PST LDetek MULTIDETEK 3 User manual

MultiDetek 3

Trace impurities analyzer

USER’S MANUAL

V1.4

Printed in Canada

Copyright 2023

Table of Contents

Table of Contents................................................................................................................4

Table of Figures..................................................................................................................6

1. Forewarning........................................................................................................................8

2. Warranty, maintenance, and service policies.......................................................................9

3. Declaration of conformity..................................................................................................12

4. Specifications.....................................................................................................................14

5. Installation..........................................................................................................................15

5.1.Detector cautions..........................................................................................................15

5.2.Analyzer application ....................................................................................................16

5.3.Start-up.........................................................................................................................16

5.4.Shut-off........................................................................................................................21

5.5.Typical installation.......................................................................................................22

6. Hardware description.........................................................................................................30

6.1.Detectors......................................................................................................................30

6.2.Motherboard.................................................................................................................31

6.3.Sample gas proportional valve, mini pump and septum injector.................................32

6.4.Diaphragm valve and purged/heated valve box...........................................................32

6.5.Carrier gas electronic pressure regulator (LDepc) .......................................................33

6.6.Ovens and columns......................................................................................................33

6.7.Large 15.6’’ touch screen LCD & LDChroma+..........................................................34

6.8.Built-in sample purging and monitoring system..........................................................34

6.9.Bolt-on compact purifier..............................................................................................36

6.10.Advanced Quartz Crystal Microbalance sensor.........................................................36

7. LDChroma+.......................................................................................................................37

7.1.Configuration...............................................................................................................37

7.2.Chromatogram tab........................................................................................................41

7.3.Settings Menu ..............................................................................................................49

7.4.Calibration Menu .........................................................................................................69

7.5.Diagnostics Menu ........................................................................................................70

7.6.Regeneration................................................................................................................73

7.7.About menu..................................................................................................................74

7.8.Firmware Update..........................................................................................................74

7.9.LDChroma+ Procedures ..............................................................................................75

8. LDReport ...........................................................................................................................88

8.1.Local and remote..........................................................................................................88

8.2.Machine list..................................................................................................................89

8.3.Settings menu...............................................................................................................90

8.4.Analysis menu..............................................................................................................92

8.5.Analyze menu ..............................................................................................................93

8.6.Report generation.........................................................................................................94

8.7.LDReport’s procedures................................................................................................98

9. Back panel terminal identification....................................................................................101

10. Drawings & Schematics..............................................................................................102

11. Maintenance and troubleshooting...............................................................................107

11.1.Spare part list ............................................................................................................107

11.2.Tools .........................................................................................................................108

11.3.Maintenance procedures ...........................................................................................109

11.4.Troubleshooting........................................................................................................113

Table of Figures

Figure 1: Boot up screen........................................................................................................17

Figure 2: Boot-up alerts .........................................................................................................17

Figure 3: Oven setpoint..........................................................................................................18

Figure 4: Flow setpoint..........................................................................................................19

Figure 5: Operating Parameters .............................................................................................20

Figure 6: Typical Installation.................................................................................................24

Figure 7: Same source actuation............................................................................................26

Figure 8: 2 sources of actuation.............................................................................................27

Figure 9: O2 doping...............................................................................................................29

Figure 10: Type of Detectors.................................................................................................30

Figure 11: MultiDetek3 printed circuit board (PCB).............................................................31

Figure 12: Solenoid proportional valve .................................................................................32

Figure 13: Isothermal and programmable oven.....................................................................33

Figure 14: Built-in sample purging and monitoring system..................................................34

Figure 15: Compact LDP-1000..............................................................................................36

Figure 16: LDChroma+ logo .................................................................................................37

Figure 17: Machine Manager.................................................................................................37

Figure 18: Method Manager ..................................................................................................38

Figure 19: Calib Manager......................................................................................................39

Figure 20: Network................................................................................................................39

Figure 21: Set Language........................................................................................................40

Figure 22: Chromatogram menu............................................................................................41

Figure 23: Legend menu........................................................................................................41

Figure 24: Bottom bar............................................................................................................42

Figure 25: Left-bottom bar menu...........................................................................................43

