Position sensors

SDAP

Festo AG & Co. KG

Postfach

D-73726 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions 8068263

1612a

[8068265]

Original: de

Position sensor SDAP English..........................................

Note

Installation and commissioning only by qualified personnel.

For all available product documentation èwww.festo.com/pk

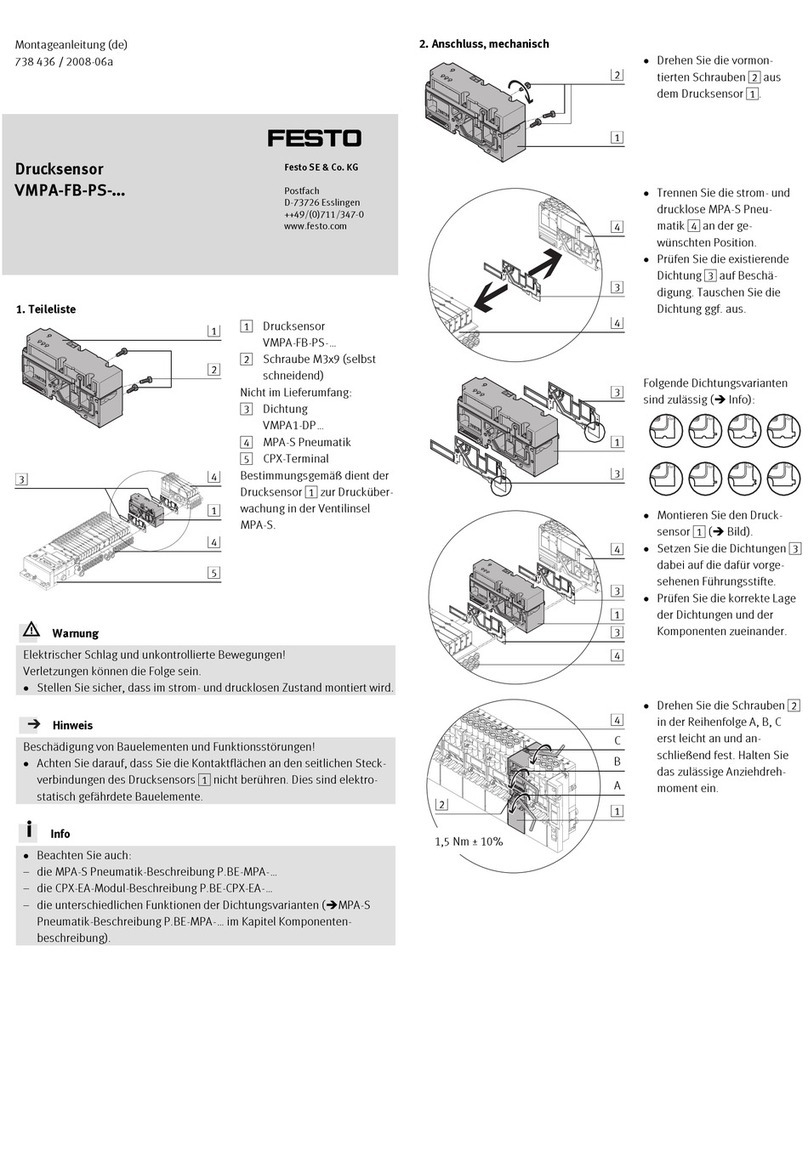

1

2

3

2

4

5

6

7

Fig. 1

0.5 Nm

ß1.5

0.3 Nm

9

8

2

1Connecting cable

2Mounting screw

3Plug M8, rotatable

4Red LED: status display

5Green LED: ready status display

6Yellow LED: malfunction display

7Key (without function)

8Internal hexagon socket key

9T-slot (profile slot 8)

Fig. 2

1 Function and application

The position sensor SDAP is intended to be used for contactless detection of the

piston position of magnetically detectable drives in combination with the analogue

input module CTMM-S1-A-... (optional component of the VTEM Motion Terminal).

The SDAP position sensor records the magnetic field of the piston magnet and

continuously senses the piston movement in the sensing range.

An analogue current signal (4 ... 20 mA) is available as output signal.

Power supply is through the analogue input module CTMM-S1-A-....

2 Requirements for product use

Only use the product in its original status, without any unauthorised modifica

tions.

Use only in combination with the analogue input module CTMM-S1-A-... (optional

component of the VTEM Motion Terminal).

Avoid having magnetic bodies near the position sensor. These could influence

the magnetic field and thereby the behaviour of the sensor.

The product is intended for use in industrial environments. Interference suppres

sion measures may be required in residential areas.

Range of application and certifications

The information in this section, in combination with the UL and CSA marking on the

product, must be observed in order to be compliant with the certification condi

tions of Underwriters Laboratories Inc. (UL) for the USA and Canadian Standards

Association (CSA) for Canada.

UL approval information

Product category code NRKH, NRKH7

File number E232949

Considered standards UL 60947-1 and UL 60947-5-2,

CAN/CSA C22.2

UL mark

Only for connection to an NEC Class 2 supply.

3 Installation

Warning

Only use power sources which guarantee reliable electrical isolation of the oper

ating voltage in accordance with IEC/EN 60204-1. Observe also the general

requirements for PELV power circuits in accordance with IEC/EN 60204-1. Switch

power packs are permitted providing they guarantee reliable disconnection as

defined by EN 60950/VDE 0805.

Circuit diagram and pin allocation

Fig. 3

Port pattern Pin Allocation

M8×1, 4-pin 1Operating voltage + 24 V DC

2Analogue output 4…20 mA

30 V

4No function. Can be connected with ground 0 V.

Fig. 4

Installation

1. Insert sensor into the T-slot of the drive or mounting kit.

2. Lightly clamp mounting screws.

3. Connect connecting cable to the input module.

4 Commissioning

Note

Observe commissioning notes in the documentation of the VTEM Motion Terminal.

1. Switch on the operating and load voltage supply (UEL/SEN and UVAL) of the VTEM

Motion Terminal.

– The LEDs illuminate (dependent on the piston position).

– The device is ready for operation.

2. Move the piston into an end position of the application.

3. Remove the mounting screws of the sensor.

4. Push sensor in the direction of the piston until the red LED goes out.

5. Tighten mounting screws with tightening torque.