Provia QDC 311 User manual

INSTALLATION INSTRUCTIONS

NON-RESIDENTIAL ENTRY DOOR

STANLEY®CLOSER HARDWARE

(QDC 311 AND QDC 312 HOLD OPEN)

* Find QR Codes inside for additional information,

helpful installation tips and videos.

Contact the local recycling waste management center for waste disposal in the area.

Always check local waste requirements and carefully dispose of waste in accordance

with Federal and other regulations.

Homes built before 1978 may contain lead paint. All replacement installations must

comply with the U.S. EPA’s Lead-Based Paint Renovation, Repair, and Painting

Program (RRP Rule). Read more about the RRP Rule and lead-safe work practices, on

the U.S. EPA’s website at: www.epa.gov/lead

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

ATTENTION!

YOU CAN ALSO SCAN

THE PACKAGING QR CODE

TO ACCESS THIS DOCUMENT

Printed instructions included

with each product will be

phased out in the

near future

1

GETTING STARTED

IMPORTANT NOTES BEFORE YOU BEGIN

• Inspect your package for any visible damages to the product. In addition, double check your paperwork

with label on product(s) and verify all information is a match. Open packaging to confirm order was shipped

complete. If damages or irregularities are found, please document with pictures and call

Customer Service, 1-800-669-4711.

• If you have ordered optional items, verify that they are included in packaging contents. This includes checking

for multiple packages (For example, 1 of 2 and 2 of 2).

• For additional information and helpful videos, visit our 'Homepage for Installers' by

scanning the Quick Reference Code shown, using your QR Code Scanner App.

• Tape Measure

• Pencil

• Drill and Drill Bits

•Level

• 1⁄4"-20 Tap and #7 Drill Bit

•Screwdriver

TOOLS & MATERIALS YOU WILL NEED

REMEMBER: ALWAYS USE THE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Read these instructions carefully before starting installation. Product warranty does not cover damages

resulting from improper installation.

2

This document is to assist with specific instruction for the installation of

Stanley®Closer Hardware, Model QDC 311or Model QDC 312 Hold Open

to a ProVia®Non-Residential Door. This instruction provides (3) installation options.

Refer to the following pages for the installation procedure required:

IMPORTANT DOCUMENT INFORMATION

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

PUSH to OPEN

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

PUSH to OPEN

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

PULL to OPEN

QDC 311 Closer Installation Screw Packs and Part

Identification, Page 3

QDC 312 Hold Open Closer Installation Screw Packs and

Part Identification, Page 4

Section A - Parallel Arm Installation for Push Side Mount,

Pages 5 - 6

Section B - Top Jamb Installation for Push Side Mount,

Pages 7 - 8

Section C - Regular Arm Installation for Pull Side Mount,

Pages 9 - 10

Section D - Door Closer Adjustments, Page 11

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

•

•

•

•

•

•

3

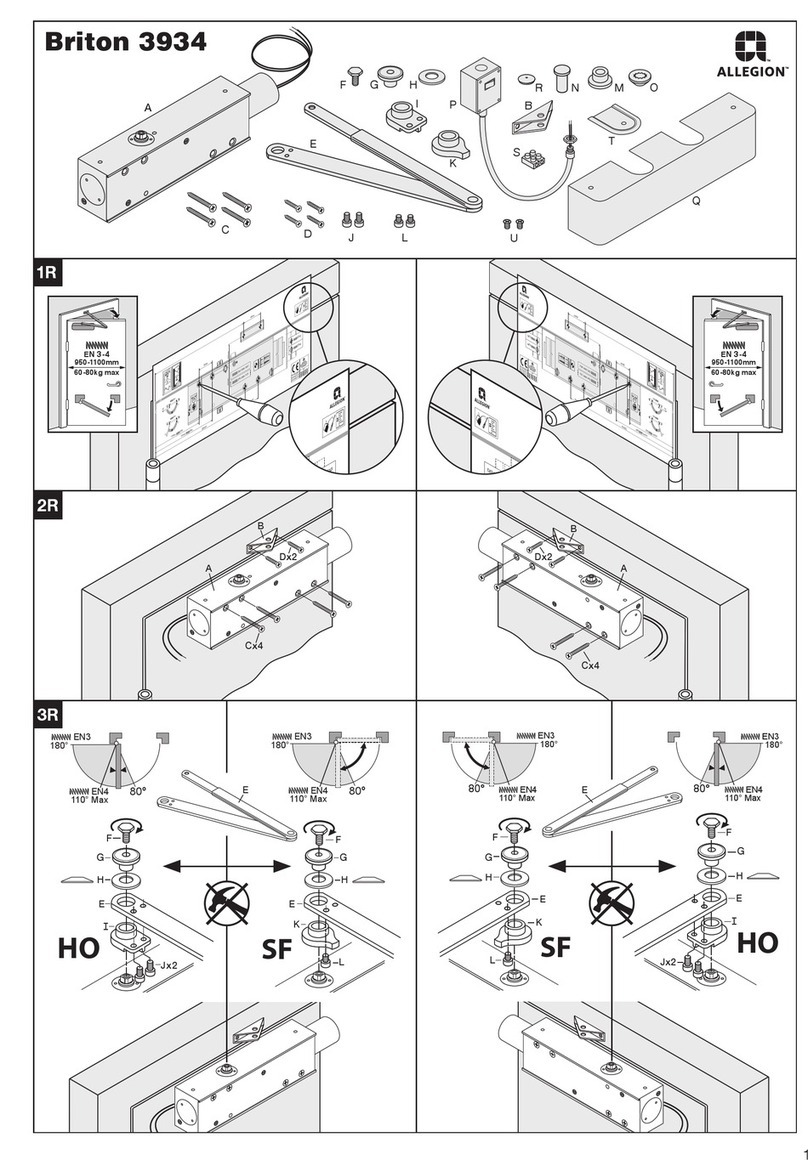

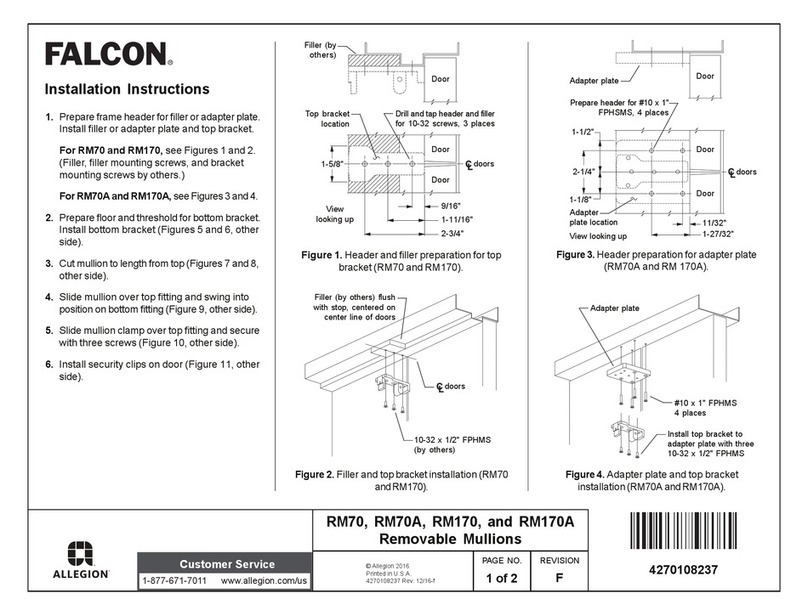

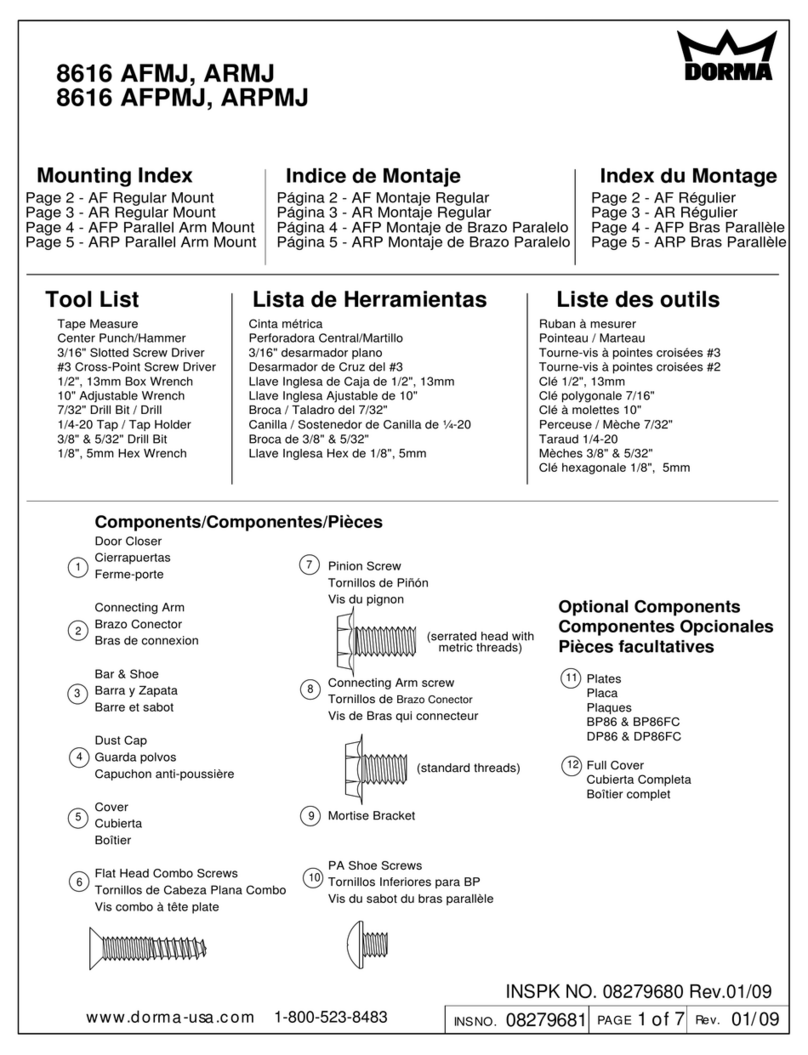

QDC 311 CLOSER INSTALLATION SCREW PACKS

AND PART IDENTIFICATION

Closer Installation Screw Pack (Stanley provided, large bag)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Parallel Bracket

(For parallel arm

installation only)

Arm Shoe

(For top jamb or regular

arm installation)

Closer Body

Speed

Adjusting Valves

Main Arm

Forearm

Back Check

Adjusting Valve

Power

Adjusting Valve

Closer Pinion

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Pan Head

Machine Screws

(Arm shoe install to steel)

Flat Head

Machine screws

(Closer install to steel)

Hex Screw

w/ Lock Washer

(Main arm to pinion)

Pan Head

Wood Screws

(Arm shoe install to wood or fiberglass)

Flat Head

Wood screws

(Closer install to wood or fiberglass)

Hex Screw

w/ Washer

(Forearm to main arm)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Flat Head

Machine Screws

(Parallel bracket install to steel)

Flat Head

Wood Screws

(Parallel bracket install to wd. or fb.)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Pan Head

Self-Taping Screws

(Arm shoe install to all types)

Flat Head

Self-Taping Screws

(Closer install to all types)

Hex Wrench

(Power adjustments)

(2)

(4)

(1)

(2)

(4)

(1)

(2)

(4)

