PSA Products LIF5000 LIFESAVER User manual

MODEL LIF5000

INSTALLATION AND USER MANUAL

LIFESAVER SMOKE ALARM IONISATION DESIGN

IMPORTANT: READ ALL INSTRUCTIONS BEFORE INSTALLATION.

NO USER REPLACEABLE PARTS INSIDE THIS SMOKE ALARM.

WARNING: Disconnecting smoke alarm from mounting base and/or removing the 9V battery

will render this smoke alarm inactive.

240VAC MAINS POWERED SINGLE STATION AND/OR INTERCONNECTABLE

(24 UNITS) IONISATION SMOKE ALARM. 9V REPLACEABLE BATTERY

BACKUP . TEST AND HUSH CONTROL AND LOW BATTERY INDICATION.

SPECIFICATION

ELECTRICAL RATING: 240VAC 50Hz, 80mA per alarm and interconnectable to

24 alarms.

WARNING: THIS SMOKE ALARM MUST ONLY BE WIRED TO A

240Vac 50Hz SINE WAVE CURRENT SUPPLY.

THE SMOKE ALARM USES AN EXTREMELY SMALL AMOUNT OF A

RADIOACTIVE ELEMENT IN THE DUAL IONISATION CHAMBER.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 1

RECOMMENDED LOCATIONS OF ALARMS ................................................................................1

MOBILE HOME INSTALLATION.................................................................................................................3

AVOID THESE LOCATIONS............................................................................................................................. 3

FALSE ALARMS.............................................................................................................................................................4

HOW TO REMOVE SMOKE ALARM FROM BASE PLATE..............................................5

INSTALLATION...............................................................................................................................................................5

OPERATION, TESTING AND MAINTENANCE..........................................................................10

BATTERY INSTALLATION, REPLACEMENT AND TEST..............................................13

9V TERMINAL AND REMOTE TEST & HUSH............................................................................15

REPAIRS AND SERVICES..................................................................................................................................19

GOOD SAFETY HABITS.....................................................................................................................................19

THE LIMITATIONS OF SMOKE LARMS..........................................................................................19

OPERATING PRINCIPLES OF SMOKE ALARMS....................................................................21

DEVELOP AND PRACTICE A PLAN OF ESCAPE...................................................................22

WHAT TO DO WHEN THE ALARM SOUNDS.............................................................................23

INSTALLER PLEASE NOTE...........................................................................................................................24

WARNING: INSULATION TEST.................................................................................................................24

WARRANTY AND LIABILITY.....................................................................................................................25

CONTENTS

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 2

1

1. RECOMMENDED LOCATIONS OF ALARMS

1.1 Locate an alarm for each separate sleeping area in the immediate vicinity of

the bedrooms. Try to monitor the exit path as the bedrooms are usually far-

thest from an exit. If more than one sleeping area exit, locate additional

alarms in each sleeping area in the immediate vicinity bedrooms.

1.2 Locate additional alarms to MONITOR any stairway as stairways act like

chimneys for smoke and heat.

1.3 Locate at least one alarm on every floor level.

1.4 Locate an alarm in every room where a smoker sleeps.

1.5 Locate an alarm in every room where electrical appliances are operated (i.e.

portable heaters or humidifiers).

1.6 Locate an alarm in every room where someone sleeps with the door closed.

The closed door may prevent an alarm not located in that room from waking

the sleeper.

1.7 Smoke, heat and other combustion products rise to the ceiling and spread

horizontally. Mounting the alarm on the ceiling in the center of the room

places it closest to all points in the room. Ceiling mounting is preferred in or-

dinary residential construction.

1.8 For mobile home installation select location carefully to avoid thermal bar-

rier that may form at the ceiling. For more details see Mobile Home Installa-

tion (Section 2).

