Prosense AUTOMATIONDIRECT DPTW Series User manual

InstallatIon and

MaIntenance InstructIons

for dPtW serIes

dIfferentIal Pressure

transMItter

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

2

In this Chapter...

Caution...........................................................................................................................4

1. Preface .......................................................................................................................5

2. Overview....................................................................................................................5

3. Features......................................................................................................................5

4. Specifications.............................................................................................................6

Specifications Cont.......................................................................................................7

5. Mounting ...................................................................................................................8

5.1 General ..................................................................................................................8

5.2 Mounting Orientation ............................................................................................8

5.3 Installing Pressure Port Manifold ............................................................................8

6. Piping.........................................................................................................................9

7. Wiring ......................................................................................................................10

7.1 Cable/Wire Specifications .....................................................................................10

7.2 Wiring Instructions ...............................................................................................10

9. Mode Changes.........................................................................................................14

10. Power-On Message................................................................................................14

11. Measurement Mode ..............................................................................................15

11.1 Filter (Damping).................................................................................................15

11.2 Differential Pressure Display Mode (Re-scaling in “inH20” units)........................15

11.3 Linear Display Mode (Re-scaling in arbitrary user defined units).........................16

11.4 Square Root Display Mode.................................................................................18

11.5 Out of Range Display .........................................................................................23

12. Zero Adjustment Mode .........................................................................................23

13. Key Lock.................................................................................................................24

14. Setting Mode.........................................................................................................24

14.1 Setting Items for Differential Pressure Display Mode ..........................................24

14.2 Setting Items for Linear Display Mode................................................................26

14.3 Setting Items for Square Root Display (Flow Measurement) ...............................27

14.4 Setting Procedure (Setting Examples from 14.1, 14.2).......................................28

14.5 Loop Check........................................................................................................30

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

3

15. Dimension Drawings .............................................................................................31

16. Maintenance and Warranty ..................................................................................32

17. Advanced Water Flow Rate and Volume Application Example............................33

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

4

Caution

Warning! Read Before Installation

General

A failure resulting in injury or damage may be caused by excessive overpressure, excessive

vibration or pressure pulsation, excessive instrument temperature, corrosion of the pressure

containing parts, or other misuse. Contact AutomationDirect.com technical support before

installing if there are any questions or concerns.

Overpressure

Pressure spikes in excess of the rated overpressure capability of the transmitter may cause

irreversible electrical and/or mechanical damage to the pressure measuring and containing

elements.

Water/Fluid hammer and surges can destroy any pressure transmitter and must always be

avoided. A pressure snubber should be installed to eliminate the damaging hammer effects.

Fluid hammer occurs when a liquid flow is suddenly stopped, as with quick closing solenoid

valves. Surges occur when flow is suddenly begun, as when a pump is turned on at full power

or a valve is quickly opened.

Liquid surges are particularly damaging to pressure transmitters if the pipe is originally empty.

To avoid damaging surges, fluid lines should remain full (if possible), pumps should be brought

up to power slowly, and valves opened slowly. To avoid damage from both fluid hammer and

surges, a surge chamber should be installed.

Symptoms of fluid hammer and surge’s damaging effects:

• Pressure transmitter exhibits an output at zero pressure (large zero offset).

• Pressure transmitter output remains constant regardless of pressure

• In severe cases, there will be no output.

Freezing: Prohibit freezing of media in pressure port. Unit should be drained to prevent possible

overpressure damage from frozen media.

Static Electrical Charges

Any electrical device may be susceptible to damage when exposed to static electrical charges. To

avoid damage to the transmitter observe the following:

• Ground the body of the transmitter BEFORE making any electrical connections.

• When disconnecting, remove the ground LAST!

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

5

1. Preface

The personnel for installation, commissioning, diagnostics and maintenance must fulfill the

following requirements:

• Trained, qualified specialists must have a relevant qualification for this specific function

and task

• Are authorized by the plant owner/operator

• Are familiar with federal/national regulations

• Before beginning work, the specialist staff must have read and understood these

instructions

2. Overview

The ProSense DPTW differential pressure transmitter series is precision engineered for accurate

differential or gauge pressure measurement. The wet-wet design uses a silicon based variable

capacitance sensor with stainless steel media isolation diaphragms and silicone pressure

transmission fluid making it compatible with a wide variety of liquids, gases, and steam applied

to both pressure sensing ports. The DPTW series is ideal for industrial, commercial, and OEM

process measurement applications including differential, positive, or negative pressures;

hydrostatic liquid level in pressurized or open tanks; and flow measurement using primary

differential pressure flow elements such as an annular pitot tube, orifice plate or venturi tube.

