ProTec Polymer Processing FG 20 Series User manual

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

2

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

3

Table of Contents

1Introduction......................................................................................6

1.1 The FG 20x conveyor................................................................................. 6

1.1.1 Intended use ............................................................................................................. 6

1.1.1 Improper use............................................................................................................. 6

1.2 About this Manual ...................................................................................... 6

1.3 Model plates and serial number.................................................................. 7

1.4 Warranty .................................................................................................... 7

2Safety................................................................................................8

2.1 Safety labelling........................................................................................... 8

2.1.1 Structure of the warning information......................................................................... 8

2.1.2 Safety labelling and meanings.................................................................................. 9

2.2 Personnel selection and qualification ........................................................10

2.3 Safety-related instructions for specific operating phases...........................10

2.3.1 Normal operation .................................................................................................... 10

2.3.2 Special operating modes ........................................................................................ 11

2.4 Instructions for special types of risks.........................................................12

2.4.1 Electrical energy ..................................................................................................... 12

2.5 Declaration of Conformity..........................................................................12

3Technical Data and Structure .......................................................13

3.1 Conveyor / station designation key............................................................13

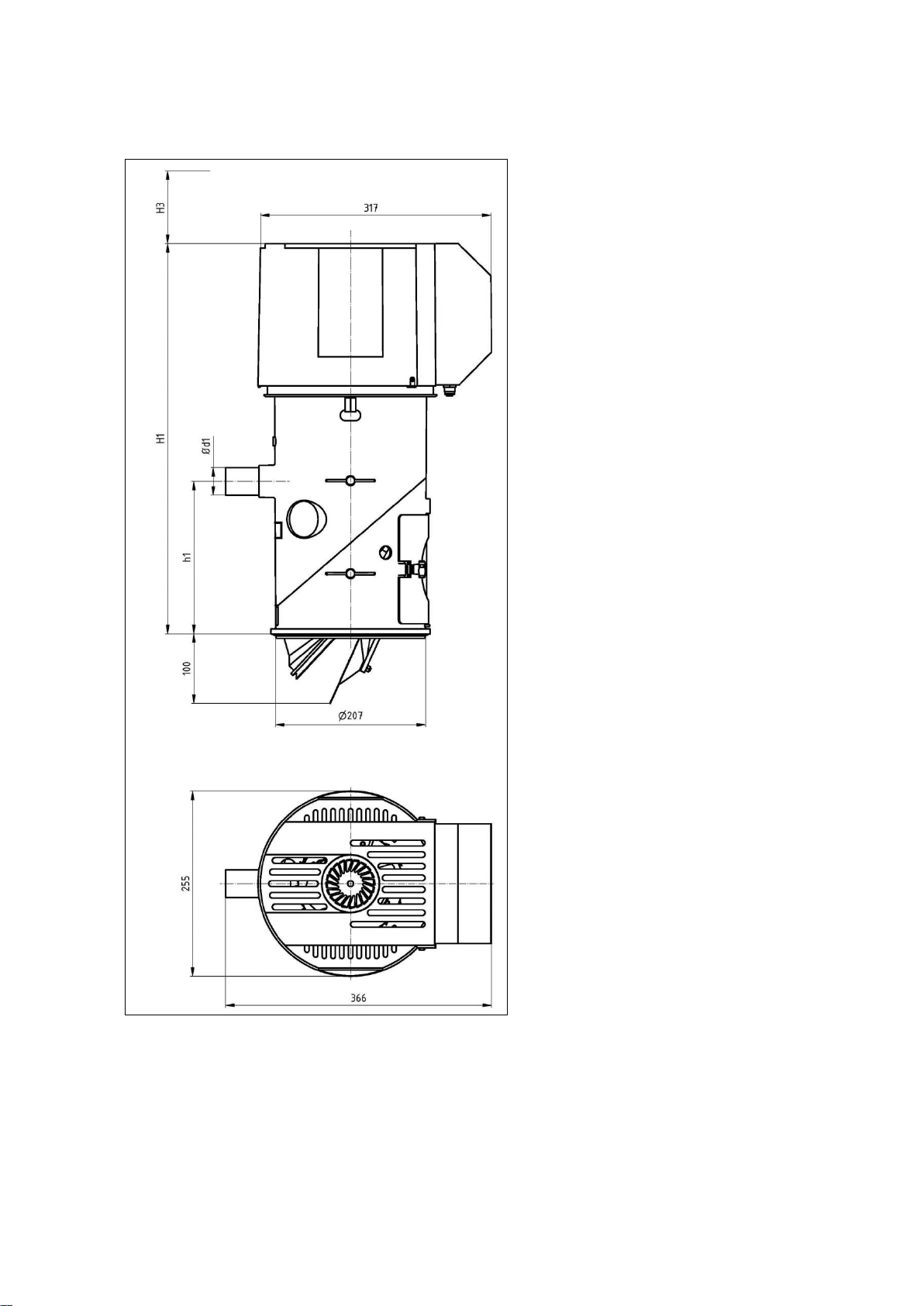

3.2 Dimensional drawing FG 201 to FG 204....................................................14

3.2.1 Dimensions ............................................................................................................. 15

3.2.2 Electrical data..........................................................................................................15

3.2.3 Environmental requirements................................................................................... 15

3.2.4 Materials.................................................................................................................. 15

3.2.5 Noise emissions < 80 dB (A) ................................................................................ 15

3.2.6 Options....................................................................................................................15

3.2.7 Weight.....................................................................................................................15

3.2.8 Compressed air.......................................................................................................15