1.9 When mounting alarms on the ceiling locate it at least 300mm away from the

side wall and 300mm away from any corner. (see diagram)

1.10 When mounting alarms on a wall, use the inside wall. The recommended po-

sition is between 300mm and 500mm off the ceiling. (see diagram)

NOTE: The performance of smoke alarms mounted on walls is unpredictable

and this mounting position is not recommended when ceiling mounting can be

implemented.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 1

2

1.11 When mounting the alarm at the apex of a sloping ceiling it should be

located at least 500mm away from the apex but should not exceed

1500mm (see diagram).

1.12 Locate smoke alarm at both ends of a bedroom hallway or large room

if the hallway or room is more than 9m long.

1.13 Do not locate smoke alarms in kitchen areas due to potential nuisance

alarms from cooking fumes.

1. RECOMMENDED LOCATIONS OF ALARMS

5

INSTALLATION OF SMOKE ALARM

IMPORTANT: INCORRECT ORIENTATION OF SMOKE ALARM MAY DECREASE

OPERATIONAL EFFECTIVENESS

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 2

33

2.1 Modern mobile homes have been designed and insulated to be energy effi-

cient. Install smoke alarms as recommended (refer to RECOMMENDED

LOCATIONS).

2.2 In older mobile homes that are not well insulated compared to present stan-

dards, extreme heat or cold can be transferred from the outside through

poorly insulated walls and roof. This may create a thermal barrier which can

prevent smoke from reaching a smoke alarm mounted on the ceiling. In such

units, install smoke alarm on inside partition between 300mm and 500mm

from the ceiling.

2.3 If you are not sure about the insulation in your mobile home, or if you notice

the walls and ceilings are either hot or cold, install alarm on an inside wall.

For minimum protection, install one alarm close to the bedrooms.

For additional protection, see SINGLE FLOOR PLAN.

NOTE:TEST YOUR SMOKE ALARM OPERATION AFTER MOBILE

HOME VEHICLE HAS BEEN IN STORAGE, BEFORE EACH TRIP

AND AT LEAST ONCE WEEK DURING USE.

2. MOBILE HOME INSTALLATION

3. AVOID THESE LOCATIONS

3.1 Do not locate your alarm in the garage - products of combustion are present

when you start your automobile. Use Lifesaver Heat Alarm in this location.

3.2 Do not locate your alarm in front of forced air supply ducts used for heating

and air conditioning and other high air flow areas.

3.3 Do not locate your alarm less than 500mm from the peak of an "A" frame

type ceiling.

3.4 Do not locate your alarm in areas where temperatures may fall below 5°C or

rise above 45°C, or in humidity higher than 85% as these conditions may re-

duce battery life.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 3

44

3.5 Avoid dusty areas, dust particles may cause smoke alarm to false alarm or

fail to alarm. Use Lifesaver Heat Alarm in this location to avoid false alarms.

3.6 Avoid very humid areas or near a bathroom, moisture can cause false alarm.

3.7 Avoid insect-infested areas.

3.8 Do not locate alarm within 0.9m of the following: the door to a kitchen, the

door to a bathroom containing a tub or shower, ceiling or whole house venti-

lating fans, or other high flow areas.

3.9 Avoid locating near fluorescent lights or other electrical equipment. Electronic

magnetic interferences or “noise” may cause nuisance alarms or chirping.

3.10 Smoke alarms are not to be used with detector guards unless the combination

(alarm and guard) has been evaluated and found suitable for that purpose.

3. AVOID THESE LOCATIONS

4. FALSE ALARMS

4.1 This smoke alarm is designed to minimize false alarms. Smoking will not

normally set off the alarm unless smoke is blown directly into the alarm.

4.2 Combustion particles from cooking may set off the alarm if the alarm is lo-

cated close to the kitchen cooking surface.

4.3 Large quantities of combustion particles are generated from spills and over-

boil.

4.4 An alarm with a Hush® Control device is preferable near a kitchen environ-

ment for this reason.

