Far Tools PRO ML 550 User manual

TOUR A MÉTAUX 114070

206, rue Marcel Cachin

37700 Saint-Pierre des Corps

FRANCE

FAR

GROUP

Europe

METAL LATHE

GB

ML 550

ML 550

ML 550

114200-A-22/08/2003

ML 550

TOUR A MÉTAUX 114070

ML 550

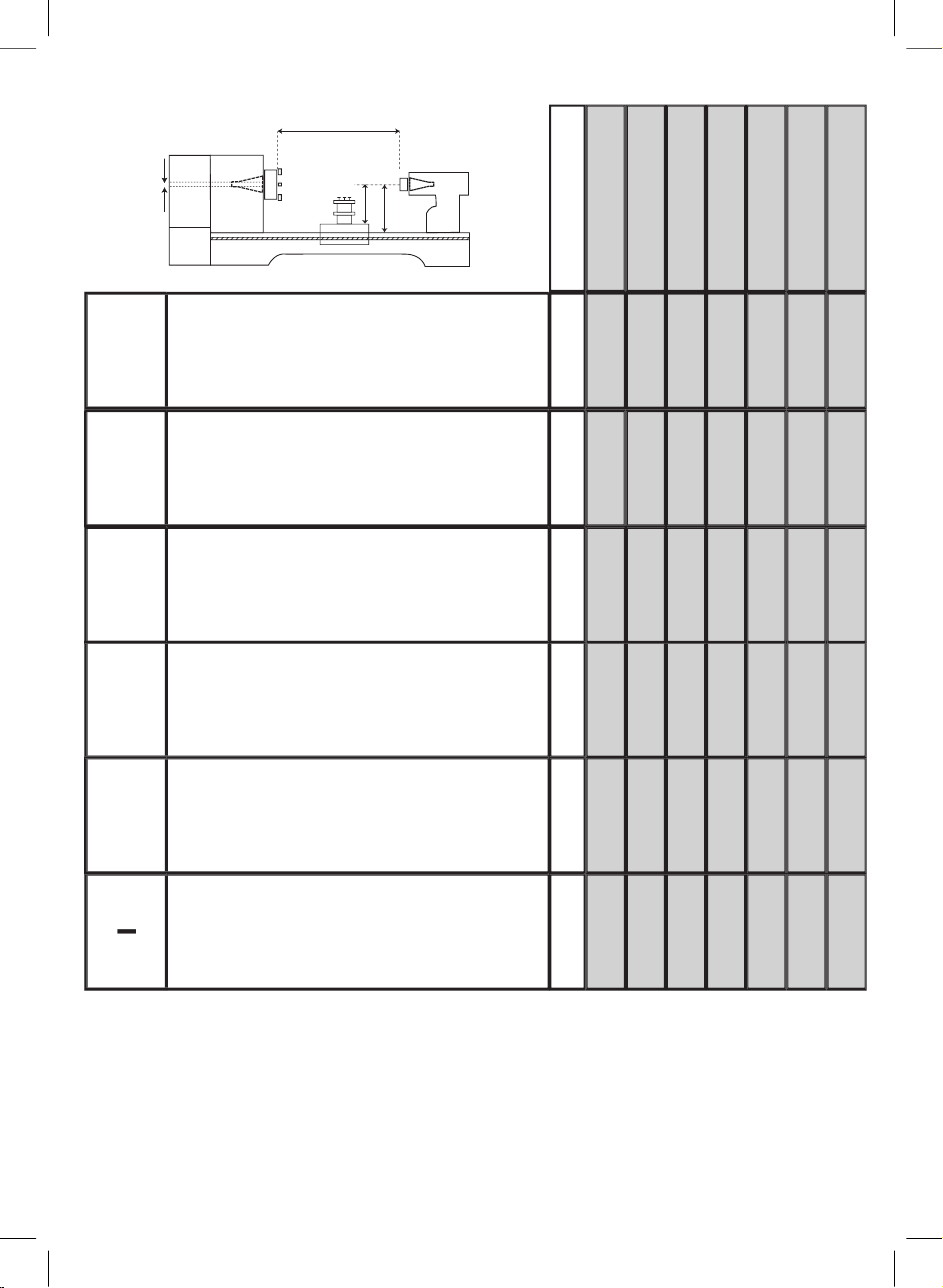

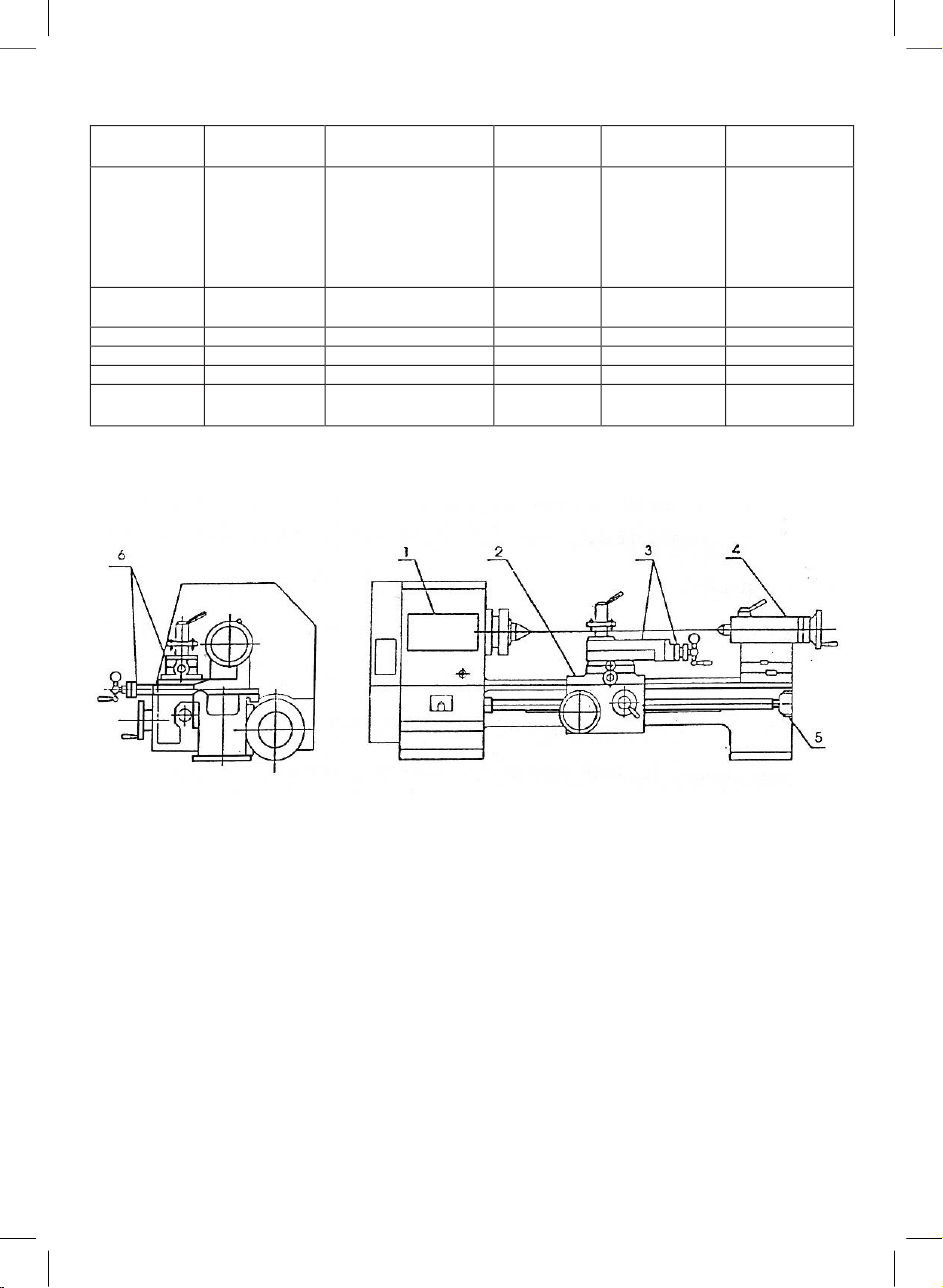

Automatic slide speed table

Threading

Slide-lathing

1

2

1

2

Chuck speed

3

3

5

4

6

Motor pulley

Receiving pulley

Slicing gears

4

5

6

ML 550

(6x) 120 -> 2000 min-1

Vitesse à vide:

No-load speed:

Drehzahl unbelastet:

Velocidad vacía:

Velocità a vuoto:

Velocidade no vácuo:

Leerlaufdrehzahl:

:

Prędkość bez bciążenia:

Nopeus tyhjillään:

Tomgånghastighet:

Скорост на празни обороти:

/MIN

370 W 230V~50 Hz

Tension et fréquence assignée:

Nominal frequency and power:

Spannung und Frequenz:

Tensión y frecuencia fijada:

Tensione e frequenza assegnata:

Tensão e frequência fixa:

Aangewezen spanning en frequentie:

:

Napięcie i częstotliwość przydzielona:

Jännite ja määrätty taajuus:

Angiven spänning och frekvens:

Консумирано напрежение и честота :

Puissance assignée:

Nominal power:

Leerlaufdrehzahl:

Potencia fijada:

Potenza assegnata:

Potência assinada:

Onbelast toerental:

:

Prędkość na biegu jałowym:

Teho:

Angiven effekt:

Консумирана мощност:

Да се използват защитни очила :

X

X

Porter des gants :

Use rubber gloves :

Scchutzhandschuhe tragen :

Llevar guantes de protección :

Indossare i guanti di protezione :

Utilizar luvas de protecção :

Draag veiligheidshandschoenen :

ρήση πρστατευτικών γαντιών :

Używać rękawic ochronnych :

Käytä suojakäsineitä :

Använd skyddshandskar :

а се използват предпазни ръкавици :

Porter un masque anti-poussière:

Wear a dust mask :

Staubschutzmaske tragen :

Llevar puesta una careta de protección contra el polvo :

Indossare una mascherina anti-polvere :

Utilizar uma máscara anti-poeira :

Draag een stofmasker :

ρήση πρστατευτική µάσκα :

Zakładać maskę przeciwpyłową :

Käytä pölysuojust :

Bär mask mot damm :

Да се използва защитна маска :

X

Porter des lunettes de sécurité :

Wear protective eyewear :

Schutzbrille tragen :

Llevar puestas gafas protectoras :

Portare de gli occhiali di sicurezza :

Utilizar óculos de segurança :

Draag een veiligheidsbril :

:

Zakładać okulary ochronne :

Käytä suojalaseja :

Använd skyddsglasögon :

X

Porter une protection auditive:

Wear hearing protective equipment:

Gehörschutz tragen:

Llevar puesta una protección auditiva:

Portare una protezione uditiva:

Utilizar uma protecção auditiva:

Draag gehoorbeschermers:

:

Zakładać słuchawki ochronne:

Käytä kuulosuojaimia:

Bär hörselskydd:

Да се използва слухови защитни средства:

m/s2

131 Kg dB(A)

Niveau de puissance acoustique :

Acoustic power level :

Schallleistungspegel :

Nivel de potencia acústica :

Livello di potenza acustica:

Nível de potência acústica:

Niveau akoestisch vermogen :

:

Poziom mocy akustycznej :

Käytä suojalaseja :

Ljudstyrkenivå :

Равнище на вибрации :

Poids :

Weight :

Gewicht :

Peso :

Peso :

Peso :

Gewicht :

:

Masa :

Käytä suojakäsineitä :

Vikt :

Тегло :

Niveau de vibration :

Hand/arm vibration level :

Vibrationspegel Hand/Arm :

Nivel de vibración mano/brazo :

Livello di vibrazione mano/braccio :

Nível de vibração mão/braço :

Trillingsniveau hand/arm :

:

Poziom wibracji rźka/ramiź :

Käytä pölysuojust :

Vibrationsnivå hand/arm :

Равнище :

dB(A)

Niveau de pression acoustique :

Acoustic pressure level :

Schalldruckpegel :

Nivel de presión acústica :

Livello di pressione acustica :

Nível de pressão acústica :

Niveau akoestische druk :

:

Poziom mocy akustycznej :

Käytä kuulosuojaimia:

Ljudtrycksnivå :

Равнище на акустично налягане :

!

X

X

Conformité Pologne :

Conforms to Polish requirements :

Konformität Polen :

Conformidad Polonia :

Conformità Polonia :

Conformidade Polónia :

Overeenstemming Polen :

Πρδιαγραέ Πλωνία :

Zgodność z normami polskimi :

Yhdenmukaisuus Puola :

Överensstämmelse Polen :

Полски стандарт :

B

B

Danger :

Danger :

Gefahr :

Peligro :

Pericolo :

Perigo :

Gevaar :

:

Niebezpieczńestwo :

Vaara :

Fara :

Опасност :

X

Conforme aux normes CE :

Conforms to EC standards :

CE-Konformität :

Cumple con las directivas CE :

Conforme alle norme CE :

Conforme às normas CE :

Voldoet aan de EG-normen :

:

Zgodność z normami CE :

EU-standardien mukainen :

EU-standardien mukainen :

Съответствие с европейските норми :

X

Lire les instructions avant usage :

Read the instructions before use :

Vor Einsatz des Geräts Anweisung lesen :

Léase las instrucciones antes de usar :

Leggere le istruzioni prima dell’uso :

Ler as instruções antes da utilização :

Lees voor het gebruik de instructies :

:

Zapoznać sięz instrukcją przed użyciem :

Lue ohjeet ennen käyttöä :

Läs anvisningarna före användning :

Прочетете указанията за употреба :