(1)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Parallel Bracket Installation Screw Pack (Stanley provided, small bag)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

(4) (4) Screw w/ Washer

(Forearm to bracket install)

(1)

Wood Frame Unit Screw Pack, Part # P-HW-ACCSZN-00 (ProVia provided with wood frame units only)

#14 x 3" Pan Head Screws

(Arm shoe install to wood jamb)

(2) #14 x 3" Flat Head Screws

(Parallel bracket install to wood jamb)

(4)

Through Bolt Screw Pack (Stanley provided) - DISCARD!

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

QDC 311 PART IDENTIFICATION

DO NOT USE for installation to a ProVia door.

ALL ProVia door units are internally reinforced.

Through Sleeve with Screw

(4)

4

Flat Head

Machine screws

(Closer install)

Flat Head

Self-Taping Screws

(Optional Cover)

Oval Head

Wood screws

(Closer install)

Hex Wrench

(Power adjustments)

Flat Head

Self-Taping Screws

(Closer install)

(4)

(1)

(4)

(1)

(4)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Flat Head

Machine Screws

(Parallel bracket install)

Locknut

(Arm assembly to

bracket install)

Oval Head

Wood Screws

(Parallel bracket install)

Hex Wrench

(6)

(2)

(4)

(1)

(1)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Wood Frame Unit Screw Pack, Part # P-HW-ACCSZN-00 (ProVia provided with wood frame units only)

#14 x 3" Pan Head Screws

(Arm shoe install to wood frame)

(2) #14 x 3" Flat Head Screws

(Parallel bracket install to wood frame)

(4)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

QDC 312 HOLD OPEN CLOSER INSTALLATION SCREW PACKS

AND PART IDENTIFICATION

Closer Installation Screw Pack (Stanley provided, large bag)

Parallel Bracket Installation Screw Pack (Stanley provided, small bag)

QDC 312 PART IDENTIFICATION

Arm Assembly

Parallel Bracket

(For parallel arm

installation only)

Back Check

Adjusting Valve

Power

Adjusting Valve

Closer Body

Speed

Adjusting Valves

Main Arm

Closer Pinion Hold Open Nut

Hex Screw

w/ Lock Washer

(Main arm to pinion)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Through Bolt Screw Pack (Stanley provided) - DISCARD!