4.5 If the alarm does sound, check for fire first. If a fire is discovered, escape

quickly and call the Fire Brigade. If no fire is present, check to see if one of

the reasons listed above may have caused the alarm.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 4

55

5. HOW TO REMOVE SMOKE ALARM FROM BASE PLATE

5.1 Look for ‘SLIDE TO REMOVE’.

5.2 Remove Tamper Locking Screw if installed.

5.3 Push firmly towards arrow until smoke alarm unhinges from base plate.

5.4 To re-install smoke alarm follow FIGURE 2 procedure 1 to 3. See page 9.

6. INSTALLATION

WARNING: THIS SMOKE ALARM MUST BE INSTALLED BY QUALIFIED

(LICENSED) ELECTRICIANS ONLY.

6.1 Wiring Instructions:

6.1.1 In the interests of safety, this smoke alarm and all wiring must be installed by

a licensed electrician in accordance with the relevant requirements of the

SAA Wiring Rules - AS3000.

6.1.2 DO NOT connect this smoke alarm on the base plate without the presence of

240V mains power.

6.1.3 This Smoke Alarm can only interconnect with LIFESAVER Model 5000,

5800, 5800RL, 3000, 4800RL Smoke Alarms; Heat Alarm model HA240

and visual Signaling Device model SL240 and isolation relay model

RK10A/9. Interconnection with other brands may cause damage or result in a

shock or fire risk and void warranty.

6.1.4 Due to “noise” from electromagnetic interference, up to 24 units of smoke

alarms and compatible products may be interconnected.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 5

66

6.1.5 There are five terminals in the supply terminal block, marked 9V, A, SW, N,

LOOP. It is important that the alarm be wired correctly to ensure correct opera-

tion. Incorrect wiring to the Smoke Alarm will damage the unit and void the

warranty.

6.1.6 A total maximum of 250 meters (820 feet) of wire can be used in interconnect-

ing smoke alarms.

6.1.7 All final sub-circuit conductors including the signal conductor must be a mini-

mum size of 1mm² with 250V grade insulation.

6.1.8 Interconnected Smoke Alarms must be connected to the same final subcircuit.

6.1.9 Do not use any wire that could later be confused with the normal house wires

for the interconnect wire. For example, green/yellow earth wire.

6.1.10 Do not connect AC power wires to SW interconnect terminal. These will dam-

age smoke alarms.

6.1.11 Do not connect the SW interconnect wire to any device, except the SW inter-

connect terminal of smoke alarm. Otherwise, smoke alarm will be damage.

6.1.12 Switch wire (SW) only can drive the RK10A/9 and smoke alarms.

6.1.13 Do not connect 9V wire to AC power or SW interconnect terminal.These may

damage smoke alarms.

6.1.14 Smoke alarms should be interconnected only within the confines of a single

family living unit. If smoke alarms are interconnected between different units,

there may be excessive nuisance alarms. Residents may not be aware that

smoke alarms are being tested or that it is a nuisance alarm caused by cooking,

etc.

6. INSTALLATION

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 6

77

6.1.15 Terminals at back of mounting base are marked and coloured as follows:

MARKINGS

(Yellow) 9V 9Vdc POSITIVE POWER SOURCE

(Red) A ACTIVE

(White) SW SWITCH WIRE (FOR INTERCONNECTION ONLY)

(Blue) N NEUTRAL

(Orange) LOOP DEAD TERMINAL

WARNING: Connecting the Switch wire terminal to any other supply conduc-

tor may result in damage to the alarm, failure to operate or shock hazard and

void the warranty of the alarm.

EXAMPLE OF MULTIPLE ALARM WIRING / ISOLATION UNIT WIRING

6. INSTALLATION

LOOP

1

N

9V SW

A

LOOP

2

SW

9V AN

BLUE

ORANGE

ORANGE

YELLOW

WHITE

RED

YELLOW

BLUE

WHITE

RED

24

9V ASW N

LOOP

MAXIMUM OF 24 SMOKE ALMARMS

CONNECTION TO A

SW N

FUSE ON

CIRCUIT

BREAKER

SEE INSTALLATION INSTRUCTIONS

FOR LIFSAVER RK10A/9 RELAY MODULE

TO ALARM PANEL

OR

AUXILIARY DEVICES

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 7

88

Note: For interconnection of smoke alarms to Fire Panel or Auxiliary de-

vices, use only LIFESAVER Isolation Relay Model RK10A/9.