550 mm

ML 550

110 mm

70 mm

CM3

CM2

20 mm

I

H

G

D

C

A

H

G

I

D C

A

E

F

AUTO

E

F

H

G

I

D C

A

AUTO

500 mm

ML 550

115 mm

X

Ø 3 mm

ML 550

B1

F

E

H

G

I

D C

A

E

F

AUTO

E

F

H

G

I

D C

A

AUTO

H

G

I

D C

A

E

F

AUTO

E

F

H

G

I

D C

A

AUTO

B1 B2

Ø 80 mm

B2

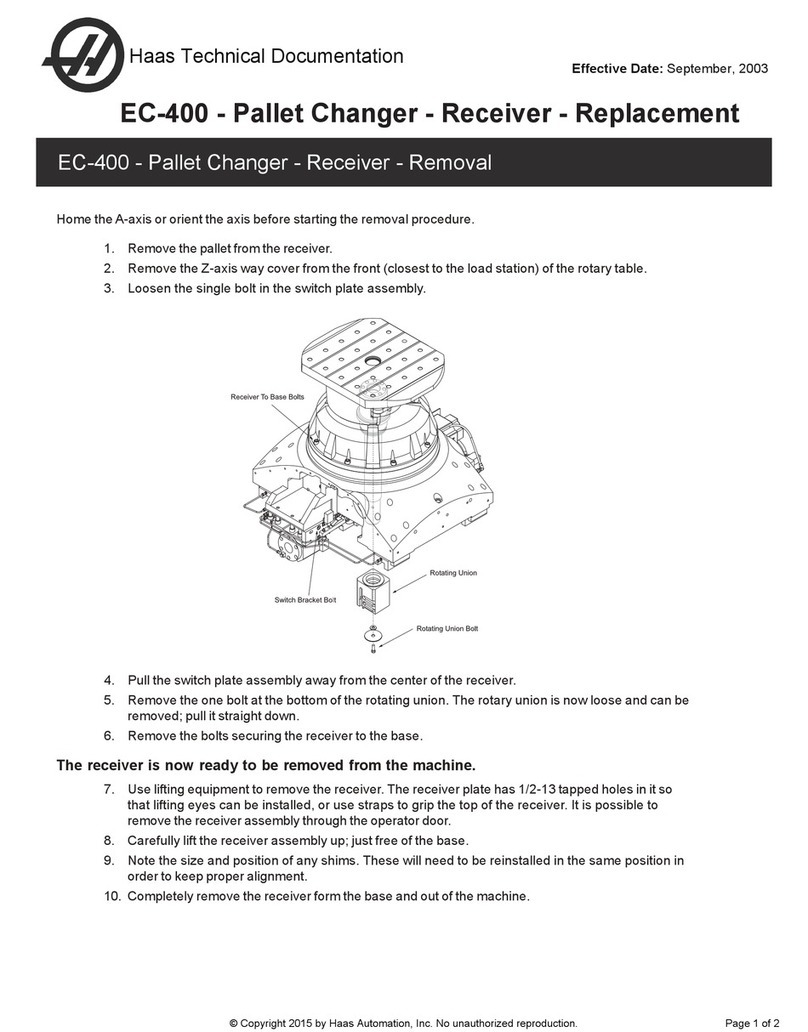

1. Features and applications

This Machine Tool is a lathe, with compact in struture, flexible in operation, safety in use and easy in instal-

lation. This Machine Tool is especially suitable for applications of family industry, small workshop, schools,

laboratory, and trial-producing workshops. It can also be used in operation sequence on the production

line.

This Machine Tool can machine external and internal circle, planes and various of metric thread. It can also

be operated with bit reamer, conessi, spanner, ect. The machine tool can expand its function with various

of accessories.

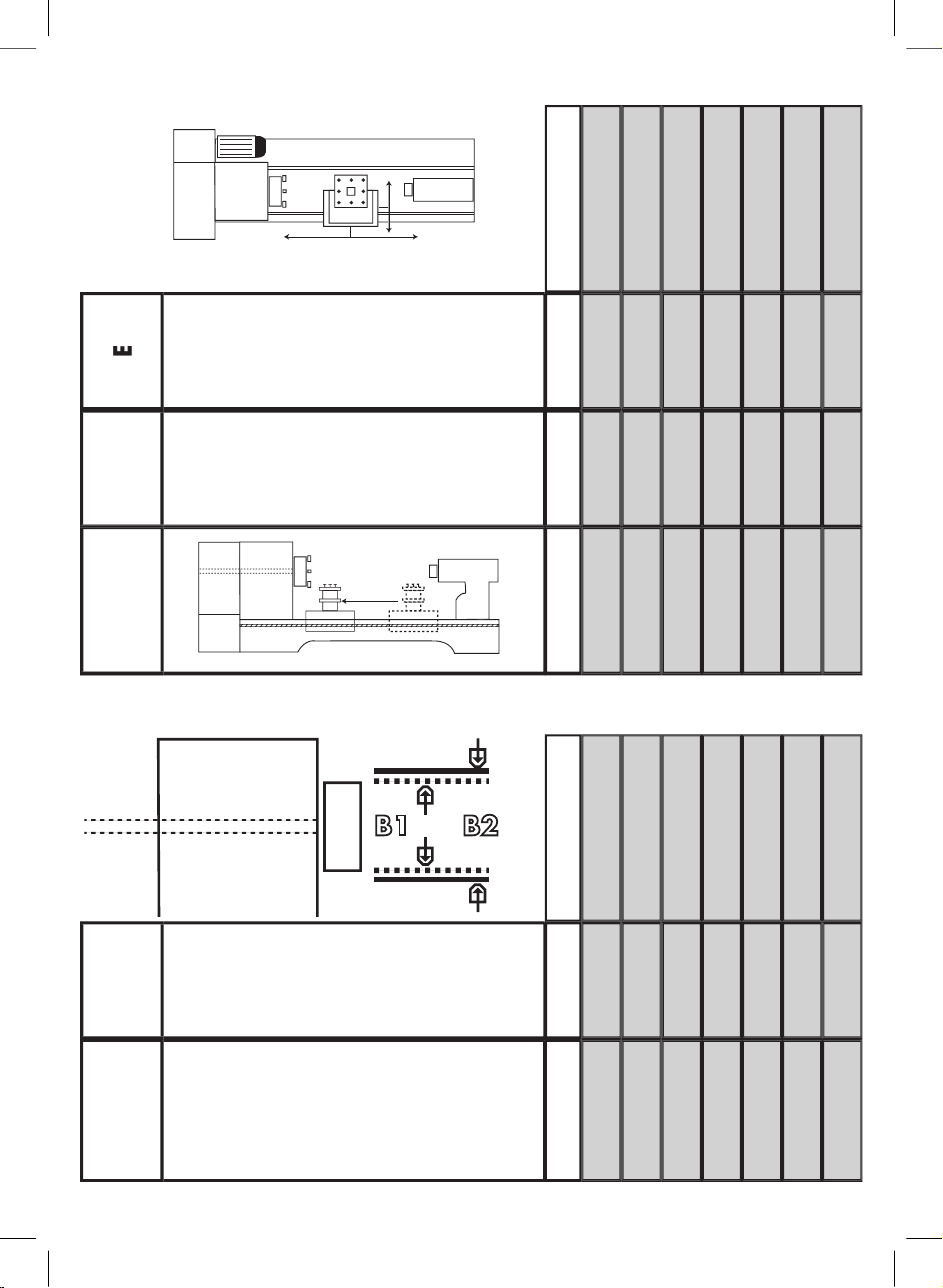

2.Change speed of the mainshaft

The change speed of the main shaft is done by striking two gears. When the change speed is required, first

stop running and then change the speed.