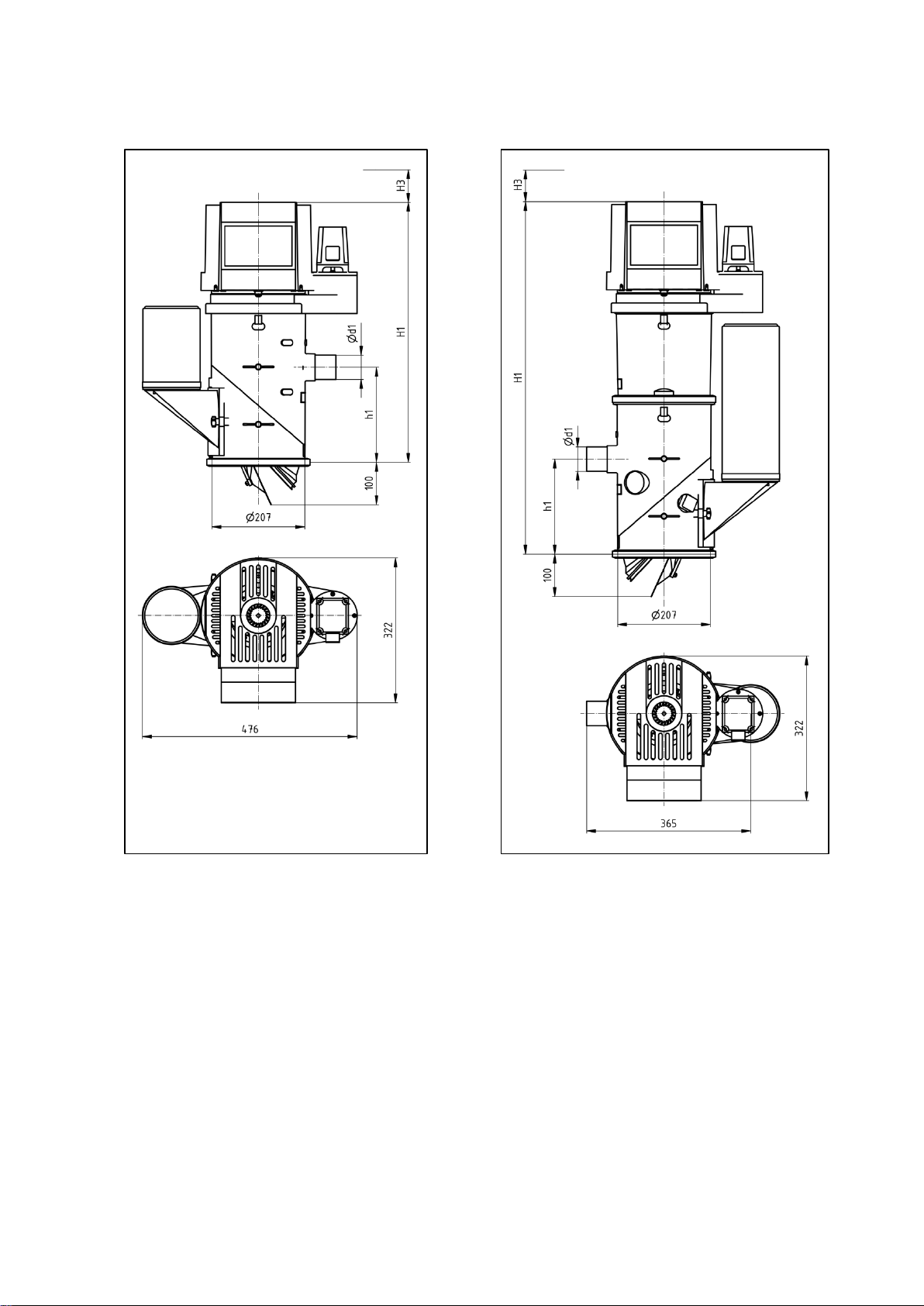

3.3 Dimensional drawing FG 205 to FG 206....................................................16

3.3.1 Dimensions ............................................................................................................. 17

3.3.2 Electrical data..........................................................................................................17

3.3.3 Environmental requirements................................................................................... 18

3.3.4 Materials.................................................................................................................. 18

3.3.5 Noise emissions < 80 dB (A) ................................................................................ 18

3.3.6 Options....................................................................................................................18

3.3.7 Weight of conveyor without options........................................................................ 18

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

4

3.3.8 Compressed air.......................................................................................................18

3.4 Assembling ...............................................................................................19

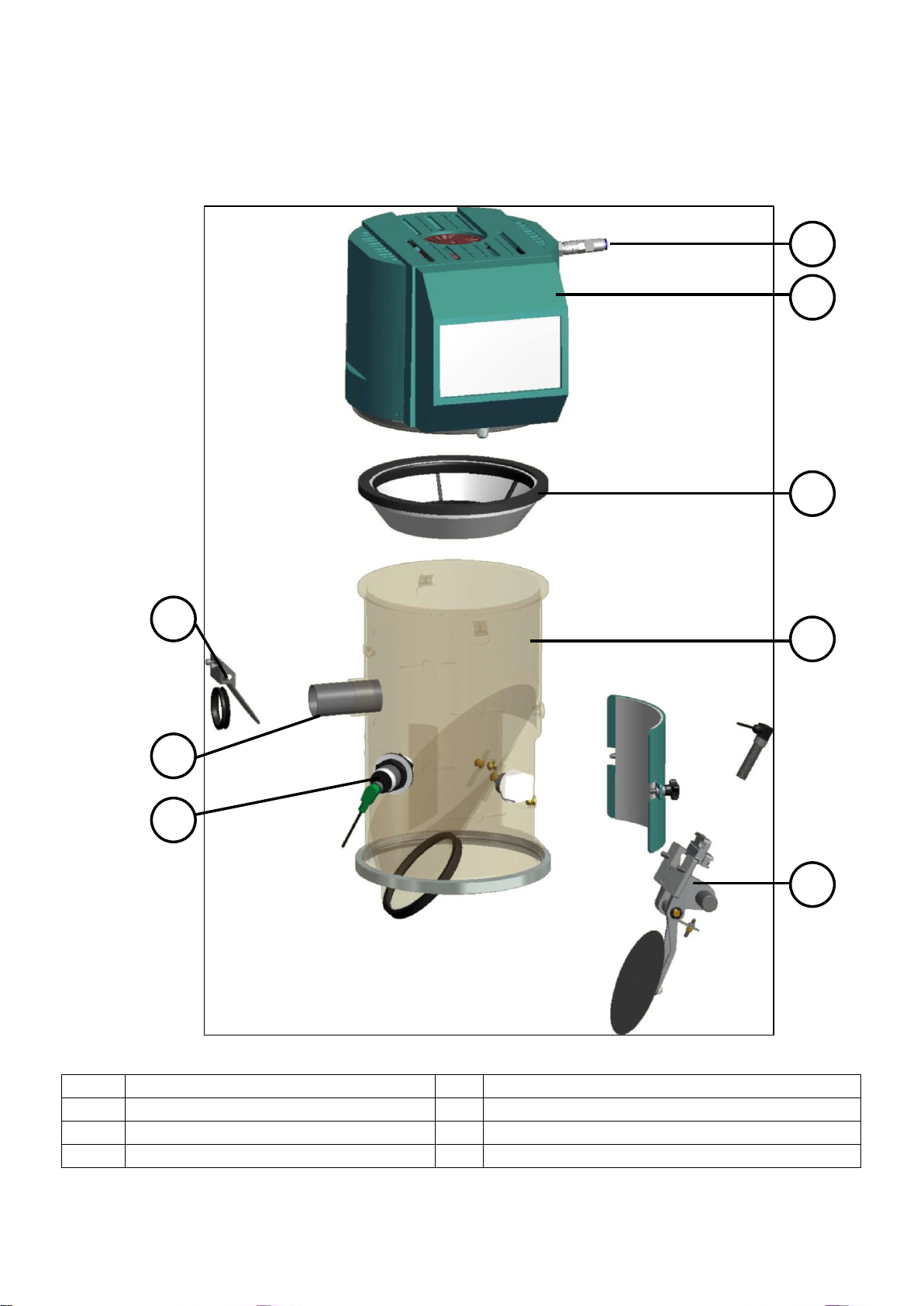

3.4.1 FG 201 to FG 204................................................................................................... 19

