PROTEA SODCUTTER 460 User manual

PROTEA TURF EQUIPMENT

Manufacturers of Industrial Lawnmowers, Scarifiers & Sodcutters

Reg. No. CK 1989/023716/23

Vat Reg. No. 4830119907

P.O. Box 1673

Bedfordview

2008

www.proteamachines.com

32 Shaft Rd

Knights, Germiston

Tel: +2711 828 9935

PROTEA SOD CUTTER

MODEL 460

OPERATING INSTRUCTIONS AND SPARE PARTS

MANUAL

Tel: +2711 828 9935

Mobile: +2782 458 7257

P.O. Box 1673 32 Shaft Road

Bedfordview Knights

2008 Germiston

Gauteng Gauteng

South Africa South Africa

Email: [email protected]

Email: sean@proturf.co.za

For further information on any Protea products, please visit our website www.proteamachines.com

Postal Address

Physical Address

Contact Numbers

Email: [email protected]

CONTACT DETAILS:

1. Know your controls. Read the owner's manual 13. Stop the engine whenever you leave the

carefully. Learn how to stop engine quickly in the mower unattended, even for a moment.

event of an emergency.

14. Stop the engine before pushing the mower

2. Ensure the lawn is clear of sticks, stones, across gravel drives, walks or roads.

wire and debris. They could be thrown

by the blade. 15. Do not allow children or people

unfamiliar with these instructions operate

3. Stop the engine and disconnect the spark plug wire the mower.

before checking or working on the mower.

16. On slopes or wet grass, be extra careful of

4. Before use, always visually inspect to see that the your footing.

blade bolts and cutter assembly are not worn or

damaged. Replace worn or damaged blades and 17. Never cut grass by pulling the mower towards

bolts in sets to preserve balance. you.

Damaged blades and worn bolts are a

major hazard. 18. Never use an electrically powered mower in

the rain or when the grass is wet.

5. Check all nuts, bolts and screws often. Always

ensure the mower is in a safe operating condition. 19. Be extremely careful when using a ride on

Use only replacement parts made and guaranteed

mower on slopes.

by the original manufacturer of your mower.

20. Never leave wind-up starters in a wound

6. Add fuel BEFORE starting engine. Avoid spilling condition.

gasoline and do not fill the tank while the engine is

running or while you are smoking. 21. Do not over speed the engine or alter governor

settings. Excessive speed is dangerous

7. Do not mow whilst people, especially children and shortens mower life.

or pets, are in the mowing area.

22. It is advisable to wear suitable eye protection

8. Never use the mower unless the grass catcher , when operating a mower.

or guards provided by the manufacturer,

are in position. 23. Turn the fuel off at the conclusion of mowing

and reduce the throttle setting during

9. Do not mow barefoot or in open sandals. engine run-out.

Wear long trousers and heavy shoes.

24. Store fuel in a cool place in a container

10. Disengage all blade and drive clutches before specifically designed for the purpose.

starting.

25. Never pick up or carry a mower when it is

11. Start the engine carefully with feet well away operating.

from the blades.

12. Do not operate the engine in a confined space where

exhaust fumes (carbon monoxide) can collect.

LAWNMOWER SAFETY PRECAUTIONS

1

SODCUTTER

MODEL 460

TO OPERATE TURF CUTTER AND ATTACHMENTS

Start motor by using choke and throttle lever. Lift Sodcutter by the handle and adjust depth of cut. Have

motor running about 2000 revolutions per minute. Engage cutter bar so that is oscillates, then engage drive

wheels, and lower Sodcutter slowly on to the grass. The cutter blade will automatically dig into the earth as

you move. At the end of the run, disengage both cutter and drive and then lift blade clear off ground by

lifting machine. The Sodcutter blade is adjustable for hard, soft and normal (center position) soil

conditions.

MAINTENANCE INSTRUCTIONS FOR SOD CUTTER

-Keep drive belts adjusted firmly, using adjustable tensioning screws

-Grease countershaft every three (3) months

-Grease wheel bearing every six (6) months

-Grease conrod bushes (120223) and bearings (1124440) daily

-Check machine regularly for loose bolts

-To sharpen turf cutter blade, re-grind top and sides

-Operating conditions should be taken into account when determining maintenance intervals

-Important: Maintain strong camshaft V belt (3602060 / 3602061) tensioning at all times. As soon

as the tension slackens off, drop the camshaft (120200) downwards into the next slotted hole –both

sides. Finer adjustments can be made with the adjuster screw (120153) on the tensioner assembly.