3. Feed system and driving system

Feed of tool carriage, turning screw thread

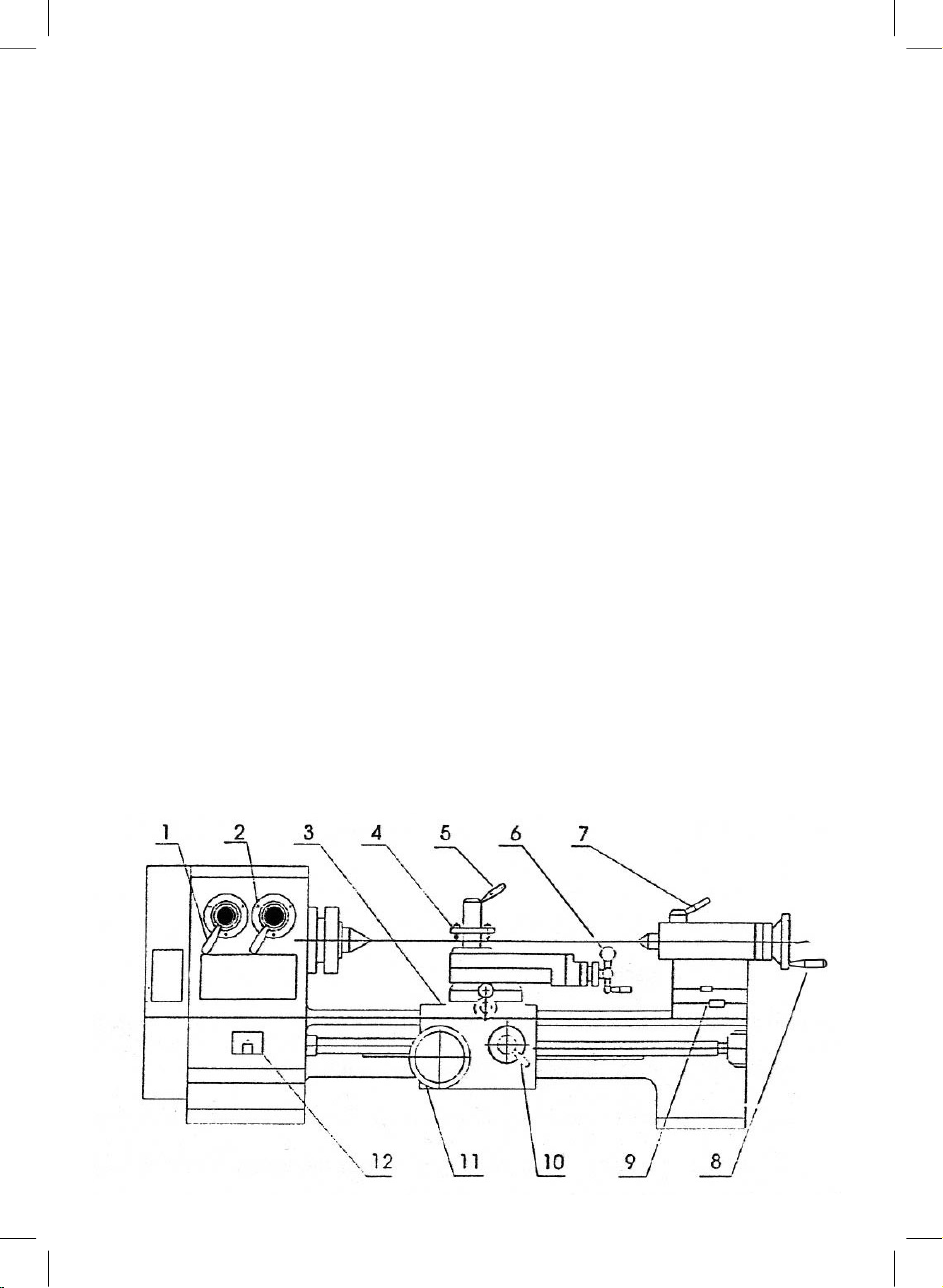

4. Installation and Test run of the machine tool

4.1 First examine whether you have received all the accessories of the machine tool according to the

packing list after opening the case.

4.1 The machine tool should be installed and fixed with nuts and bolts on the solid table made of wood or

iron. The table dimension can be determined based on the machine tool dimension (Refer to Fig.4). In

any way, the machine tool mustn’t be installed on fragile wood table to avoid the vibration when it is

running, resulting, in affection the service accuracy. When the lathe needs moving, the machine tool

saddle should be close to the tailstock support and clamped.

4.2 During the installation, a level gauge should be used for squaring the machine tool.

4.3 Anti-rust oil is applied to the sliding surface and non-portion and it can be cleaned with turpentine oil

or paraffin during the installation.

4.4 Using gasoline or paraffin to clean the main shaft box, and then inject filtered of #7 of#10 machine

lubrication oil.

4.5 Sufficient lubrication oil should be splashed into the oil holes or lubrication surface of the machine

tool and then examines the operation handles and the saddle longitudinal movement and tool carrier

lateral movement. If necessary, making the adjustment to the press plate and play iron.

4.6 Before starting the machine, check the motor and electrical equipment carefully to avoid such accidents

as electricity leakage, etc. due to the circuit damage when moving the machine tool.

4.7 When starting the test run, first use the lowest speed and keep it for running 20 minutes, if everything

is OK, increase the speed step by step.

4.8 Waiting until the machine tool stops completely, then change the main shaft speed or change the

feed.

4.9 Before the machine tool is normally operated, operators should read the service manual carefully and

have the idea of operation, lubrication and maintenance to guarantee the machine tool for a long-term

service.