The DPTW series is available in pressure measurement ranges from 4 inches water column up to

400 inches water column with static (line) proof pressure of 300 psig and can easily be rescaled

to a different linear pressure range and units of measure using display pushbuttons. An integral

square root function also allows for the display and output of flow in instantaneous flow rate units

of measure such as gallons/minute or display of integrated flow volume in units such as gallons.

The integral pressure port manifold has 1/4-inch NPT female process pressure connections and

includes a built-in equalizing valve used to open both ports to the line pressure during installation

to prevent sensor damage or calibration shift due to overpressure. The DPTW series is powered

with nominal 24VDC power and provides a two-wire, 4-20mA output signal proportional to the

measured pressure. The very compact design of the DPTW series is up to 8-times smaller than

conventional style DP transmitters and features a rugged NEMA 4X (IP65) rated aluminum die

cast housing and rotatable 6-digit LCD display with bright LED backlight.

3. Features

• Media Compatibility: Wetted materials consist of 316 stainless steel, alumina ceramic

and viton to handle a wide range of media with the ability to offer ranges as low as 4˝

W.C. F.S. (URL).

• Linear Scaling Function: The linear (scaling) function allows the user to adjust zero

and span values providing a corresponding 4-20mA output signal.

• Flow Measurement/Square Root Extraction Function: Momentary flow rate and

integrated volume can be displayed and analog signal can be output.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

6

• Digital Filter Function: User adjustable damping of the output signal by means of

internally calculated moving average to provide a stable output signal in applications

where the user wants to reduce the pulsating of the display and / or output signal.

• LED Back Light: To supplement the LCD display when conditions require (dark area,

night etc.).

• Loop Check Function: Allows the user to output an analog signal corresponding to

differential pressure without applying pressure, simplifying system maintenance and

troubleshooting.

• Zero and Span Adjustment: The adjustment of the Zero (4mA) and Span (20mA)

reading via internal push buttons.

• Key Lock Function: Prevents inadvertent overwriting of setting values. Can not be

reset by restoring power when activated.

• IP65 / NEMA 4X Environmental Rating: Enclosure environmental rating suitable

for indoor and outdoor installation, depending upon operating temperature range.*

• CE Compliant

*Display not to be mounted in direct sunlight.

4. Specifications

* Upper Range Limit (URL)

** For steam or other higher temperature processes, ensure that the temperature at the DPTW process connections do not

exceed the Medium Temperature Limits. For steam use longer sensing lines and/or a siphon (pigtail) and fill with water

to lower the medium temperature to acceptable limits.

DPTW Series Specifications

Performance Specifications

Reference Temperature 73°F (23°C)

Accuracy ± 0.50% of span (URL*)

Includes the effects of linearity, hysteresis, and repeatability

Display Accuracy ± 0.5% of span (URL) + 1 digit

Stability ± 0.25% of span (URL)/year

Output Resolution 0.1% of span (URL)

Temperature Effects Temperature Effects: (–10°C to 60°C) ± 0.03% FS/C°

Memory Permanently stored in EEPROM nonvolatile memory

Environmental Specifications

Temperature Limits

Storage: 5°F to 150°F (–15°C to 65°C)

Operating: 14°F to 140°F (–10°C to 60°C)

Medium: 14°F to 140°F (–10°C to 60°C)**

Compensated: 14°F to 140°F (–10°C to 60°C)

Functional Specifications

Rangeablility/Adjustment

Zero –10% to 110% Span

Span –10% to 110% Span

(Accuracy and output resolution based upon full scale (URL) value)

Unit of Measure inH2O (IWC) or User defined

Static (Line) Pressure

Pressure Range: 4 inH2O to 400 inH2O

Proof: 300 psi

Burst: 800 psi

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

7

Specifications Cont.

