SPX FLOW HANKISON HF Series User manual

HF Series

Compressed Air Filters

Models HF(grade)-12 through HF(grade)-48

FORM NO.: 4011203 REVISION: 10/2015 READ AND UNDERSTAND THIS MANUAL PRIOR TO OPERATING OR SERVICING THIS PRODUCT.

INSTRUCTION MANUAL

General Safety Information

1. Pressurized devices

• Donotexceedmaximumoperatingpressure

indicatedonserialnumbertag.

• Makecertainlterisfullydepressurizedbefore

servicing.

2. Breathing Air

• Airtreatedbythisequipmentmaynotbesuit-

ableforbreathingwithoutfurtherpurication.

RefertoOSHAstandard1910.134forbreathing

airrequirements.

3. Flammable gases

Whilethematerialsofconstructionarecompatible

withmanyammablegases,thefollowingapplica-

tionlimitationsmustbeconsidered:

• Housingmaterialsareslightlyporous.Theprod-

uctmustbeusedinawellventilatedareainthe

absenceofsparksorignitionsources.Donot

useinClass1,Division1,GroupDenvironments.

• Thetypeofarea-forcedexhaustsystemused

(i.e.,highorlowlevel)wouldbedependenton

thegasinvolved.

• Eachapplication(otherthanforairorinertgas)

mustbereviewedtominimizereorexplosion

hazard.

Contents

MODELNUMBERCONFIGURATION.......................... 1

1.0INSTALLATION.................................................... 2

2.0OPERATION....................................................... 5

3.0MAINTENANCE.................................................. 6

DIMENSIONSANDWEIGHTS..................................... 8

WARRANTY.............................................................. 9

1

Grade Identification

Filtergradecanbeidentiedbythethirddigitofthemodelnumber.Inaddition,elementswithafoamoutersleevecan

beidentiedbycolor.

Grade Description Type Outer foam color

11 Mechanical Separator Impaction type separator none

9 Separator/filter Mechanical separator and 3 micron coalescer none

7 General purpose air line filter 1 micron coalescer none

6 Dry Desiccant Afterfilter 1 micron after-filter for desiccant dryers none

5 High efficiency oil removal filter High efficiency (99.99+%) coalescer Red

3 Maximum efficiency oil removal filter Maximum efficiency (99.999+%) coalescer Blue

1 Oil vapor removal filter Activated carbon adsorber Green

Model Number Configuration

HF (1) -(2) -(3) -(4)

1. Filter Grade is indicated in space (1).

2. Housing Number is indicated in space (2).

3. Connection Size is indicated in space (3)

4. Features

D = Internal Automatic Drain Mechanism

P = Differential Pressure Slide Indicator

G = Differential Pressure Gauge Indicator

L = Liquid Level Indicator

S = Corrosion Proof Stainless Steel Element

X = External Drain Adapter

M = Filter Monitor

Example: A Grade 5 high efficiency oil removal filter with a capacity of 100 scfm

and 3/4” NPTF connections, internal drain, filter monitor and liquid level

indicator would be configured as: HF5-24-6-DML

(2) Housing (3) Connection Sizes

Number Capacity

scfm [m3hr] @

100 psig [7 kgf/cm2]

12

16

20

20 [35]

35 [60]

60 [105]

3- 3/8” NPTF or

4- 1/2” NPTF

3B - 3/8” BSP or

4B - 1/2” BSP

24

28

100 [170]

170 [290]

6- 3/4” NPTF or

8- 1” NPTF

6B - 3/4” BSP or

8B - 1” BSP

32

36

250 [425]

375 [640]

8- 1” NPTF or

10 - 1-1/4” NPTF or

12 - 1-1/2” NPTF

8B - 1” BSP or

10B - 1-1/4” BSP or

12B - 1-1/2” BSP

40 485 [825] 16 - 2” NPTF or

20 - 2-1/2” NPTF

16B - 2” BSP or

20B - 2-1/2” BSP

44

48

625 [1060]

780 [1325] 20 - 2-1/2” NPTF 20B - 2-1/2” BSP

(4) Features

D= Internal Automatic Drain

Mechanism

P= Differential Pressure Slide

Indicator

G= Differential Pressure Gauge

Indicator

L= Liquid Level Indicator

S = Corrosion Proof Stainless

Steel Element

X= External Drain Adapter

M= Filter Monitor

(1) Filter Grade

11 - Mechanical Separator

9- Separator/Filter

7- Air Line Filter

6- Dry Desiccant Afterfilter

5- High Efficiency Oil Removal Filter

3- Maximum Efficiency Oil Removal Filter

1- Oil Vapor Removal Filter

2

1.0 Installation

A. Where Used/Air Quality After Filtration

Grade Where used

Solid particle

removal (maximum

size in microns)

