PSI Woodworking Turncrafters Commander KWL1018VS User manual

© 2013 PSI Woodworking • Philadelphia, PA 19115 v5/13

™

Lathe

CONFORMS TO

UL STD.

No. 987

Certified to

CSA STD.

C22.2 No. 71.2

Manufactured by: Penn State Industries • Philadelphia, PA 19115

User’s Manual for models

KWL1018VS(10" swing) and KWL1218VS(12" swing)

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manual #KWLMAN

Turncrafters Commander V4

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

2

1. KEEP GUARDS IN PLACE and in working order.

2. KEEP WORK AREA CLEAN. Cluttered areas and benches invite

accidents.

3. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lighted.

4. KEEP CHILDREN AWAY. All visitors should be kept safe distance

from work area.

5. MAKE WORKSHOP KID PROOF removing starter keys.

6. DON’T FORCE TOOL. I t will do the job better and safer at the rate

for which it was designed.

7. USE RIGHT TOOL. D on’t force tool or attachment to do a job for

which it was not designed.

8. USE PROPER EXTENSION CORD. M ake sure your extension cord

is in good condition. When using an extension cord, be sure to use

one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. Table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage number, the

heavier the cord.

SPECIFIC SAFETY RULES FOR WOOD LATHES

WARNING - No adjustment should be made until the tool has been

stopped.

WARNING - Risk of injury due to accidental starting. Do not use in an

area where children may be present.

WARNING For Your Own Safety Read Instruction Manual Before

Operating Lathe.

a) Wear eye protection.

b) Do not wear gloves, necktie, or loose clothing.

c) Tighten all locks before operating.

d) Rotate workpiece by hand before applying power.

e) Rough out workpiece before installing on faceplate.

f) Do not mount split workpiece or one containing knot.

g) Use lowest speed when starting new workpiece.

WARNING : DO NOT EXPOSE TO RAIN OR USE IN DAMP

LOCATIONS.

ADDITIONAL SAFETY RULES FOR WOOD LATHES

1. Do not allow the turning tools to bite into the wood. The wood could

split or be thrown from the lathe.

2. Always position the tool rest above the centreline of the lathe when

shaping a piece of stock.

3. Do not operate the lathe if it is rotating in the wrong direction.

The workpiece must always be rotating toward you.

4. Before attaching a workpiece to the faceplate, always rough it out to

make it as round as possible, this minimizes the vibrations while the

piece is being turned. Always fasten the workpiece securely to the

faceplate, failure to do this could result in the workpiece being

thrown away from the lathe.

5. Position your hands so that they will not slip onto the workpiece.

9. WEAR PROPER APPAREL. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewelry which may get caught in

moving parts. Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

10. ALWAYS USE SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

11. DON’T OVERREACH. Keep proper footing and balance at all

times.

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

best and safest performance. Follow instructions for lubricating and

changing accessories.

13. DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

14. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure

switch is in off position before plugging in.

15. USE RECOMMENDED ACCESSORIES. Consult the owner’s

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

16. NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

17. CHECK DAMAGED PARTS.Before further use of the tool, a guard

or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function – check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

18. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER

OFF. Don’t leave tool until it comes to a complete stop.

GENERAL & SPECIFIC

SAFETY RULES

2

1. KEEP GUARDS IN PLACE and in working order.

2. KEEP WORK AREA CLEAN. Cluttered areas and benches invite

accidents.

3. DON’T USE IN DANGEROUS ENVIRONMENT. Don’t use power

tools in damp or wet locations, or expose them to rain. Keep work

area well lighted.

4. KEEP CHILDREN AWAY. All visitors should be kept safe distance

from work area.

5. MAKE WORKSHOP KID PROOF removing starter keys.

6. DON’T FORCE TOOL. I t will do the job better and safer at the rate

for which it was designed.

7. USE RIGHT TOOL. D on’t force tool or attachment to do a job for

which it was not designed.

8. USE PROPER EXTENSION CORD. M ake sure your extension cord

is in good condition. When using an extension cord, be sure to use

one heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of

power and overheating. Table shows the correct size to use

depending on cord length and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller the gage number, the

heavier the cord.

SPECIFIC SAFETY RULES FOR WOOD LATHES

WARNING - No adjustment should be made until the tool has been

stopped.

WARNING - Risk of injury due to accidental starting. Do not use in an

area where children may be present.

WARNING For Your Own Safety Read Instruction Manual Before

Operating Lathe.

a) Wear eye protection.

b) Do not wear gloves, necktie, or loose clothing.

c) Tighten all locks before operating.

d) Rotate workpiece by hand before applying power.

e) Rough out workpiece before installing on faceplate.

f) Do not mount split workpiece or one containing knot.

g) Use lowest speed when starting new workpiece.

WARNING : DO NOT EXPOSE TO RAIN OR USE IN DAMP

LOCATIONS.

ADDITIONAL SAFETY RULES FOR WOOD LATHES

1. Do not allow the turning tools to bite into the wood. The wood could

split or be thrown from the lathe.

2. Always position the tool rest above the centreline of the lathe when

shaping a piece of stock.

3. Do not operate the lathe if it is rotating in the wrong direction.

The workpiece must always be rotating toward you.

4. Before attaching a workpiece to the faceplate, always rough it out to

make it as round as possible, this minimizes the vibrations while the

piece is being turned. Always fasten the workpiece securely to the

faceplate, failure to do this could result in the workpiece being

thrown away from the lathe.

5. Position your hands so that they will not slip onto the workpiece.

9. WEAR PROPER APPAREL. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewelry which may get caught in

moving parts. Nonslip footwear is recommended. Wear protective

hair covering to contain long hair.

10. ALWAYS USE SAFETY GLASSES. Also use face or dust mask if

cutting operation is dusty. Everyday eyeglasses only have impact

resistant lenses, they are NOT safety glasses.

11. DON’T OVERREACH. Keep proper footing and balance at all

times.

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for

best and safest performance. Follow instructions for lubricating and

changing accessories.

13. DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

14. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure

switch is in off position before plugging in.

15. USE RECOMMENDED ACCESSORIES. Consult the owner’s

manual for recommended accessories. The use of improper

accessories may cause risk of injury to persons.

16. NEVER STAND ON TOOL. Serious injury could occur if the tool is

tipped or if the cutting tool is unintentionally contacted.

17. CHECK DAMAGED PARTS.Before further use of the tool, a guard

or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended

function – check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other part that is damaged

should be properly repaired or replaced.

18. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER

OFF. Don’t leave tool until it comes to a complete stop.

