ProWorld TransPro Plus Cap User manual

961 Bethel Ave.

1. Connecting the System

1.1 Connect the power cord into a

properly grounded electrical outlet with

a sucient amperage rating.

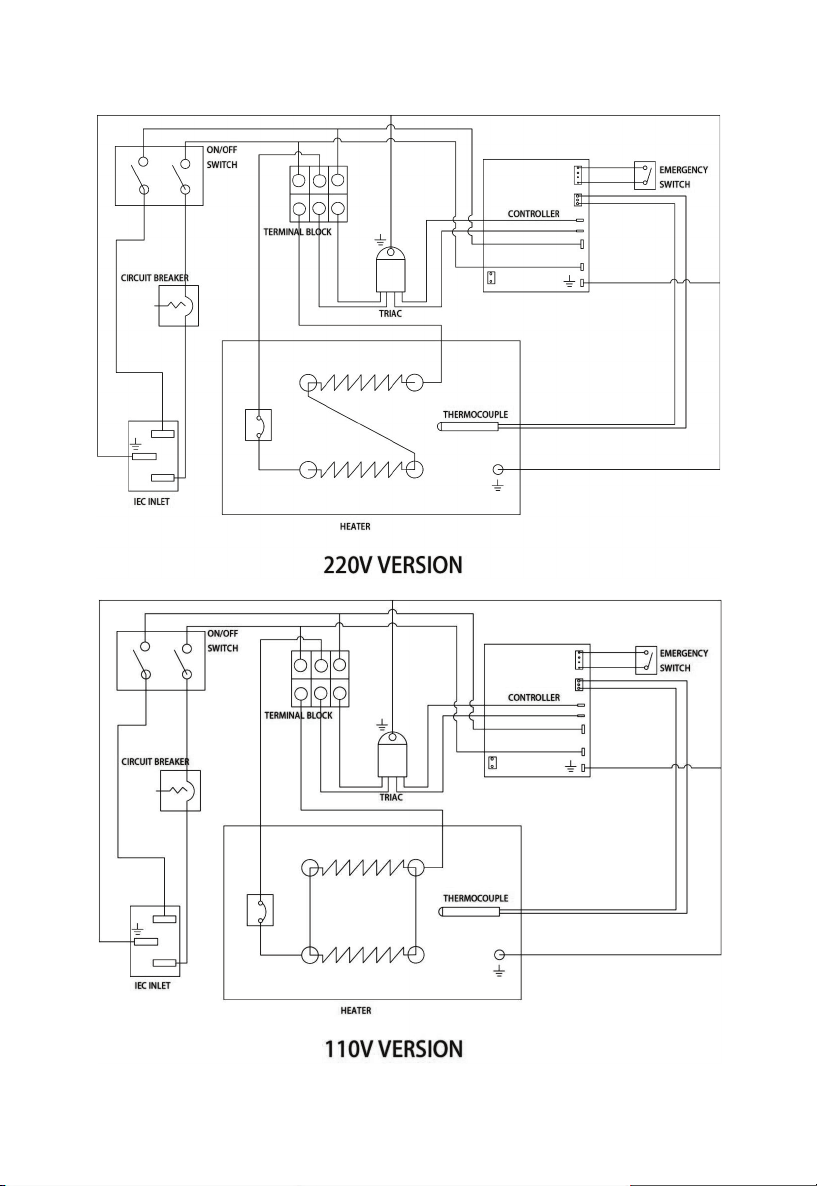

1.2 VOLTAGE: 120 Volt – The GS-601

requires a full 20 amp grounded circuit

for 120 volt operation. 240 Volt –The

GS-601 requires a full 10 amp grounded

circuit for 240 volt operation.

1.3 EXTENSION CORDS: If used, should

be as short as possible and not less than

12 gauge.Heavy duty cords are

recommended.

1.4 CIRCUITS: that have less than 15

amps or that have other high demand

equipment or appliances(especially more

than one heat seal machine) plugged in,

should not be used.

CAUTION: Failure to follow these

instructions will cause:

1. Erratic controller functions.

2. Inaccurate displays & slow heat-up.

3. The circuit breaker to disengage.

NOTE: If the supply cord is damaged, it

must be replaced by the manufacturer,

its service agent or a similarly qualied

person in order to avoid hazard.