6.1.16 This Smoke Alarm can be interconnectable only with other LIFESAVER

models of Smoke Alarms; whether it be of Ionisation or Photoelectric design.

Interconnection with other brands may cause damage or result in a shock or

fire risk.

6.1.17 When interconnected all Smoke Alarms will sound upon activation.

6.1.18 WARNING: This alarm cannot be operated from power derived from a

square wave, modified square wave or modified sine wave inverter. These

type of inverters are sometimes used to supply power to the structure in

off grid installations, such as solar or wind derived power sources. These

power sources produce high peak voltages that will damage the alarm.

6.1.19 PSA recommend the smoke alarms to be installed on its own subcircuit to

avoid false alarms and nuisance chirping that may be caused by electromag-

netic interferences from other electrical equipment.

6.2 Mounting Instructions:

6.2.1 Separate Smoke Alarm from mounting base by sliding cover (in direction of

arrow) with one hand on the back of the mounting base and one hand sliding

Smoke Alarm(See Fig. 1).

6.2.2 Connect supply cable to terminal block and fix terminal cover.

6.2.3 Align and slide smoke alarm up onto mounting base (Fig. 2) then slide in the

reverse direction of arrow to ensure proper connection.

6.2.4 Switch on power and check the green light on alarm cover. It should be lit

when mains power is switched on indicating that the smoke alarm is properly

connected to the mounting base.

6.2.5 Secure Tamper Locking Pin (supplied) to smoke alarm.

6.2.6 Test alarm by pressing Test button.

6. INSTALLATION

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 8

99

6. INSTALLATION

Australia Patent

S/N 2008200075

Australia Patent

S/N 2008200075

Figure 1:To remove smoke alarm

Slide smoke alarm carefully

away from the base plate to

remove the smoke alarm.

Figure 2: To connect smoke alarm

1 Place smoke alarm in line with the

base plate.

2 Push smoke alarm towards connec-

tor (A). Ensure the smoke alarm

slides fully into the connector.

3 Green AC Power light will come

on when connected to mains.

A

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 9

1010

7. OPERATION, TESTING AND MAINTENANCE

7.1 Operation:

7.1.1 The smoke alarm is operational once all wires are properly connected, a fresh

battery is installed (LIF5000), The smoke alarm is correctly installed on the

mounting base and the alarm has been tested.

7.1.2 There are two LED indicators. Each of them has a unique function:

7.1.3 Red LED

7.1.3.A Stand-by condition: will flash once approximately every 40 seconds to

indicate unit is functioning properly.

7.1.3.B Alarm condition: the Red LED will be on solid state when unit goes into

alarm, indicating that products of combustion have been detected. Red

LED will latch on for about 5 minutes after the alarm stop. After 5

minutes the Red LED to diminish. For interconnected units, the originat-

ing smoke alarm Red LED will stay on. All other units will sound but the

Red LED will not be on or flash.

7.1.4 Green LED

7.1.4.A AC Mains-ON Indicator: indicates that the unit is operating with AC

power. If this LED goes out, it indicates that the AC power is off.

6. INSTALLATION

Figure 3: Wall mounting smoke alarm

For wall mounting,the connector must

be at the bottom. Ensure“ SLIDE TO

REMOVE ” arrow on the cover is

pointiong upwards (vertical) as shown.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 10

1111

7.2 False Alarm Hush Control Feature:

Note: Dense smoke will override Hush control feature and

sound a continuous alarm.

7.2.1 This smoke alarm has the capability of being temporarily

desensitized for approximately 5 minutes.

7.2.2 The smoke alarm is desensitized by pressing the“ H U S H ”

button on the smoke alarm cover.

7.2.3 After pressing the“ H U S H ” button, the alarm will silence

immediately and “ c h i r p ”every 40 seconds for approximately 5 min-

utes to indicate the alarm is in the temporary desensitized condition.