SAFETY RULES

KWL1018VS KWL1218VS PSI Woodworking Products

Distributed by: © 2022PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

KWL1018VS KWL1218VS PSI Woodworking Products

3

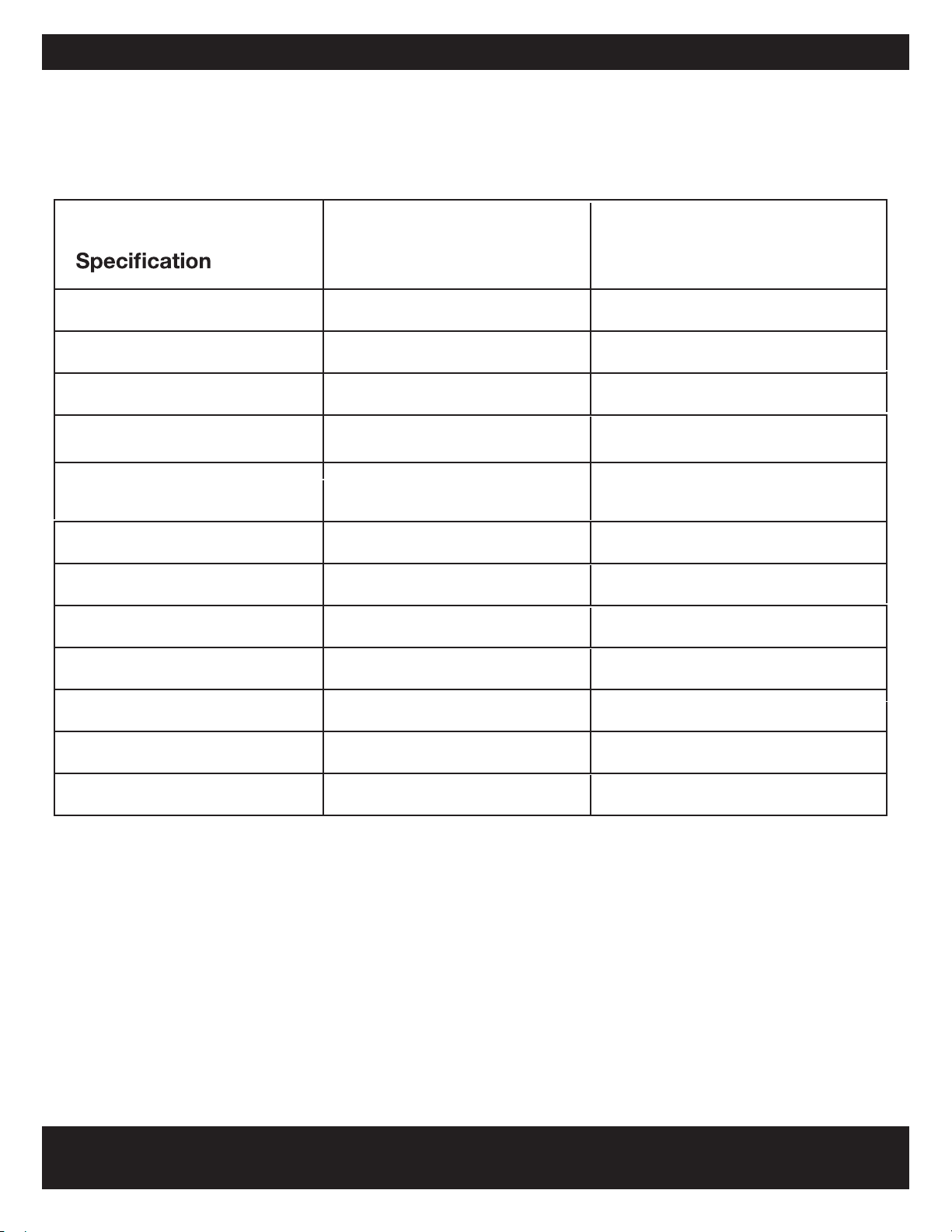

SPECIFICATIONS OF THE TURNCRAFTER COMMANDER MIDI LATHE

Turncrafter Commander 10” Swing Commander

Item No. #KWL-1018VS

Motor Power 1HP -7.4A

Belt Positions 2

Spindle Speeds (Variable) Variable 450-1700 RPM &

950-3800 RPM

Headstock/Tailstock 1” x 8tpi / #2 MT

Between Centers 18”

Construction Cast Iron

Swing over bed 10”

Weight 82 lbs.

Footprint 31” x 7-1/4”

Tailstock Triavel 4”

WARRANTY

Turncrafter Commander Lathes are warranted against defects in materials and workmanship for a period of three (3) years

from the date of purchase. This warranty applies to the purchaser of this product, and is limited to repair or replacement of the

product or it’s parts at PSI Woodworking Products’ discretion. Excluded are parts, which have been misused, abused, altered,

or consumed by normal operation of the machine. Also excluded are direct or consequential damages to the persons, prop-

erty, and/or materials. Your invoice serves as proof of purchase and must be referenced prior to return authorization. Contact

your dealer where you purchased your lathe for service or repair issues.

12” Swing Commander

#KWL-1218VS

1.5HP -11.19A

2

1” x 8tpi / #2 MT

18”

Cast Iron

12”

106 lbs.

31” x 9-1/2”

4”

Motor Speeds Variable Speed 110v 1Variable Speed 110v

Variable 450-1600 RPM &

950-3600 RPM

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

4

RECEIVING

1. Remove all parts and components from shipping carton. Remove all the packing and locate all loose parts.

2. Inspect the contents of the carton for shipping damage. Compare the contents of the loose parts to the list

provided. Report any missing or damaged parts to your distributor.

3. Keep the carton and packing material in case you need to pack and move the lathe.

4. Some metal surfaces on the lathe may have been treated with a protective coating prior to shipping.

Clean them with a soft rag prior to use. DO NOT use paint thinner, gasoline, or any other heavy solvents

to remove the protective coating or you will damage the lathe’s painted surface. Clean the lathe using only

a damp cloth or a very mild solvent.

A. Tool rest (6”) and (12”)

B. Faceplate (3” pre-installed)

C. Spur Drive Center (#2 MT)

D. Hex wrench (set of 4)

E. Rubber feet (4) (if not installed)

F. Safety Goggles

G. Knock out rod

H. Tool Caddy

I. Phillips Screw Driver

J. Heavy duty tailstock

live center

K. Tailstock Handle and bolt

A

B

C

D

E

F

G

H

J

IK

Loose Parts Included with Lathe (Box no.2)

KWL1018VS KWL1218VS PSI Woodworking Products

(packed in box#1).

NOTE: KWL1018VS is delivered in one box

The packing of the KWL1218VS is in two boxes. The first box contains the lathe bed with motor assembly

and switch box (mounted).