DPTW Series Specifications

Performance Specifications Continued

Single Side (Differential)

Pressure Range: ≤8 inH2O

Proof: 30 psid

Burst: 130 psid

Pressure Range: ≥20 inH2O

Proof: 100 psid

Burst: 130 psid

Static (Line) Pressure Effects

Pressure Range: Effect:

≥20 inH2O ± 0.3% Range/100 psi (URL)

8 inH2O ± 0.7%Range/100 psi (URL)

4 inH2O ± 1.5% Range/100 psi (URL)

Response Time 100ms (when Filter Function set to 0)

Filter Function 0, 2, 4, 8, or 16 seconds

Vibration 5g’s 150Hz

Shock Effect 10g’s 16ms

Electrical Specifications

Output Signal 4-20 mA (2 Wire)

Load Impedance 545Ω@ 24VDC (refer to Load Limitations graph)

Supply Voltage 12-32 Vdc

Insulation Resistance 50Vdc (>100 MΩ)

EMC Compliance

EMC Directive 2014/30/EU

EN 61326-1:2013

EN 61326-2-3:2013

(EMI Class A/EMS Table 2)

Physical Specifications

Environmental Rating IP65 / NEMA 4X

Mounting Mounting bracket included

Process Connections Manifold with 1/4 NPT Female ports and equalizing valve

Display 6-digit LCD with LED backlight, 10mm character height

Display Update 500ms

Electrical Connection 1/2 NPT Female Preinstalled Cable Gland (Cable diameters 0.35” to 0.47”)

Terminal block: 14-22 AWG stranded or solid wire

Wetted Material

Diaphram 316 SS, Viton® & Alumina Ceramic

Process Connection 316 SS

Media Compatibility Fluids and gases compatible with 316 SS, Viton® and Alumina Ceramic

Non-Wetted Material

Enclosure Aluminum, epoxy coated

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

8

5. Mounting

5.1 General

The DPTW was designed to be mounted using the bracket supplied. Pressure connections

are made via the (2) 1⁄4” NPT female pressure ports. Although the display can be rotated in

90 degree increments by removing the display cover it is preferable to orientate the electrical

termination downward, particularly in applications where protection from the environment is

required.

5.2 Mounting Orientation

It is preferable to orientate the unit with the pressure ports either downward or upward. If

mounting with pressure ports to the side an “orientation effect” will be seen at zero pressure

as the pressure generated by the silicone oil fill will appear as a zero offset. If mounting in this

manner this effect may be taken out by resetting zero (refer to Section 12) in final mounting

orientation.

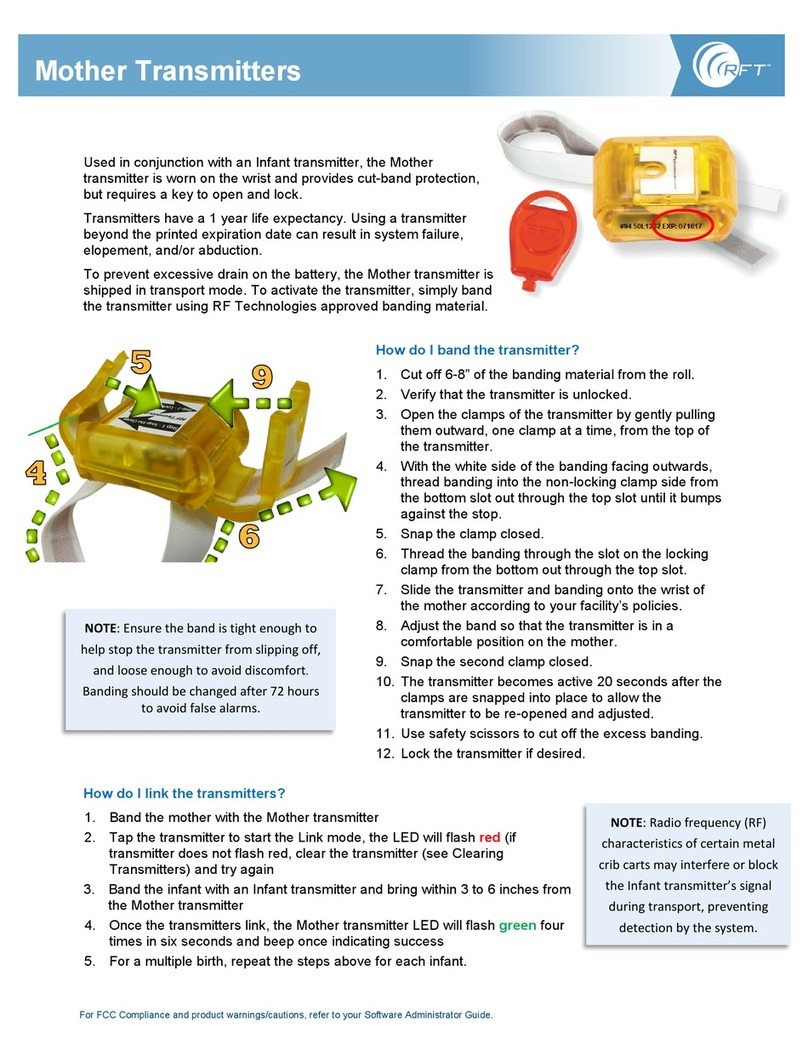

5.3 Installing Pressure Port Manifold

(1) Mounting 25.4mm Manifold (1⁄4˝ NPT female ports)

Manifold is secured using the (4) socket head bolts (M4x40) and appropriate allen

wrench which is supplied. Check for dust and dirt on the O-ring and seal area, clean if

necessary, before installing to ensure proper connection. The direction of the manifold

is not important, determine best position by ability to operate the equalizing valve.The

equalizing valve is used to open both ports to the line pressure at time of installation.

