ProsKit SS-969E User manual

SS-969 SMD Rework Station

User’s Manual

1st Edition,2011

©2011 Copy Right by Prokit’s Industries Co., Ltd.

SAFETY INSTRUCTIONS

WARNING

Warnings and cautions are placed at critical points in this manual to direct the

operator’s attention to significant items. They are defined as follows:

WARNING: Failure to comply with a WARNING may result in serious injury or

death.

CAUTION: Failure to comply with a CAUTION may result in injury to the

operator, or damage to the items involved. Two examples are given below.

NOTE: A NOTE indicates a procedure or point that is important to the process

being described.

EXAMPLE: AN EXAMPLE is given to demonstrate a particular procedure,

point or process.

Be sure to comply with following WARNINGS and CAUTIONS for your safety.

WARNING

Do not change or disassemble any components related to this product, it may

cause product damaged.

When you need to replace the fuse, be sure turn off the power before

operating.

During working period, do not turn off the power suddenly, the heat gun

should be placed on the heat gun holder until cool off after power turn off,

otherwise it will damage the product。

CAUTION

When the power is ON, the temperature of the hot air and the nozzle ranges

from 100 to 450 (212 to 842 ). To avoid injury to personnel or damage to℃℉

items in the work area, observe the following:

** Do not direct the hot air toward personnel or touch the metal parts near the

nozzle.

** Do not use the product near combustible gases or flammable materials.

** Advise those in the work area that the unit can reach very high temperatures

and should be considered potentially dangerous.

** Turn the power OFF when no longer using the Pro’sKit SS-969 or when

leaving it unattended.

** Before replacing parts or storing the unit, allow the unit to cool and then turn

the power OFF.

To prevent accidents and failures, be sure to take the following precautions:

1

** Do not strike the handpiece against hard surfaces or otherwise subject it to

physical shock.

** Be sure the unit is grounded.Always connect power to a grounded receptacle.

** Do not disassemble the machine.

** Do not modify the unit.

** Use Pro’sKit provides replacement parts.

** Do not wet the unit or use the unit with wet hands.

** Remove power cord by holding the plug – not the wires.

** Make sure the work area is well ventilated.

** The Pro’sKit SS-969 is not intended for use by children or infirm persons

without supervision.