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

5

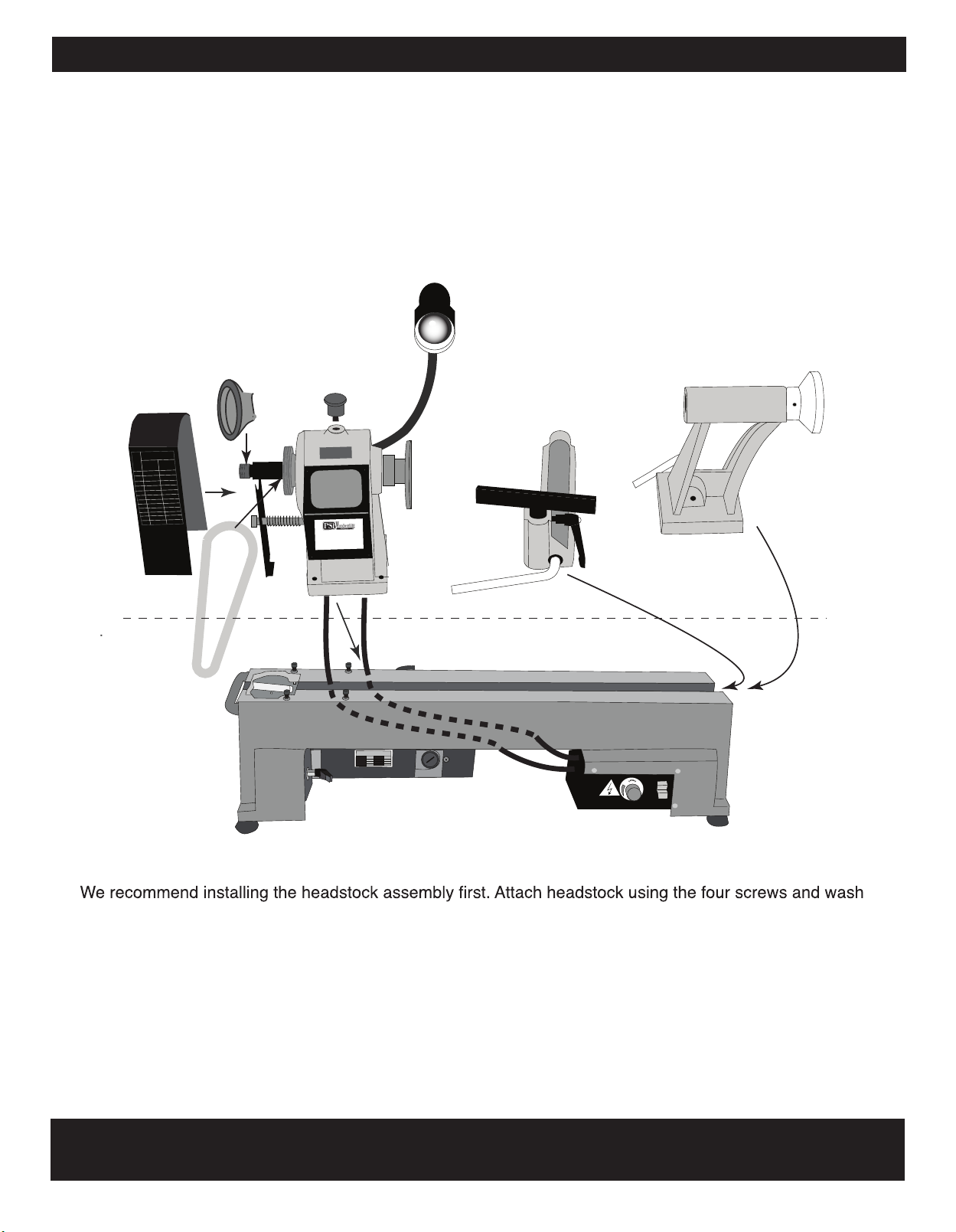

ASSEMBLY OF MAJOR COMPONENTS

Maximum

Speed For

Balanced

Turnings

Maximum RPM

Roughing

Maximum RPM

Finishing

r

e

t

e

m

ai

D

e

c

i

ep

k

r

o

W

1”

2”

3”

4”

”5

6”

”

7

”

8

”

9

10”

11”

12”

4100 4100

4000

3000

2000

2000

2600

1500

1200 1600

1000 1330

850 1100

750 1000

660

660

900

600 800

540

500

725

HEAD STOCK SPINDLE SPEED

ON

OFF

DC Motor

Headstock Assembly

Tailstock Assembly

Toolrest(s)

Lathe Bed

Belt Cover

Handwheel

Belt Contents of Box 2

Contents of Box 1

Indexing Knob

The second contains the headstock assembly, toolrest and tailstock assembly.

0

0

0

ers

KWL1018VS KWL1218VS PSI Woodworking Products

cord

and power

inside the bottom of the headstock. Plea

attach to circut board

Lead the digital readout cable

MOTOR CONNECTION (Both Models)

Manufactured by: Penn State Industries

6

To make connection to the control box

1. Plug the wire from the motor to the box (A) CAUTION: DO NOT PLUG A into B

2. Plug power cord intocontrol box.(B) CAUTION: DO NOT PLUG INTO OUTLET.

3. Plug in cord from switch box to headstock (C)

4. Plug power cord into outlet.(B)

Notch on plug

and socket must

be align, for

proper operation.

C

Control Box

Mot

Reset button

or connection

motor to control box

Power connection

Speed digital readout

to headstock

Speed digital readout

to headstock

Powercord

motor to outlet

To worklight

AB

C

D E

A

B

C

Brush cap

5. Plug worklight wire from switch box (D)

to female socket (E)of worklight wire from headstock.

already plugged into control box.

(C) from the switch box, through the lathe bed and

se note your lathe is delivered with the motor cable (A)

(B)

