Clenergy PV-ezRack SolarTerrace II-F User manual

Other Clenergy Inverter manuals

Clenergy

Clenergy PV-ezRack Ascent User manual

Clenergy

Clenergy PV-ezRack SolarRoof Technical manual

Clenergy

Clenergy PV-ezRack SolarRoof User manual

Clenergy

Clenergy PV-ezRack SolarTerrace II Technical manual

Clenergy

Clenergy PV-ezRack User manual

Clenergy

Clenergy SPH15 User manual

Clenergy

Clenergy PV-ezRack SolarFloating I User manual

Clenergy

Clenergy PV-ezRack User manual

Clenergy

Clenergy PV-ezRack SolarRoof Technical manual

Clenergy

Clenergy PV-ezRack Grounding system Technical manual

Clenergy

Clenergy PV-ezRack SolarRoof User manual

Clenergy

Clenergy SPH50 User manual

Clenergy

Clenergy PV-ezRack SolarRoof Isolator Shade User manual

Clenergy

Clenergy PV-ezRack SolarRoof Technical manual

Clenergy

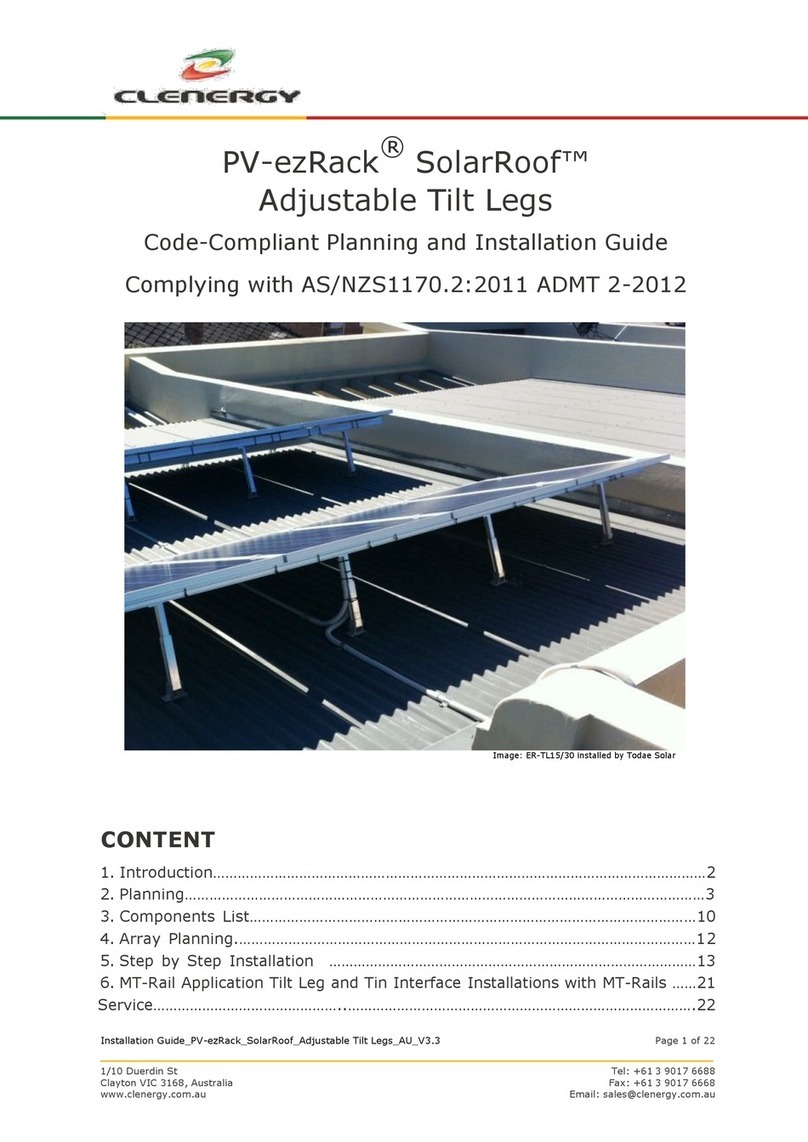

Clenergy PV-ezRack SolarRoof ER-TL-10/15 User manual

Clenergy

Clenergy PV-ezRack PostMount 4-A User manual

Clenergy

Clenergy PostMount 6-A User manual

Clenergy

Clenergy PV-ezRack Commercial Tilt User manual

Clenergy

Clenergy PV-ezRack SolarTerrace Eco User manual