SPECIFICATIONS

ENGINES ADJUSTMENTS

•Honda GX240HX (8HP) Petrol Blade depth of cut: by pin-in-hole

Driven with 6:1 reduction gear box adjuster

•Kohler CH395 (9HP) Petrol “V”Belts: jacking bolts/sliding bearings

Driven with 6:1 reduction gear box Width of cut: 460mm (18 inch)

Cutting Depth: 6-100mm (1/4 –4 inch)

TRANSMISSION CUTTING TIME

A) Three (3) “V”Belts to crank arm Approximately 1500-2000 square

B) Three (3) V Belts to drive rollers meters per day, depending on soil

C) One (1) “V”Belt from motor to counter shaft condition

BEARINGS CUTTING BLADE

Selected ball and pillar block bearings Heavy-duty precision machined, the

material is high tensile, hardened

tempered

PLEASE NOTE: SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE

SPARE PARTS

PAGE 1

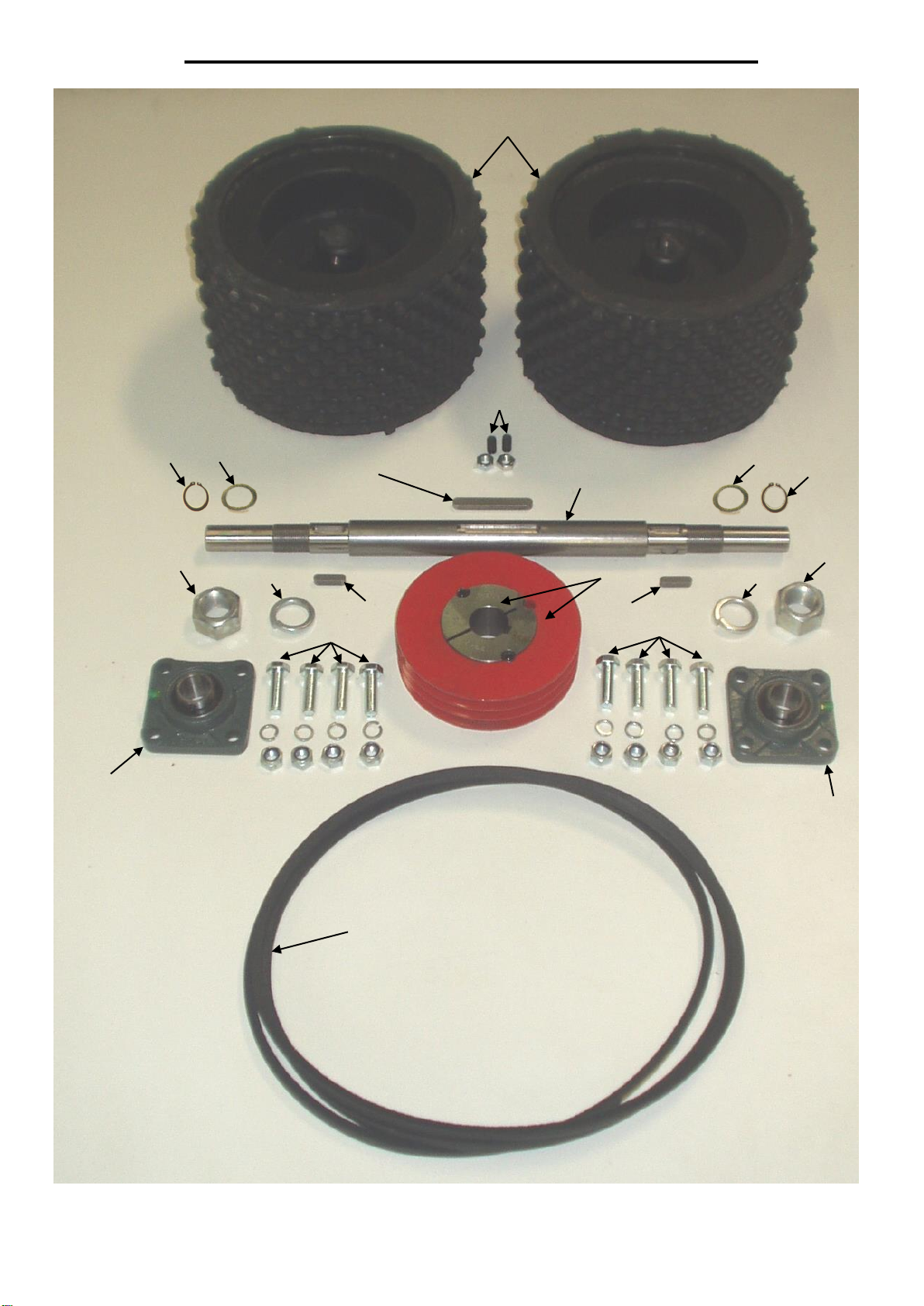

FIGURE 1: FRONT WHEEL ASSEMBLY

1

2

3

4

4

5

5

6

6

8

7

9

9

10

11

11

12

13

12

13

ILLUS. NO DESCRIPTION PART NO

1 FRONT WHEEL (EACH) 120340

2 M10x20 GRUB SCREW + M10 NUT STANDARD

3 FRONT WHEEL PULLEY (COMES WITH TAPER LOCK) 120155