Liquid removal

efficiency (at

rated conditions)

Maximum inlet

liquid loading

ppm w/w

Remaining

oil content

ppm w/w

11 Separator - downstream of an aftercooler

Point-of-use - where no aftercooler is installed

upstream

— 95% of water 30,000

bulk liquids

—

9 Separator - downstream of an aftercooler

Point-of-use - where no aftercooler is installed

upstream or as prefilter to refrigerated dryer

3 99+% of water 25,000

aerosols &

bulk liquids

5

aerosols

7 Prefilter -

•PreltertoGrade3&Grade5-highefciency

coalescing filters

Point-of-use - where aftercooler is installed

upstream

1 100% of water 2,000

aerosols

1

aerosols

6 Afterfilter - downstream of a pressure-swing

(heatless) desiccant dryer

•DownstreamofanActivatedCarbonor

Desiccant Tower

1 No liquid should be

present at inlet

No liquid should be

present at inlet

—

5 Prefilter

•Aheadofdesiccantandmembranedryers

Afterfilter

•Downstreamofrefrigerateddryer

•Downstreamofpressure-swing(heatless)

desiccant dryers for finer solid particle removal

•Oilremovalatpoint-of-use

0.01 99.99+% of oil 1,000

aerosols

0.008

aerosols

3 Prefilter - ahead of desiccant and membrane

dryers (use after Grade 7 to reduce liquid and

solids load, prolong element life and ensure

filtration efficiency)