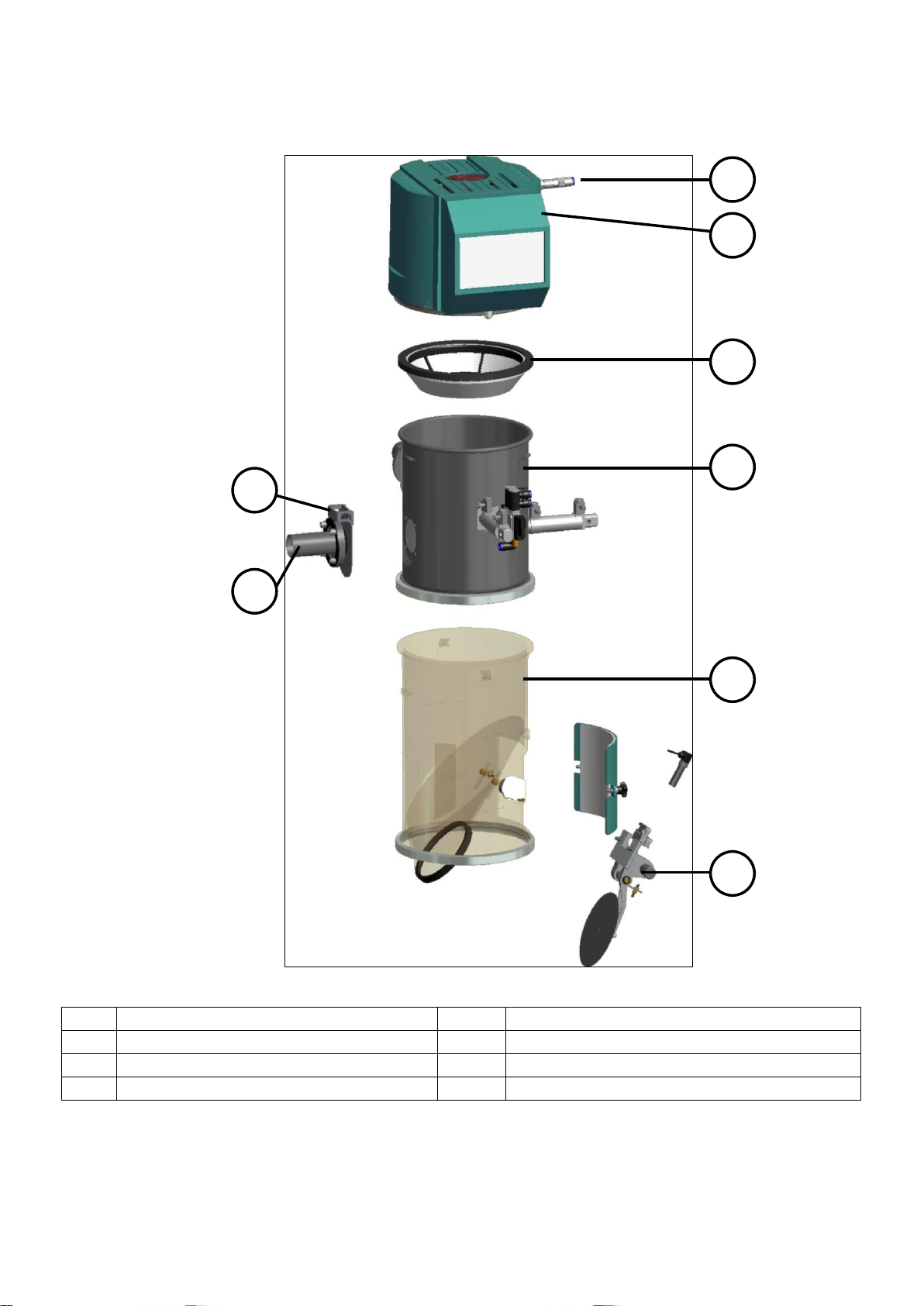

3.4.2 2K - Conveyor FG 201 to FG 204........................................................................... 20

3.4.3 Conveyor FG 205 to FG 206...................................................................................21

3.4.4 Function .................................................................................................................. 22

3.4.5 Automatic cleaning of the conveying air filter .........................................................22

3.4.6 Feed of a 2nd component.......................................................................................23

3.4.7 Empty suctioning (suction valve, accessory).......................................................... 23

3.5 OPTION and function: Separator OFF- and acknowledgement switch ......23

4Assembly/Disassembly.................................................................24

4.1 Mounting accessories................................................................................25

4.2 Connecting conveying line.........................................................................26

4.2.1 Earthing of conveyors and conveyor lines.............................................................. 26

4.2.2 Earthing the conveyor line ...................................................................................... 27

4.2.3 Earthing on a base plate / frame (example)............................................................ 30

4.2.4 Mounting a suction hose.........................................................................................31

4.2.5 Devices with automatic cleaning of the conveying air filter / dosing attachment.... 32

4.3 Disassembly..............................................................................................33

4.4 Storage and transport................................................................................33

4.5 Disposal....................................................................................................34

5Commissioning..............................................................................35

6SOMOS® control/basic –device control system........................36

7Options + Accessories..................................................................37

7.1 Filling level indicator (Optional) .................................................................43

7.2 2K- turnout and suction valve....................................................................44

7.3 Other connection options...........................................................................44

7.3.1 External fault indicator (lamp, alarm)...................................................................... 44

7.3.2 External START/STOP switch................................................................................ 44

7.4 Equipment and options..............................................................................45

7.4.1 Volume expansion stainless steel...........................................................................45

7.4.2 Dosing attachment (optional instead of volume expansion)................................... 46

8Service and maintenance..............................................................47

8.1 Clean conveyor .........................................................................................47

8.1.1 Cleaning or replacing conveying air filter................................................................ 49

8.1.2 Replacing the conveying air filter............................................................................ 49

8.1.3 Cleaning/replacing the balance filter (no continuous service) ................................51

8.2 Service......................................................................................................52

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

5

8.3 Removing the blower attachment..............................................................52

8.3.1 Before maintenance................................................................................................ 52

8.3.2 Replacing the carbon brushes................................................................................53

8.3.3 Replacing the blower ..............................................................................................55

8.3.4 Removing the blower (Version FG 201 and FG 204) .............................................55

8.3.5 Install new blower (Version FG 205 and FG 206)................................................... 56

8.3.6 Plug in the cable ..................................................................................................... 57

8.3.7 Earthing blower....................................................................................................... 58

8.3.8 Replacing the compressed air valve on the cleaning valve.................................... 59

8.4 Conveyed goods container........................................................................60

8.4.1 Replacing the proximity switch................................................................................ 60

8.4.2 Replacing the V-gasket on the discharge flap........................................................ 60

8.4.3 Replacing the discharge flap assembly ..................................................................61

8.4.4 Replacing the plate on the discharge flap............................................................... 61

8.4.5 Replacing check valve ............................................................................................62

8.4.6 Replacing the V-gasket on the check valve............................................................63

8.5 Dosing attachment (optional).....................................................................64

8.5.1 Replacing compressed air cylinder 2...................................................................... 65

8.5.2 Replacing compressed air cylinder 1...................................................................... 66

8.5.3 Replacing the control valve.....................................................................................67

9Appendix ........................................................................................69

9.1 Setting the fill level sensor.........................................................................69

9.2 Option: Setting the type B fill level sensor .................................................71

9.2.1 Sensor without cover flap........................................................................................ 71

9.2.2 Capacitive sensors (CAS) can be installed non-flush for level control...................71

9.3 Pneumatic connection diagram (2-K conveyor).........................................73

9.4 Chemical resistance of the material container...........................................74

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

6

1 Introduction

1.1 The FG 20x conveyor

1.1.1 Intended use

The FG 20x is a plastic granulate conveyor designed for industrial use. Its exclusive use is for

the conveying of free-flowing plastic granulate or mill stock. Any use deviating from this is not

intended use and must have a written approval from ProTec Polymer Processing GmbH. For

uncertainties in the use of your mill stock or in the operation of your conveyor please contact

ProTec Polymer Processing GmbH customer service.

