PROSEP FILTER SYSTEMS RP65139715 Manual

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

Thank you for choosing your Reverse Osmosis Drinking Water System from

PROSEP Filter Systems Ltd. With proper care your water filtration system will

produce high quality drinking water for many years.

Read carefully and follow the instructions in this manual before proceeding with

the actual installation. Pay particular attention to all warnings, cautions and

notes. Failure to do so could result in personal injury or damage to equipment

or other property. System and installation need to comply with local laws and

regulations. If you have questions, please contact us.

CONTENTS:

PAGE: DESCRIPTION

3 Checklist

3 Recommended Tools List

4 Product Specifications

4 Installation Diagram

4 Replacement Parts

5 Fitting the Tap

5 Fitting the Saddle Tapping Valve

5 Fitting the Tank Ball Valve

5 Mounting the Drain Clamp

6 System Start Up

7 Filter Maintenance and Cartridge Change Instructions

8 Trouble Shooting

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

RP65139715 Reverse Osmosis Water storage tank with valve Tap assembly

TOOLS LIST

1 Drill

2 Drill bits 1/8”, 1/4”, 7/16”

3 1/2” and 9/16 spanner ( or adjustable)

4 Philips screwdriver

5 Utility knife

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

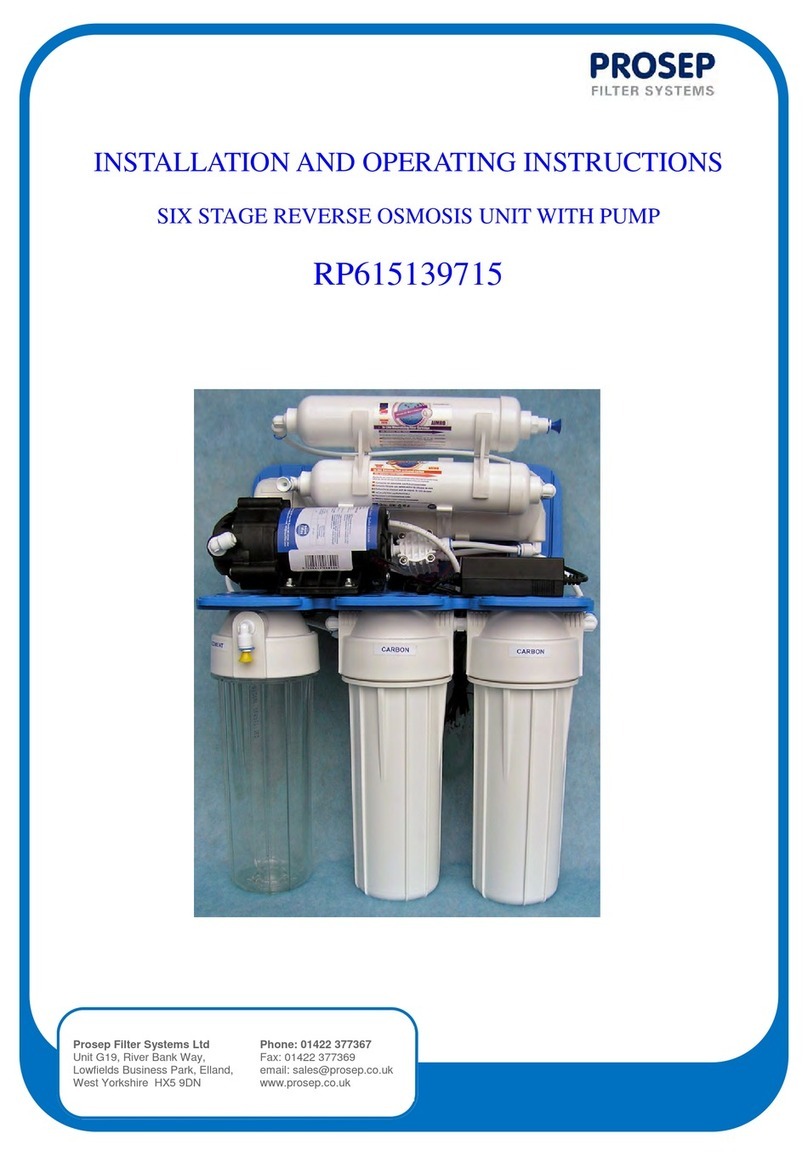

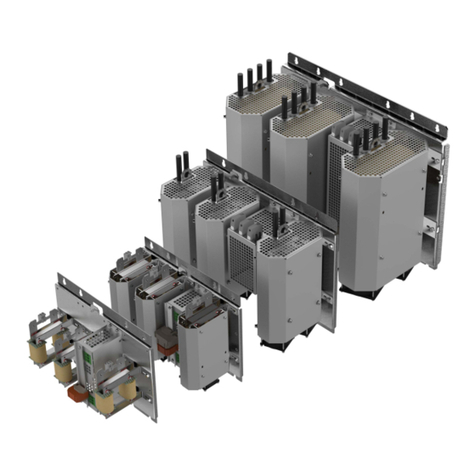

SPECIFICATION

1st Stage 5 micron sediment filter HTPP-DM-05N9.8 Change 6 monthly

2nd Stage Activated granular carbon type GAC GAC-9 Change 6 monthly

3rd Stage Carbon block cartridge type PAC PAC-9 Change 6 monthly

4th Stage Reverse Osmosis membrane. 75 GPD 1812 75GPD As needed (2 years)

5th Stage Post RO carbon filter AICRO 6 monthly

6th Stage Remineraliser and pH balance unit AIMCRO QC 6 monthly

FLOW DIAGRAM

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

FITTING INSTRUCTIONS:

Fitting The Pre-Plumbed RO System

Use the bracket as a template to mark the position of the unit on a suitable wall or cupboard panel. Allow a

minimum of 40mm clearance below the filter bowls to allow for filter change out. Drill and plug two holes and

screw in 2 screws (not supplied) allowing the screw heads to protrude from the wall by approx. 5mm. Place

the bracket over the screws and slide to left or right (as preferred) to lock bracket in position.

Fitting The Tap

Select a suitable position on the work top or corner of the sink. Before drilling the hole, check there is

nothing directly underneath that could be damaged i.e. water or waste pipes, cables etc. Also make sure

that there is room for the locating washer and that you can physically reach the tap stud to connect the nut.

Use a centre punch to mark the location of the hole to be drilled. Drill a 3mm pilot hole. Enlarge the hole to

11mm (7/16”). If you are drilling through stainless steel, deburr and rough edges around the hole. Wipe