Afterfilter - downstream of refrigerated dryer

0.01 99.999+% of oil 100

aerosols

0.0008

aerosols

1 Afterfilter to Grade 3 & Grade 5 for true oil free

applications

0.01 Removes vapors

only

No liquid should be

present

0.003

vapor

3

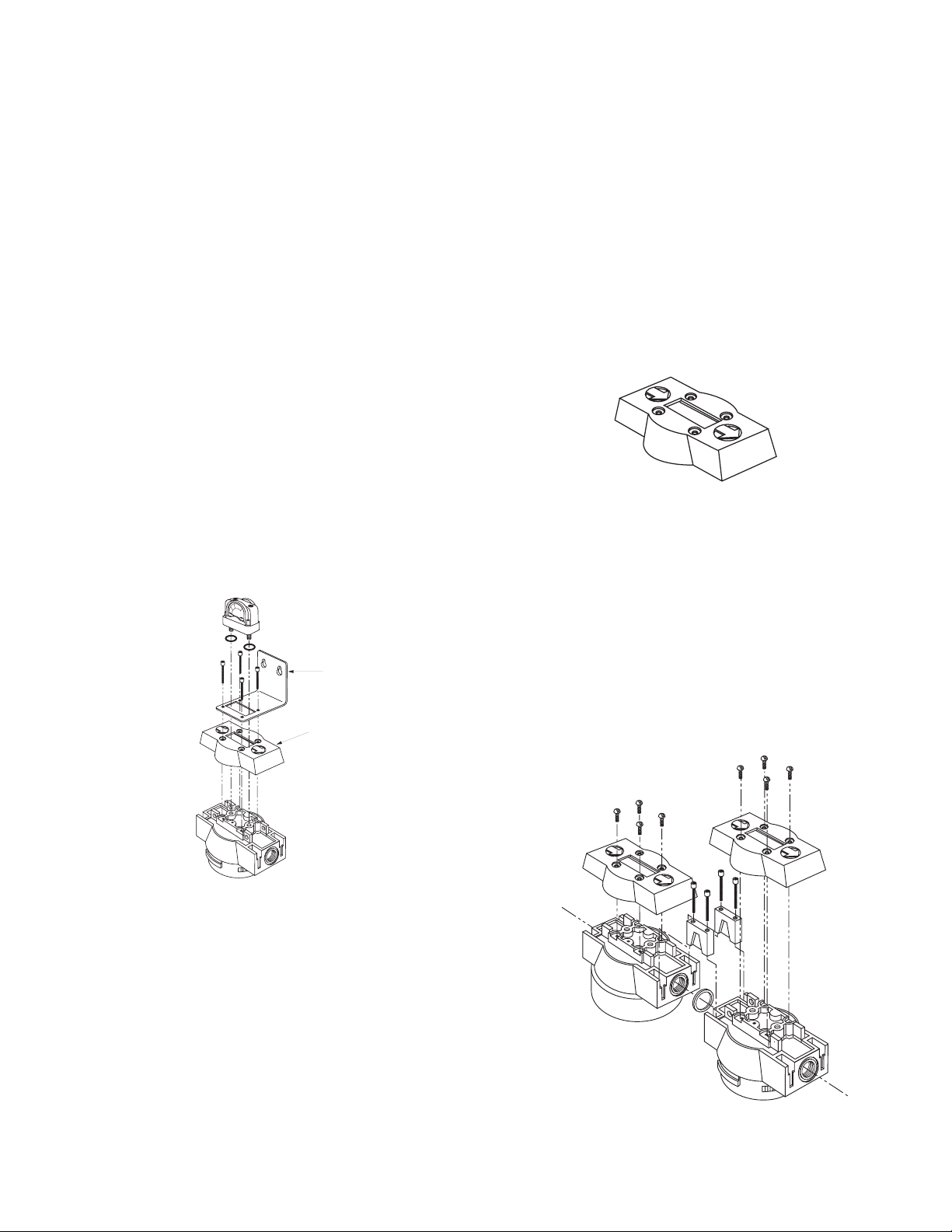

B. Mounting

1. Wallmountingbrackets-Mountbrackettolter

head:

(1) removefour(4)screwsholdingblackplastictop

captolterhead

(2) placebracketonheadoverplasticcap

(3) installscrewssuppliedwithbracket.

2. DifferentialPressureGaugeMountingtoFilterHead

(1) makecertaino-ringsareinplaceonthebot-

tomofthegaugebody.

(2) connectthelowpressuretransmissionbolt

(boltnexttotheREDbandongauge)tothe

gaugeportatthelteroutlet(downstream

sideoflter).

(3) connectthehighpressuretransmissionbolt

(boltnexttoGREENbandongauge)tothe

gaugeportatthelterinlet(upstreamsideof

thelter).

(4) useacoinoraatheadscrewdrivertotighten/

loosenbolts.Thetipwidthofthescrewdriver

shouldbeatleast3/8"inch(9.5mm).Torque

boltsto25+/-5inchoz.DO NOT OVER

TIGHTEN

Wall Mounting

Bracket

Top Cap

Figure 1.1

C. Piping

1. Beforeinstalling,blowoutpipelinetoremovescale

andotherforeignmatter.

2. ThisunithasDRYSEALpipethreads;usepipecom-

poundortapesparinglytomalethreadsonly.

3. Mounting(Grades11,9,7,5,3)-mountsothatinlet

andoutletconnectionsarehorizontal(lterbowl

vertical)toensureproperliquiddrainage.

4. FlowDirection-installsothattheairowisinthe

directionofarrowsonthelterhead.

NOTE:Grade6owsfromoutsidetoinsidethe

element.Allothergradesowfrominsidetoout-

sidetheelement.Observeowarrowsoncap.

5. Directlter-to-lter(modular)connection-Filter

headsmaybejoinedwithoutusingapipenipple

a. Bayonettypeheads-Usetwo(2)modularcon-

nectors,o-ring,andfour(4)socketheadcap

screws(soldaskit)

Removeblackplastictopcap,applygenerous

amountoflubricanttoo-ring,installo-ringin

groove,andinsertconnectors.Screwconnec-

torstoheadusingsocketheadcapscrews.

Figure 1.3

Figure 1.2

4

b. Threadedheads

Usefourcarriagebolts,nutsando-ring(soldas

kit).Removeblackplastictopcaps,applygen-

erousamountoflubricanttoo-ring,installo-ring

ingroove,andinstallboltsandnuts.

NOTE: Make certain ow direction through lters is

correct(observepinholeusedforaligningtopcaps).

Grades11,9,7,5,3,1 -when holeis onside closestto

you,inletistoleft.Grade6-whenholeisontheside

fartherfromyou,inletistoleft.

NOTE:Lubricateo-ringwithgenerousamountoflubri-

cantbeforeinstallation.

6. Isolationvalvesandby-passpiping-Foreaseof

service,isolationandby-passvalvesaredesirable.

Incriticalapplications,twoltersinstalledinparallel

maybenecessarytoavoidinterruptionofairsup-

ply.

Figure 1.4

D. Drain provisions

1. InternalAutomaticDrains-Drainline

Thebottomofinternalautomaticdrainsarepro-

videdwith1/8"(insidethreads)forconnectionof

adrainlineifdesired.

2. ExternalAutoDrains-Externalautodrainsmaybe

addedasfollows:

Models12through28-removeinternaldrainand

installadapter(availablefromfactory).Adapter

outletconnectionis1/8"(insidethreads).

Dischargeisatsystempressure;

anchordrainline.

Models32through48-removeadaptertting

frombottomofbowl;1/2"(insidethreads)portis

availableforexternaldrainconnection.

5

2.0 Operation

Donotoperatelteratpressuresin

excessofMaximumWorkingPressureindicatedon

SerialNumberTag.

NOTE:MaximumOperatingTemperature-150°F,66°C.

Liquidltrationabove120°F,49°Cisnotrecommended

sincethereistypicallyoilpresentinavaporstatewhich

passesthroughthelterandcondensesdownstream.