1.1.1 Improper use

Conveying ignitable or metallic substances.

Conveying liquid materials.

Loads above the rating limits in terms of operating time and volume.

Use in explosion-endangered areas or in open air.

1.2 About this Manual

This operating manual should make it easier for you to learn about the system and its proper

use.

The operating manual contains important information about operating the system safely and

properly. Your compliance helps:

Hazards to avoid.

Reducing downtimes.

Increasing the reliability and lifetime.

The operating manual must be read and used by any person that is authorized to work with or

on the system and must be available and easily accessible to these persons, especially for:

Operation (including fitting, troubleshooting and error removal during work sequences,

removing production waste, care, disposal of operating and auxiliary materials).

Maintenance (maintenance, inspection, service).

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

7

1.3 Model plates and serial number

Model plate with information for device

1.4 Warranty

Exclusively use original replacement parts from ProTec Polymer Processing GmbH.

Independent modifications or add-ons and the use of replacement parts that are not approved by

ProTec Polymer Processing GmbH lead to the loss of warranty and guarantee. The illustrations

in this operating manual can deviate from the actual design. This does not affect informational

content and facts.

1

Device description and series

2

Consecutive serial number and year of manufacture

3

Component number/ order number / possible

position number in the order

4

Data on power connection

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

8

2 Safety

The system was built to the technical state of the art and the recognised safety rules and

regulations. However, with its use, there can occur hazards for life and limb of the user or third

parties or negative influences on the system and other property.

The system must only be used in technically perfect condition as well as to intended use, safety

and hazard conscious observing this operating manual! Especially malfunctions that could

negatively influence the safety must be remedied immediately.

2.1 Safety labelling

2.1.1 Structure of the warning information

The following signal words are used in connection with the safety labelling to display certain

hazards in this document.

Danger!

Death or severe injuries will occur, if the corresponding

precautionary measures are not made.

Warning!

Death or severe injuries may occur, if the corresponding

precautionary measures are not made.

Caution!

Slight injuries can occur if the corresponding precautionary

measures are not made.

Caution!

Property damage may occur if the corresponding precautionary

measures are not made.

Information

Here you receive information and instructions for effective and safe

execution of the following activities.

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

9

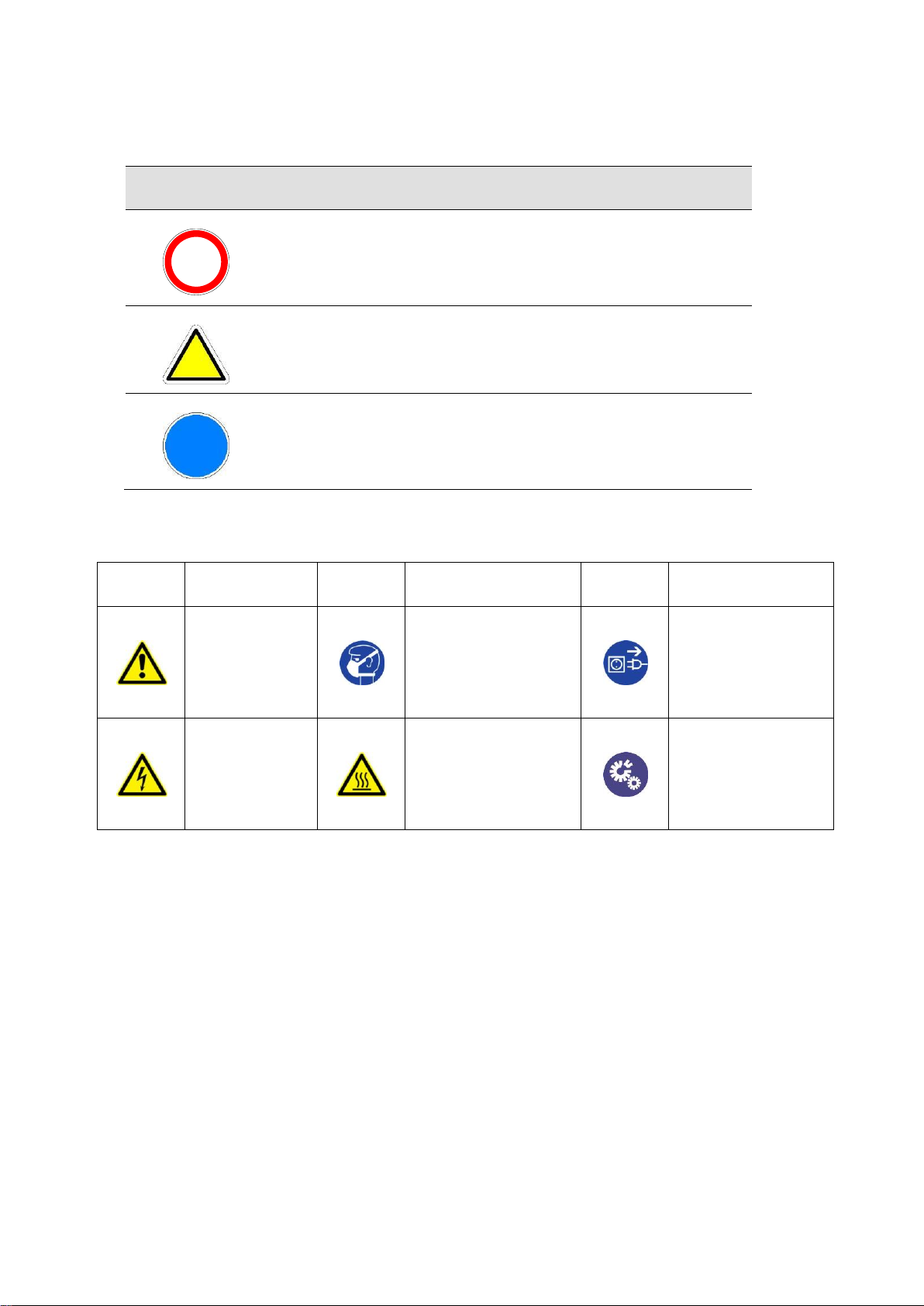

2.1.2 Safety labelling and meanings

The meaning of safety labels is indicated by their shape and colour.

Shape

Colour

Meaning

Safety colour red

Contrast colour white

Prohibited

Safety colour yellow

Contrast colour black

Warning

Safety colour blue

Contrast colour white

Order

The following symbols are used in the manual:

Symbol

Description

Symbol

Description

Symbol

Description

Warning!

Follow

information!

Caution!

Fine dust:

Wear breathing

protection!

Caution! Danger!

Disconnect device

from power!

Danger!

Electric

current!

Danger to life!

Danger of injury!

Hot!

Do not touch!

Caution!

Damages to the

equipment

possible.

Only open or remove protective and safety equipment for service work. Before

commissioning, these must be remounted / repowered.

Systems and units must be depressurised before opening.

Comply with maintenance and service intervals!

Keep all safety instructions and hazard warnings on the equipment complete and legible!