clean with a soft cloth. Check that the tap stud fits easily through the hole. Place the nut and then the

plastic olive over the blue tube leaving 3-4mm of blue tube showing. Push tube insert into the open end of

the blue tube. Tighten the nut onto the end of the tap stud.

The tap is off when the lever is pointing down. Turn lever to the right for flow.

Fitting The Saddle Tapping Valve (Red tubing attached)

Although not essential, we recommend that you turn off the cold water stopcock and relieve the water

pressure by opening cold water tap. If the stopcock is under the sink, fit the valve after the stopcock. The

valve must be fitted on the cold water supply copper pipe only, (if you are uncertain, run the hot tap for a

minute and feel the pipes under the sink to distinguish the cold pipe).

Do not fit the valve on a bend, a join or where there is solder on the copper pipe. Attach the clamp around

the pipe and tighten the clamp bolt to ensure a water tight seal. Do not over tighten the clamp bolt as this

may distort the water pipe. Firmly push the open end of the red tubing attached to the saddle tapping valve

into the collar on the front of the sediment filter housing (Stage 1).

Note: Later designs have the red tubing already permanently fitted to the valve. The saddle tapping valve

supplied with the Reverse Osmosis System is designed to comply with British plumbing codes. (See

‘System Start Up’ Section for further details regarding the saddle tapping valve.)

Fitting The Tank Ball Valve

Connect the ball valve to the threaded connector on the tank, make sure it is tight but not over-tight.

Connect the yellow tubing to the tank ball valve. Turn the tank ball valve off. ie handle at 90 degrees to the

tube. Note: The air valve on the lower side of the storage tank has been preset at 8-10 psi by the

manufacturers. In time it may need topping back up to pressure—see troubleshooting.

Mounting The Drain Clamp

Connect the red tubing to the output of the flow restrictor. Turn off the membrane flush valve.

Note: The drain clamp will fit most standard drain pipe 1 1/2” diameter. It should be installed above the trap/

u-bend - between the sink and the U Bend and on the vertical or horizontal tailpiece. If a waste disposal unit

is fitted, the drain clamp must not be fitted into the same waste pipe. It is important that the drain is NOT

connected into the foul side of the sink U Bend.

Position the drain saddle in the desired location by hand, mark a spot on the waste pipe through the tube

connector, remove saddle. Drill 1/4” (6.3mm) hole into the drain pipe above the water line of the trap/U-

bend. Align the hole drilled in the drain pipe with the drain saddle using a drill bit. Make sure to align drain

saddle to drilled hole. Attach self adhesive seal on the inside of the saddle over the drain hole. Attach drain

saddle to waste pipe and tighten the two screws evenly. Connect the red tubing to the drain push fit

connector.