7.2.4 The smoke alarm will automatically reactivate after approximately

5 minutes and sound the alarm if particles of combustion are still

present.

7.2.5 The “HUSH” feature may be used repeatedly until the air has

cleaned.

WARNING: Before using the alarm HUSH feature, identify

the source of smoke and be certain that a safe condition

exists.

7. OPERATION, TESTING AND MAINTENANCE

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 11

7. OPERATION, TESTING AND MAINTENANCE

Function LED Status Recommendation

Normal Green ON Green LED indicate the AC mains

power is present.

Normal Red FLASHING every

40 seconds.

Red LED flashes every 30-40

seconds is normal. The smoke alarm

performs a self test every 30-40

seconds. The battery and electronics

is tested for the life of the unit.

Alarm mode Red light is SOLID.

Smoke alarm

activated.

Indicate smoke alarm has activated and is

in alarm mode. The Red LED will latch

solid for 5 minutes after the alarm and

then fade when alarm stops.

Alarm mode Red Light is OFF.

Smoke alarm

activated.

Smoke alarm in full alarm. Other intercon-

nected units may have activated the alarm.

Check other smoke alarms or devices.

Hush mode Green light ON. Red

light flashing every 40

seconds.

HUSH button is pressed. Smoke alarm

emits a chirp every 40 seconds for approx-

imately 5 minutes. Wait 5 minutes and the

chirp will automatically stop.

Low Battery Green ON, Flashing

red light every 40

seconds.

Smoke alarm chirp every 40 Seconds.

May indicate low battery status. Replace

the battery.

Fault Red light is SOLID

If the red light is constantly solid for more

than 15 minutes and there is no sign of

alarms. Could mean a potential fault with

the unit. Replace the alarm.

7.3 Operating and Alarm Characteristics.

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 12

13

8. BATTERY INSTALLATION , REPLACEMENT AND TEST

8.1 Battery Installation

8.1.1 The smoke alarm uses one 9V battery to automatically provide back-up

power to the alarm if AC power fails. The battery will operate the alarm for

approximately one to three months with AC power off.

8.1.2 The smoke alarm has a low battery indicator that will cause the unit to chirp

and flash the Red LED at approximately 40 second intervals for a minimum of 7

days. Missing battery with main power connected will cause the unit to chirp

and flash the Red LED at approximately 40 second intervals.

8.1.3 Replace battery when chirping occurs. To ensure proper operation, the bat-

tery should be replaced once a year.

8.1.4 To replace battery, remove alarm from mounting base(see section 6.2) and

remove the battery from compartment. Replace the old battery with a new one.

8.1.5 USE ONLY THE FOLLOWING 9-VOLT

ALKALINE BATTERIES FOR

REPLACEMENT:

EVEREADY/ENERGIZER 522

DURACELL MN1604, MX1604

These batteries can be purchased

at your local retail outlet or super-

market.

Caution: Use only specified bat-

teries. Use of different battery

may have a detrimental

effect on operation or may

cause the battery to explode re-

sulting in injury or fire.

RED BATTERY LEVER

Australia Patent

S/N 2008200075

Australia Patent

S/N 2008200075

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 13

14

8. BATTERY INSTALLATION , REPLACEMENT AND TEST

8.1.6 USE ONLY BATTERIES SPECIFIED ON THE LABEL .

8.1.7 Fold Red Battery Lever down into compartment with fresh replacement

battery. If the Red Battery Lever is not held down in the battery compart-

ment by the battery, the smoke alarm will not close and will not be opera-

tional. Battery can only be inserted in one direction, ensure polarity is correct.

WARNING: Use of inferior batteries or incorrect types may cause a malfunction of the

alarm. When replacing the battery and on reconnection of the detector to the base plate,

make sure that the detector is fully connected and flush with the base plate. Verify that

the Green LED is ON after reinstalling the alarm on the base plate.