4 FRONT WHEEL BEARING 120446

5 M12x40 SET SCREW + M12 SPRING WASHER + M12 NYLOC NUT STANDARD

6 M30 FRONT WHEEL SPRING WASHER STANDARD

7 "V" BELT - FRONT WHEEL (3 PER MACHINE) 3602050

8 FRONT WHEEL SHAFT 120341

9 FRONT WHEEL KEY (2 PER MACHINE) 120514

10 FRONT WHEEL PULLEY KEY 120515

11 1 1/8" FRONT WHEEL LOCKNUT STANDARD

12 SHAFT WASHER 120585

13 25mm EXTERNAL CIRCLIP 1501052

PAGE 2

REFER FIG. 1

PAGE 3

FIGURE 2: MAIN FRAME ASSEMBLY

1

2

3

6

7

8

9

10

11

12

13

14

15

16

17

18

19

ILLUS. NO DESCRIPTION PART NO

1 HONDA GX240HX - 6:1 REDUCTION 6200500H

1 KOHLER CH395 - 6:1 REDUCTION 6200500K

2 ENGINE PULLEY: HONDA 120151

2 ENGINE PULLEY: KOHLER 120150

3 THROTTLE CABLE 656720

4 M8x25 ENGINE PULLEY GRUB SCREW (NOT SHOWN) STANDARD

5 ENGINE PULLEY KEY (NOT SHOWN) 120516

6 ENGINE PULLEY CAP & BOLT 120154

7 ENGINE GUARD: HONDA 120191

7 ENGINE GUARD: KOHLER 120192

8 MAIN FRAME 120230

9 "V" BELT GUIDE 120519

10 BELT GUARD BRACKET 120555

11 BELT TENSIONER LEVER 120152

12 HANDLE GRIPS (SET) 1851069

13 BELT TENSIONER LEVER BRACKET 120509