NOTE:Grade1-Ifoperatedabove100°F,38°Cmay

experiencelessthan1000hoursoflifebecauseof

greateroilvaporcontent.

A. Liquid Draining - Grades 11, 9, 7, 5, 3

NOTE:Collectedliquidsmustberemovedtoensure

properoperation.

NOTE:Depressurizeslowly,toavoidlterelement

damage.

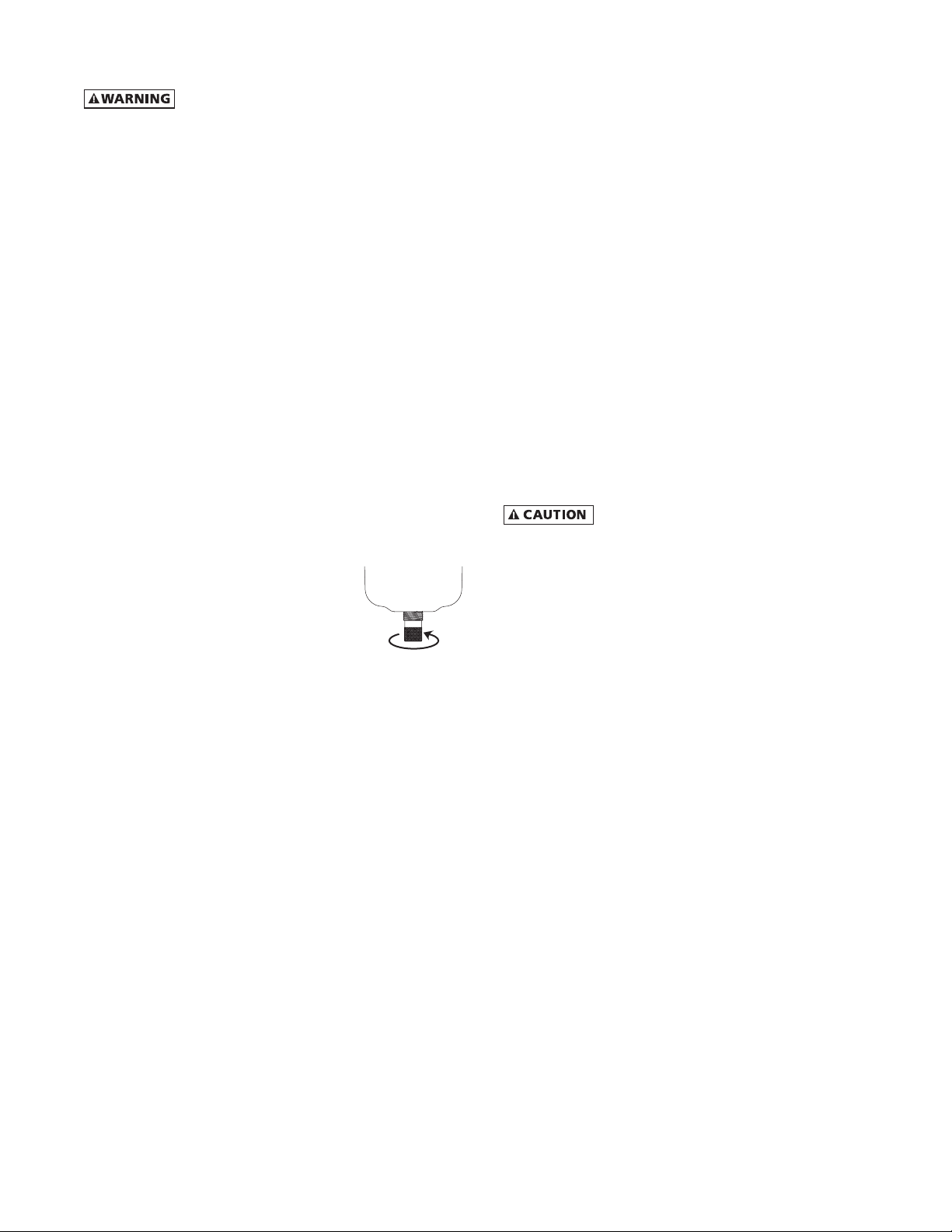

1. ManualDrain-Turntoyourright(clockwise)to

openandtoyourleft(counterclockwise)toclose.

2. AutomaticDrain-Liquidswillautomaticallydis-

chargewhensufcientaccumulationoccurs.

a. InternallyMountedAutoDrains-Thesedrains

maybemanuallydrainedbyturningtoyour

right(clockwise)toopenand

toyourleft(counterclockwise)

toclose.

NOTE:Manuallydraininternalauto

drainsdailytoverifydrainfunction.

B. Operational Checkpoints

All Grades

Checkow,pressure,andtemperaturetomakecertain

lterisbeingoperatedwithindesignconditions.