5. Operation maintenance and structure of the machine tool

5.1.1 Main shaft box: Six kinds of the rotation speed can be obtained by turning handle “1”and “2” accor-

ding to the speed change table. Be sure to stop the machine tool and then change the handle.

5.1.2 Feed box: Knob “12” is used for controlling the start, stop, clock-wise and reverse movement of the main

shaft. Turn the knob to the position “1”, the main shaft turns clockwise, to the position “0”, the main shaft stops

and to the position “2” . the main shaft turns reversely.

5.1.3 Apron: Turn hand wheel “11” and make the apron and machine tool in lateral movement manually. If

the hand wheel rotates clockwise, the apron and machine tool saddle move in the left direction and if the hand

wheel rotates counter clockwise in the right direction.

Handle “10” is used for controlling the opening and closing of the split nuts. When Handle “10” is closed,

the metric screw thread can be machined and longitudinal feed

can be done. Before operating handle wheel “11”, the handle must be opened.

5.1.4 Tailstock: “9” indicates hex nuts and are used for locking tailstock and fix it on the machine tool bed.

Turn hand wheel “8” for controlling the stretch and contraction of the tailstock. If the hand wheel rotates cloc-

kwise, the tailstock quill stretches, otherwise, the tailstock quill contracts.

Handle “7” is used for locking tailstock quill. Before operating hand wheel “8”, the handle must be turned

loosely. When the tailstock moves to the required position, lock it with the handle.

5.1.5 Machine tool saddle and tool carrier:

Handle “6” is used for operating small tool carrier movement. If the handle rotates clockwise, the tool carrier

moves forward, otherwise, it moves back.

Handle “5” is used for securing square tool carrier. If the handle is loosed, the square tool carrier can rotate,

otherwise the square is secured.

Handle “4” is for lateral feed operation, If it rotates clockwise, the lateral trail plate bring the tool carrier to

move forward, otherwise, the lateral plate moves backward.

“4” indicates a hex screw and used for machining end surface and fixing machine saddle.

6.2 Service and maintenance of the machine tool.

Keep the maintenance of the machine tool during the operation to guarantee the accuracy and service life of

the machine tool.

6.2.1 After the normal operation of the machine tool for 10 days, the lubrication oil inside the machine tool

head needs changing and then clean with gasoline or paraffin, which will be done later at set intervals.

6.22 Before the operation every day, the lubrication should be done according to the requirement of the

machine tool and timely examine the oil level inside the main shaft box .

6.2.3 During the operation, the chippings which falls on the sliding surface should be cleaned timely, and the

inspection should be often made to prevent chippings falling into the position between the machine tool saddle

and lathe bed guide way. Asphalt felt should be cleaned at certain time.

6.2.4 After the operation every day, eliminate all the chippings and clean different part of the machine tool and apply

machine tool oil to prevent rusting.

6.2.5 In order to maintain the machining accuracy, take care of the center, the surface of the machine tool for the chuck

and the guide way and avoid mechanical damage and the wear due to improper guide.

6.2.6 If the damage is found, the maintenance should be done immediately

7. Electric Equipment of the machine tool

7.1 Principle the electric equipment

7.2 The electric equipment of the machine tool includes Model JY7134 Single-phase induction motor with

electric-capacity starting and magnetic switch.

7.3 The power of the machine tool motor is 370W, the voltage is 220V, 50HZ, and we can provide special

specification according to the voltage in customer’s request.

7.4 Magnetic switch has the function of stopping, clockwise rotation, counter-clockwise rotation and has

the protective function to the machine tool and electric equipment when power cut or the voltage is too low.

Caution in operation: R shows clockwise rotation L shows counter-clock rotation “STOP” shows stop the

machine or stop quickly.

7.4.1 It is forbidden to change the direction after starting the motor. Be sure to change the direction after

stopping the machine.

7.4.2 After operation, don’t cut off the electricity supply directly and should stop the lathe first.

7.5 Lighting conditions: This machine tool isn’t disposed the lighting, customers’ dispose the lighting condition

by themsevve. The lighting equipment should be 600 LUX. It should not lead to dangerous frequency flash

and should not take place the appearance of disturbing dizzy, shade area and it should be according to

EN60204-1.

8. Safe protection, safe operation of the machine tool.

8.1.1 A position switch is disposed on the gear change cover to lock with the main

shaft electric circuit each other, When operation will change the speed or exchange the gears. Open the back

cover the main electric. circuit shut off by itself. So can safety operation. After the cover is closed, the main

electric circuit is reput through by the magnetic switch, the machine tool can work normally.

8.1.2 Safe protection of the main spindle chuck protective cover is disposed on the main spindle chrck to

lock, with main electric circuit each other upon you open the protective cover, the main electric circuit can be

put through by opening the magnetic switch.

8.1.3 Safe protection of longitudinal leading screw longitudinal leading screw is disposed a sealed cover. It

can not only safeguard the precision of the leading screw but also avoid the dangerous of the leading screw

twine the hair and clothes.

8.1.4 Safe protection of the carriage. Avoiding the dangerous of twining and spraying when running.

8.1.5 Don’t proceed the workpiece exceeding the design capacity of the machine tool. When the long-thin

shaft stretch out the back of spindle. Please remove the screw and cover on back take the safe protection

measures by yourself to avoid the dangerous owing or rotation of the workpiece. After finishing work, please

reset and tightly the back cover. Please note the warning brand.