8.2 Battery Test:

8.2.1 Switch off mains power. The Green LED on the smoke alarm will be OFF.

8.2.2 Test alarm by pressing on the Test Button for a few seconds. This should sound the alarm.

8.2.3 If the battery module has a fault, the alarm will chirp every 40 seconds.

8.2.4 Watch the Red LED for about 40 seconds. It should flash at least once.

8.2.5 Switch on mains power only when smoke alarm passes the above tests. The Green

LED on the smoke alarm will come ON.

NOTE: NO USER REPLACEABLE PARTS INSIDE.

NOTE: WEEKLY TESTING IS RECOMMENDED!

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 14

15

9. 9V TERMINAL AND REMOTE TEST & HUSH

WARNING: THIS TERMINAL IS NOT ISOLATED FROM THE MAINS SUPPLY.

This first terminal (Yellow) has a 9Vdc positive output and can be used for the following

applications: As an output to operate smoke alarm as an early warning indicator system.

The 9V terminal in this smoke alarm is intended for use with a security/fire alarm

panel where a signal from that panel can be used to activate a single Smoke Alarm or

interconnected Smoke Alarms to alert residents/occupants that an alarm has been acti-

vated elsewhere and there may be cause to evacuate the area. The diagram below

shows the 9V terminal and the Signal terminal, marked SW, connected to the N/O (nor-

mally open) contacts of a suitable relay, the coil of which when energized from an

extra-low voltage signal from an alarm panel, closes the contacts thereby activating the

Smoke Alarm(s). This can be an Early Warning Indicator System.

Note: The presence of an audible sound from the smoke alarm and the absence of a

flashing RED LED in the smoke alarm(s), means the smoke alarm(s) have been acti-

vated externally. It is an Early Warning Indicator.

However, check also for the presence of fire or smoke in the vicinity of your

dwellings. If there is fire, follow actions in Section 15.

It is essential that the relay and associated base must be of a type providing effective

isolation between the coil and contacts (having an isolation voltage [Dielectric

Strength] of 4kV and creep/clearance distances of no less than 8mm between the coil

and contacts). We recommend using an OMRON Relay Type G2R-2-SN and Base

Type 17X5W which meet the necessary isolation requirements.

The use of an unsuitable relay and base could also lead to an electric shock risk.

The wiring between the Smoke Alarm and the relay must be installed in accordance

with the relevant requirements of the SAA Wiring Rules, AS3000, for low voltage

(240V) conductors.

9.1 9V TERMINAL

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 15

16

Wiring Instruction Showing Smoke Alarms Interconnected

and Used as part of an Early Warning Indicator System

LOOP

N

SW

A

9V

LOOP

N

SW

A

9V

LOOP

N

SW

A

9V

1224

YELLOW

RED

WHITE

BLUE

ORANGE

ORANGE

YELLOW

RED

WHITE

BLUE

FIRE INDICATOR

PANEL

LOCAL ALARM PANEL

CONNECTION TO A

MAXIMUM OF 24 SMOKE ALARMS

FUSE ON

CIRCUIT

BREAKER

See installation manual

for isolation relay RK10A/9

N

SW

9V

24V

9. 9V TERMINAL AND REMOTE TEST & HUSH

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 16

17

9.2 REMOTE TEST & HUSH PLATE:

9. 9V TERMINAL AND REMOTE TEST & HUSH

This alarm has the ability to be connected to a Remote Test & Hush Plate(LIFTHP)

(optional accessory, sold separately). The diagram below shows a sample of the wiring

connection required for the Remote Test and Hush Plate. In order for this alarm to op-

erate properly with the LIFTHP, a Remote Test & Hush card (LIFTHC) is required for

each alarm in the interconnected system. See the owners manuals for the LIFTHP and

LIFTHC for complete operation and instructions.