** Children should be supervised to ensure that they do not play with the SS-969.

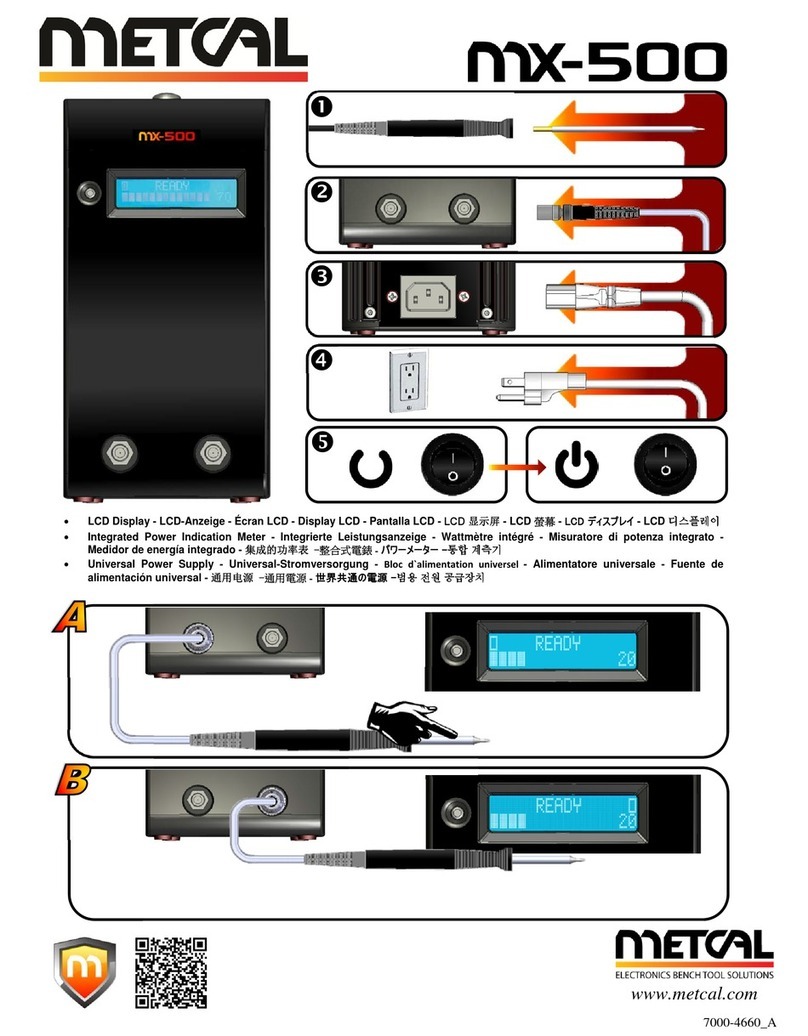

Packing list and name of parts

Name of Parts

Heat gun holder

Temperature

Dis

p

la

y

Airflow

adjustment

knob

Power

Switch

Heat gun

Temperature

adjustment button

Packing List:

SS-969 SMD Rework Station (include holder) x1

Heat Gun x1

Air nozzle x 3

Powercordx1

User’s manual x1

2

Features:

1. Microprocessor-controlled, closed circuit sensor design, high power and

quick warm-up times

2. Adjustable air flow, air volume and temperature, suitable for a variety of

applications.

3. Handle with sensor design switching work & sleep mode for real-time

operation convenience.

4. Auto Cool-Off Process to prolong the life of heating element

5. Plastic shell, compact body, beautiful, small footprint.

6. Comes with brushless motor provides long service life, quiet in operation

7. Safe solder QFP, PLCC, BGAand other temperature-sensitive components.

Also for heating shrink, viscidity removal, lacquer removal, preheating and

more

Specification:

Model No. SS-969E SS-969E7 SS-969B SS-969H

Power Input 110V 127V 220V 220V

Power Consumption 700W

Temperature Range 100-450℃

Air Volume 120L/min(Max)

Heating Element Metal Heating core

Equipment noise <45dB

Temperature Display LED

Weight 1.43kgs

Plug Type EEB H

Machine Size(mm) 170x170x140 (include holder)

Overall package(mm) 280x182x170

Fuse Type 250V/10A 250V/10A 250V/5A 250V/5A

3

Optional replacement

Replacement Nozzle

IC Package Model No. ID (mm)

9SS-969-A1 Ø4.5

9SS-969-A2 Ø7.5

9SS-969-A3 Ø11.2

Replacement Heat Gun

Model No. Description Dimensions

5SS-969E-HG Heat Gun for

SS-969E (110V)

5SS-969B-HG Heat Gun for

SS-969B/H (220V)

5SS-969E7-HG Heat Gun for

SS-969E7 (127V)

225x60x40mm

(wire length

115cm)

Application

1.Suitable for desoldering multiple components.

Such as: SOIC, CHIP, QFP, PLCC and BGAetc. (especially for flat cables

and cable connectors).

2.Ideal for heating shrink, viscidity removal, lacquer removal, preheating and

more

Operation Instruction

1.Put the rework station ready and place handle on the holder.

2.Connect the power cord to the power receptacle on the back panel of the

station.

3.Set the blast nozzle (large caliber nozzle preferred).

4.Switch the power on, the screen displays “- - -“, it represents standby mode.

(Available in microcomputer with digital LED)

4

5.Press “▲”or “▼”button as to set up the temperature.

6.Adjust the airflow knob to set up the required air volume.

7.Hold the handle, the equipment begins to heat. Adjust the knob of airflow in

order to set proper air volume, operate normally when temperature is stable.

8.Put the handle back on the holder after work, the SMD station switched from

heating mode to cooling - off mode automatically. When the temperature is

lower than 100℃, the station switching to standby mode.

9.Switch the power off and unplug the power cord if there has no operation for a

long time.

Attention

Please set up the temperature as lower as possible in high airflow volume as to

prolong heating element service life and better IC chips protection.

Setting up Temperature

1. Press “▲”or “▼”button to set up the temperature, the screen displays the

setting temperature.

2. Press “▲” once the temperature degree increase 1℃, and the screen displays

the setting temperature.

Press “▼” once the temperature degree decrease 1℃,and the screen

displays the setting temperature.