14 M10x70 SET SCREW + M10 NUT STANDARD

15 M8x40 SET SCREW + M8 NUT STANDARD

16 EXHAUST DEFLECTOR 658362

17 SWIVEL CASTOR WHEEL 6361800

18 BELT GUARD RUBBER 120497

19 BELT GUARD 120495

PAGE 4

REFER FIG. 2

PAGE 5

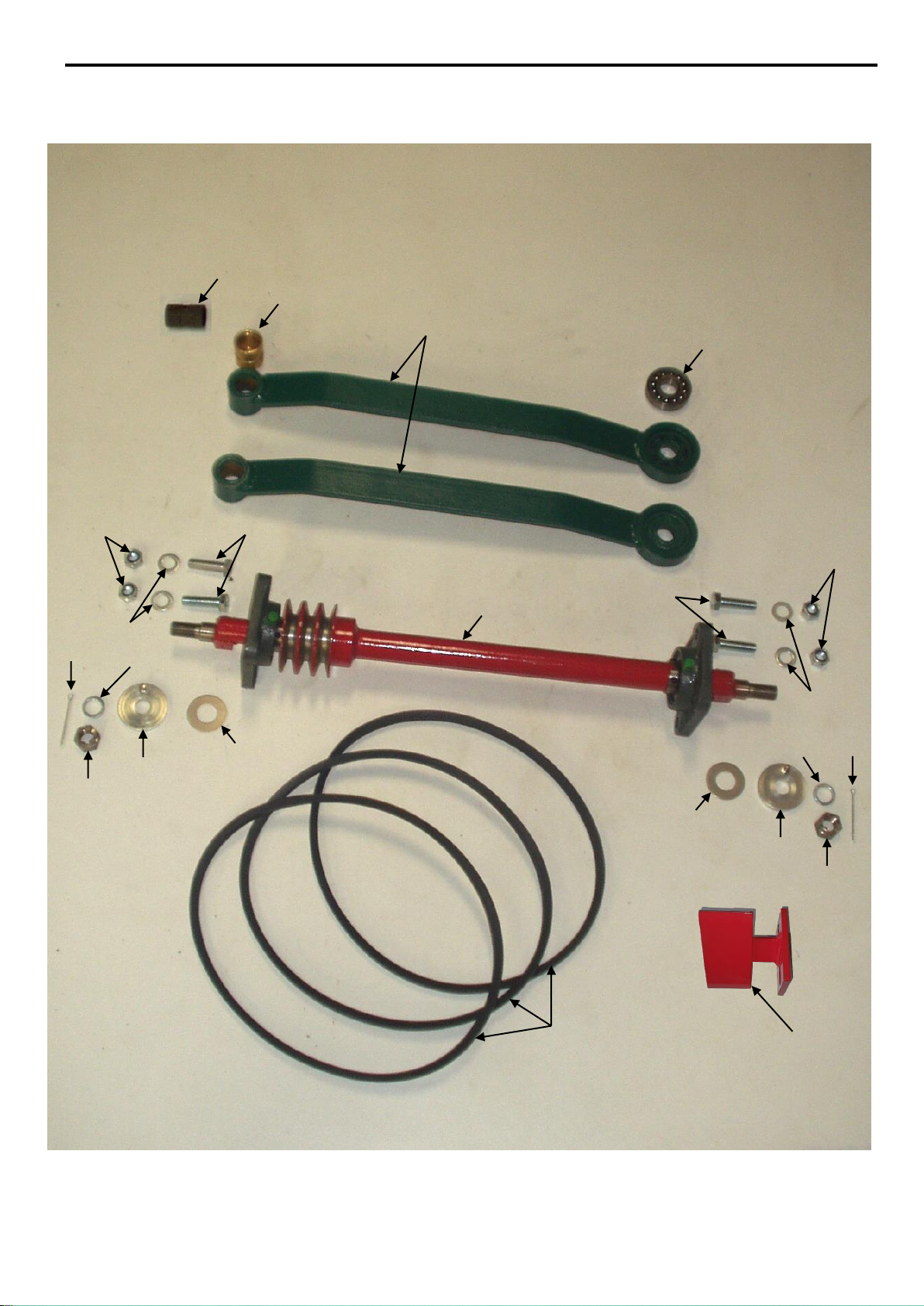

FIGURE 3: COUNTERSHAFT ASSEMBLY

2

1

3

4

5

5

6

6

8

8

9

9

7

7

7

7

10

10

11

12

13

13

ILLUS. NO DESCRIPTION PART NO

1 COUNTERSHAFT 120331

2 COUNTERSHAFT PULLEY: 3 GROOVES (COMES WITH GRUB SCREWS) 120330

3 COUNTERSHAFT PULLEY: 1 GROOVE (COMES WITH TAPERLOCK) 120332

4 "V" BELT - COUNTERSHAFT (1 PER MACHINE) 3602040

5 COUNTERSHAFT BEARINGS 1125550

6 M12 SPRING WASHER STANDARD

7 M12x40 SET SCREW STANDARD

8 M12 NUT STANDARD

9 M12 FLAT WASHER STANDARD

10 25mm EXTERNAL CIRCLIP 1501052

11 COUNTERSHAFT KEY (LONG) 120512

12 COUNTERSHAFT KEY (SHORT) 120513

13 SHAFT WASHER 120585

PAGE 6

REFER FIG. 3

PAGE 7

FIGURE 4: HEIGHT ADJUSTER LEVER ASSEMBLY

1

2

3

4

4

4

4

5

5

5

5

6

6

7

8

9

10

11

12

12

13

13

14

15

15

16

16

17

17

17

17

18

18

19