DO NOT USE for installation to a ProVia door.

ALL ProVia door units are internally reinforced.

Through Sleeve with Screw

(4)

5

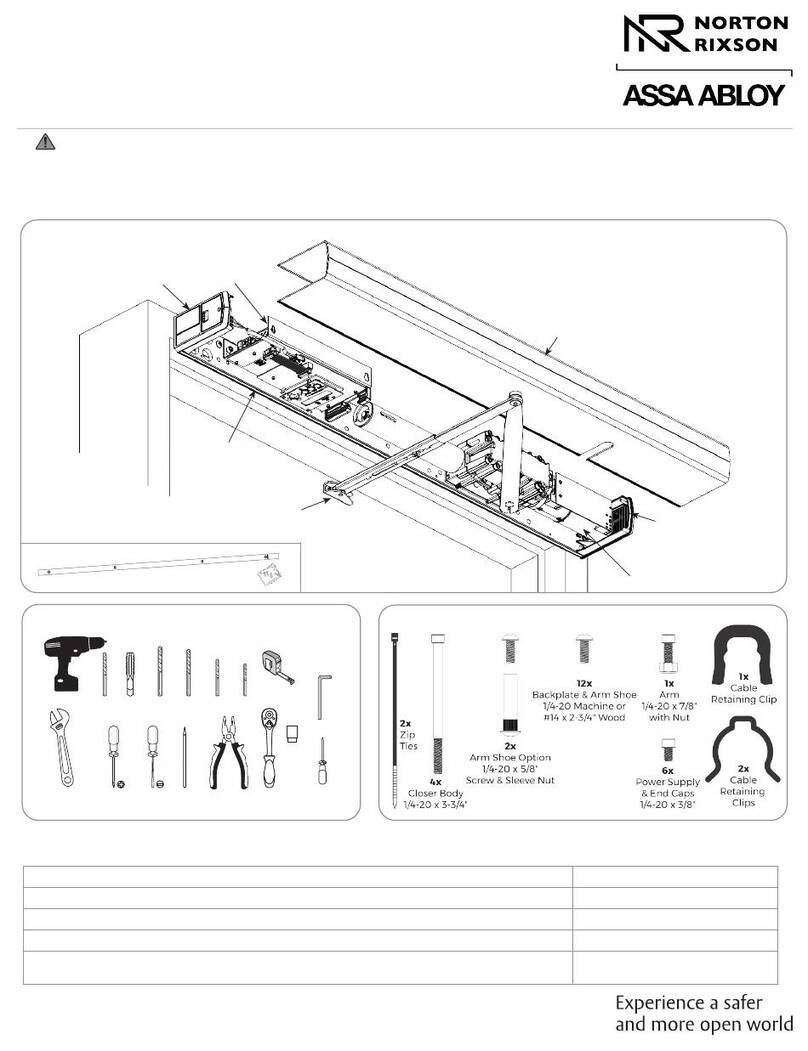

A. PARALLEL ARM INSTALLATION FOR PUSH-SIDE MOUNT

Determine the door handing and degree of

opening required for the closer installation.

Refer to the correct 'Dimension Reference

Chart' above and to the appropriate Figure

A.1 or A.2 for the dimensions required.

(Figure A.1)

(Figure A.2)

LEFT Hand Out-Swing Door

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

C

L

'A'

1⁄2"

3/4"

'B' 91⁄16"

Parallel bracket

required

PUSH

to

OPEN

Hinge

or Pivot

Plan ViewElevation View

QDC 311 DIMENSION REFERENCE CHART

Door Opening Dim. 'A' Dim. 'B' Dim. 'C'

To 100° 91⁄4" 75⁄8" 31⁄4"

100° to 120° 73⁄4" 61⁄8" 31⁄4"

121° to 180° 53⁄4" 41⁄8" 31⁄4"

RIGHT Hand Out-Swing Door

Parallel bracket

required

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

PUSH

to

OPEN

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Plan ViewElevation View

C

L

Hinge

or Pivot

'A'

1⁄2"

3/4"

'B'

91⁄16"

1Use dimensions as indicated on the Elevation

View to locate and mark the center of all (4)

closer screw holes on door slab. (Fig A.1 or A.2)

Parallel bracket

Closer

Closer

Parallel bracket

2Use dimensions as indicated on the Plan

View to locate and mark (1) parallel bracket

screw hole on underside of frame header.