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

ATTENTION

KWL1018VS KWL1218VS PSI Woodworking Products

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

7

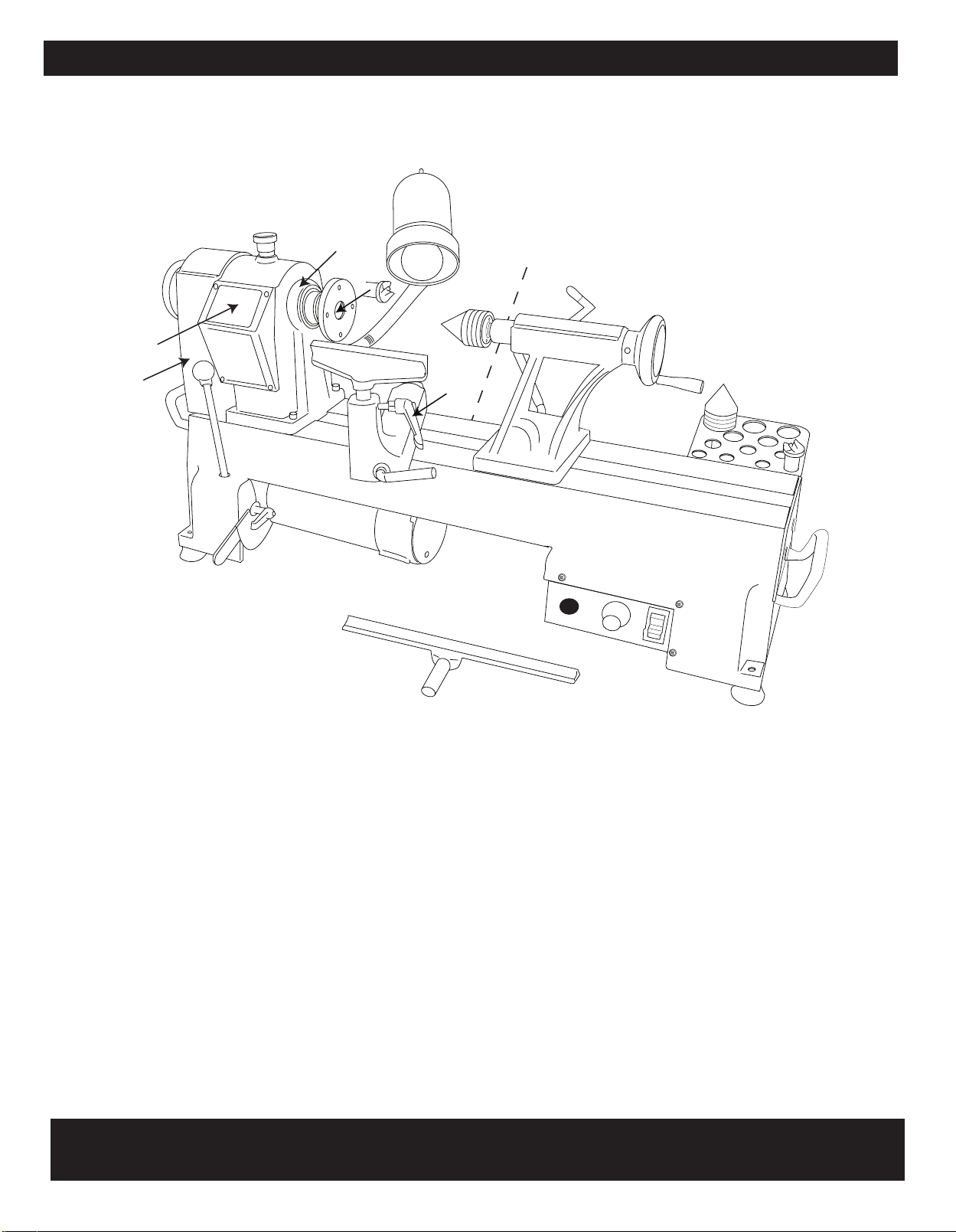

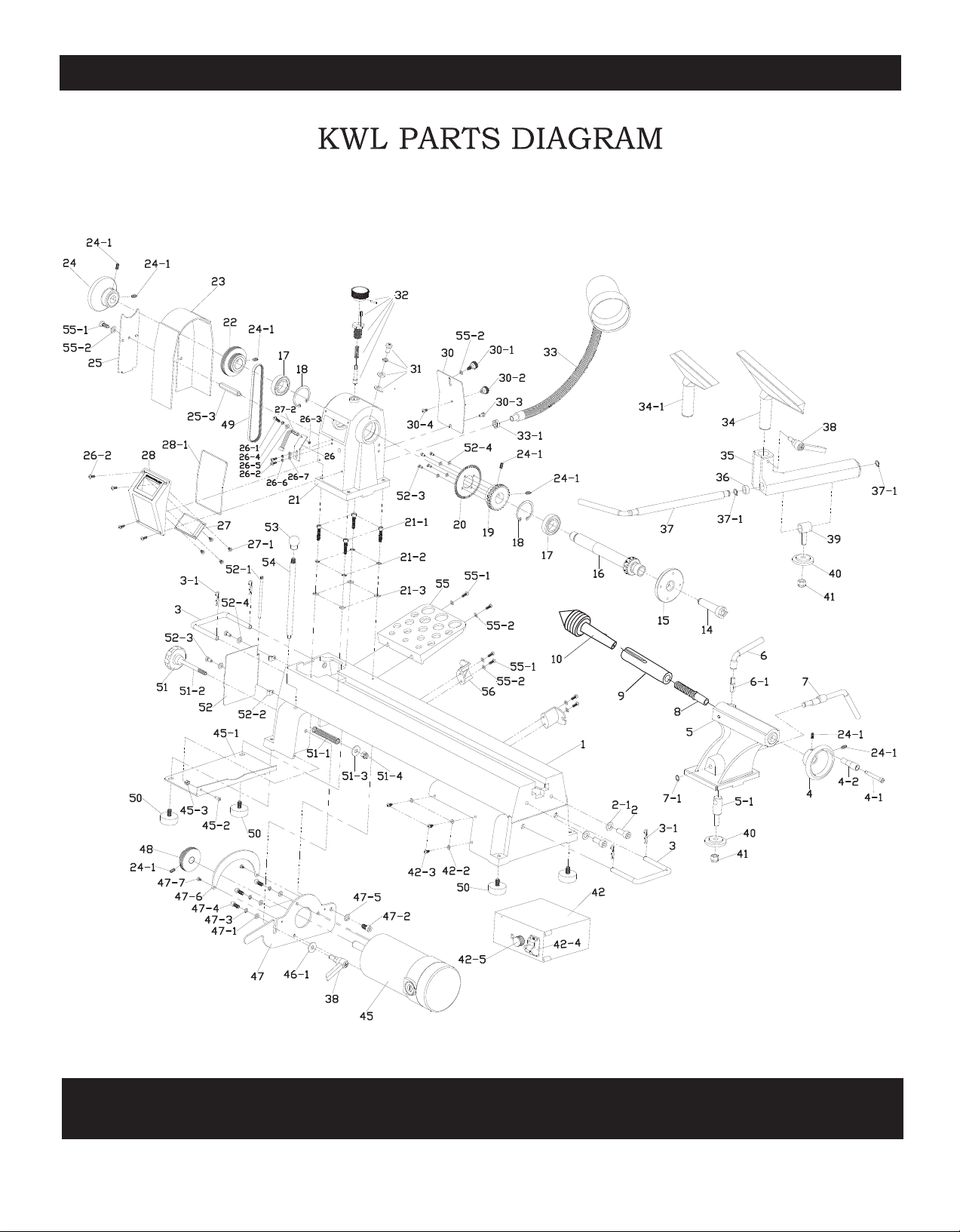

1. Lathe Bed

2. Tailstock

3. Hand Wheel (Quill Adjustment)

4. Quill Tightening Lever

5. Live Tailstock Center

6. 6” Toolrest, 12” Toolrest (6A)

7. Headstock

8. Faceplate (Installed for shipping)

9. Headstock Hand Wheel

10. Motor & Adjustment lever (10A)

11. Speed Control

12. Power Switch

13. Spindle Lock Knob

14. Index Indicator

15. Cord Wrapping Supports

16. Tool Caddy

17. Knockout Rod

18. Work Light (BULB INCLUDED)

19. Mounting Holes for extension bed

20. Rubber Feet (4)

21. Variable Speed Indicator Window

22. Tailstock tightening lever

23. Tool rest holder Assembly

24. Spur Drive Center

25. Reset Button

26. Carry Handles

27. Tool rest post tightening lever

28. Tool rest holder tightening lever

29. Belt Cover

30. Tailstock handle

LATHE COMPONENTS

1

2

3

4

5

6

7

8

9

10

11 12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

6

10A

27

28

29 30

KWL1018VS KWL1218VS PSI Woodworking Products

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

Mounting Lathe to worksurface:

The lathe can be permanently attached to a work surface

by inserting screws through the holes in the base instead of

rubber feet. Be sure to position the lathe so that there is an

open space directly beneath the motor and work surface to

prevent shavings from building up and fouling the motor or

switch box (about the thickness of rubber feet between lathe

bed feet and work surface). For general tabletop work, install

the four rubber feet (20).

Install Tool Caddy: (16)

Using the two pan head screws, install the tool caddy on the

rear of the lathe bed.

Work Lamp: (18)

Use only a 40 watt or smaller bulb in the work lamp. Position

the lamp to prevent shavings from accumulating in the hous-

ing. Bulb not included.

Lock Pin: (13)

IMPORTANT - When NOT using the indexing feature, Pull up

the pin and rotate it to the UNLOCK position and drop it in place.

Check the lathe’s spindle to make sure it is spinning freely. The

pin MUST BE UNLOCKED with the spindle spinning freely before

turning on your Lathe – neglecting to do this may damage your

lathe when you next turn it on. See page 9 for indexing feature.

1. Install loose parts as indicated in the Assembly Diagram on pg.5.

2. Inspect Tailstock (2): Verify that all knobs and handles work properly and that the tailstock slides

along bed and live center bearings spin freely and locks with lock knobs

3. Tool rest: (6) - Verify all handles work properly and assembly (23) slides and locks properly along bed.

4. Headstock: (7) - Belt is attached and tight. Door levers and bearings operate properly and

spindle turns freely.

5. Control Box: (11) - Check that the knob and switch are intact and operate without power.

6. Indexing Spindle Lock: (13) - Make sure it engages and disengages and it properly locks spindle at

indexing indicator.

IMPORTANT - When NOT using the indexing feature, Pull up the pin and rotate it to the UNLOCK position and drop it in place. Check the

lathe’s spindle to make sure it is spinning freely. The pin MUST BE UNLOCKED with the spindle spinning freely before turning on your Lathe –

neglecting to do this may damage your lathe when you next turn it on.Unlock knob before turning on lathe.

7. Turn Power switch (12) - to off position. Plug in lathe. Test work light switch. (with power

switch in off position)

8. Dial speed to lowest speed. Make sure spindle turns freely and does not interfere with loose parts or

obstructions. Turn on lathe. Test speed knob (11) from slow to fast.

INSTRUCTIONS Prior to use

Tool Rest & Tailstock Assembly:

From the opposite end of the lathe bed, attach the toolrest (23) rst, then follow with the tailstock assembly (2).