Carry out daily visual inspections for outwardly recognisable damage and deficiency!

Immediately report any changes that occur (including the operating behaviour) to the

responsible department/ person! In the case of functional faults the equipment must be

immediately shut down and secured! Malfunctions should be immediately remedied.

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

10

Never do this:

Operating the equipment outside of given parameters.

Any changes to the device NOT APPROVED by ProTec Polymer Processing GmbH.

2.2 Personnel selection and qualification

Only use trained or instructed personnel. Clearly establish responsibilities of the personnel

for operation, fitting, servicing and repair!

Make sure that only authorised personnel are working on the system!

Establish responsibilities of the system operator and empower him to reject unfavourable

safety instructions from third parties!

Personnel that are being trained, instructed or are in the scope of a general apprenticeship

should only be working on the system under the continual supervision of an experienced

person!

Working on electrical equipment of the system must only be done by an electrician or

trained persons under the guidance and supervision of an electrician according to the

electrotechnical regulations!

Work on hydraulic equipment may only be performed by personnel with special hydraulic

knowledge and experience!

2.3 Safety-related instructions for specific operating phases

2.3.1 Normal operation

Only operate the machine if all safety equipment and safety-related equipment, e.g.

removable safety equipment, Emergency Stop equipment, soundproofing, exhaust

equipment, etc. are present and functional!

Support highly constructed equipment! Especially in connection with dynamic loads, high

constructional parts on the system have to be additional support.

At least once per shift check the system for visible damage and deficiencies! Immediately

report any changes that occur (including the operating behaviour) to the responsible person

/ department! If necessary, immediately stop the system and secure it!

Before switching on / engaging the system make sure that no one is endangered by the

running system!

Observe switching on and off processes, control indicators.

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

11

2.3.2 Special operating modes

Comply with settings, service and inspection activities and intervals including information on

replacing parts / subassemblies specified in the operating manual. These activities must

only be performed by specialist authorised personnel.

Inform operating personnel before starting to perform special and maintenance work! Name

supervisors!

Ensure that the maintenance area is as adequately secured as necessary! If the system is

completely switched off during maintenance and repair work it must be secured against

restart:

Lock the main command device and pull out the key

Attach a warning sign on the main switch

Always tighten any loosened screwed connections during maintenance and repair work!

If the removal of safety equipment is required during fitting, maintenance and repair, it

should be reassembled immediately after completing the maintenance/repair work.

Larger single parts and assemblies must be carefully fastened and secured on hoisting gear

during replacement, so that no hazards occur here. Use only suitable and technically

correct hoisting devices and load attachment devices with sufficient load carrying capacity!

Do not stand or work under swinging loads!

When performing installation work above body height use ascending aids and work

platforms provided for this or other safety-related ones. Do not use system parts as

ascending aid! Wear fall protection when working at great heights!

Keep all handles, steps, railings, pedestals, platforms, ladders, etc. free of dirt!

Clean the systems, and especially here connections and screwed joints, before starting

maintenance/repair of oil, fuel or cleaning materials! Do not use any aggressive cleaning

agents! Use lint-free cleaning cloths!

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

12

2.4 Instructions for special types of risks

2.4.1 Electrical energy

Only use original fuses with specific current rating! For faults in the electrical supply, switch

off the system immediately!

Working on electrical equipment or operating equipment must only be done by an

electrician or trained persons under the guidance and supervision of an electrician

according to the electrotechnical regulations.

The power to system parts, on which inspection, service and repair work is performed, must

be switched off, if so specified. First check the parts that are switched off if there is no

voltage, then ground and short-circuit as well as insulate adjacent live parts!

The electrical equipment of the system must be inspected and checked regularly. Defects

such as loose connections or scorched cables must be rectified immediately.

If work is required on live parts, a second person who can activate the emergency- off- or

main switch in case of emergency needs to get involved. Block off the work area with a red

and white safety chain and a warning sign. Only use voltage insulated tools.

2.5 Declaration of Conformity

The Declaration of Conformity must be presented in both German and English.

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

13

3 Technical Data and Structure

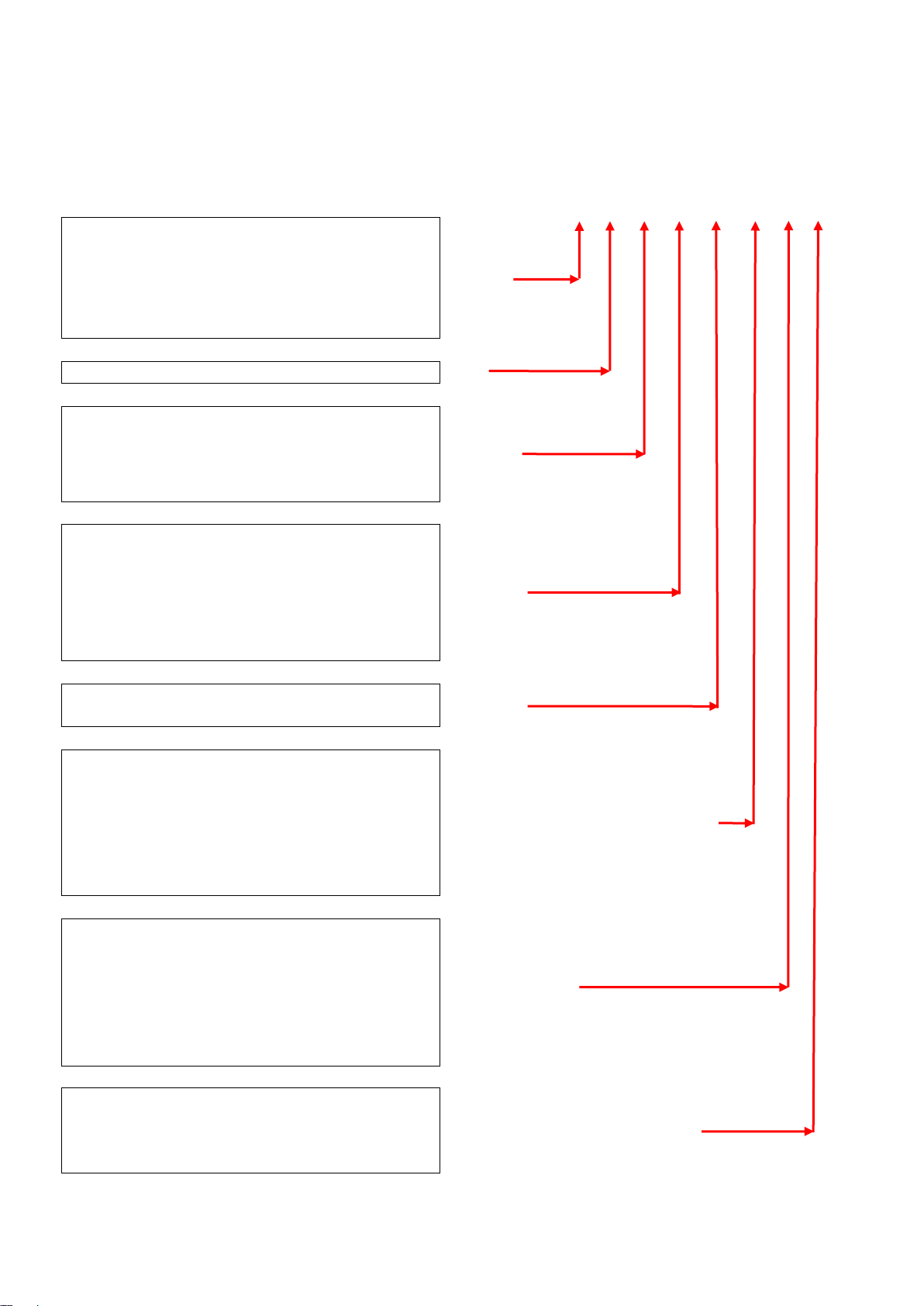

3.1 Conveyor / station designation key

Conveyor / station designation key

FG

2

0

4.