Use bracket as template to locate remaining

screw hole locations. (Figure A.1 or A.2)

3Pre-drill all marked screw hole locations on

door slab and frame header. For wood or

fiberglass, use a 7⁄32" drill bit. For steel, drill

and tap #7 for 1⁄4"-20 machine screws.

4Install the parallel bracket to frame header

using the appropriate screws provided.

NOTE: For wood jamb application only, insert

wood blocking to fill space between jamb and

header at bracket location. Use ProVia wood

screws provided.

5Position and install closer to the door slab.

The speed adjustment valve MUST BE

positioned AWAY from the hinge-side. Use

the appropriate screws provided.

NOTE: DO NOT USE THROUGH BOLTS to

install closer to the door slab.

'C'

'C'

QDC 312 DIMENSION REFERENCE CHART

Door Opening Dim. 'A' Dim. 'B' Dim. 'C'

To 100° 91⁄4" 75⁄8" 31⁄2"

100° to 120° 73⁄4" 61⁄8" 31⁄2"

121° to 180° 53⁄4" 41⁄8" 31⁄2"

6

(Figure A.4)

(Figure A.5)

(Figure A.3)

A. PARALLEL ARM INSTALLATION FOR PUSH-SIDE MOUNT

6Set main arm on top closer pinion,

PARALLEL to door slab. Use wrench to

rotate bottom closer pinion approximately

45° towards hinge-side. As bottom closer

pinion is rotated, main arm will slide onto top

pinion. Use the 'L' and 'R' marked on main

arm to determine direction of swing. Main

arm will point away from hinge-side. Refer to

Figure A.3 for illustration of handing. Tightly

secure using (1) 3⁄4" hex screw with lock

washer. (Figure A.3 & A.4)

8For QDC 311, remove the arm shoe from the

forearm. Install and secure the forearm to

the parallel bracket pin using screw provided.

Open door to allow the forearm to slide into

the main arm. Loosely fasten the forearm

to the main arm using (1) 1⁄2" hex screw with

washer. Close door, rotate main arm until 1"

away from door slab. Tighten hex screw to

secure forearm in place.

For QDC 312, Install and secure the arm

assembly to the parallel bracket pin using

screw provided. (For LEFT hand door,

position the hold open nut down. For RIGHT

hand door, position the hold open nut up.)

Open door to allow the main arm to slide into

the arm assembly. Close door, rotate main

arm until 1" away from door slab. Tighten set

screw to secure the arm assembly in place.

(Figure A.5)

7

8Adjust door closing speed and power. Refer

to Section D, 'Closer Adjustments' for

instruction.

8

9Snap the pinion cap cover onto the bottom

closer pin or install the QDC 312 optional

cover with screw provided.

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Main Arm Installation

(Left Hand Out-Swing Shown)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

LH Out-Swing RH Out-Swing

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Top view of main

arm placed parallel

to door slab

Hinge-Side

Hinge-Side

Set main arm on top of closer pin,

PARALLEL to door slab and away from hinge-side

CORRECT Main Arm Installation

CORRECT

Main arm is installed

parallel to slab. Closer is

loaded under pressure, will

fully close door slab.

NOT CORRECT

Main arm is installed

angled away from slab.

Closer has little pressure,

will not fully close door

slab.

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Door Slab Door Slab

Closer with parallel arm installation is

COMPLETE.

QDC 312 Hold Open Arm Assembly

to Bracket

LEFT Hand

Position nut down

RIGHT Hand

Position nut up

Bracket Bracket

Arm Assembly Arm Assembly

7

B.TOP JAMB INSTALLATION FOR PUSH-SIDE MOUNT

Determine the door handing and

degree of opening required for the

closer installation. Refer to the correct

'Dimension Reference Chart' above and

to the appropriate Figure B.1 or B.2 for

the dimensions required to locate closer.