Make sure all connections are tight and secure.

e

3000

Tool Caddy

Work Lamp:

Lock Pin

e

3000

KWL1018VS KWL1218VS PSI Woodworking Products

8

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

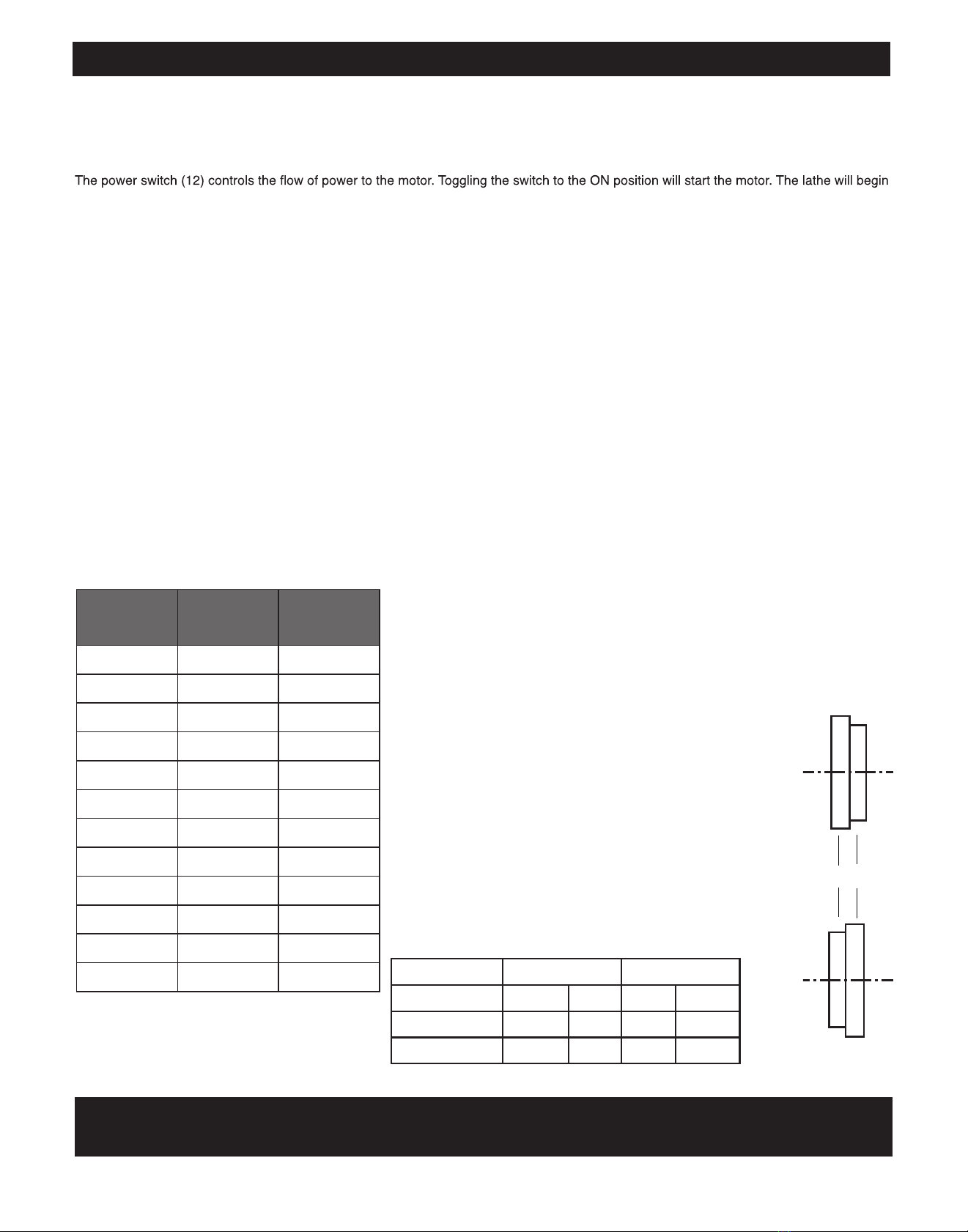

KWL1018VS KWL1218VS

Position A B A B

Minimum 450 950 450 950

Maxium 1700 3800 1600 3600

Speeds RPM*

A B

Spindle

Motor

USING YOUR LATHE

Powering the Lathe:

turning and reach its full speed within a few seconds. The time the motor takes to reach its full speed will depend on the size of the work

piece and the speed setting. Toggle the switch to the OFF position to stop the lathe. Wait for the tool to come to a complete stop before at-

tempting any further operation.

Variable Speeds

The speed control knob (11) determines the rate at which the lathe will turn. Turn the knob clockwise to increase speed control and counter

clockwise to decrease speed. Always set this to the lowest setting prior to turning on the lathe. The lathe speed is indicated digitally through

the window. (21)

Changing Belt Speeds - Make sure the lathe is unplugged. Loosen the knob on the cover plate. Slide the cover up and off the lathe.

Loosen the motor plate ratchet handle (10a) to allow the motor plate to swivel upwards. To change the speed, move the belt drive from one

pulley to another. (Note, Always go from the headstock pulley to the motor pulley) After moving the belt, tighten the motor pulley with the

ratchet handle (10a); this also tightens the belt. Turn your lathe’s power on, and make sure that the belt is running consistently in its parallel

groove. If all is smooth, turn the power off, reattach the cover.

Work piece

Diameter

Max RPM

Roughing

Max RPM

Finishing

1” MAX MAX

2” 3000 MAX

3” 2000 2600

4” 1500 2000

5” 1200 1600

6” 1000 1330

7” 850 1100

8” 750 1000

9” 660 900

10” 600 800

11” 540 735

12” 600 660

Maximum Speeds for Balanced Turning

MAX = Maximum Lathe Speed 3600

Replacing the Belt

The Turncrafter Commanders are designed with a special

feature that allows quick and easy belt changes.

· Remove belt cover

· Loosen motor plate handle (10a)

· Loosen belt and remove old belt

· Slide the new belt over the headstock spindle

pulley and onto the motor pulley.

· Tighten belt with motor plate handle (10a)

Pulley Positions and Speeds:

Remove the belt cover (29). Loosen motor

racket handle (10). Move belt to speed

position as indicated in illustration below.

KWL1018VS KWL1218VS PSI Woodworking Products

9

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

Spur Center (24) - The spur drive center locks into the headstock with a #2 Morse Taper and holds the work piece in place while the

spindle is in operation. The knockout rod (17) slides into the headstock from the rear to tap the spur center free. The knockout rod can be

stored in the hole (17) in the front of the lathe. When performing this operation, be sure to hold the spur center to prevent it from falling and

damaging the tip. Use the dead safety center (31) to help avoid catches.

Faceplate (8) - Note: The faceplate is pre-installed with your lathe. Remove it prior to using the lathe. The faceplate screws directly on

to the headstock spindle. Use brass wood screws (not included) to secure your work piece to the face plate. Use screws that are not overly

long to ensure that they do not enter the portions of the work piece where you plan to remove the material. To remove the faceplate from the

spindle, hold the headstock hand wheel, unscrew the faceplate.

Tool Rest (6) - The tool rest is used to steady the cutting tool while the lathe is in operation. You can position the tool rest by releasing

the lock handle (28) positioned on the side of the rest and sliding the rest into the desired position. Tighten the lock handle to secure the tool

rest into position. The height of the tool rest can be adjusted releasing the lock handle (27) located on the front of the rest and adjusting the

height to the desired position and then tightening the lock handle. The position of the tool rest locking handle can be adjusted by reaching

under the bed and loosening the clamp nut. Slide the handle into position. Tighten the clamp nut. The tool rest should be positioned just

above the center line of the work piece.