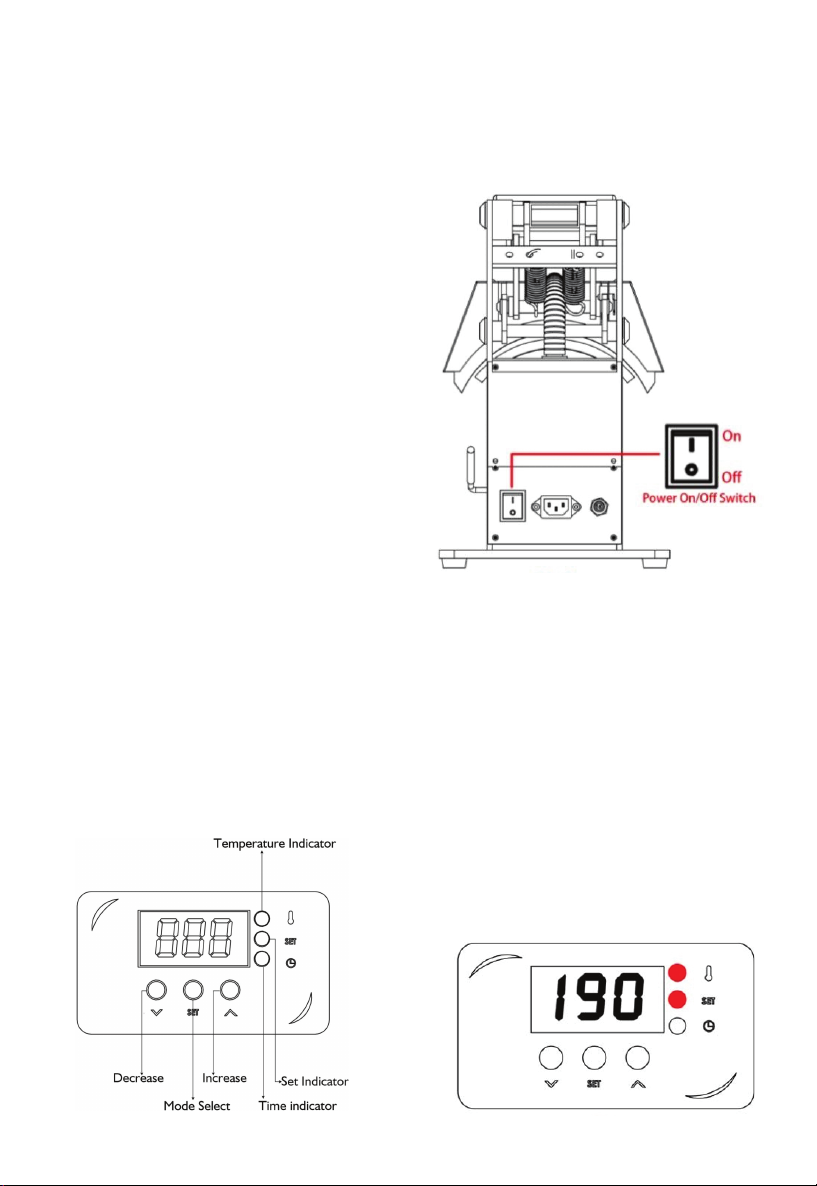

2.1 Switch The System On

2. Turn On The System

3.1 Press the Mode Select button located

in the center of the Control Panel.

“Temp” lights and “set” lights located in

the display will illuminate indicating you

are in the adjust temperature mode.

3.2 Next, press the (-) button located to

the bottom of the Mode Select button to

lower the temperature setting,or press

the (+) button located to top of the Mode

Select button to raise the temperature

setting.The temperature can be set from

0° F (0° C) to 430° F (221° C).

3. Adjusting The Temperature

7.3 Press“set” button to select “F-C”mode

(see image below), press“set”button to

enter then press“up”and “down” button

to set F or C, C for celsius, F for Fahrenheit

4. Adjusting The Time

4.1 Once you have adjusted the

temperature, press the Mode Select

button again. “Time” lights and “set” lights

located in the display will illuminate

indicating you are in the adjust time

mode.

4.2 Next, press the (-) button located to

the bottom of the Mode Select button to

lower the value ,or press the (+) button

located to top of the Mode Select button

to raise the time value .The time setting

range can be set from 0~999.

5. Adjusting the Pressure

5.1 The Pressure Adjustment Knob is

located in the bottom of the lower platen

5.2 Adjust the pressure by turning the

knob clockwise to increase pressure and

counter clockwise to decrease pressure.

REMEMBER: To allow for the thickness of

your garment when adjusting the

pressure.

6. Printing And Pressing

•Once your equipment has reached the

designated temperature:

•Position the garment and application

and proceed to press.Lower and lock the

heat platen into the press position.

•This procedure will start the automatic

timing

•The timer will automatically count down

circuit board will alarm when the press

cycle is complete.

•The time will automatically re-set and

you are ready to continue with the next

application.