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

SYSTEM START UP:

Turn on the cold water supply at the stopcock and turn the cross piece on the saddle tap valve

anti-clockwise to fully open. Close the tank ball valve. Open the tap for continuous flow (Lever

to the side). Check the system for leaks, tighten as necessary. Connect the pump to a power

supply and turn on. After 10-30 minutes, water will start to drip out of the tap. Let it drip for

about 10 minutes and then turn the tap off. TURN ON THE TANK BALL VALVE NOW. It may

now take 2-4 hours for the storage tank to completely fill.

Note: DO NOT DRINK THE WATER FROM THE FIRST TANK PRODUCED BY YOUR NEWLY PURCHASED

REVERSE OSMOSIS SYSTEM.

After the tank is full (you will hear the water stop), flush the system by placing the tap in the

open position until all the water is completely discharged. Upon complete discharge of the

storage tank, return the tap handle to the closed position and let the refilling process begin.

This process could take 2-4 hours to complete. After the second tank is filled, you may enjoy

the pure water. Check for leaks daily for the first week and periodically thereafter. You may

notice that the water may be milky coloured during the first week. This is caused by air bubbles

in the water released from the carbon filter, they will dissipate on allowing to stand. It is normal

and safe.

NOTE:

DO NOT USE WITH WATER THAT IS MICRO BIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY WITHOUT

ADEQUATE DISINFECTION BEFORE OR AFTER THE SYSTEM. SYSTEMS CERTIFIED FOR CYST

REDUCTION MAY BE USED ON DISINFECTED WATER THAT MAY CONTAIN FILTERABLE CYSTS.

THIS REVERSE OSMOSIS SYSTEM CONTAINS A REPLACEABLE COMPONENT CRITICAL TO THE

EFFICIENCY OF THE SYSTEM. REPLACEMENT OF THE REVERSE OSMOSIS COMPONENT SHOULD BE

WITH ONE OF IDENTICAL SPECIFICATIONS, AS DEFINED BY THE MANUFACTURER, TO ASSURE THE SAME

EFFICIENCY AND CONTAMINANT REDUCTION PERFORMANCE.

WARNING: DO NOT USE THIS SYSTEM TO PURIFY NON-DRINKABLE SOURCES OF WATER THAT

ARE UNSAFE OR WITH WATER OF UNKNOWN QUALITY

WARNING: NEVER USE HOT WATER OR ALLOW THE UNIT TO FREEZE.

WARNING: INCORRECT INSTALLATION WILL VOID THE WARRANTY.

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

FILTER MAINTENANCE & CHANGE INSTRUCTIONS:

This recommendation is intended for maximum efficiency of RO water production by your system.

1, Filter Maintenance

a, It is OK to put pre & post filters on the shelf for several years.

b, Keep the sealed, non-opened filter in an air tight container to prevent it from absorbing contaminants

from the air.

2, Membrane Maintenance

a, The dry packed membrane usually has a two-year shelf life. To prolong the shelf life, we recommend

you keep the non-opened dry membrane in the refrigerator.

b, Once being used, we recommend you run the RO system every day, at least 10-15 minutes (about 1

gallon or 4 litres drinking water.) This helps to maintain the membrane performance.

c, If the RO system is not used for a few weeks, drain the storage tank. To bring the unit into service fill the

tank and drain it twice, and allow to refill. Your RO system will then be ready to reuse.

Your system is fitted with a membrane flush valve. The purpose of this valve is to flush impurities from

the membrane using a water flow higher that allowed by the flow restrictor. We suggest you open this

valve for 2-3 minutes every 6 –8 weeks. This will help to extend the membrane life.

3, Filter & Membrane Change Procedures:

a, Shut off the water supply.

b, Turn off the tank ball valve by turning the handle through 90 degrees.

c, Open the tap fully for continuous flow.

d, Slide the housing wrench in (bowl spanner) over the filter bowl. Use one hand to hold the system and

the other hand to turn the wrench clockwise to separate the head from the bowl.

NOTE: IF IT IS TOO TIGHT TO OPEN THE HOUSING YOU MAY TRY TO UNPLUG THE FITTING

BETWEEN THE RED TUBING AND THE SYSTEM IN ORDER TO REDUCE THE AIR AND WATER

PRESSURE INSIDE THE HOUSING.

e, To change the sediment cartridge and the pre-carbon cartridge you need to open the clear and opaque

housings, remove the used filters and put the new filters into the housings. Make sure the O-rings are in

place and smear a little Silicone grease on the O-rings. Replace the filter bowls and tighten by turning

the bowl anti-clockwise.

f, The Carbon Post-Filter and remineraliser must be installed the correct way, with the flow arrow

pointing in the direction of flow. Remove the existing cartridges by disconnecting from the threaded or

pushfit connectors.