8.1.6 When turning the thread of 2mm pitch, select the spindle speed less than 390rpm to avoid the dange-

rous of twining the clothes owing to the hand wheel out-of –speed.

8.1.7 A position lump is disposed on end face of bed’s guide way to avoid sliding of the tailstock.

8.1.8 Chuck wrench has automatic leap back system. Once fixing the work piece wrench leap back automa-

ticly, avoiding the dangerous of forgetting to put down the wrench.

8.2 Safe Operation.

8.2.1 Operators must mot wear oversized clothes and gloves, tie up the hair in case of accident wearing

protective glasses.

8.2.2 Changing cutter or measure the workpiece, the first is stopping the machine.

8.2.3 Operators can not leave from machine, only in the time of leaving in the condition of stopping the

machine the tool and shutting the power supply.

8.2.4 In the time of operating, if there is unormal moise, operator must stop the machine and maintain it.

9. Machine tool lubrication

Ser.No.in

Fig Part Lubricating point method kind Period

1 Spindle box Gear, bearing Spray Machine oil 10days after

the start-up;

20days after

the fist lube;

from then on,

every 60days.

2 Saddle Longitudinal gui-

deways of saddle Oil gun Machine oil Every day

3 Tool slide Leadscrew Oil gun Machine oil Every day

4 Tailstook tailstock barrelt Oil gun Machine oil Every day

5 Leadserew Screw Oil gun Machine oil Every day

6supporter

Cross Screw Oil gun Machine oil Every day

Before and after the operation, the lubricated surfaces of the machine tool should be lubricated each time

10. Bearing Arramgement of the machine tool

List of Bearings

Dwg. No Model Name Specification Qty Install. position

1 104 Deep-slot ball bearing 20×42×12 1 Mshaft

2 104 Ditto Ditto 1 Ditto

3 103 Ditto 17×35×10 1 Ditto

4 103 Ditto Ditto 1 Ditto

5 46107(LevelD) Angular contact ball bearing 35×62×14 1 Ditto

6 46108(LevelD) Ditto 40×68×15 1 Ditto

7 103 Deep-slot ball bearing 17×35×10 1 Ditto

8 103 Ditto Ditto 1 Ditto

9 103 Ditto Ditto 1 Ditto

10 103 Ditto Ditto 1 Ditto

11 8104 Thrust ball bearing 20×35×10 1 Feed box

code

FARTOOLS PRO / 114200 / ML 550

73/23/CEE, 93/68/CE, 89/336/CEE, 98/37/CE

EN 55014-1 (93)+A1 (97)+A2 (99), EN 55014-2 (97), EN 61000-3-2 (95)+A1 (98)+A2 (98)

EN 61000-3-3 (95)

B. Chandonnay,

P-D.G

22/08/2003

VERKLARING VAN OVEREENSTEMMING DECLARACION DE CONFORMIDAD

DECLARATION DE CONFORMITE DICHIARAZIONE DI CONFORMITA

KONFORMITÄSERKLÄRUNG DECLARATION CONFORMITY

DECLARAÇÃO DE CONFORMIDADE DEKLARACJA ZGODNOSCI Z NORMAMI

OM ÖVERENSSTÄMMELSE VAATIMUSTENMUKAISUUSVAKUUTUS

FAR GROUP

206, rue Marcel CACHIN

37700 Saint-Pierre-des-Corps

FRANCE

Ondergetekende,

Le soussigné,

Der Unterzeichner,

O abaixo assinado,

Undertecknad,

Долуподписаният

El suscrito,

Il sottoscritto,

The undersigned,

Niņej podpisany

Allekirjoittanut,

Verklaart hiermede dat,

Déclare par la présente que,

Erklärt hiermit daß,

Declara pela presente que,

Förklarar härmed att

Заявява с настоящото

Declara por la presente, que,

Dichiare che,

Declares that,

OŌwiadcza niniejszym, ņe

Ilmoitetaan täten että,

In overeenstemming is met en Voldoet aan EG richtlijnen,

Est conforme et satisfait aux normes CE,

Den folgenden EU-Bestimmungen entspricht,

Respeita e está em conformidade com as normas CE,

Överensstämmer med och uppfyller EG-standarder,

Съответства и отговаря европейските норми

Cumple con la directivas de la CE,

È conforme alle direttive CEE,

Complies with the EEC standards,

Odpowiada normom UE,

Täyttää EU-vaatimukset,

CE

Декларация за съответствие с нормите

METAL LATHE

F. GARANTIE

Cet outil est garanti contractuellement contre tout vice de construction et de matière, à compter de la date de vente à lʼutilisateur et sur

simple présentation du ticket de caisse. La garantie consiste à remplacer les parties défaillantes. Cette garantie nʼest pas applicable en

cas dʼexploitation non conforme aux normes de lʼappareil, ni en cas de dommages causés par des interventions non autorisées ou par

négligence de la part de lʼacheteur. La garantie ne sʼapplique pas sur les dommages causés par une défaillance de lʼoutil.

D. GARANTIE

Die Garantiezeit für dieses Gerät in bezug auf Konstruktions- und Materialfehler beträgt lt. Vertrag bei Vorlage des Kassenbons.

Die Garantieleistung besteht im Ersatz schadhafter Teile. Die Garantie erlischt bei einen Einsatz des Geräts, der nicht norments-

prechend ist, bei Schäden, die auf unsachgemäße Eingriffe zurückzuführen sind bzw. bei Nachlässigkeit seitens des Käufers.

