3

PRS-UM-DP-X-EN-Rev1.0-17.11.2021

Contents

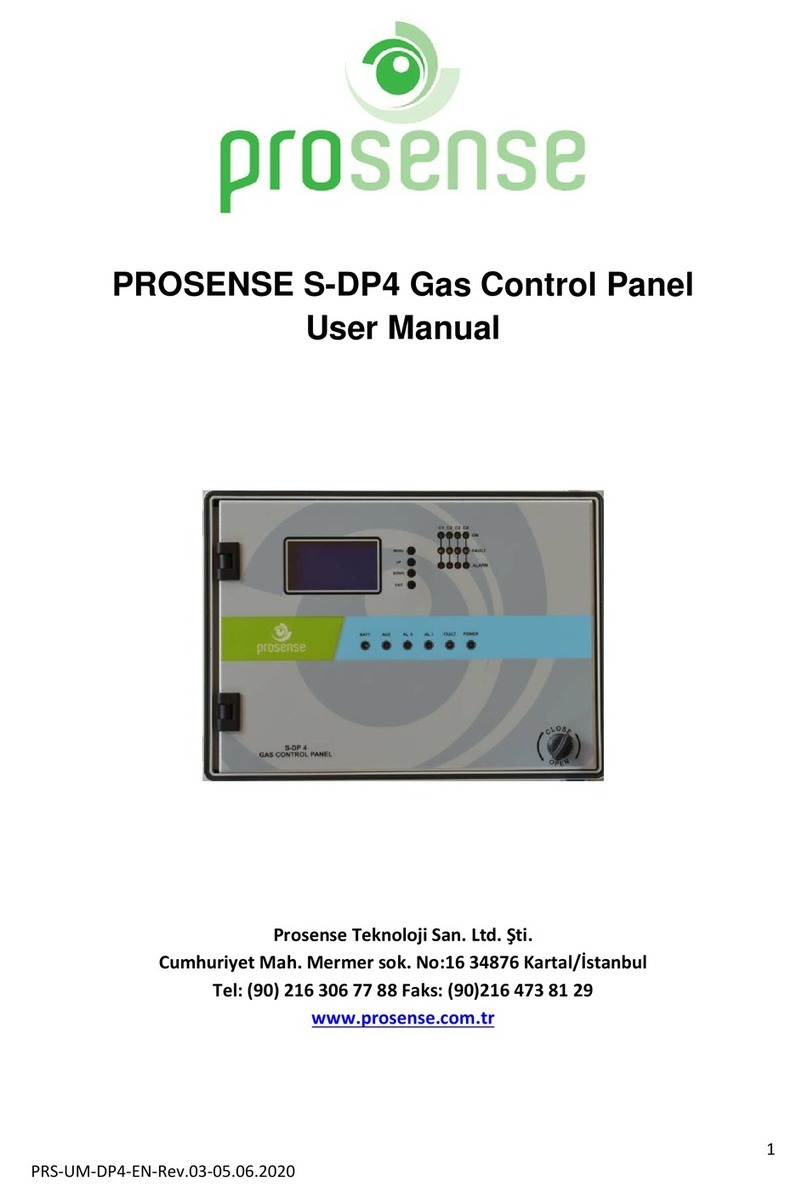

1 Introduction..................................................................................................................................... 5

2 Technical Specifications................................................................................................................... 6

3 Panel Dimensions ............................................................................................................................ 7

4 Installation....................................................................................................................................... 8

5 Connections................................................................................................................................... 11

5.1 MODBUS and Siren Outputs:................................................................................................. 12

5.2 Analogue Channel Inputs: ..................................................................................................... 13

5.3 Relay Outputs ........................................................................................................................ 14

5.4 MODBUS Channel Inputs:...................................................................................................... 16

5.5 Power Inputs: ........................................................................................................................ 18

5.5.1 Main Power Connection................................................................................................ 19

5.5.2 Backup Battery Connection........................................................................................... 19

5.6 Fuses...................................................................................................................................... 20

5.7 Analogue Input Module......................................................................................................... 20

6 Indicators....................................................................................................................................... 22

6.1 Display: .................................................................................................................................. 23

6.2 Special States......................................................................................................................... 25