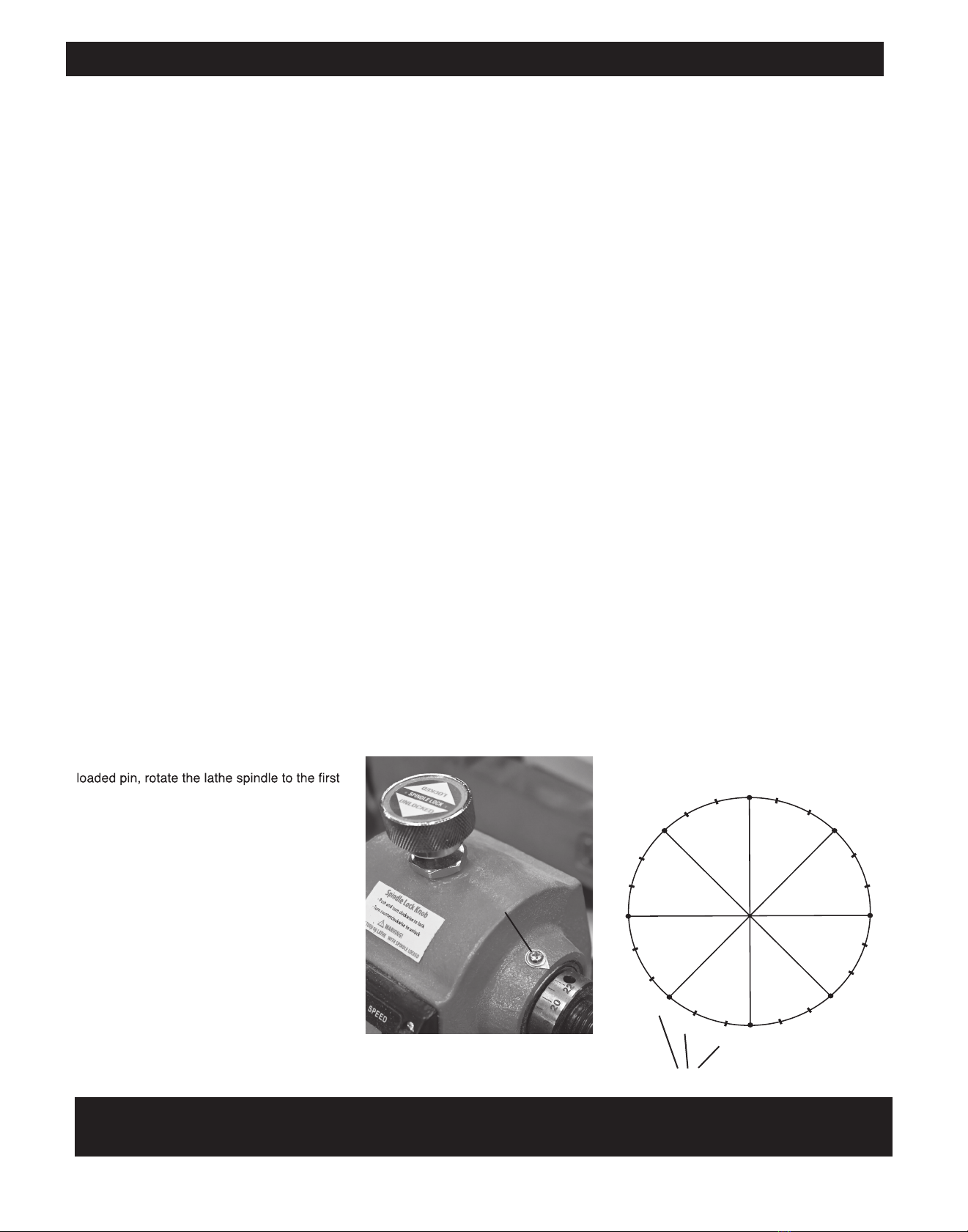

Indexing Operation:

The indexing knob (13) allows you to make evenly spaced cuts on a work piece while keeping the headstock spindle locked. The

spindle index indicator (14) points to 24 grooves available on the spindle so the turning’s sections can be made in multiples of 24,

12, 8, 6, 4, 3, and 2. For example, to make 8 equal sections, mark your work at 1, 4, 7, 10, 13, 16, 19, and 22.

Example of Indexing 8 equal sections

1

1

2

2

3

3

4

5

6

7

8

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23 24

IMPORTANT - When NOT using the indexing fea-

ture, Pull up the pin and rotate it to the UNLOCK po-

sition and drop it in place. Check the lathe’s spindle

to make sure it is spinning freely. The pin MUST BE

UNLOCKED with the spindle spinning freely before

turning on your Lathe – neglecting to do this may

damage your lathe when you next turn it on.

To use the lathe’s indexing feature you need

to use the lock pin (13). Pull up on the spring

indexing position. Rotate and drop the pin into

the “LOCK” position and perform your indexing

operation while the spindle is locked in place.

Use the index indicator to locate the index

stops you want. Continue to pull up the pin

and rotate the spindle to subsequent index po-

sitions and drop the pin to secure the spindle

until all indexing operations are completed.

Warning - Be sure to clean both the taper on the spur center and the inside of the headstock spindle prior to mounting the spur

center. Failure to do so may cause the two components to separate causing possible injury or damage to the tool.

Lock Pin

Index indicator

Index positions marked on spindle

KWL1018VS KWL1218VS PSI Woodworking Products

10

KWL1018VS KWL1218VS PSI Woodworking Products

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries 11

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Manufactured by: Penn State Industries