20

ILLUS. NO DESCRIPTION PART NO

1 HEIGHT ADJUSTER LEVER 120020

2 BELT TENSIONER LEVER 120152

3 HEIGHT ADJUSTER ARM 120201

4 HEIGHT ADJUSTER LEVER PIVOT BOLT 120212

5 PIVOT SLEEVE 120211

6 M10 CASTLE NUT 2641303

7 HEIGHT ADJUSTER CLIP 120203

8 HEIGHT ADJUSTMENT PIN 120202

9 HEIGHT ADJUSTER RUBBERS (SET) 120510

10 HEIGHT ADJUSTER SUPPORT ANGLE 120511

11 SIDE ARM 120210

12 SIDE ARM BUSH 120213

13 M10x40 CAP SCREW + FLAT WASHER + SPRING WASHER + NYLOC NUT STANDARD

14 SOD CUTTER BLADE 120174

15 5/8" UNF CASTLE NUT 2641300

16 SIDE ARM GREASE COVER 120590

17 M3x50 SPLIT PIN STANDARD

18 M16 SPRING WASHER STANDARD

19 M10x70 SET SCREW + M10 FLAT WASHER + 2xM10 NUTS STANDARD

20 HEIGHT ADJUSTER REINFORCING PLATE 120700

PAGE 8

REFER FIG. 4

PAGE 9

FIGURE 5: CONROD AND CAMSHAFT ASSEMBLY

1

2

3

2

4

6

5

7

7

8

8

9

9

10

10

11

11

12

13

13

14

14

15

15

ILLUS. NO DESCRIPTION PART NO

1 CONROD ASSY (C/W BEARING (1124440) & BRONZE BUSH (120223)) 120220

2 CAMSHAFT ASSY 120200

3 CAMSHAFT "V" BELTS - STANDARD (3 PER MACHINE) 3602060