QDC 311 DIMENSION REFERENCE CHART

Door Opening Dim. 'A'

To 100° 71⁄2"

100° to 120° 6"

121° to 180° 31⁄2"

3Pre-drill all marked screw hole locations on

door slab and frame header. For wood or

fiberglass, use a 7⁄32" drill bit. For steel, drill

and tap #7 for 1⁄4"-20 machine screws.

4Position and install the closer onto the frame

header. The speed adjustment valve MUST

BE positioned TOWARDS the hinge-side.

Use the appropriate screws provided.

NOTE: For wood jamb application only, wood

blocking may be needed. Use the ProVia

wood jamb screws provided.

(Figure B.1)

(Figure B.2)

LEFT Hand OUT-Swing Door Elevation View

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

3/4"

'A'

6"

Arm shoe

required

PUSH

to

OPEN

RIGHT Hand OUT-Swing Door Elevation View

Arm shoe

required

Closer

C

L

Hinge

or Pivot

91⁄16"

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

PUSH

to

OPEN

1/2"

11/2"

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

3/4"

'A'

6"

Closer

C

L

Hinge

or Pivot

91⁄16"

1/2"

11/2"

QDC 312 DIMENSION REFERENCE CHART

Door Opening Dim. 'A' Hold Degree

To 100° 75⁄8" 90° - 100°

100° to 120° 61⁄8" 101° - 130°

121° to 180° 41⁄8" 131° - 180°

1Use dimensions as indicated on the

Elevation View to locate and mark the

center of all (4) closer screw holes on frame

header. (Figure B.1 or B.2)

2Use dimensions as indicated on the

Elevation View to locate and mark (1) arm

shoe screw hole on door slab. Use bracket

as template to locate remaining screw hole

location. (Figure B.1 or B.2)

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

8

5For QDC 311, Install the arm shoe with

forearm onto the door slab using the

appropriate screws provided.

For QDC 312, Install the arm assembly onto

the door slab using the appropriate screws

provided. For LEFT hand door, position the

hold open nut down. For RIGHT hand door,

position the hold open nut up. (Figure B.3)

NOTE: DO NOT USE THROUGH BOLTS

to install arm shoe or arm assembly to

the door slab.

B.TOP JAMB INSTALLATION FOR PUSH-SIDE MOUNT

6Install main arm onto the bottom closer

pinion, PERPENDICULAR to the door slab.

Tightly secure using (1) 3⁄4" hex screw with

lock washer. (Figure B.4)

8Adjust door closing speed and power. Refer

to Section D, 'Closer Adjustments' for

instruction.

8

7For QDC 311, open door to allow the

forearm to slide into the main arm. Loosely

fasten the forearm to the main arm using

(1) 1⁄2" hex screw with washer. Close door,

rotate main arm until the FOREARM is

PERPENDICULAR to door slab. Tighten

hex screw to secure forearm in place.

(Figure B.5)

For QDC 312, open door to allow the

main arm to slide into the arm assembly.

Close door, rotate main arm until the ARM

ASSEMBLY is PERPENDICULAR to door

slab. Tighten set screw to secure the arm

assembly in place.

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Door Frame

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

QDC 311 Forearm Installation

Rotate forearm perpendicular to door slab

Secure forearm to main arm using

1⁄2" hex screw with washer

(Figure B.5)

(Figure B.3)

(Figure B.4)

QDC 312 Hold Open Arm Assembly

LEFT Hand

Position nut down

RIGHT Hand

Position nut up

Arm Assembly

CORRECT Main Arm Installation

CORRECT

Main arm is installed

perpendicular to slab.

Closer is pre-loaded, will

fully close door slab.

NOT CORRECT

Main arm is installed

angled away. Closer has

little pressure, will not

fully close door slab.

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Door Frame

Arm Assembly

9Snap the pinion cap cover onto the bottom

closer pin or install the QDC 312 optional

cover with screw provided.

Closer with top jamb installation is

COMPLETE.

9

C. REGULAR ARM INSTALLATION FOR PULL-SIDE MOUNT

Determine the door handing and

degree of opening required for the

closer installation. Refer to the correct

'Dimension Reference Chart' above and

to the appropriate Figure C.1 or C.2 for

the dimensions required to locate closer.

QDC 311 DIMENSION REFERENCE CHART

Door Opening Dim. 'A'

To 100° 71⁄2"

100° to 120° 6"

121° to 180° 31⁄2"

3Pre-drill all marked screw hole locations on

door slab and frame header. For wood or

fiberglass, use a 7⁄32" drill bit. For steel, drill

and tap #7 for 1⁄4"-20 machine screws.