12

KWL1018VS KWL1218VS PSI Woodworking Products

Part No. KWL1018VS QTY Part No. KWL1018VS KWL1218VS Description QTY

1 ZTCLC1 1 30-3 ZTCLC30-3 ZTCLC30-3 Screw 1

2 ZTCLC2 2 30-4 ZTCLC30-4 ZTCLC30-4 Screw 1

2-1 ZTCLC2-1 2 31 ZTCLC31 ZTCLC31 Connecting stand Assembly 1

3 ZTCLC3 2 32 ZTCLC32 ZTCLC32Z Stop bolt Assembly 1

3-1 ZTCLC3-1 4 33 ZTCLC33 ZTCLC33 Work light 1

4 ZTCLC4 1 33-1 ZTCLC33-1 ZTCLC33-1 Hex nut M12 1

4-1 ZTCLC4-1 1 34 ZTCLC34 ZTCLC34Z Tool rest 6” 1

4-2 ZTCLC4-2 1 34-1 ZTCLC34-1 ZTCLC34-1Z Tool rest 12” 1

5 ZTCLC5-10L 1 35 ZTCLC35 ZTCLC35Z Tool rest base 1

5 ZTCLC5-10S 1 36 ZTCLC36 ZTCLC36 Bushing 1

5-1 ZTCLC5-1 1 37 ZTCLC37 ZTCLC37Z Lock handle for tool rest base 1

6 ZTCLC6 1 37-1 ZTCLC37-1 ZTCLC37-1 Tool rest retaining ring 2

6 ZTCLC6Z 1 38 ZTCLC38 ZTCLC38 Toolrest/Motor Locking Handle assy 2

6-1 ZTCLC6-1 1 39 ZTCLC39 ZTCLC39 Tool rest cam follower 1

7 ZTCLC7 1 40 ZTCLC40 ZTCLC40 Step washer 2

7-1 ZTCLC7-1 1 41 ZTCLC41 ZTCLC41 Lock nut M10 2

8 ZTCLC8Z 1 42 ZTCLC10VSB ZTCLC10VSB Control Switch box 1

8 ZTCLC8 1 42-2 ZTCLC42-2 ZTCLC42-2 Washer Ø4 3

9 ZTCLC9Z 1 42-3 ZTCLC42-3 ZTCLC42-3 R.H. machine screw M4x25 3

10 LCENTLT2 1 42-4 ZTCLC42-4 ZTCLC42-4 Control box switch 1

14 ZTCLC14 1 42-5 ZTCLC42-5 ZTCLC42-5 Control box speed control knob 1

15 CF3J 1 45 ZTCLC10VMO ZTCLC12VMO Motor 1

16 ZTCLC16 1 45-1 ZTCLC45-1 ZTCLC45-1Z Motor guard 1

17 ZTCLC17 2 45-2 ZTCLC45-2 ZTCLC45-2 Round head bolt M4x10 1

18 ZTCLC18 2 45-3 ZTCLC45-3 ZTCLC45-3 Nut M6 1

19 ZTCLC19 1 46-1 ZTCLC46-1 ZTCLC46-1 Lock Washer 1

20 ZTCLC20 1 47 ZTCLC47 ZTCLC47Z Motor plate with notch 1

21 ZTCLC21 1 47-1 ZTCLC47-1 ZTCLC47-1 Washer Ø6 1

21-1 ZTCLC21-1 4 47-2 ZTCLC47-2 ZTCLC47-2 Hex socket screw M8x16 1

21-2 ZTCLC21-2 4 47-3 ZTCLC47-3 ZTCLC47-3 Spring washer Ø4 3

21-3 ZTCLC21-3 4 47-4 ZTCLC47-4 ZTCLC47-4 Hex socket screw M6x16 3

22 ZTCLC22 1 47-5 ZTCLC47-5 ZTCLC47-5 Washer Ø8 1

23 ZTCLC23 1 47-6 ZTCLC47-6 ZTCLC46-6Z Guard 1

24 ZTCLC24 1 47-7 ZTCLC47-7 ZTCLC47-7 Round head bolt M4x16 2

24-1 ZTCLC24-1 8 48 ZTCLC48 ZTCLC48Z Motor pulley 1

25 ZTCLC25 1 49 ZTCLC1049W ZTCLC1249W Drive belt 1

25-3 ZTCLC25-3 1 50 ZTCLC50 ZTCLC50 Adjustable Rubber Feet 4

26 ZTCLC26 1 51 ZTCLC51 ZTCLC51 Knob 1

26-1 ZTCLC26-1 1 51-1 ZTCLC51-1 ZTCLC51-1 Spring 1

26-2 ZTCLC26-2 6 51-2 ZTCLC51-2 ZTCLC51-2 Bolt M8 1

26-3 ZTCLC26-3 1 51-3 ZTCLC51-3 ZTCLC51-3 Washer Ø8 1

26-4 ZTCLC26-4 1 51-4 ZTCLC51-4 ZTCLC51-4 Nut M8 1

26-5 ZTCLC26-5 1 52 ZTCLC52 ZTCLC52 Mounting plate 1

26-6 ZTCLC26-6 2 52-1 ZTCLC52-1 ZTCLC52-1 Pin hinge 1

26-7 ZTCLC26-7 2 52-2 ZTCLC52-2 ZTCLC52-2 Hinge 2

27 ZTCLC27 1 52-3 ZTCLC52-3 ZTCLC52-3 R.H. machine screw M4x8 6

27-1 ZTCLC27-1 4 52-4 ZTCLC52-4 ZTCLC52-4 Washer Ø4 6

27-2 ZTCLC27-2 1 53 ZTCLC53 ZTCLC53 Ball 1

28 ZTCLC28 1 54 ZTCLC54 ZTCLC54 Knock-out rod 1

28-1 ZTCLC28-1 1 55 ZTCLC55 ZTCLC55 Tool rack 1

30 ZTCLC30 1 55-1 ZTCLC55-1 ZTCLC55-1 R.H. machine screw M5x12 7

30-1 ZTCLC30-1 1 55-2 ZTCLC55-2 ZTCLC55-2 Washer Ø5 7

30-2 ZTCLC30-2 1 56 ZTCLC56 ZTCLC56 Cable Support 2

ZTCLC2-1 Washer Ø10

ZTCLC3Z Handle

ZTCLC3-1 Retaining ring

KWL1218VS Description

ZTCLC1Z Bed

ZTCLC2 Hex socket screw M10x25

ZTCLC5Z-12L Long Tailstock Red

ZTCLC5-1 Cam follower tailstock

ZTCLC6 Handle Assy. w/point (old)

ZTCLC4 Quill adjusting wheel

ZTCLC4-1 Bushing

ZTCLC4-2 Screw

ZTCLC5Z-12S Short Tailstock Red

ZTCLC8 Tailstock axis Long 3-9/16”

ZTCLC9Z Tailstock quill /assy.

LCENTLT2 Tailstock Center

ZTCLC6-1 Lock bolt

ZTCLC7Z Eccentric axis

ZTCLC7-1 Tailstock retaining ring

ZTCLC17 Ball bearing 80105

ZTCLC18 Head stock retaining ring

ZTCLC19 Gear

ZTCLC14 Headstock spur center

CF3J Face plate

ZTCLC16 Headstock spindle

ZTCLC21-2 Spring washer

ZTCLC21-3 Washer Ø8

ZTCLC22 Drive pulley

ZTCLC20Z Round plastic plate

ZTCLC21Z Headstock assy.

ZTCLC21-1 Hex socket screw M8x30

ZTCLC25 Side plate

ZTCLC25-3 Connecting rod

ZTCLC26 Connecting plate

ZTCLC23Z Side protection guard

ZTCLC24 Hand wheel

ZTCLC24-1 Socket set screw M6x12

ZTCLC26-5 Washer Ø3

ZTCLC26-6 Spring washer Ø4

ZTCLC26-1 Round head bolt M3x12

ZTCLC26-2 Round head bolt M4x10

ZTCLC26-3 Hex nut M3

ZTCLC6Z Handle Assy. (new)

ZTCLC8Z Tailstock axis Long 5-5/8”