Once installed and the system has been pressurized the valve needs to be closed to iso-

late the low and high pressure sides of the device.

Tighten the equalizing valve with a torque of 0.75 ft-lbs ±5%. When loosening the

valve do not back off by more than three turns from the closed position.

Bleed port set screws should not be fully removed as sealing components can be

dislodged from housing.

(2) Panel Mounting

Similar to (1) above except that the DPTW is put between the manifold and the panel

mounting bracket then the (4) socket head bolts (M4x40) are installed.

(2) 1/4˝NPTF

1.4 (35)

.55 (14)

.83 (21)

1.8 (45.4)

1.0 (25.4) Hex .83 (21)

.33 (8.5)

Equalizing

valve

• 1.0 in. (25.4mm) mounting manifold

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

9

Low pressure

inlet (L)

Panel mounting

bracket

High pressure

inlet (H)

Equalizing

valve

M4 x 40

O-rings

6. Piping

Note: High (H) and Low (L) pressure sides of the device are marked on the yellow label

affixed to the housing of the unit.

Install the high pressure side of the applied differential pressure in the pressure inlet of the

high pressure side (H) and the low pressure side in the pressure inlet of the low pressure side

(L).

(Refer to the Dimension Drawings Section 15.)

After the piping is completed check for leaks.

Piping of 1.0 in (25.4mm) Manifold (1⁄4˝ NPT female ports)

Use caution when installing to keep metal chips and other debris from entering pressure

transmitter. In addition, when sealing tape is used, do not apply to last two threads at the end

of the fitting

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

10

Note:

• When transporting and / or mounting do not apply excessive shock or use device as a

step.

• The piping should be of proper length so as not to apply load to the connection point

on the transmitter.

• CAUTION! At the time of mounting or when bleeding air from the device be

sure to open the equalizing valve with a flathead screwdriver so that excessive

pressure (more than the allowable maximum differential pressure) is not applied

to the differential pressure sensor. Maximum torque to apply to equalizer valve

is 0.75 ft-lbs ±5%. Bleed port set screws should not be fully removed as sealing

components can be dislodged from housing.

7. Wiring

7.1 Cable/Wire Specifications

Use appropriate cable described below which is suitable for power supply requirements and

ground to housing.

Wiring Terminals

Terminal Strip

Cable

Requirements

SMKDSP1.5/2-5.08 Phoenix Contact

• Two core shielded cable

• Cable outer diameter: 0.35˝to 0.47˝9-12mm

(Required for correct installation with Cable

Gland)

• Wire Gauge: 14-22 AWG (multi-strand or solid)

7.2 Wiring Instructions

• To reduce potential for noise do not run pressure transmitter cable /wires alongside

(same conduit as) high voltage (line power) lines. For optimum results use dedicated

conduit for DPTW cable / wires.

• Must use cable within previously noted diameters to maintain environmental ratings

when using the cable gland.

• When connecting shield / drain wire, only connect one end which should be at the

receiver ground.

• Wiring stripping instructions, remove cable jacket 2-3˝ and strip wires 0.25˝. Shield /

drain wire should not be exposed at the pressure transmitter termination.

• Remove cover and carefully remove the display to access the terminal strip, take care

not to mishandle the display and associated electronics.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

11

• Turn display over to

expose terminal strip,

make positive and

negative connections,

insert wire depth is

equal to recommended

strip length (0.25˝).

+

-

Terminal box

Display (board)

Shield

Power source

+-

Receiver

Transmission cable

CASE

DISPLAY

COVER

Inside sensor Line

LCD holder

Notch

Transmission cable

(Twist)

Cable Jacket

Display

W

ire terminals

Wire Turn with a screwdriver

LCD clips (4)

Display board

Power supply

terminal block

Cable Gland

12-32 VDC

4-20 mA

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

12

• After completing connections locate retaining clips in the appropriate notches and

carefully place into the housing. Be sure that internal sensor transmission wire does not

cross the power supply lines just installed.