When press the “▲”or “▼” button continuously, the temperature will

increase or decrease rapidly, after the button is released, the screen

displays temperature for two seconds and displays setting temperature

or display “- - -“ for standby mode.

5

Note: Explanation of Symbols

A. “- - -“represents the temperature is lower than 100℃in standby mode,

and the handle put on the holder.

B. “S-E” represents the switch turned on but the connector of heat gun did not

connect to the station properly or the sensor of heat gun damaged, please

replace a new heat gun.

Terms of use

1. The air outlet and its surrounding area may be very hot. Be cautious of scald.

2. The heating handle shall not be put on the working table or other place

except its holder.

3. Please keep the air outlet unblocked.

4. Place the heating handle on its holder after the work, and keep it cool

naturally and turn into standby mode, then switch the power off.

5. The distance between the air outlet and the object shall be no less than 2mm.

6. Choose suitable nozzle in accordance with working requirements. Different

nozzles may have different temperatures.

Fuse replacement

When fuse is blown, replace with the same type of fuse. (see below picture)

1. Unplug the power cord from the power receptacle.

2. The fuse holder is located under the AC power receptacle, use the slotted (–)

screwdriver to loosen the fuse holder

3. Replace the fuse with new one

4. Put the fuse holder back in place

6

Basic troubleshooting guide

WARNING

To avoid personal injury or equipment damage, disconnect power cord before

making any servicing to the equipment.

Problem 1: The unit has no power / display does not light up.

1. Check if the unit is switched ON.

2. Check the fuse, replace with the same type of fuse if blown.

3. Check the power cord and make sure there is no disconnection.

4. Verify that the unit is properly connected to the power source.

5. Check if local voltage matches the product requirement.

Problem 2: The temperature of the SMD station is not rising.

Description: Display lights up but the temperature of heat gun is relative low and

not heating up.

Solution: heat gun cord or heating element may be damaged, please replace

a new heat gun.

Problem 3: Heat gun temperature is intermittent.

Description: Display lights up but the heat gun temperature rises and falls

uncontrollably.

The temperature is less than 50℃, and no longer heating up when

at the working。

Solution:

** Heat gun plug may be loose from the receptacle, unplug the heat gun and

re-attach

** Heat gun cord or heating element may be damaged, please replace new

heat gun.

7

SS-969 柔風型 SMD 拆焊台

說明書

@2011 寶工實業版權所有,請勿翻印使用. 2011001

.

8

使用說明書

警告

本說明書之注意事項,區分為如下的”警告”及”注意”二者加以表示。請充分理解其

內容後再閱讀本文。

警告:濫用將可能導致使用者發生嚴重傷害。

注意:可能導致使用者受傷或對涉及物體造成實質破壞,為了使用者的安全著想,

請嚴格遵守”注意事項”。

為了您的安全,請務必遵守下面的”警告”及”注意”事項。

警告

建議不要變更或拆解任何與本產品相關的部件。這樣的行為可能會損壞本產品。

當需要更換 fuse 時,請關閉電源後再作業。

正常使用時,確保不要突然關閉開關,關閉電源。應該放置于熱風槍掛架,正常冷

其卻。否則會對本產品造成損壞。

注意

當電源為開啟的狀態,熱風槍噴嘴的溫度範圍約在 100 to 450℃(212 to 842℉)之

間。為了避免傷害使用者或是損壞使用區域物件,請注意下列事項:

** 熱風不可以對著人吹,不可以碰觸接近噴嘴的金屬部份以免燙傷。

** 不可以在有可燃氣體或可燃材料附近使用本產品。

** 在高溫工作區域應該注意潛在的危險性。

** 當長時間不使用或是附近沒人的時侯,請將本產品的電源關閉。

為預防意外的發生,請遵守下列注意事項:

** 手握持的裝置不要敲打堅硬的地方,否則會造成主體的震動而損壞。

** 請確認產品接地的元件有連結電源的接地插座。

** 不要拆開產品。

** 不要任意修改任何原件。

** 請使用本公司所提供的替換元件。

** 不要弄濕產品或是用濕的手去使用產品。

** 拔掉電源線時請拉拔插頭,不要直接拉電線。

** 請確認工作的區域通風良好。

** 本產品請妥善放置在小孩拿取不到的地方。

9

This manual suits for next models

3

Table of contents