The panel is already programmed and ready for using when shipped. User should adjust the gas type,

alarm settings for each detector. Each detector should be defined independently. These adjustments

can be done via using the keys near by LCD screen. The menu content includes below items:

Menu Item

Function

Set Ext1

Set fan1 relay alarm level

Set Ext2

Set fan2 relay alarm level

Set Alrm

Set alarm level

Actv Typ

Set alarm raising method

Gas Type

Set gas type of the detector

Language

Set Language

Scan Det

Start scanning detectors

Show Det

Show each detector status

Table 7: Menu structer

6.1 Set FAN1 Relay Level:

To set alarm level for FAN1 press menu button to see menu items. The first item on menu is Set Ext1

to set level for FAN1:

Set Ext1

17

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Press menu button again to start adjustment. It will ask the gas type :

Gas type can be changed via pressing up and down arrow buttons. There are three gas type

supported by PPS Manager which are CO, NO2, LPG. Once decided press Menu button to continue. It

will show the current level:

Alarm level can be increased or decreased via pressing up and down arrow buttons. For CO gas levels

will increase or decrease by steps 10PPM while for NO2 1PPM and for LPG 1LEL steps. Once the level

set use T button to return back to main menu or press again to exit from menu. FAN1 level cannot be

adjusted higher than the FAN2 relay level or Alarm relay alarm level. Thus user should adjust first the

FAN2 level or Alarm level.

6.2 Set FAN2 Relay Level:

To set alarm level for FAN2 press menu button to see menu items. The second item on menu is “Set

Ext2 “ to set level for FAN2. Thus up and down arrow buttons should be used to reach to “Set Ext2 “

menu item:

Press menu button again to start adjustment. It will ask the gas type :

Gas type can be changed via pressing up and down arrow buttons. There are three gas type

supported by PPS Manager which are CO, NO2, LPG. Once decided press Menu button to continue. It

will show the current level:

Sel Gas

CO

Ext1 Lv:

040

Set Ext2

Sel Gas

CO

Ext2 Lv:

100

18

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Alarm level can be increased or decreased via pressing up and down arrow buttons. For CO gas levels

will increase or decrease by steps 10PPM while for NO2 1PPM and for LPG 1LEL steps. Once the level

set use T button to return back to main menu or press again to exit from menu. FAN2 level cannot be

adjuster higher than the Alarm relay level. Thus user should adjust first the Alarm level.

6.3 Set Alarm Relay Level:

To set alarm level for FAN2 press menu button to see menu items. The third item on menu is “Set

Alrm “ to set level for Alarm relay. Change the menu item via up and down arrow buttons to reach

“Set Alrm “ menu item:

Press menu button again to start adjustment. It will ask the gas type :

Gas type can be changed via pressing up and down arrow buttons. There are three gas type

supported by PPS Manager which are CO, NO2, LPG. Once decided press Menu button to continue. It

will show the current level:

Alarm level can be increased or decreased via pressing up and down arrow buttons. For CO gas levels

will increase or decrease by steps 10PPM while for NO2 1PPM and for LPG 1LEL steps. Once the level

set use T button to return back to main menu or press again to exit from menu.

6.4 Set Alarm Activation Type:

PPS Manager can activate relay in two mode. Either it can use each detectors gas measurement level

independently and activate alarms when any one of the detectors reached the adjusted level or it

can collect each gas detectors gas measurement level and calculate average gas measurement level

at the time of the reading to activate alarms. To set alarm activation type press menu button to see

menu items. The fifth item on menu is “Actv Typ“ to adjust alarm activation method. Change the

menu item via up and down arrow buttons to reach “Actv Typ“ menu item:

Set Alrm

Sel Gas

CO

Alrm Lv:

150

Actv Typ

19

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Press menu button again to start adjustment. It will show default method :

Activation method can be changed via up and down arrow buttons:

Once decided use T button to return back to main menu or press again to exit from menu.

6.5 Set Gas Type:

PPS Manager can work together simultaneously three different gas type which are CO, NO2 and LPG.

Althugh PPS Manager can automatically recognize the connected detectors, it asks user to confirm

gas type. The reason is to make sure whether user connected the detector by mistake or real usage

as different gas types have different behaviours. To set gas type of the detector press menu button.

The sixth item on menu is “Gas Type“ to set gas type of the detector. Change the menu item via up

and down arrow buttons to reach “Gas Type“ menu item:

Press menu button again to start adjustment. It will show each gas type by order:

If the gas type is incorrect change the answer from “Yes” to No” via using up and down arrow

buttons:

Alm Typ

Avrg Val

Alm Typ

Max Val

Gas Type

CO

Yes

CO

No

20

PRS-UM-PPSM-EN-Rev.03-10.04.2020

Once confirmed use T button to return back to main menu. If you the gas type is not the gas shown

on the menu, change the gas type via pressing to menu button.

Then press again to see other option:

The fault LED will be activated in case user given “Yes” answer for two different gas type as detectors

in this series can measure only one type of gas. Once gas type set use T button to return back to main

menu or press again to exit from menu.

6.6 Set Language:

PPS Manager currently supports two languages which are English and Turkish. User can change the

language via seventh menu item “Language”. Press menu button and use up and down arrow

buttons to reach “Language“ menu item:

Press menu button again to start adjustment. It will show current language on screen:

To change Language use up and down arrow buttons:

Once confirmed use T button to return back to main menu.

NO2

No

LPG

No

Language

English

Language

Language

Turkce

Table of contents

Other Prosense Control Panel manuals