Grades 11,9,7,6,5,3

Checkpressuredropacrossthelter

1. Pressuredifferentialinexcessof6psi(0.42kgf/cm2)

-pressureindicatorinyellowarea-indicatesthatthe

ltersleeveorelementshouldbereplaced.Refer-

encepage7,Figure3.3forgaugescaledetail.

NOTE:Elementshouldbechangedannuallyorwhen

indicatorchangestoyellow,whicheveroccursrst.

NOTE:Pressuredropshouldneverexceed50psi

(3.5kgf/cm2).

2. Checkforsuddenreductioninpressuredrop.This

mightindicate:

a. Possibleleakacrosselemento-ringseal

b. Leakthroughtheelementduetophysicaldamage

OPEN ( TO RIGHT )

Grades 11,9,7,5,3

1. Checktoseethatlterisinstalledleveltoinsure

properdrainage.

2. Checkthatmanualdrainsaredrainedperiodicallyor

thatautomaticdrainsarefunctioning.

3. OnmodelswithLiquidLevelSightglass-Checkthat

liquidlevelisbelowtopofSightglass.

Grade 1

1. Checkforanoilysmellbyopeningthemanualvalve.

Ifanoilysmellexists,thefollowingshouldbe

checked:

a. Filterelementadsorptioncapacityexhausted

b. Leakacrosselemento-ringseal

c. Leakthroughelementduetophysicaldamage

d. Presenceofliquidsbecauseoflackoforfailureof

prelters

e. Flow,pressureandtemperaturesoutsidedesign

conditions

f. Presenceofgaseousimpuritieswhichcannotbe

adsorbed

Methane,carbonmonoxide,carbondioxide

andvariousinorganicgasescannotberemovedbyan

activatedcarbonlter.

6

3.0 Maintenance

A. When to Replace Filter Element

NOTE:Grades7,6,5,3,1-completeelementisreplaced;

Grade9-unlessseparatorcoreisdamagedoutersleeve

onlyisreplaced.

1. Grade6(drydesiccantafterlter)

Initialdrop:1psi(0.07kgf/cm

2

).Pressuredrop

increasesaselementloadswithsolidparticles.

Replacewhenpressuredropreaches6psi

(0.42kgf/cm

2

)(indicatorinyellowarea)orannually,

whicheveroccursrst.Referencepage7,Figure3.3

forgaugescaledetail.

2. Grade11(mechanicalseparator)

Elementshouldnotrequirereplacementunlessphysi-

callydamaged.Ifsludgeaccumulates,elementcanbe

removedandcleanedwithsoapandwater.

3. Grades9,7,5,3

a. Initial(dry)pressuredrop:1psi(0.07kgf/cm

2

)to

2psi(0.14kgf/cm

2

)

b. Operatingpressuredrop:Aslterbecomesliquid

loaded(wetted),pressuredropwillincreaseto2to

6psi(0.14to0.42kgf/cm

2

).Furtherpressuredrop

occursaselementloadswithsolidparticles.

c. FORMAXIMUMFILTRATIONEFFICIENCY,REPLACE

ELEMENTWHENPRESSUREDROPREACHES6PSI

(0.42KGF/CM

2

)(INDICATORINYELLOWAREA)OR

ANNUALLY,WHICHEVEROCCURSFIRST.Reference

page7,Figure3.3forgaugescaledetail.

NOTE:Pressuredropmaytemporarilyincreasewhenow

isresumedafterowstoppage.Pressuredropshould

returntonormalwithinonehour.

NOTE:Grades5and3-Duringnormaloperationbottom

offoamsleevewillhaveabandofoil.Spottingabovethe

bandindicatesthatliquidsareaccumulatingfasterthan

theycanbedrainedandthatpreltrationisrequired.

4. Grade1(activatedcarbonlters)

a. Adsorptioncapacity-1000hoursatratedcapacity.

Elementlifeisexhaustedwhenodorcanbe

detecteddownstreamofthelter.

B. Procedure for Element Replacement

THISFILTERISAPRESSURECONTAINING

DEVICE.DEPRESSURIZEBEFORESERVICING.Iflterhasnot

beendepressurizedbeforedisassembly,anaudiblealarm

willsoundwhenthebowlbeginstoberemovedfromthe

head.Ifthisoccurs,stopdisassembly,isolateand

completelydepressurizelterbeforeproceeding.

1. Isolatelter(closeinletandoutletvalvesifinstalled)or

shutoffairsupply.

2. Depressurizelterbyslowlyopeningmanualdrain

valve.

C. Flow Capacity

Maximumairowforthevariousltersat100psig

(7kgf/cm

2

)isindicatedinTable1.Todeterminemaximum

airowsatinletpressuresotherthan100psig(7kgf/cm

2

),

multiplyowfromTable1byairowcorrectionfactor

fromTable2thatcorrespondstotheminimumoperating

pressureattheinletofthelter.