4Position and install the closer onto the door

slab. The speed adjustment valve MUST BE

positioned TOWARDS the hinge-side. Use

the appropriate screws provided.

NOTE: DO NOT USE THROUGH BOLTS to

install arm shoe to the door slab.

(Figure C.1)

(Figure C.2)

RIGHT Hand In-Swing Door Elevation View

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

11/4"

3/4"

'A' 91⁄16"

Arm shoe

required

PULL

to

OPEN

LEFT Hand In-Swing Door Elevation View

Arm shoe

required

Closer

C

L

Hinge

or Pivot

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

PULL

to

OPEN

6"

7/8"

1/8"

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

11/4"

3/4"

'A'

91⁄16"

Closer

C

L

Hinge

or Pivot

6"

7/8"

1/8"

QDC 312 DIMENSION REFERENCE CHART

Door Opening Dim. 'A' Hold Degree

To 100° 75⁄8" 90° - 100°

100° to 120° 61⁄8" 101° - 130°

121° to 180° 41⁄8" 131° - 180°

1Use dimensions as indicated on the

Elevation View to locate and mark the center

of all (4) closer screw holes on the door

slab. (Figure C.1 or C.2)

2Use dimensions as indicated on the

Elevation View to locate and mark (1) arm

shoe screw hole on frame header. Use

bracket as template to locate remaining

screw hole location. (Figure C.1 or C.2)

10

C. REGULAR ARM INSTALLATION FOR PULL-SIDE MOUNT

Closer with regular arm installation is

COMPLETE.

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Door Frame

QDC 311 Forearm Installation

Rotate forearm perpendicular to door slab

Secure forearm to main arm using

1⁄2" hex screw with washer

(Figure C.5)

(Figure C.3)

(Figure C.4)

QDC 312 Hold Open Arm Assembly

LEFT Hand

Position nut down

RIGHT Hand

Position nut up

Arm Assembly

CORRECT Main Arm Installation

CORRECT

Main arm is installed

perpendicular to slab.

Closer is pre-loaded, will

fully close door slab.

NOT CORRECT

Main arm is installed

angled away. Closer has

little pressure, will not

fully close door slab.

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

Door Frame

Arm Assembly

Option A – Regular Arm Installation

Top Jamb Installation

Option B –

Machine X2

Machine X4

Machine X4

Wood X2

Wood X4

Wood X4

Optional

cover

(a)

screw.

(c)

(e)

(b)

(d)

(f)

(g) (h)

(i) (j)

X1

X1

X1

X1

L

R

S

S

R

L

L

R

S

S

R

L

S

R

L

5For QDC 311, Install the arm shoe with

forearm onto frame header using the

appropriate screws provided.

For QDC 312, Install the arm assembly onto

frame header using the appropriate screws

provided. For LEFT hand door, position the

hold open nut down. For RIGHT hand door,

position the hold open nut up. (Figure C.3)

NOTE: For wood jamb application only, insert

wood blocking to fill space between jamb and

header at arm shoe or arm assembly location.

Use ProVia wood screws provided.

NOTE: DO NOT USE THROUGH BOLTS

to install arm shoe or arm assembly to the

door slab.

6Install main arm onto the top closer pinion,

PERPENDICULAR to the door slab. Tightly

secure using (1) 3⁄4" hex screw with lock

washer. (Figure C.4)

8Adjust door closing speed and power. Refer

to Section D, 'Closer Adjustments' for

instruction.

8

7For QDC 311, open door to allow the

forearm to slide into the main arm. Loosely

fasten the forearm to the main arm using

(1) 1⁄2" hex screw with washer. Close door,

rotate main arm until the FOREARM is

PERPENDICULAR to door slab. Tighten hex

screw to secure forearm in place. (Figure C.5)

For QDC 312, open door to allow the

main arm to slide into the arm assembly.

Close door, rotate main arm until the ARM

ASSEMBLY is PERPENDICULAR to door

slab. Tighten set screw to secure the arm

assembly in place.

9Snap the pinion cap cover onto the bottom

closer pin or install the QDC 312 optional

cover with screw provided.