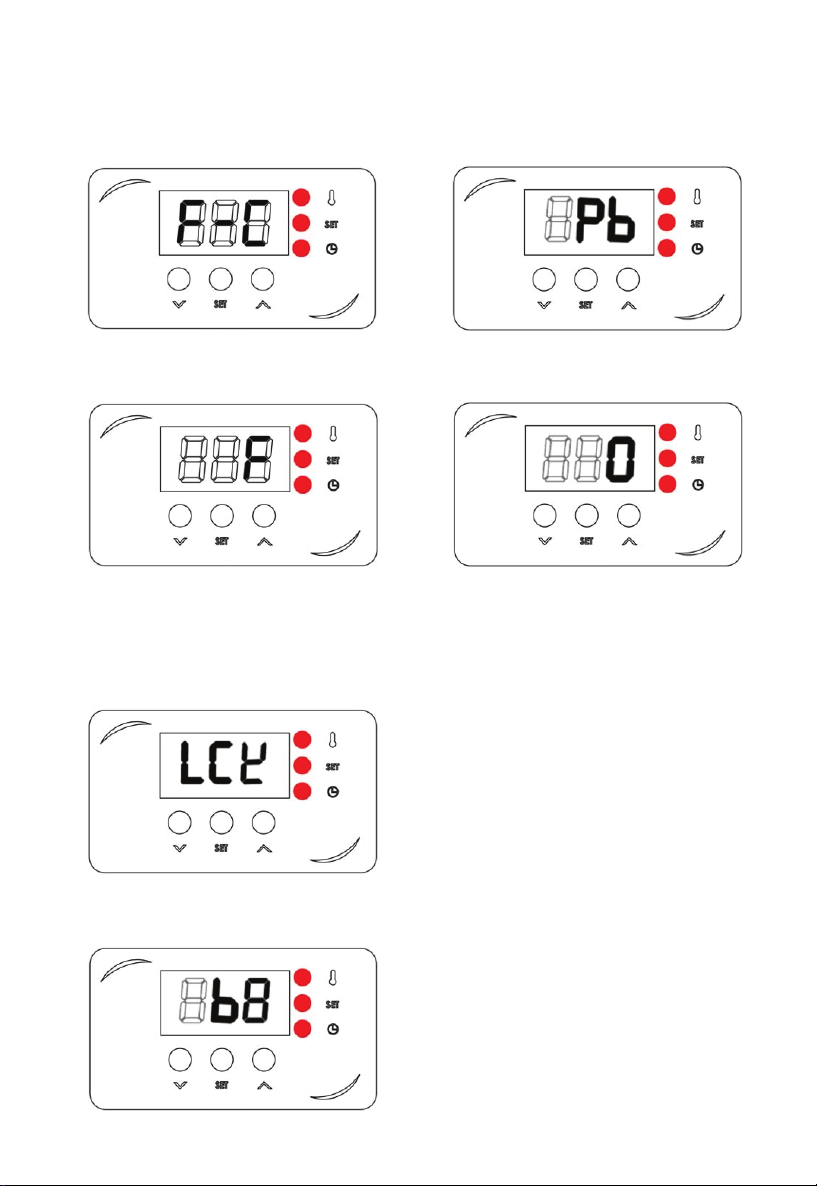

7. Changing From Fahrenheit To Celsius

7.1 Press and hold “down” and “up”

button then press“set” button,display

shows LCK

7.2 Input 68 to enter into second level

menu

7.3 Press“set” button to select “F-C”mode

(see image below), press“set”button to

enter then press“up”and “down” button

to set F or C, C for celsius, F for Fahrenheit

7.4 After setting,press“set”button 4

seconds to quit.

8. Temperature Calibration

8.1 Press and hold“(-)”and“(+)”button

then press “set” button, display shows LCK

8.2 Input 68 to enter into second level

menu

8.3 Press“set” button to select “Pb” mode

press up and down button to make

temperature calibration. (see 8.4)

8.4 Press“set” button for 4 seconds to

quit.

7.1 Press and hold “down” and “up”

button then press“set” button,display

shows LCK

7.2 Input 68 to enter into second level

menu

Technical Parameters

Model: MP353

Lower Platen Size: 3.5’’*6.5’’ (with machine)

3’’*5.75’’ (choosable)

2.75’’*6.5’’ (choosable)

4’’*6.5’’ (choosable)

4’’*8’’ (choosable)

Pressure Display:No

Auto Open:No

Power(120volt) 700W/6.4Amps

Power(240volt) 700W/5Amps

Temperature Range:Max.221"/430#

Heating Up

Time(180)

15minutes

Time Range$0~999S

Machine Size (open

size)

40%31%59cm

Packing Size: 46%38%35cm

Packing Weight: 15kg

Certificate: FCC, CE

No. Part Name(English) Part No. Qty.