Pull cartridge gently to remove from the holding brackets, discard used cartridge. Place new cartridge

over the holding brackets & push gently into place. Re-attach the threaded/speedfit connectors.

g, Turn on the water supply and make sure there are no leaks.

h, Let the water drip from the tap for about 10 minutes. If the water flow is less than 1 cup (8 oz or 240 ml)

per minute, it may be a signal to change the membrane.

i, Membrane Change Procedure:

Shut off water supply.

Unscrew the cap of the membrane housing using the wrench provided.

Slide out the used membrane & discard. (You may need thin nosed pliers to grip the membrane spigot.)

Insert the new membrane with the 2 O-rings into housing first with the black brine seal at the open end

of the membrane housing.

Be sure it is fully seated into bottom end.

Screw cap back on to the membrane housing, make sure O-ring is still in place.

Turn on water supply & check for leaks.

It may take 10-20 minutes for new membrane to run to normal flow.

Carry out system start up procedure.

for all your filter requirements

Phone: 01422 377367

email: sales@prosep.co.uk

www.prosep.co.uk

Prosep Filter Systems Ltd

Unit G19, River Bank Way,

Lowfields Business Park,

Elland, West Yorkshire

HX5 9DN

Note: Turn off the system before servicing

PROBLEM CAUSE SOLUTIONS

Milky Coloured Water Air in system Air in the system is a normal

occurrence with initial startup of

the RO System. This milky look

will disappear during normal use

within 1 to 2 weeks.

Noise from tap Location of drain saddle

Restriction in drain line

Relocate the drain to above

water trap

Blockage sometimes caused by

debris from garbage disposal or

dishwasher

Small amount of water in

storage tank

System just starting up

Air pressure in storage tank is

low

Normally it takes 2—3 hours to

fill the tank.

Low water pressure and/or

temperature can reduce

production rate

Add pressure to storage tank.

The pressure should be 8—10

psi when the tank is empty

Slow production Low water pressure

Crimps in tubing

Clogged pefilters

Fouled membrane

Make sure tubing is straight

Replace prefilters

Replace membrane

Water taste or smell

offensive

Post carbon is depleted

Fouled membrane

Sanitiser not flushed out

Replace post carbon

Replace membrane

Drain storage tank and refill

overnight

No drain water Clogged flow restrictor Replace flow restrictor

Leaks Fittings are not tightened

Twisted O-ring

Misalignment of hole in drain

saddle

Tighten fittings as necessary

Replace O-ring

Realign drain saddle

Table of contents

Other PROSEP FILTER SYSTEMS Water Filtration System manuals

Popular Water Filtration System manuals by other brands

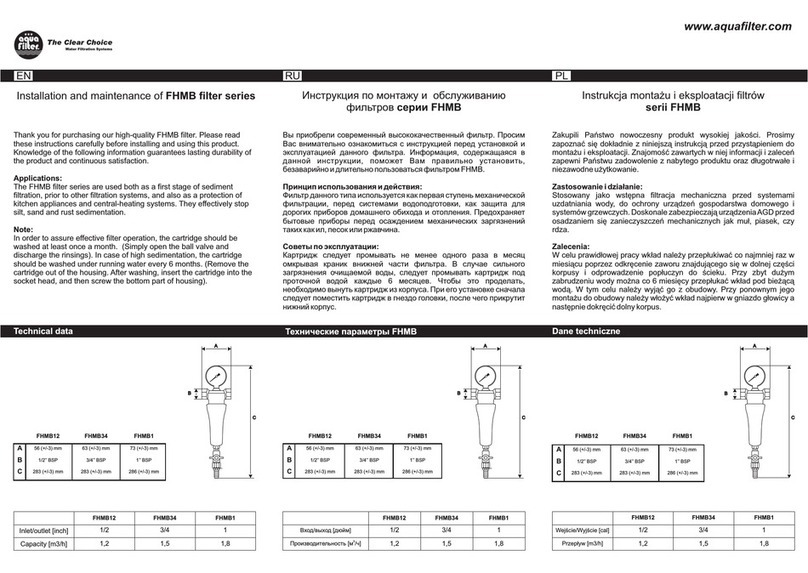

AQUA FILTER

AQUA FILTER FHMB12 Installation and Maintenance

KEBCO

KEBCO COMBILINE Z1I05-1001 Series Instructions for use

AQUA EL

AQUA EL ULTRA FILTER user manual

Ecoplus

Ecoplus EP-1000-UV Owner's manual & installation guide

DELTA PLUS

DELTA PLUS M9000 Series Instructions for use

Aquapure

Aquapure MCA SERIES Installation and operating instructions