ZTCLC30Z Rear plate

ZTCLC30-1 Moving knob

ZTCLC30-2 Stationary knob

ZTCLC27-2 Connector

ZTCLC28Z Display housing

ZTCLC28-1Z Seal ring

ZTCLC26-7 Washer Ø4

ZTCLC27 Display plate

ZTCLC27-1 Tapping screw

ZTCLC26-4 Spring washer Ø3

Manufactured by: Penn State Industries

13

ACCESSORIES AVAILABLE FROM PSI WOODWORKING

PRODUCTS FOR YOUR COMMANDER LATHE

+VGO &GUETKRVKQP 6[RKECN2TQFWEVU

.CVJG'ZVGPUKQP$GF 'ZVGPFUVJGNCVJGCPF5RKPFNG[QWECPVWTPVQr 6%.%:$HQTr5V[NG

&WRNKECVKPI#VVCEJOGPV 'PCDNGUFWRNKECVKPIUOCNNRTQLGEVUVQrNQPI/CMGUHCUV

CPFGCU[EQRKGU

%/.&72/#:HQTr5V[NG

%JWEMU 6QOQWPVWRCXCTKGV[QHYQTMQPVQ[QWTJGCFUVQEM

5V[NGUKPENWFGFTKNNEJWEMUOKPKEJWEMUUETGYEJWEMUEQN

NGVEJWEMUCPFEJWEMUV[NGUHQTNCTIGTYQTM

%5%%8GTUCVKNGUGNHEGPVGTKPI

OWNVKEQORQPGPVU[UVGO

2NWUOCP[QVJGTUV[NGUCXCKNCDNG

2GP/CPFTGNU 'UUGPVKCNHQTOCMKPIRGPUCPFQVJGTUOCNNRTQLGEVUQP

[QWTNCVJG/QWPVURGPDNCPMUHQTVWTPKPICPF뺝PKUJKPI

2-/(.%(KVUKPVQVJG/6

QRGPKPIKPVJGJGCFUVQEM

.CVJG6QQNU 5MGY%JKUGNUHQT뺝PCN뺝PKUJKPICPFUOQQVJEWVU

CPFDGCFKPI

2CTVKPI6QQNUVQVTKOQHHYCUVGGUVCDNKUJCFKCOGVGT

QTEWV뺞CVCTGCU

4QWIJKPI)QWIGU(QTCIITGUUKXGN[VCMKPIUSWCTG

URKPFNGUVQCTQWPF

5RKPFNG)QWIGU(QTIGPGTCNRWTRQUGVWTPKPICURKPFNG

HTQOTQWIJTQWPFVQCPGCT뺝PKUJ#HCXQTKVGHQTRGPU

5ETCRGTU(QTUOQQVJKPICPFHQTKPVGTKQTENGCPWRKPUKFG

CDQYNCHVGTIQWIGYQTMKUEQORNGVGF

$QYN)QWIGU7UGFHQTJQNNQYKPIQWVDQYNEGPVGTU7UGF

QPOQUVHCEGRNCVGYQTM

.CVJG6QQNUGVU+PENWFGCXCTKGV[QHUK\GUCPFUV[NGUQH

VJGCDQXG

5RGEKCNV[6QQNUHQT/CMKPIDGCFUCPFEQXGUKPVGTKQTCPF

GZVGTKQTDQYN뺝PKUJKPIDQYNJQNNQYKPIOCMKPIVGPQPU

CPFFQXGVCKNUCPFOQTG

.:rRNWUQVJGTU

.:rRNWUQVJGTU

.:rRNWUQVJGTU

.:rRNWUQVJGTU

.:rRNWUQVJGTU

.:rRNWUQVJGTU

.%*55REXCTKGV[

1VJGTURGEKCNV[UGVUCXCKNCDNG

.%*1.5'6$QYNJQNNQYKPIUGV

YKVJTGRNCEGCDNGEWVVGTUCPFQVJGTU

(CEGRNCVGU (QT/QWPVKPIDQYNU/CP[UK\GUCTGCXCKNCDNGFGRGPFKPI

QPVJGUK\GQHVJGDQYNDGKPIVWTPGF

%(rHCEGRNCVGOCP[QVJGTUK\GU

CXCKNCDNG

&TKXG%GPVGTU /CP[UV[NGUCXCKNCDNGHQTURGEKCNCRRNKECVKQPU .%'06555WRGTFTKXG

OWNVKRTQPIUV[NGRNWUQVJGTU

6QQNTGUVU /CP[URGEKCNRTQ뺝NGUCXCKNCDNGHQTDQYNVWTPKPINQPIGT

YQTMUJQTVGTYQTM

%.65,q5rVQQNTGUVHQTDQYN

VWTPKPIRNWUQVJGTU

1VJGT'SWKROGPV 5RGEKCNV[KVGOUVQWUGYKVJ[QWTNCVJGKPENWFGUCPFKPIU[UVGOUURGEKCNEJWEMLCYUOGCUWTKPI

CPFOCTMKPIRTQFWEVUVCKNUVQEMEGPVGTUOCPFTGNUCXGTCPFOQTG

KWL1018VS KWL1218VS PSI Woodworking Products

Distributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

Distributed by:

Manufactured by: Penn State Industries

For more information visit your local PSI dealer.

TYPICAL LATHE OPERATIONS

NOTE: Remove Faceplate (8) prior to using lathe

Spindle Turning

• Work mounted between headstock spur center and live tailstock center

• Requirements: no additional accessories

• Optional headstock mounting with lathe chuck

Bowl Turning

• Mount work to faceplate with screws

• Requirements: no additional accessories

• Lathe chuck optional

Pen Making

• Work mounts on pen mandrel - secured with live tailstock center

• Requirements: pen mandrel

Drilling

• Work mounted in headstock chuck

• #2MT drill chuck mounted in tailstock

• Requirements: lathe chuck, #2MT drill chuck, drill bit

Sanding

Use the fastest speed possible without burning the wood. Use graduated grits from 150 grit for

best results.

Finishing

Generally nishing can be done at faster speeds than turning. Finish using nishing polishes,

waxes and bufng compounds on or off the lathe.

KWL1018VS KWL1218VS PSI Woodworking Products

14 © 2022 PSI Woodworking • Philadelphia, PA 19115

© 2013 PSI Woodworking • Philadelphia, PA 19115 v5/13

Distributed & Manufactured by: © 2016 PSI Woodworking • Philadelphia, PA 19115

D

Manufactured by: Penn State Industries

The ETL Listed Mark is an alternative to the CSA and UL marks.

ETL Testing Laboratories has been conducting electrical performance and reliability tests since

1896. Intertek Testing Services (ITS) acquired ETL from Inchcape in 1996 . ITS is

recognized by OSHA as a Nationally Recognized Testing Laboratory (NRTL), just as Underwriters

Laboratories (UL), Canadian Standards Association (CSA) and several other independent

organizations are recognized.

ITS tests products according to nearly 200 safety and performance standards. The ETL Listed Mark

and C-ETL Listed Mark are accepted throughout the United States and Canada when denoting

compliance with nationally recognized standards such as ANSI, IEC, UL and CSA.

This certification mark indicates that the product has been tested to and has met the minimum

requirements of a widely recognized (consensus) U.S. Product safety standard, that the

manufacturing site has been audited, and that the applicant has agreed to a program of periodic

factory follow-up inspections to verify continued conformance.

If the mark includes a small US and/or C, it follows product safety standards of United States/or

Canada, respectively.

KWL1018VS KWL1218VS PSI Woodworking Products

istributed by: © 2022 PSI Woodworking • Philadelphia, PA 19115

15

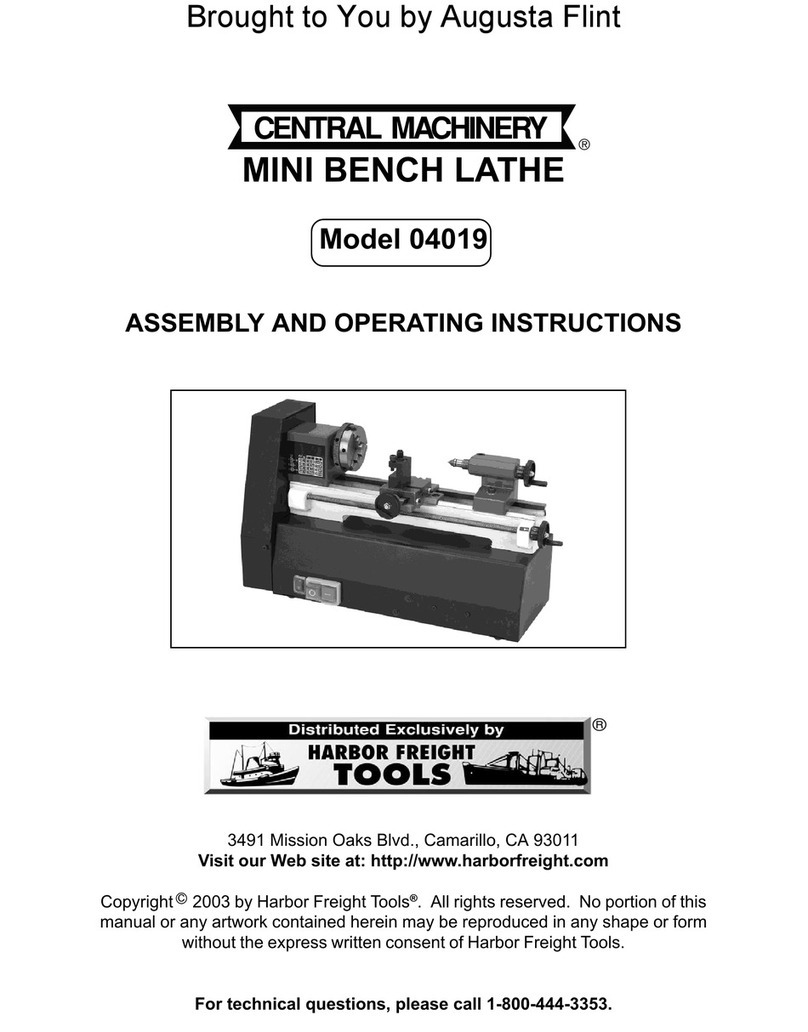

This manual suits for next models

1

Table of contents

Other PSI Woodworking Lathe manuals

Popular Lathe manuals by other brands

Central Machinery

Central Machinery 4019 Assembly and operating instructions

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN ED 400FD user manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN ED1000F user manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN ED 300ECO user manual

Jet

Jet BD-8VS operating manual

Auto Pro-Up

Auto Pro-Up DBL-STAR STD/MINI operating manual