2150 State Route 39, Sugarcreek, OH 44681

Phone: 330.852.4711 • Fax: 877.735.2057

provia.com

Version 1.1 · 12.17.2021 · © 2021 Provia · P-MK-61027

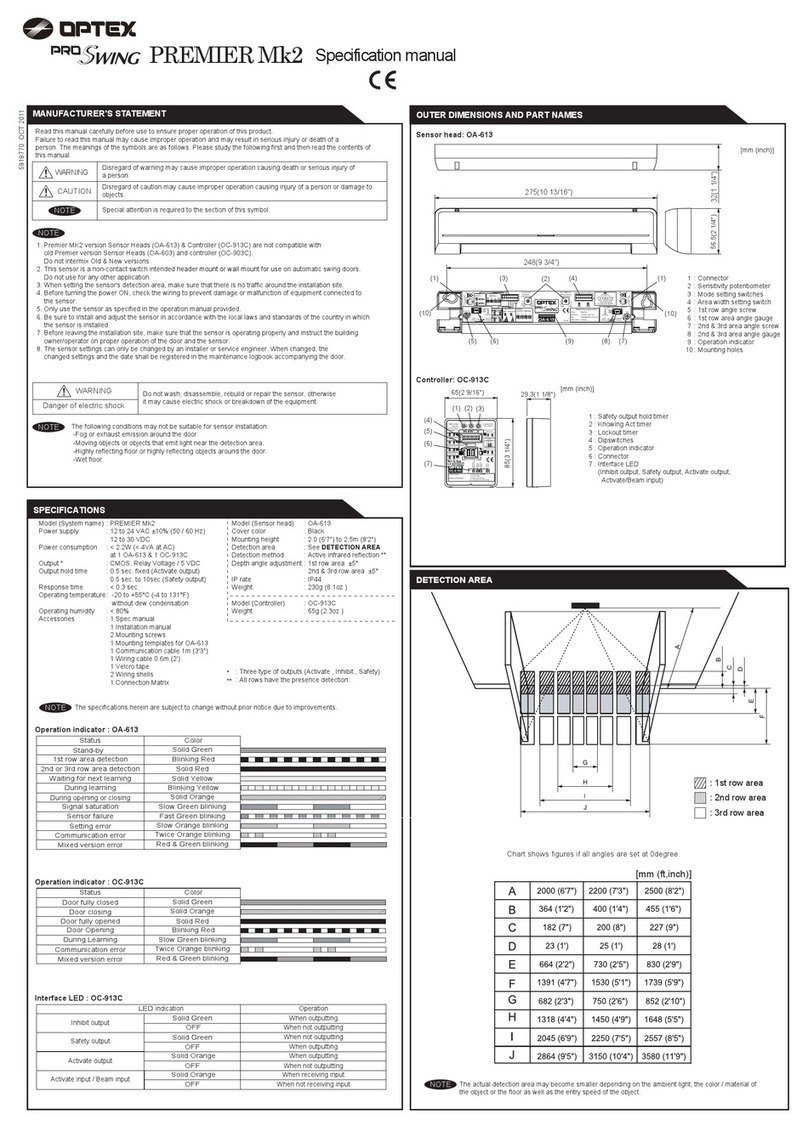

D. DOOR CLOSER ADJUSTMENTS

L

S

POWER ADJUSTMENT CHART

Door

Closer Size

Full Turn of Power

Adjusting Screw

Applicable Door Leaf Width Applicable Door Weight

Interior Exterior (Out-Swing)

1 - 4 32" 28" 33 to 56 LBS

2 - 2 36" 32" 56 to 99 LBS

3 0 (Preset) 42" 36" 99 to 143 LBS

4 + 3 48" 42" 143 to 187 LBS

5 + 6 54" 48" 187 to 264 LBS

6 + 10 58" 54" 264 to 330 LBS

L

S

Clockwise for Full Numbers (+)

Counter-Clockwise for Full Numbers (-)

Use 5⁄32" Hex Wrench

for this adjustment

Power Adjusting

Screw

Closer Elevation Views - Adjustment Screws and Valve Identification

Delayed Action

Adjusting Valve

Latch

Adjusting Valve

Sweep

Adjusting Valve

Back Check

Adjusting Valve

Power

Adjusting Screw

L

S

Opening Cycle Adjustment

L

S

Closing Cycle Adjustment

Increase opening tension

Decrease opening tension

Slower

Faster

Back Check

Opening

Delay

Sweep

Latch

*Please call Customer Service for additional installation inquiries at 1-800-669-4711.

NOTE: When closer is paired with a panic hardware exit device, closer adjustments will affect the exit device

latching process.

This manual suits for next models

1

Table of contents