1/

2

1

C

FG = Conveyor / station

Product

ZF = Central filter

FGG = Conveyors for gravimetric dosing unit

(without floor flap)

FG3- = Conveyor installed from ∅315 to ∅200

FG 2K = 2-component conveyor/station

2 = 200 (∅conveyed goods container 200 mm)

Size

0 = Conveyor with blower, central filter installed

Unit type

2 = Conveyor station with filter cartridge cleaning with

circulating air with microcontroller control system for

separate fan station

4 = Conveying station

1 = Cloth filter without cleaning

Filter type

3 = Filter plate

4 = Cloth filter with cleaning (compressed air)

5 = Filter element 0.2 m2 with cleaning (circulating or

compressed air)

6 = Filter element 1.5 m2 with cleaning (circulating or

compressed air)

0 = For separately installed blower station

Blowers

1 = Installed blower (50/60 Hz) 0.8 kW

Material conveyed goods container

1 = PA, low / FGG

2 = PA, high

3 = VA, FGG

4 = VA, high

5 = VA, FGG HG2

6 = VA high HG

0 = Without controls / connection box / terminal box

Electrical design

1 = Microcontroller control system

5 = Terminal box

6 = Plug connection:

A = Murr plug connection- (custom)

B = M12-Y plug connection- (custom)

Plug connection system - design

C = Phönix plug connection

HM = Solenoid

HZ = Lift cylinder

HG2 = Hot granulate max. 150° C

(Normal temperature max. 80°C)

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

14

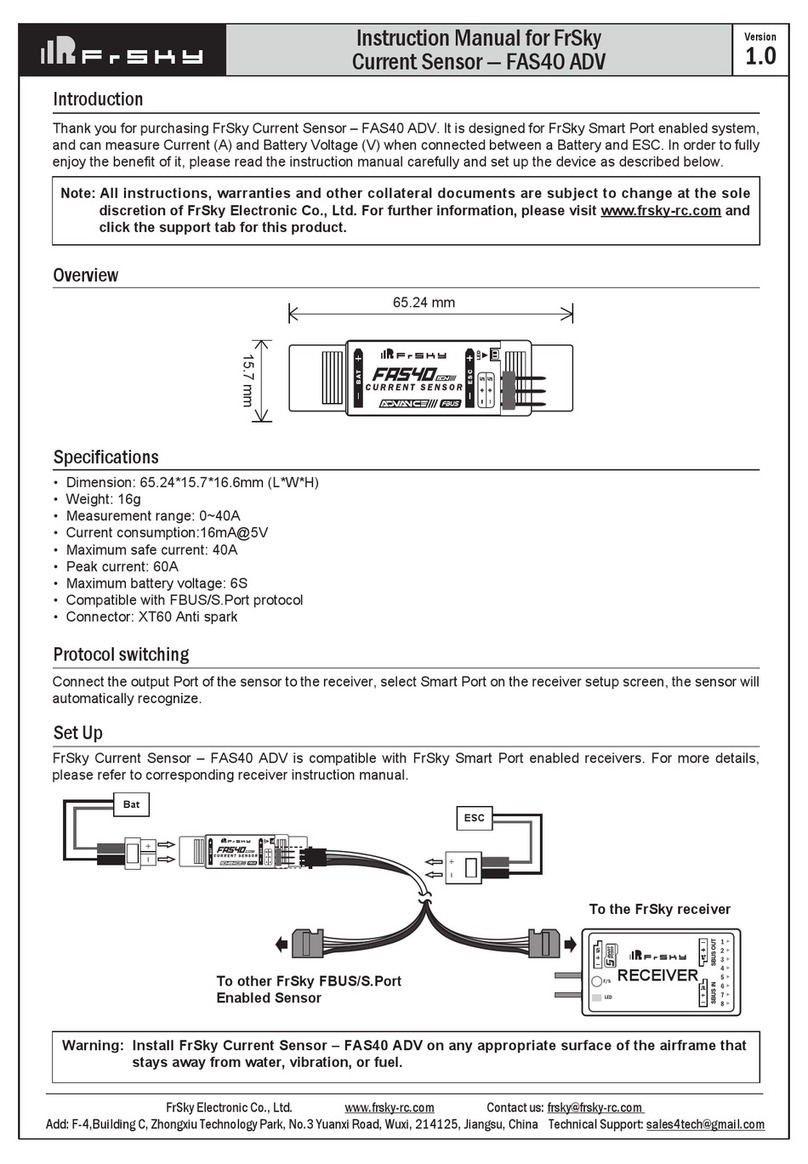

3.2 Dimensional drawing FG 201 to FG 204

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

15

3.2.1 Dimensions

H1 with/without volume expansion 550 / 750 mm

H3 (for filter change) < 200 mm

h1 with/without volume expansion 210 / 410 mm

d1 38 mm

d1 with volume expansion VA 38 or 55 mm

3.2.2 Electrical data

Mains connection 1/N PE AC 50/60Hz 230V

Blower rated output 800 W

Current consumption 4 A

Protection class IP 20

3.2.3 Environmental requirements

Max. Temperature for conveyed material +80 °C

Max. Ambient temperature in operation +5°c … +40°C

Rel. Humidity < 80 %

Noise emissions < 80 dB (A)

3.2.4 Materials

Conveying air filter Cloth filter

Conveyed goods container PA

Discharge flap Stainless steel

Seals EPDM/Perbunan (1

Balance filter Polyester woven fabric

3.2.5 Noise emissions < 80 dB (A)

3.2.6 Options

Volume expansion Stainless steel / PA

Dosing attachment Stainless steel

Filling level indicator Capacitive

3.2.7 Weight

Conveyor without options

FG 201 8.4 kg

FG 204 9.7 kg

For automatic cleaning of the conveying air filter

Compressed air supply

3.2.8 Compressed air

For automatic cleaning of the conveying

air filter

compressed air supply

Excess pressure 4 … 6 bar

Compressed air connection PK 8

Compressed air consumption 3 net litres / conveying cycle

1) Standard design not suitable for use with food!