6.3 Warm-up Status: ................................................................................................................... 25

6.4 Fault Status:........................................................................................................................... 26

6.5 Overrange Status:.................................................................................................................. 26

6.6 Alarm Status: ......................................................................................................................... 27

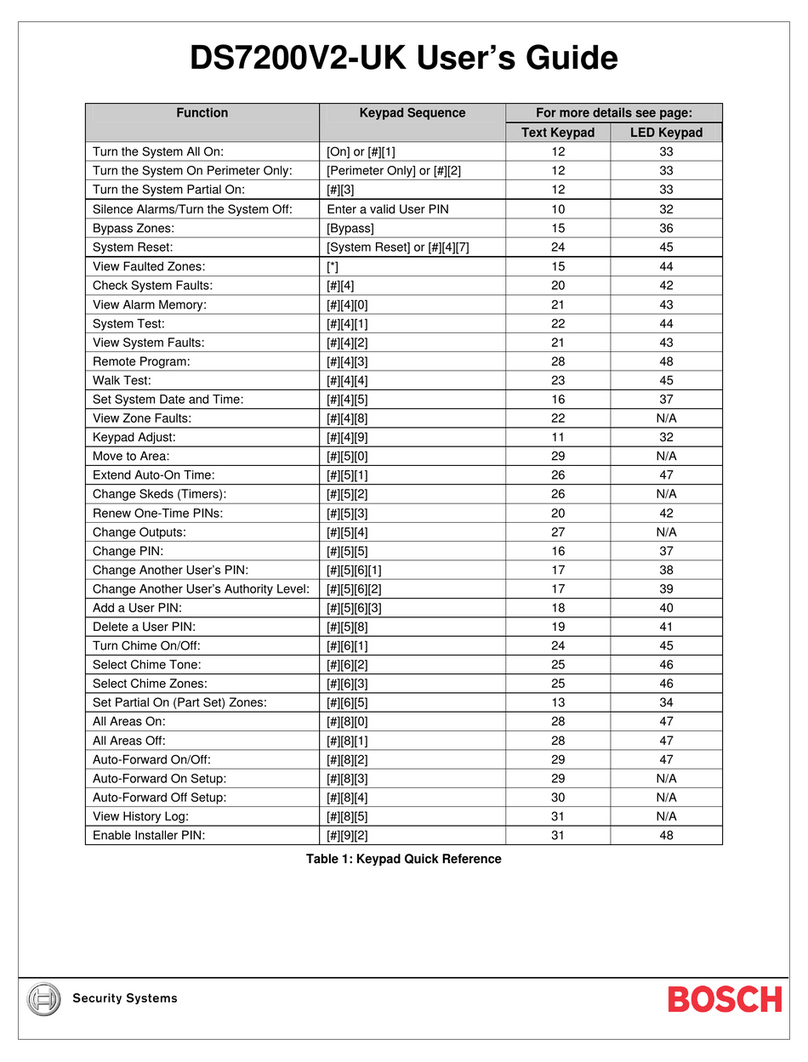

7 Programming................................................................................................................................. 28

7.1 Panel Configuration:.............................................................................................................. 29

7.1.1 Setting Up Network Parameters: .................................................................................. 29

7.1.2 Setting Up Passwords:................................................................................................... 30

7.1.3 Setting Up Date and Time: ............................................................................................ 31

7.1.4 Setting Up Language:..................................................................................................... 31

7.1.5 Setting Up Battery: ........................................................................................................ 32

7.2 Detector Settings:.................................................................................................................. 32

7.2.1 Analogue Detector Configuration: ................................................................................ 32

7.2.2 Analogue Detector Alarm Settings:............................................................................... 35

7.2.3 4-20mA Settings: ........................................................................................................... 36

7.2.4 MODBUS Detector Configuration:................................................................................. 37

7.2.5 MODBUS Detector Alarm Settings: ............................................................................... 38

7.2.6 MODBUS Detector Calibration: ..................................................................................... 39

7.3 Relay Settings: ....................................................................................................................... 41

7.4 Test Options: ......................................................................................................................... 42

7.5 Information: .......................................................................................................................... 43

7.6 Resetting Alarms: .................................................................................................................. 45