• If using the Cable Gland be sure to properly tighten sealing grommet before applying

any tension on the cable, the cable gland provides strain relief and environmental sealing.

• Tighten DPTW cover to maintain environmental rating.

• Connect to power source and receiver and power on to confirm correct wiring (see

Section 10 for more detail).

• Power Supply Requirements: Although the 4-20mA signal can travel over long distances

one of the most common problems is inadequate power at the pressure transmitter due

to the voltage drop across the loop. Be sure to review table below to determine that

12-32V is getting to the pressure transmitter.

Vmin= 12V+ [.022A*(RL)]

(Includes a 10% safety factor)

RL =R

S + RW

RL =Loop Resistance (ohms)

RS =Sense Resistance (ohms)

RW=Wire Resistance (ohms)

Load Limitations 4–20mA Output

1,000

750

500

250

0

3

02

2010

909

3012 24

545

LOOP SUPPLY VOLTAGE

OPERATING

REGION

0

Loop Resistance ( )

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

13

CH+ CH–

inH

2

O

M

Differential pressure

unit monitor

Test Terminals

MODE key

DOWN key

UP key

Scaling - Arbitrary

unit monitor

No function

Measured data

display

Total flow volume

display (X100)

Total flow volume

display (X1000)

Linear scaling mode

Total flow volume

display (X10)

Total flow volume

display (X1)

DPTW

DESIGNATION FUNCTION

Measured data

display

Differential

pressure unit

monitor

Scaling;

arbitrary unit

monitor

MODE key

(M)

DOWN key

,

UP key

.

Differential pressure, linear scaling

value are displayed.

When this unit monitor is ON, the

differential pressure (inH2O)is indi-

cated on the measured data display.

When this unit monitor is ON, the

scaling value of an arbitrary unit

(linear scaling), is indicated on the

measured data display.

This key is used to switch the setting

mode and the measurement mode

and to change the setting item.

This key is used to change (de-

crease)and select the set value .

This key is used to change (in-

crease) and select the set value

and to shift from the measure-

ment mode to the zero adjust-

ment mode.

DESIGNATION FUNCTION

Linear

scaling

mode

No None

function

Used to ad-

just zero/

span values

to 4-20mA

output signal.

to

Total flow

volume

display

Display

multiplier,

X1, X10,

X100, X1000

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

14

9. Mode Changes

• Measurement Mode (Section 11 for further detail) will be entered upon power-on.

Setting Mode (Section 14 for further detail) is entered by pressing and holding the

MODE button for more than 3 seconds. If there is no button operation for 10 minutes

in the setting mode, it will shift back to the Measurement Mode automatically.

• To go from the Measurement Mode to the Zero Adjustment Mode (Section 12 for

further detail) press and hold the UP .button for more than 3 seconds.

Power ON

Power on message

Measurement mode

Setting mode Zero adjustment

(M) key for

more than

3 seconds

() key for

more than

3 seconds

(M) key for more

than 3 seconds

or if there is no

operation for

10 minutes

Finish

10. Power-On Message

After the power is turned on, the power-on message is displayed for 6 seconds as shown below

and then the display is shifted to the measurement mode (Section 11). In addition, the analog

output during power-on message is at the zero point (4mA).

......

.

All lights

two seconds

Differential

pressure range

two seconds

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

15

11. Measurement Mode

The measurement mode includes differential pressure display mode, linear display mode, and

square root display mode (flow measurement). For the Setting items 1to 27, please refer to

the Setting Mode (Section14).

11.1 Filter (Damping)

Set the filter before setting pressure display mode or linear (scaling) display mode.

The filter is based on the moving average of the pressure data to decrease display “bounce” and

to smooth the analog output due to system pressure fluctuations at the user’s discretion.

Five selections: (0, 2, 4, 8, and 16 seconds).

If “0” is selected the filter is not applied.

See Section 14.4 for full menu.

Filter Setting ==> item

11.2 Differential Pressure Display Mode (Re-scaling in “inH20” units)

This mode is used for display and analog output of the actual differential pressure.

(1) Analog output

The analog output can be adjusted as follows; the zero point (4mA) and the span point

(20mA) can each be adjusted from –10 to 110%F.S. (URL)*.

(2) Pressure display

The pressure display has a display span between the zero point and the span point

as determined by the adjustment of zero and span (see previous paragraph) and can

display the range of –5 to 105%F.S.(URL). In addition, the decimal point position of

the pressure display is fixed for each pressure range.