Die Garantie erstreckt sich nicht auf Schäden, die auf Fehlfunktionen des Geräts zurückzuführen sind.

I. GARANZIA

Quest’ attrezzo è garantito per contratto contro qualsiasi difetto di costruzione e di materia, a partire dalla data di vendita

all’ utente e su semplice presentazione dello scontrino. La garanzia consiste nel sostituire le parti difettose. Questa garanzia

non è applicabile in caso di sfruttamento non conforme alle norme dell’ apparecchio, né in caso di danni causati da inter-

venti non autorizzati o da negligenza da parte dell’ acquirente. La garanzia non si applica ai danni causati da un’avaria

dell’attrezzo.

GB. GARANTEE

This tool is guaranteed, in writing, against any defect in manufacture or parts from the date of sale, upon simple presentation of

the sales slip. The guarantee is limited to the replacement of faulty parts. This guarantee is not applicable in the event of usage

which is not conform with the intended usage of the apparatus, nor in the event of damage caused by unauthorised servicing

or negligence on behalf of the purchaser. This guarantee does not apply to any damage caused by the failure of this tool.

E. GARANTIA

Esta herramienta se garantiza contractualmente contra todo defecto de construcción y materia, a partir de la fecha de venta

a l’ usuario y sobre simple presentación del recibo de caja. La garantía consiste en sustituir a las partes defectuosas. Esta

garantía no es aplicable en caso de explotación no conforme a las normas del aparato, ni en caso de daños causados por

intervenciones no autorizadas o por negligencia por parte del comprador. La garantía no se aplica sobre los daños causados

por un fallo del herramienta.

NL. GARANTIE

Dit gereedschap heeft een garantie tegen constructiefouten en materiaaldefecten, die geldig is vanaf de aankoopdatum door

de gebruiker, op vertoning van de kassabon. De garantie betreft de vervanging van de defecte onderdelen. Deze garantie

is niet van toepassing indien het apparaat niet volgens de normen gebruikt is, noch in geval van schade veroorzaakt door

oneigenlijk gebruik of nalatigheid van de koper. De garantie is niet van toepassing op schade voortvlriend uit een defect van

het gereedschap.

PT. GARANTIA

Esta ferramenta tem uma garantia contratual contra qualquer defeito de construção e de material, a partir da data de venda

ao utilizador e sobre simples apresentação do talão da caixa.. A garantia consiste em substituir as partes defeituosas. Esta

garantia não é aplicável no caso de exploração não conforme às normas do aparelho, nem em caso de danos causados pelas

intervenções não autorizadas ou por negligência da parte do comprador. A garantia não se aplica para os danos causados

por uma falha da ferramenta.

GR.

.

. .

.

.

PL. GWARANCJA

Narz´dzie jest obj´te gwarancjà na wszelkie wady konstrukcyjne i materia∏owe, liczàc od daty sprzeda˝y u˝ytkownikowi i po okaza-

niu paragonu kasowego. Gwarancjà obejmuje wymian´ cz´Âci wybrakowanych. Gwarancjà nie znajduje zastosowania w przypadku

u˝ytkowania niezgodnego z normami urzàdzenia, ani w przypadku szkód spowodowanych dzia∏aniami niedozwolonymi lub zaniedba-

niami ze strony nabywcy. Gwarancjà nie obejmuje szkód powsta∏ych z powodu upadku urzàdzenia.

SU. GARANTI

Detta verktyg har en avtalsenlig garanti mot konstruktions- och materialfel, från och med tidpunkten för användarens inköp och

genom uppvisning av kassakvittot. Garantin består i att ersätta de bristfälliga delarna. Denna garanti gäller inte om användnin-

gen inte motsvarar apparatens standarder, inte heller vid skador som orsakas av ej tillåtna ingrepp eller på grund av köparens

vårdslöshet. Garantin gäller inte förskador som orsakats av att verktyget fungerat bristfälligt.

FI. TAKUU

Tämän laitteen takuu on voimassa sopimuksenmukaisesti kattaen kaikki rakenne- ja materiaaliviat lukien ostopäivästä kassakuit-

tia vastaan. Takuu sisältää viallisten osien korvaamisen. Takuu ei korvaa ohjeidenvastaista käyttöä eikä valtuuttamattomien

henkilöiden käsittelystä tai ostajan huolimattomuudesta aiheutuneita vahinkoja. Takuu ei vastaa myöskään toimintahäiriöistä

aiheutuneita vahinkoja.

BU. Гаранция

Този инструмент е под договорна гаранция срещу всякакъв дефект в изработката и използваните материали, считано

от датата на продажба на потребителя и само срещу представяне на касовата бележка.Гаранционното обслужване

се състои в замяна на дефектните части.Настоящата гаранция не е валидна когато апаратът се използва по начин,

несъответстващ на стандарта за работа с него, както и в случай на щети, нанесени от неоторизирани лица, или

вследствие на проявена небрежност от страна потребителя.

Гаранцията не покрива щети, произтекли вследствие на техническа неизправност на апарата.

Table of contents

Other Far Tools Lathe manuals

Popular Lathe manuals by other brands

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN LBM 220 user manual

Holzmann

Holzmann ED 750 FD user manual

Sharp

Sharp 1118H Operations manual & parts list

Hafco Metalmaster

Hafco Metalmaster CL-68A instruction manual

Baileigh Industrial

Baileigh Industrial SR-5016 Operator's manual

Record Power

Record Power DML36SH-CAM Original instruction manual