THE WIRING BETWEEN LIF5000 AND LIFTHP

1

LOOP

9V ASW N

24

SW

LOOP

9V N

ASW

2

A

9V

LOOP

N

FUSE ON

CIRCUIT

BREAKER

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 17

18

9. 9V TERMINAL AND REMOTE TEST & HUSH

Smoke alarm with Remote Test & Hush card

Remote Test & Hush Plate

18

The Remote Test & Hush Plate can be mounted in an easy to reach location to

provide convenient access to the Test and Hush functions of your Models

3000, 5000, 5800, 5800RL, LANSD240P and LANSD240I smoke alarm.

Connection diagram between smoke alarm and Remote Test & Hush Plate

1298-7207-02_V1a:_ 2012.2.16 1:54 PM Page 18

Table of contents

Other PSA Products Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

Air Products & Controls

Air Products & Controls HS-100-N Installation and maintenance instruction

Elmes Electronic

Elmes Electronic MTS-166/9V quick start guide

SPECAVTOMATIKA

SPECAVTOMATIKA DOKA Instruction

onestock

onestock 54866 manual

Sontay

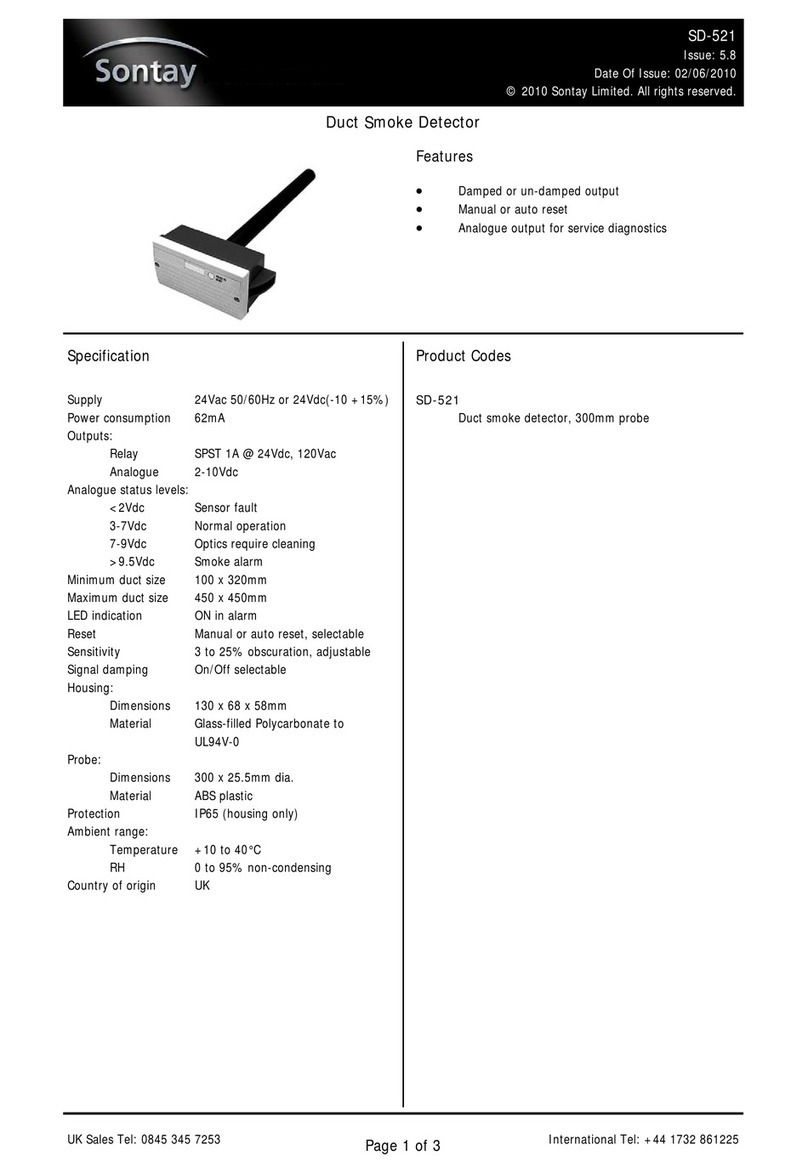

Sontay SD-521 quick guide

Ei Electronics

Ei Electronics Ei161RC Ionisation installation instructions