Pressure Unit: inH2O

See Section 14.4 for full menu.

Output zero point and span point setting ==> Setting item ,

* This means that although the zero point is typically set at 0%F.S. and the span point is set

as 100%F.S., the zero point can be adjusted to the point where zero (4mA) is 110%F.S. and

the span point (20mA) can be adjusted to -10%F.S thus reversing the output. In addition,

through this adjustment zero and span can be adjusted accordingly for elevated tank levels.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

16

Setting example 1 : Differential pressure display mode

The setting to use the differential pressure range 0 to 20 inH2O (“W.C.) and to display the

zero point and span point of the analog output as –2 inH2O and 18 inH2O respectively is as

follows:

In the example the filter (moving average time) is set at 2 seconds, the differential pressure

display and the analog output are based on the moving average equivalent to the differential

pressure data per 100ms for the past 2 seconds (20 times).

See Section 14.4 for full menu.

D isplay and analog o utput

Ex. Differential pressure of 8 inH2O

• Differential pressure display:

• Analog output: 12(mA)

.

Differential

Pressure Analog

Display Output

(inH2O) (mA)

Output span point 18.00 ==> 20

8.00 ==> 12

Output zero points –2.000==> 4

Select the filter of “2 seconds” ==> Setting item

Select the “Differential pressure display mode - [non]” ==> Setting item

Set output zero point as “–10.0%F.S.” ==> Setting item

Set output span point as “90.0%F.S.” ==> Setting item

11.3 Linear Display Mode (Re-scaling in arbitrary user defined units)

This mode is used for display / analog output of the scaling value where the differential

pressure is linearly converted to an arbitrary user defined physical quantity.

(1) Linear display

By setting the OFFSET to the minimum differential pressure P1 and the FULL SCALE

to the maximum differential pressure P2, the linear display indicates the value on the

line between the two points (the maximum display span). The actual linear display span

depends on the setting of the zero point and span point of the analog output as shown in

(2) Analog output. It can display the range of –5 to 105%F.S. of the linear display span.

• The setting range for the minimum differential pressure P1 and the maximum

differential pressure P2 is 0 to 100%F.S. of the differential pressure range, and the

maximum differential pressure P2 is set from the value which is more than 25%F.S. of

the differential pressure range above the minimum differential pressure P1.

• The setting range for the OFFSET and FULL SCALE values is –1999 to 1999, and

the decimal point can be set arbitrarily. At this time, the arbitrary unit monitor LED

turns on.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

17

Display

Display

Full Scale

F

ull Scale

(20mA)

(4mA)

Offset

(4mA)

Offset

(20mA)

Differential

Pressure

Differentia

l

Pressure

P1

(Min.) P2

(Max.)

P1

(Min.) P2

(Max.)

See Section 14.4 for full menu.

Min. differential pressure P1and

max. differential pressure P2setting ==> Setting item ,

OFFSET & FULL SCALE setting ==> Setting item , ,

(2) Analog output

The zero point (4mA) and span point (20mA) of analog output can be set in the range of

–10 to 110%F.S. of the maximum display span (between OFFSET and FULL SCALE).

The span between the zero point and the span point in this analog output is the linear

display span.

Analog output zero point

and span point setting Setting item ,

As shown in the previous diagram, usually, the OFFSET is set as Output zero point (4mA)

and the FULL SCALE is set as Output span point (20mA), but the OFFSET can be reversed

to Output span point (20mA) and the FULL SCALE can be reversed to Output zero point

(4mA).

Setting example 2 : Linear display mode

A DPTW with a differential pressure range of 0 to 200 inH2O used as a level transmitter,

the linear display setting to display the OFFSET for minimum 20 inH2O as 0.0, the FULL

SCALE for maximum differential pressure 120 inH2O as 50.0, the unit as arbitrary unit (cm),

the zero point (4mA) analog output as 0.0, and the span point (20mA) as 50.0 is as follows:

See Section 14.4 for full menu.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

18

For display mode, select “Linear display mode - [Lin]” ==>Setting item

Set min. differential pressure P1 as “20 inH2O”==>Setting item

Set max. differential pressure P2 as “120 inH2O”==> Setting item

Set decimal point position of linear display

as “one digit” ==> Setting item

Set OFFSET of linear display as “0.0cm” ==> Setting item

Set FULL SCALE of linear display as “50.0cm” ==>Setting item

Set output zero point as “0.0%F.S.”

(0.0m) of max. display span* ==> Setting item

Set output span point as “100.0%F.S.”