1washer 2000260 2

2Steel pin 1600151 1

3washer 2000589 4

4Steel pin 1800147 3

5Bridge link 1600091 2

Bridge link 1600092 2

6Thread pin 1300225 1

Thread pin 1800580 1

7spring 1600530 2

spring 1600104 2

8Magnet switch 1800614 1

9magnet 1800615 1

10 Adjust arm 1600090 2

Adjust arm 1600089 2

11 PP tube 0.13M 1800835 1

12 Tube connector 1800145 1

Tube connector 1800135 1

13 Display overlay 1600233 1

Display overlay 1600455 1

Display overlay 1600456 1

14 Back cover 1 1600098 1

Back cover 1 1600097 1

Back cover 1 1600100 1

Back cover 1 1600099 1

15 Control box 1600826 1

Control 1600914 1

Control 1600576 1

Control 1600826 1

16 Back cover 2 1600831 1

Back cover 2 1600096 1

Back cover 2 1600095 1

Back cover 2 1600094 1

17 !"#$% 1900390 6

Hucap 1900391 6

18 Circuit board 1800355 1

19 Circuit breaker 8A 1800348 1

20 socket 1800344 1

21 On/off switch 1800346 1

22 Terminal block 1800345 1

23 Triac 1800951 1

24

!

Foot Pad-

XD2512-148

1800317 5

26 Machine base

welded

1600401 1

Machine base

welded

1600400 1

27 Cap fix shell 1600359 1

28 Cap nut 1900930 1

Cap nut 1900917 1

29 Spring hook base 1600718 1

30 Cap nut 1900923 1

31 spring 1600103 1

spring 1600229

32 Balance screw 1600223

33 Pressure adjustment

spindle

1600726

34 Lower platen 1600572 1

Lower platen 1600366 1

Lower platen 1600367 1

Lower platen 1600368 1

Lower platen 1600369 1

35 Lower platen 1600363 1

36 Thermocouple 1800281 1

37 Thermosat 1800133 1

38 Heat platen 1600377 1

39 Heat platen cover 1600719 1

Heat platen cover 1600720 1

Heat platen cover 1600722 1

Heat platen cover 1600721 1

40 Handle shaft 1300150 1

41 Foam grip 1300155 1

42 Handle welded 1600396 1

Handle welded 1600424 1

www.proworldinc.com

TransPro products offered by Pro World are warranted against defects in material

and workmanship. Warranty is void if equipment has been damaged by accident,

unreasonable use, neglect, unauthorized and/or improper service, or other causes

not arising out of defects in material and workmanship. This warranty does not cover

damage caused by normal wear and tear, neglect or lack of proper maintenance.

This warranty is for the original purchaser/owner only, it is not transferable.

The heating element shall be warranted for the life of the heat press. There is a one

(1) year warranty on major components, circuit boards and all other components.

During the warranty period, and in the event that a situation cannot be resolved by

telephone/email and upon PRE-AUTHORIZATION from Pro World equipment must

be shipped, freight prepaid to Pro World for service in the original packaging. After

30 days, all shipping and insurance expenses to and from Pro World of in-warranty

equipment is solely the responsibility of the customer. Prior to 30 days the shipping

costs will be refunded if Pro World deems the equipment to be defective as stated.

Pro World cannot be held responsible for improper handling or any other damage

incurred in transit. No charge will be made for labor and components for repair of

in-warranty equipment. OUT-OF WARRANTY machines will be charged at the repair

rates in effect at the time the machine is received.

Pro World shall not be liable for loss of use of TransPro equipment or other inciden-

tal or consequential costs, expenses, or damages incurred by the original purchaser

or any other user. The above warranty provisions constitute the entire agreement

between all parties, and supersede any and all prior written and/or oral representa-

tions and understandings.

This "Limited Warranty" applies to all TransPro equipment. However, the procedure

for obtaining service may vary outside the continental United States. Contact your

Pro World representative for warranty information. The purchaser is responsible for

compliance with all local laws, regulations and measure. Agreement shall be

governed by and construed in accordance with all applicable laws of said region.

www.proworldinc.com

961 Bethel Ave.

This manual suits for next models

1

Table of contents

Other ProWorld Power Tools manuals

ProWorld

ProWorld TransPro Mug User manual

ProWorld

ProWorld TransPro Plus Mug User manual

ProWorld

ProWorld TransPro MP884 User manual

ProWorld

ProWorld TRANSPRO SEMI-AUTO CAP User manual

ProWorld

ProWorld TransPro Plus 1620 User manual

ProWorld

ProWorld TRANSPRO MINI User manual

ProWorld

ProWorld TransPro Slide MP999 User manual

Popular Power Tools manuals by other brands

JMA

JMA Ecco Automatic manual

Makita

Makita JN3200 instruction manual

EINHELL Bavaria

EINHELL Bavaria BPS 800 E operating instructions

Chicago Pneumatic

Chicago Pneumatic CP825 Series instruction manual

Vigor Equipment

Vigor Equipment V2510 operating instructions

Porter-Cable

Porter-Cable PCC710B instruction manual