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

16

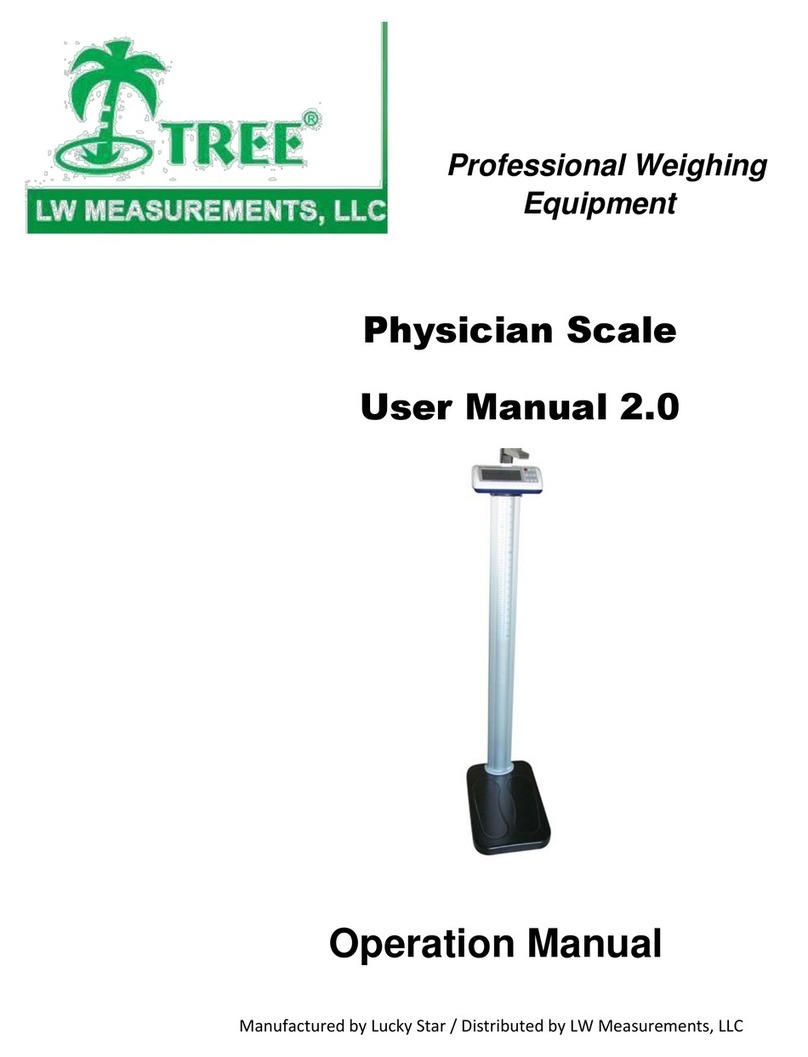

3.3 Dimensional drawing FG 205 to FG 206

FG 205 without options

FG 206 without options

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

17

3.3.1 Dimensions

FG 205

H1 with/without volume expansion: 585 / 785 mm

H3 (for filter change) min. 200 mm

FG 206

H1 with/without volume expansion 785 / 985 mm

H3 (for filter change) min. 400 mm

FG 205.x/3x

H1 without volume expansion 515 mm

H1 with volume expansion 775 mm

H3 (for filter change) min. 200 mm

FG 206.x/3x

H1 without volume expansion 715 mm

H1 with volume expansion 975 mm

H3 (for filter change) min. 400 mm

FG 205.x/4x

H1 without volume expansion 575 mm

H1 with volume expansion 835 mm

H3 (for filter change) min. 200 mm

FG 205 and FG 206

h1 with/without volume expansion 210 / 410 mm

d1 38 mm

d1 with volume expansion VA 38 or 55 mm

FG 206.x/4x

H1 without volume expansion 775 mm

H1 with volume expansion 1,035 mm

H3 (for filter change) min. 400 mm

FG 205 and FG 206

h1 with/without volume expansion 180 / 380 mm

d1 38 mm

d1 with volume expansion VA 38 or 55 mm

3.3.2 Electrical data

Mains connection 1/N PE AC 50/60Hz 230V

Blower rated output 800 W

Control magnet rated output 400 VA

Current consumption 4 A

Protection class IP 20

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

18

3.3.3 Environmental requirements

Max. Temperature for conveyed material +80 °c

Max. Ambient temp. of operation +5 … +50 °c

Rel. Humidity: < 80 %

3.3.4 Materials

Filter element Polyester

Conveyed goods container PA

Discharge flap Stainless steel

Seals EPDM/Perbunan

Balance filter Polyester woven fabric

3.3.5 Noise emissions < 80 dB (A)

3.3.6 Options

Volume expansion Stainless steel / PA

Dosing attachment Stainless steel

Filling level indicator Capacitive

3.3.7 Weight of conveyor without options

FG 205 12.3 kg

FG 206 14.2 kg

3.3.8 Compressed air

Operating pressure 4 to 6 bar, ideal 5 bar

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

19

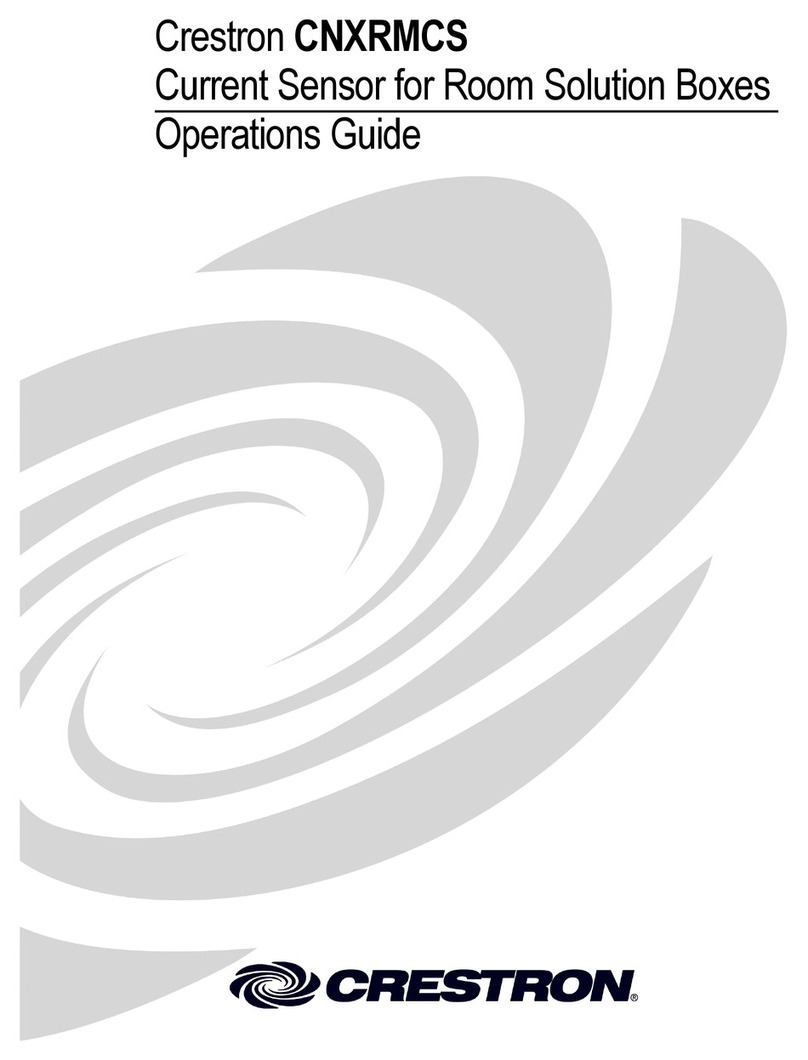

3.4 Assembling

3.4.1 FG 201 to FG 204

1

Blower hood with controls

2

Filter insert (cloth filter)

3

Conveyed goods container

4

Floor flap unit

5

Filling level sensor (Optional)

6

Nozzles

7

Check valve

8

Compressed air connection

8

7

4

3

2

6

5

1

ProTec Polymer Processing GmbH Foerdergeraet_FG201-FG206_BA_1v0_2018_en

20

3.4.2 2K - Conveyor FG 201 to FG 204

1

Blower hood with controls

2

Filter insert (cloth filter)

3

2K-attachment_A FG200 change fct.