(50.0m) of max. display span* ==> Setting item

*Maximum display span: OFFSET to FULL SCALE

Select the filter of “0 seconds” ==> Setting item

Linear display and analog output

Ex. Differential pressure 70 inH2O

• Linear display: 25.0(cm)

• Analog output: 12(mA)

.

Differential Linear Analog

Pressure Display Output

(inH2O) (cm) (mA)

120 ==> 50.0 ==> 20 Span Point

==> ==>

20 ==> 0.0 ==> 4 Zero Point

70 25.0 12

11.4 Square Root Display Mode

Flow Measurement

Combining sensing elements such as an orifice plate or pitot tube with the DPTW, the square

root display mode is used for the display of the momentary flow rate, integrated volume and

for analog output corresponding to the momentary flow rate.

(1) Momentary flow rate

Maximum display span from zero to the maximum momentary flow rate. The momentary

flow rate display span depends on the setting of the zero point and span point of the analog

output as shown in (2) Analog Output. It can display 0 to 105% F.S. of the momentary

flow rate display span. The scaling method can be performed only by setting the maximum

momentary flow rate and then generate differential pressure using the following square root

formula.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

19

Momentary flow rate Dx is expressed by the square root formula (a), and can be calculated

only by measuring the generated differential pressure Px (percent value over the differential

pressure range).

Dx= k Px(%)

100(%)

(a)

In addition, the coefficient k is determined by substituting the maximum momentary flow

rate Dm, which is measured from the formula (a), and the corresponding differential pressure

Pm into the formula (b).

k = Dm00

Pm

100

(b)

• The differential pressure Pm generated during the maximum momentary flow rate

can be set in the range of 25 to 100%F.S. of the differential pressure range.

• The setting range for values of the maximum momentary flow rate is 0 to 1999.

Note: The decimal point can be set arbitrarily.

Setting of max. momentary flow rate and then

generated differential pressure ==> Setting item , ,

• When the display resolution lowers and the wobbling of momentary flow rate increases

in the low flow domain of the differential pressure flow meter, the domain (below the

set value) will be forcedly indicated as zero by means of the low-cut for momentary

flow rate.

Moreover, the analog output has a fixed value of 4mA at the zero point. For setting of low-

cut, input the percent value over the maximum display span. Its range is 0 to 30%F.S. and the

decimal point position can be set up to one digit after decimal point as fixed point.

Setting of low-cut ==>Setting item

(2) Analog output

The zero point (4mA) and span point (20mA) of analog output can be set in the range of 0

to 110%F.S. of the maximum display span (0 to maximum momentary flow rate). The span

between the zero point and the span point in this analog output is the momentary flow rate

display span.

DPTW User Manual, 1st Edition

User Manual - DPTW Differential Pressure Transmitter

20

(3) Integrated volume

• The units of integrated volume include two standards: Time factor and flow rate

volume factor.

Setting of integrated volume unit ==> Setting item 20 , 21

• The number of digits of integrated volume display is a maximum of 6 figures

(999999); the display will return to 0 once the maximum reading has been met.

overflows

• The zero reset of an integrated volume is executed by pressing S key for more than 3

seconds and displaying “cLr” (clear) for 2 seconds.

• As backup in case of POWER OFF, the integrated volume value is stored in the

nonvolatile memory for every hour. After power returns, integration starts from the

integrated volume value stored in the memory.

• Integration is halted during the “FFF” display at the time of differential pressure range

OVER (Refer to paragraph 11.5 (1) )

• The indicated value which is blinking is integrated during the

“blink” display at the time of momentary flow rate display span OVER (Refer to

paragraph 11.5 (2) ).

(4) Display switching method of momentary flow rate and integrated volume

Display switching methods of momentary flow rate and integrated volume include the

automatic switching display method to display them by turns at intervals of fixed time (1 to

10 seconds) and the manual switching display method to change the display by pressing (M)

key.

Selection of display switching method

(automatic or manual) ==> Setting item 22

Setting of display switching time

for automatic ==> Setting item 23

Table of contents

Other Prosense Transmitter manuals

Popular Transmitter manuals by other brands

PNI

PNI VALENTINE V880 user manual

Ametek Drexelbrook

Ametek Drexelbrook Universal Lite 509-1 Series Installation and operating instructions