NOTE:Filtersshouldnotbeselectedbypipesize.Select

usingowrateandoperatingpressureonly.

Table 1 - Maximum Flow @100 psig [

7 kgf/cm2

]

Housing scfm [m3/hr]

12 20 [35]

16 35 [60]

20 60 [105]

24 100 [170]

28 170 [290]

32 250 [425]

36 375 [640]

40 485 [825]

44 625 [1060]

48 780 [1325]

Table 2 - Air Flow Correction Factor

Maximum

Inlet

Pressure

psig 20 30 40 60 80 100 120 150 200 250 300

kgf/cm

2

1.4 2.1 2.8 4.2 5.6 7.0 8.4 10.6 14.1 17.6 21.1

Correction Factor 0.30 0.39 0.48 0.65 0.82 1.00 1.17 1.43 1.87 2.31 2.74

7

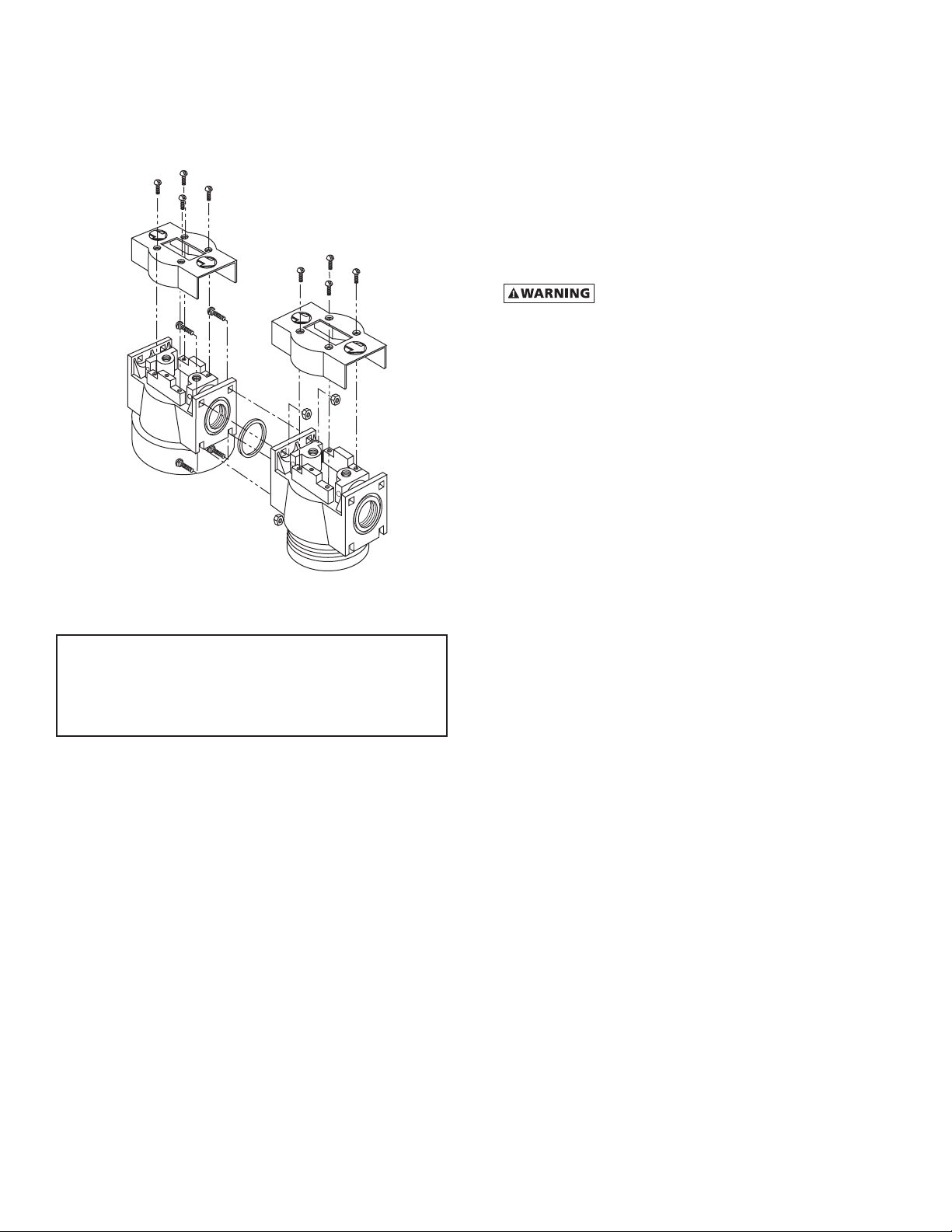

3. Removebowl

a. Formodels12through28-bayonetmount-

pushbowlup,turnbowl1/8thturntoyourleft,

andpullbowlstraightdown

b. Formodels32through48-threadedbowls-

unscrewbowlfromheadusinghand,strapwrench

orCspanner.