3 CAMSHAFT TRUEBLUE "V" BELTS - HEAVY DUTY (3 PER MACHINE) 3602061

4 CONROD SWIVEL BEARING 1124440

5 SIDE ARM INNER BUSH FOR BRONZE BUSH 120213

6 CONROD BRONZE BUSH 120223

7 OUTER GREASE COVER 120570

8 INNER GREASE COVER 120225

9 5/8" UNF CASTLE NUT 2641300

10 M12x40 SET SCREW STANDARD

11 M12 NYLOC NUT STANDARD

12 CAMSHAFT "V" BELT GUIDE 120519

13 M12 FLAT WASHER STANDARD

14 M16 SPRING WASHER STANDARD

15 M3x50 SPLIT PIN STANDARD

PAGE 10

REFER FIG. 5

PAGE 11

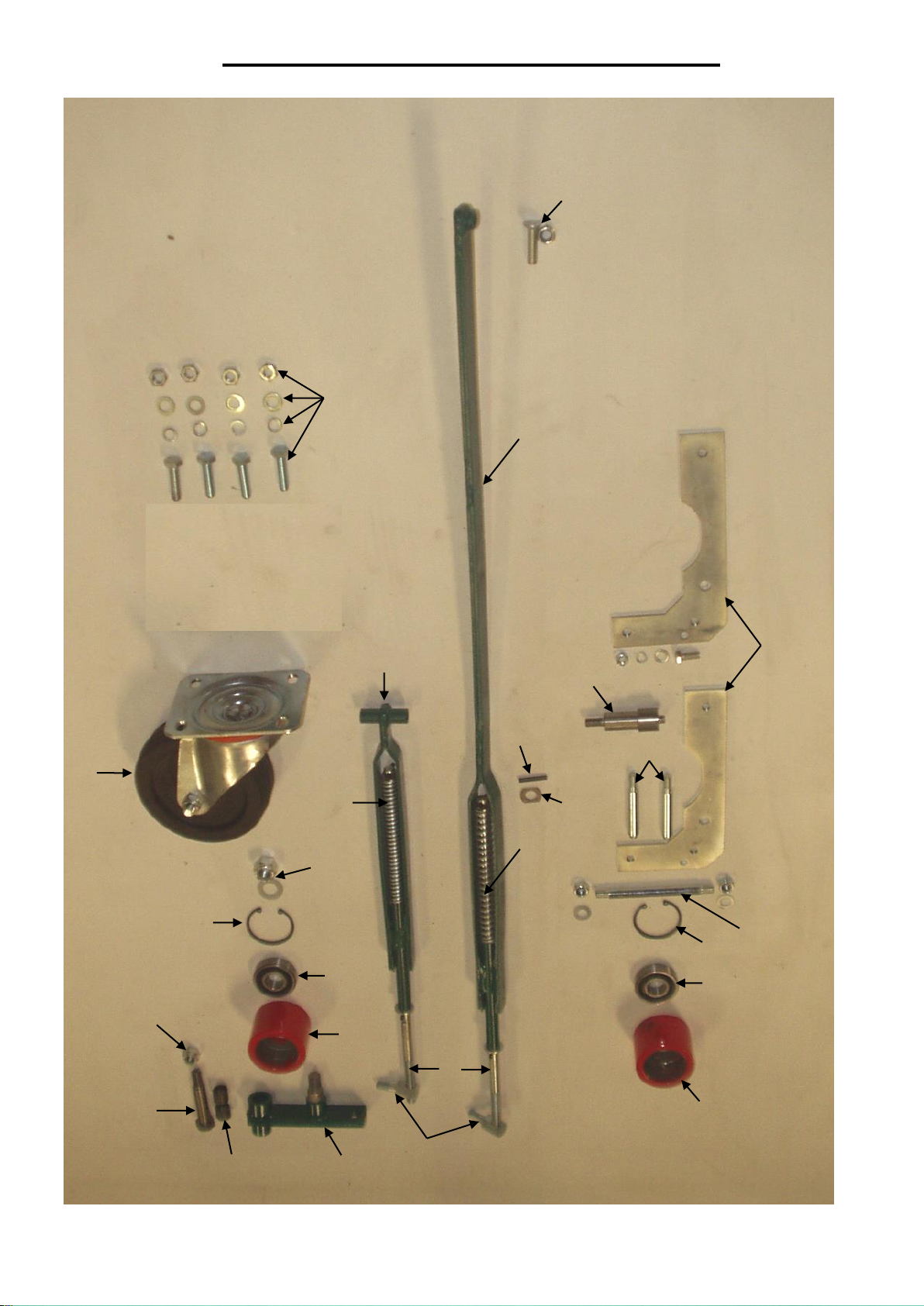

FIGURE 6: BELT TENSIONERS

2

3

1

4

5

6

7

8

9

10

10

11

12

13

14

15

16

17

8

9

18

19

20

21

22

23

ILLUS. NO DESCRIPTION PART NO

1 ENGINE PULLEY TENSIONER COMPLETE ASSEMBLY (LONG) 120181

2 ENGINE PULLEY TENSIONER SPRING 120560

3 SPRING ROD 120179

4 1/8" x 1" SELLOCK PIN STANDARD

5 FRONT WHEEL PULLEY TENSIONER COMPLETE ASSEMBLY (SHORT) 120180

6 TENSIONER WASHER 120575

7 FRONT WHEEL PULLEY TENSIONER SPRING 120562

8 6304 JOCKEY PULLEY BEARING 1123423

9 52mm INTERNAL CIRCLIP 1502520

10 JOCKEY PULLEY 120182