Intercoax

Intercoax Ipify ECP-2704R-4T-PKG Quick install guide

Star Meter

Star Meter KPE 9039G installation instructions

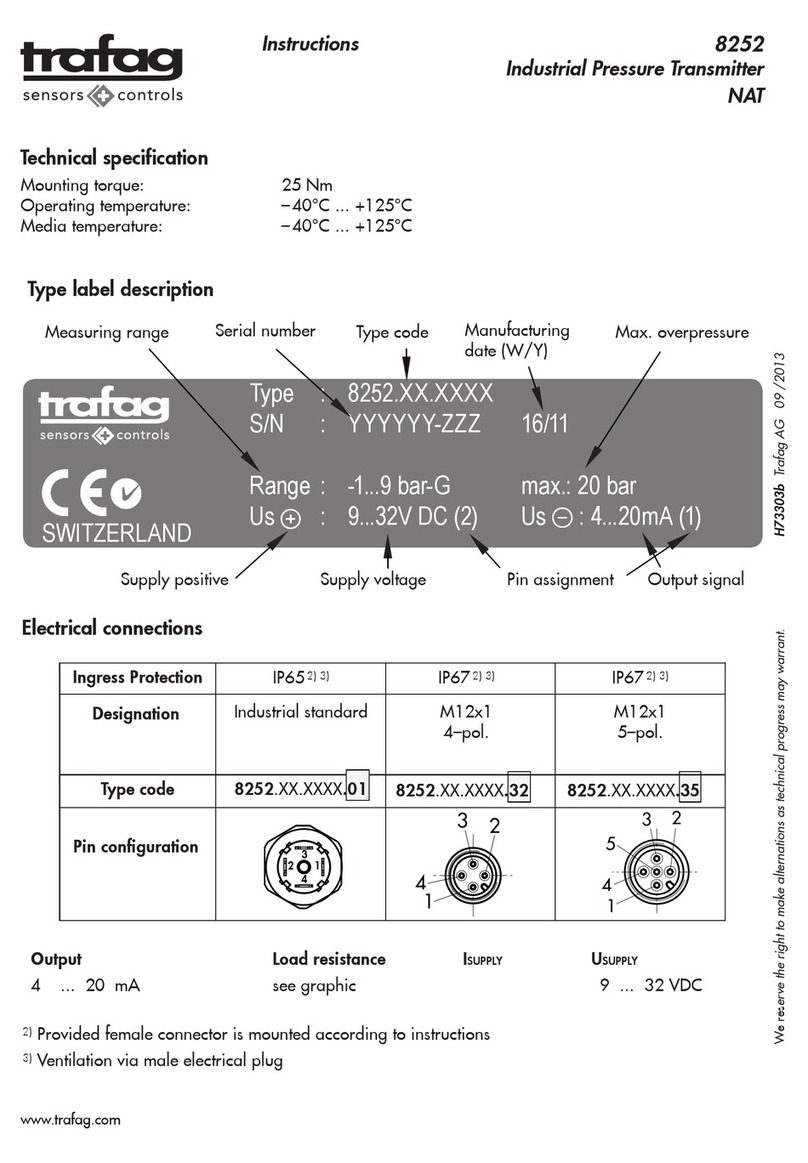

trafag

trafag 8252 instructions

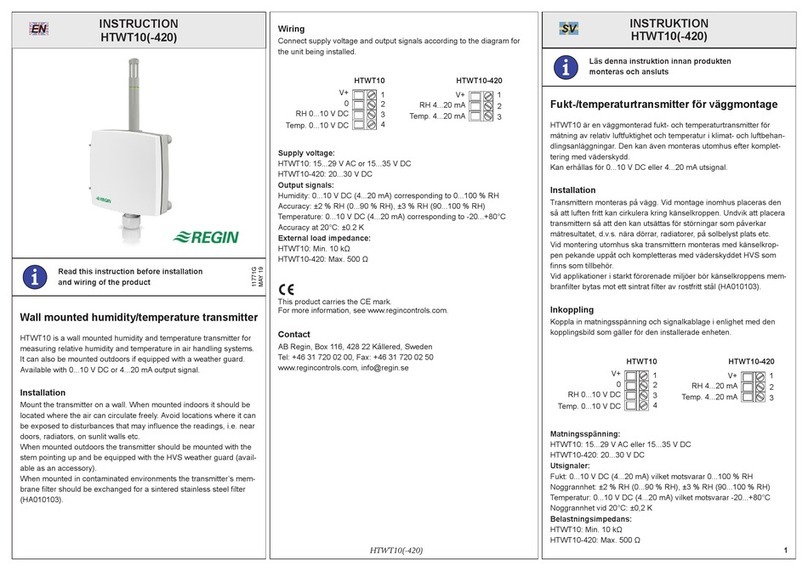

Regin

Regin HTWT10 instructions