4. Cleanlterbowl

5. Replaceelement

a. Replacingcompleteelement

1)Pulloffoldelementanddiscard.

2)Makecertaino-ringinsidetopofreplacement

elementisinplaceandpushelementontolter

head.ForHousingsizes40to48,placeelement

inbowlandsecurewithcenteringdevice.

NOTE:Grades5,3,and1-Donothandleelementsby

outsidefoamcover.Handlebybottomendcaponly.

b. Grade9-replacingsleeveonly

1) Pullelementstraightdowntoremove.

2) Removeboltandbottomcapandremovedis-

posableltersleeve.

3) Cleanseparatorcorewithsoapandwaterif

necessary.

4) Slidenewltersleeveoverseparatorcoreand

replacebottomcapandhandtightenbolt.

5) Makecertaino-ringinsidetopofelementisin

placeandpushelementontolterhead.

6. Aftermakingcertainthato-ringinsidetopofbowl

(andonbayonetmountheads,wavespring)arein

place,reassemblebowltohead.

NOTE:Makecertaino-ringisgenerouslylubricated.

NOTE:Wavespringendsshouldbepointeddowntopre-

ventthewavespringfrominterferingwithreassembly.

NOTE:Threadedbowltoheadconnection,generously

lubricatethreadswithahighgrade/temperaturelubricant

goodfor150°F,66°C.

C. Auto Drain Mechanism

Itisrecommendedthatdrainmechanismbereplaced

annually.

Separator Core

Replacement Sleeve

Bottom Cap

Bolt

Bowl o-ring

Element O-ring

Element

Bowl o-ring

Element O-ring

Grade 9 - Sleeve Replacement All Grades - Element Replacement

Wave Spring

Models 12-28

Figure3.1

8

Dimensions and Weights

Filter Type HF(Grade)- 12 16 20 24 28 32 36 40 44 48

Replacement Element E(Grade)- 12 or 12S 16 or 16S 20 or 20S 24 or 24S 28 or 28S 32 or 32S 36 or 36S 40 or 40S 44 or 44S 48 or 48S

Nominal Air Flow

scfm @100 psig (m

3

/hr @ 7.0 bar) 20 (35) 35 (60) 60 (105) 100 (170) 170 (290) 250 (425) 375 (640) 485 (825) 625 (1060) 780 (1325)

In/Out Connection NPT or BSP 3/8, 1/2 3/8, 1/2 3/8, 1/2 3/4, 1 3/4, 1 1, 1-1/4, 1-1/2 1, 1-1/4, 1-1/2 2, 2-1/2 2-1/2 2-1/2

"A" in. (mm) 4.13 (105) 4.13 (105) 4.13 (105) 5.25 (133) 5.25 (133) 6.44 (164) 6.44 (164) 7.63 (194) 7.63 (194) 7.63 (194)

"B" in. (mm) 8.15 (207) 10.05 (255) 12.40 (316) 13.32 (338) 17.57 (446) 20.80 (528) 25.29 (642) 29.08 (739) 34.83 (885) 40.96 (1040)

"C" in. (mm) 6.40 (163) 8.59 (224) 10.97 (285) 11.74 (298) 15.99 (406) 18.98 (482) 23.47 (596) 26.83 (681) 32.58 (827) 38.71 (983)

"D" in. (mm) 3.00 (76) 3.00 (76) 3.00 (76) 3.50 (89) 3.50 (89) 4.00 (102) 4.00 (102) 4.00 (102) 4.00 (102) 4.00 (102)

Weight lb. (kg) 4.14 (1.88) 4.5 (2.04) 4.7 (2.13) 6.3 (2.9) 6.9 (3.1) 10.2 (4.63) 11.3 (5.13) 28 (12.70) 33 (14.97) 38 (17.24)

Maximum Working Pressure Housing - 300 psig, 21.1 kgf/cm

2

Models with Internal Drain or

Liquid level indicator - 250 psig, 17.6 kgf/cm

2

Housing - 300 psig, 21.1 kgf/cm

2

Models with Internal Drain or

Liquid level indicator - 250 psig, 17.6 kgf/cm

2

Maximum Operating Temperature 150°F, 66°C 150°F, 66°C

Head Material Aluminum Aluminum

Bowl Material Aluminum Aluminum

Liquid Level Indicator Material Isoplast Isoplast —

NOTE:DimensionsandWeightsareforreferenceonly.Requestcertieddrawingsforconstructionpurposes.