11 M10x40 COUNTERSUNK SCREW + M10 NYLOC NUT STANDARD

12 FRONT WHEEL BELT TENSIONER SIDE PLATES (EACH) 120185.1

13 FRONT WHEEL BELT TENSIONER BEARING SHAFT 120185.4

14 FRONT WHEEL BELT TENSIONER PIVOT BAR 120550

15 FRONT WHEEL BELT TENSIONER STUD 120185.2

16 SWIVEL CASTOR WHEEL 6361800

17 M10x30 SET SCREW + FLAT WASHER + SPRING WASHER + NUT STANDARD

18 JOCKEY PULLEY BRACKET 120021

19 ADJUSTER SCREW 120149

20 JOCKEY PULLEY BRACKET BUSH 3111030

21 1/2" UNF NYLOC NUT STANDARD

22 JOCKEY PULLEY PIVOT BOLT 120190

23 5/8" UNF NYLOC NUT + M16 FLAT WASHER STANDARD

PAGE 12

REFER FIG. 6

Other manuals for SODCUTTER 460

1

Table of contents

Other PROTEA Cutter manuals

Popular Cutter manuals by other brands

Maruyama

Maruyama MC2600RS Owner's/operator's manual

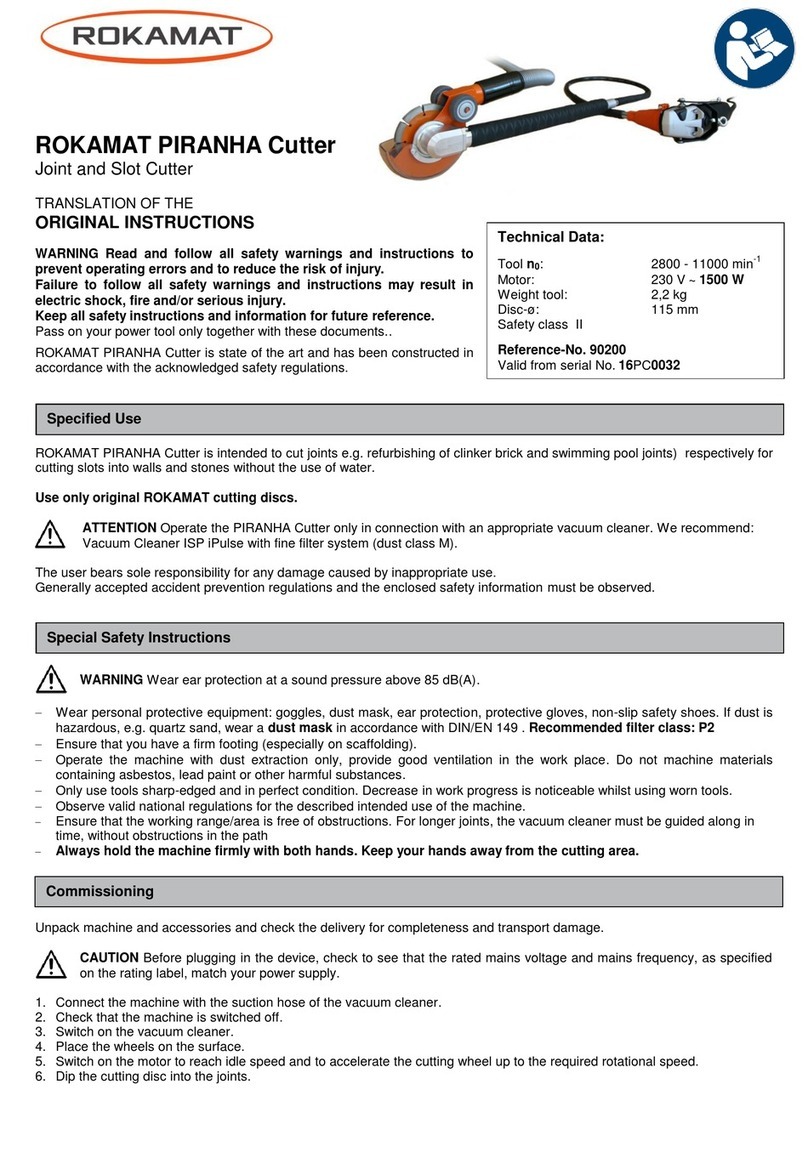

ROKAMAT

ROKAMAT PIRANHA Translation of the original instructions

Ilsco

Ilsco TaskMaster TB-CUT25-I instruction manual

QEP

QEP Vitrex Clinker XL owner's manual

Profitech Diamant

Profitech Diamant SC 350-6 instruction manual

Parkside

Parkside PSFS 250 A1 manual