4

Lower part FG200 PA

5

Floor flap unit

6

Nozzles

7

Check valve

8

Compressed air connection

8

2

3

1

4

5

7

6

This manual suits for next models

4

Table of contents

Popular Accessories manuals by other brands

Panasonic

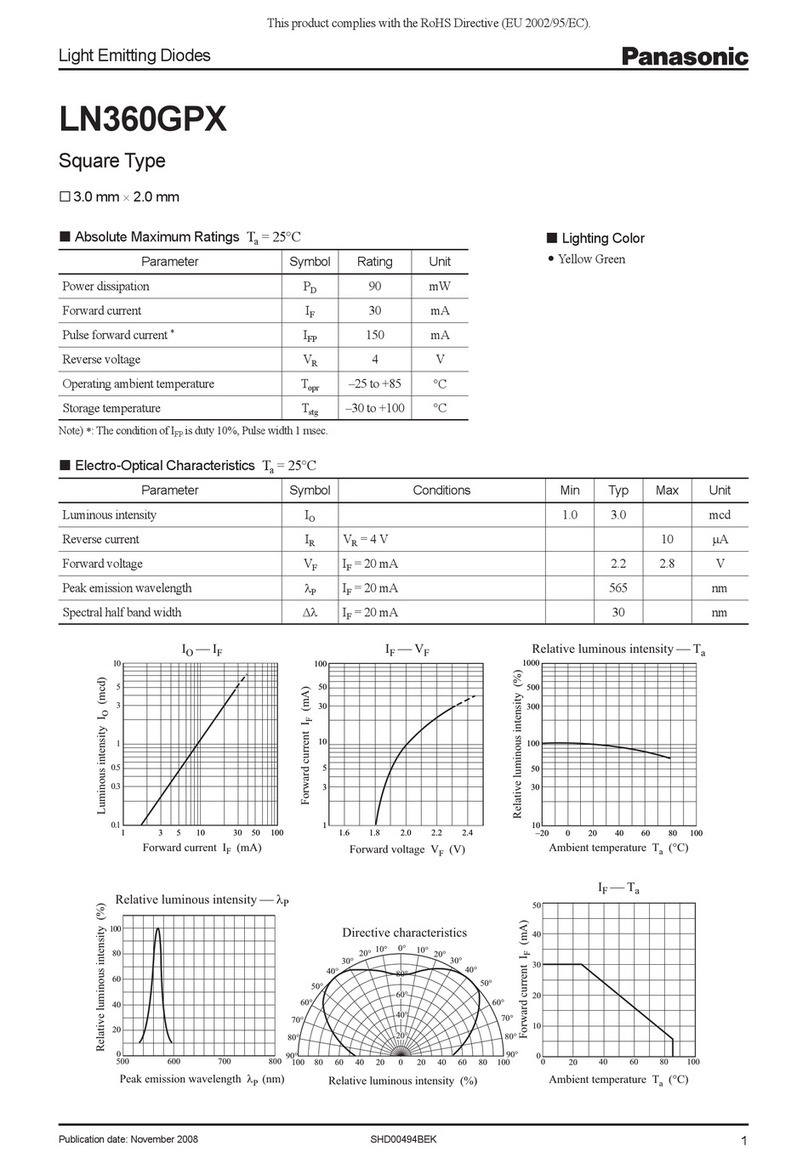

Panasonic Light Emitting Diodes LN360GPX Specifications

Movesense

Movesense MD user guide

EKEN

EKEN V5 user manual

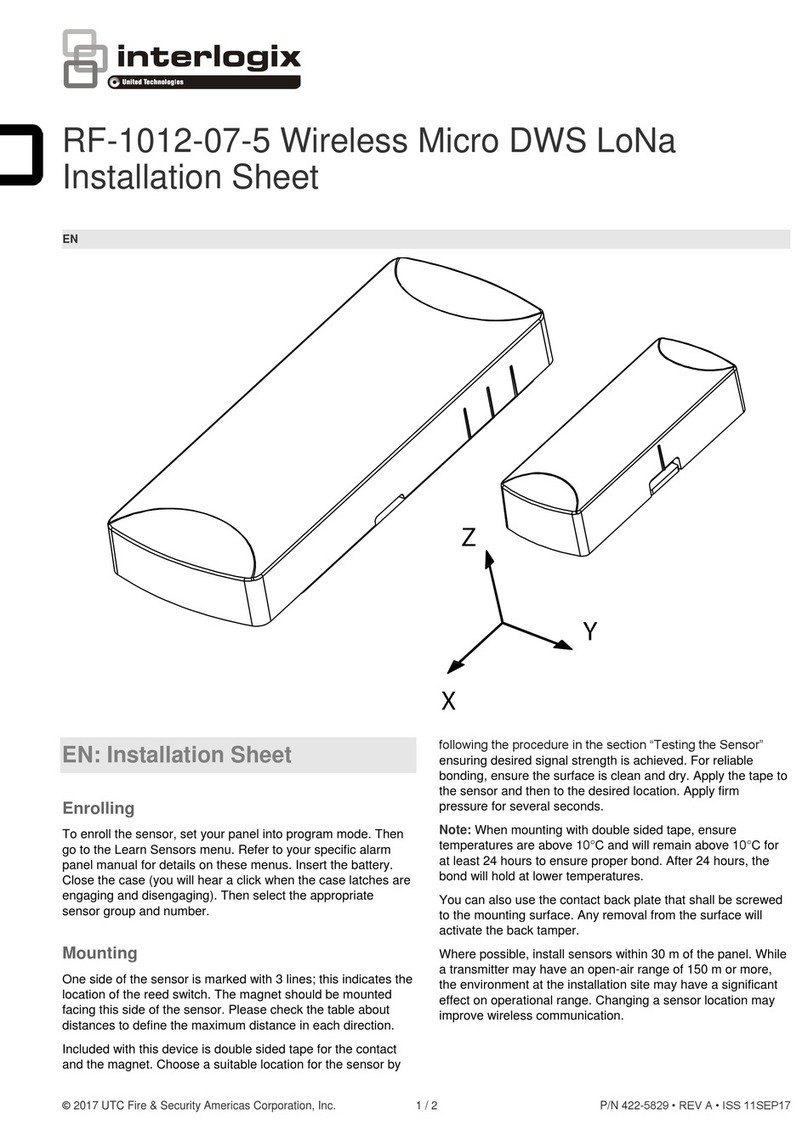

United Technologies

United Technologies Interlogix RF-1012-07-5 Installation sheet

Festo

Festo SDAP-...-M50-Series operating instructions

NINGBO DAVID

NINGBO DAVID YP-970 Operator's manual