OUTLET

CLEARANCE

FOR SERVICING

CLEARANCE

FOR SERVICING

INLET OUTLET

INLET

"A"

"C" "B"

"D"

1" (26mm)

"A"

"C"

"B"

"D"

2.3" (58.4mm)

OUTLETINLET

INLET OUTLET

CLEARANCE

FOR SERVICING

"A"

"C" "B"

"D"

2.3" (58.4mm)

CLEARANCE

FOR SERVICING

"A"

"C"

"B"

"D"

2.3" (58.4mm)

HEX WRENCH

3.00 ACROSS FLATS

Sizes HF(Grade) 12, 16, 20 Sizes HF(Grade) 24, 28 Sizes HF(Grade) 32, 36 Sizes HF(Grade) 40, 44, 48

Figure3.3

DifferentialPressure

Gauge

Figure3.2

9

SERVICE DEPARTMENT: (724) 746-1100

WARRANTY

Themanufacturerwarrantstheproductmanufacturedbyit,whenproperlyinstalled,operated,applied,andmain-

tainedinaccordancewithproceduresandrecommendationsoutlinedinmanufacturer’sinstructionmanuals,tobe

freefromdefectsinmaterialandworkmanshipforaperiodofone(1)yearfromdateshipmenttothebuyerbythe

manufacturerormanufacturer’sauthorizeddistributorprovidedsuchdefectisdiscoveredandbroughttothemanu-

facturer’sattentionwithintheaforesaidwarrantyperiod.

Themanufacturerwillrepairorreplaceanyproductorpartdeterminedtobedefectivebythemanufacturerwithin

thewarrantyperiod,providedsuchdefectoccurredinnormalserviceandnotasaresultofmisuse,abuse,neglect

oraccident.Normalmaintenanceitemsrequiringroutinereplacementarenotwarranted.Thewarrantycoversparts

andlaborforthewarrantyperiod.Repairorreplacementshallbemadeatthefactoryortheinstallationsite,atthe

soleoptionofthemanufacturer.Anyserviceperformedontheproductbyanyoneotherthanthemanufacturer

mustrstbeauthorizedbythemanufacturer.

Unauthorizedservicevoidsthewarrantyandanyresultingchargeorsubsequentclaimwillnotbepaid.

Productsrepairedorreplacedunderwarrantyshallbewarrantedfortheunexpiredportionofthewarrantyapplying

totheoriginalproduct.

Theforegoingistheexclusiveremedyofanybuyerofthemanufacturer’sproduct.Themaximumdamagesliabilityof

themanufactureristheoriginalpurchasepriceoftheproductorpart.

THEFOREGOINGWARRANTYISEXCLUSIVEANDINLIEUOFALLOTHERWARRANTIES,WHETHERWRITTEN,ORAL,ORSTATU-

TORY,ANDISEXPRESSEDINLIEUOFTHEIMPLIEDWARRANTYOFMERCHANTABILITYANDTHEIMPLIEDWARRANTYOF

FITNESSFORAPARTICULARPURPOSE.THEMANUFACTURERSHALLNOTBELIABLEFORLOSSORDAMAGEBYREASONOF

STRICTLIABILITYINTORTORITSNEGLIGENCEINWHATEVERMANNERINCLUDINGDESIGN,MANUFACTUREORINSPECTION

OFTHEEQUIPMENTORITSFAILURETODISCOVER,REPORT,REPAIR,ORMODIFYLATENTDEFECTSINHERENTTHEREIN.

THEMANUFACTURER,HISREPRESENTATIVEORDISTRIBUTORSHALLNOTBELIABLEFORLOSSOFUSEOFTHEPRODUCTOR

OTHERINCIDENTALORCONSEQUENTIALCOSTS,EXPENSES,ORDAMAGESINCURREDBYTHEBUYER,WHETHERARISING

FROMBREACHOFWARRANTY,NEGLIGENCEORSTRICTLIABILITYINTORT.

Themanufacturerdoesnotwarrantanyproduct,part,material,component,oraccessorymanufacturedbyothers

andsoldorsuppliedinconnectionwiththesaleofmanufacturer’sproducts.

AUTHORIZATION FROM THE SERVICE DEPARTMENT IS NECESSARY BEFORE MATERIAL

IS RETURNED TO THE FACTORY OR IN-WARRANTY REPAIRS ARE MADE.

HF SERIES

Compressed Air Filters

Models HF(grade)-12 through HF(grade)-48

SPX FLOW, INC.

4647 S.W. 40th Avenue

Ocala, Florida 34474-5788 U.S.A.

P: (724) 745-1555

F: (724) 745-6040

E: hankison.americas@spxflow.com

www.spxflow.com/hankison

Improvements and research are continuous at SPX FLOW, Inc.

Specifications may change without notice.

ISSUED 10/2015 Form No.: 4011203 Revision: D

COPYRIGHT ©2015 SPX FLOW, Inc.

This manual suits for next models

10

Table of contents

Other SPX FLOW Water Filtration System manuals