Figure 26: Alerts menu ..........................................................................................................44

Figure 27: Historic menu .......................................................................................................45

Figure 28: Historic advanced tools ........................................................................................46

Figure 29: Historic list window .............................................................................................47

Figure 30: Peak Results..........................................................................................................48

Figure 31: Settings menu .......................................................................................................50

Figure 32: Peak setting menu.................................................................................................52

Figure 33: Flow setting menu ................................................................................................54

Figure 34: Oven setting menu................................................................................................56

Figure 35: Detector setting menu...........................................................................................58

Figure 36: Sensor setting menu..............................................................................................59

Figure 37: Valve setting menu...............................................................................................60

Figure 38: Machine setting menu...........................................................................................61

Figure 39: 4-20mA settings menu..........................................................................................62

Figure 40: Stream settings menu............................................................................................63

Figure 41: Sequence setting menu.........................................................................................64

Figure 42: Column setting menu............................................................................................65

Figure 43: Modbus setting menu ...........................................................................................66

Figure 44: QMA setting menu...............................................................................................67

Figure 45: Maintenance menu................................................................................................68

Figure 46: Calibration menu..................................................................................................69

Figure 47: Analog input window...........................................................................................70

Figure 48: Analog output window.........................................................................................70

Figure 49: Digital output window..........................................................................................71

Figure 50: LDepc diagnostic window....................................................................................71

Figure 51: Modbus register window......................................................................................72

Figure 52: Modbus information window...............................................................................72

Figure 53:Regeneration window............................................................................................73

Figure 54: About menu..........................................................................................................74

Figure 55: Firmware Update..................................................................................................74

Figure 56: LDReport logo......................................................................................................88

Figure 57: LDReport local.....................................................................................................88

Figure 58: LDReport remote..................................................................................................89

Figure 59: LDReport - Machine List .....................................................................................89

Figure 60: LDReport - Misc section......................................................................................90

Figure 61: LDReport - Template and Data sections..............................................................91

Figure 62: Analysis menu......................................................................................................92

Figure 63: Peak graph............................................................................................................92

Figure 64: Analyze menu.......................................................................................................93

Figure 65: Default report........................................................................................................95

Figure 66: Custom Report......................................................................................................96

Figure 67: Pass-Fail template.................................................................................................97

Figure 68: HCD box..............................................................................................................110

Figure 69: MultiDetek3 fans.................................................................................................110

MULTIDETEK3

User’s manual

8

1.Forewarning

Any user that wants to use the MultiDetek3 Trace Impurity analyzer must read this manu-

al. It contains important information to successfully operate this instrument. LDetek as-

sumes that all operators have taken the time to read thisinformation before installing, oper-

ating and troubleshooting this analyzer.

If any error is suspected by the reader, please contact LDetek. LDetek reserves the right to

make any changes to subsequent editions of this document without prior notice to holders

of this edition.

We want to thank you for choosing LDetek as your gas analyzer supplier.

MULTIDETEK3

User’s manual

9

2.Warranty, maintenance, and service policies

Goods and part(s) (excluding consumables) manufactured by the seller are warranted to be

free from defects in workmanship and material under normal use and service for twelve

(12) months after installation and start-up and not exceeding eighteen (18) months from

shipment date. Consumable, chemical traps, O-rings, etc., are warranted to be free from de-

fects in workmanship and material under normal use and service for a period of ninety

(90) days from the date of shipment by the seller. Goods, part(s) proven by the seller to be

defective in workmanship and/or material shall be replaced or repaired, free of charge,

F.O.B. Seller's factory provided that the goods, part(s) are returned to Seller's designated

factory, transportation charges prepaid, within the twelve (12) months after installation and

start-up and not exceeding 18 months from shipment date. In the case of consumables,

within the ninety (90) days period of warranty, a defect in goods, part(s) and consumable

of the commercial unit shall not operate to condemn such commercial unit when such

goods, part(s) and consumable are capable of being renewed, repaired or replaced.

The Seller shall not be liable to the Buyer, or any other person, for the loss or damagedi-

rectly or indirectly, arising from the use of the equipment of goods, from breach of anywar-

ranty, or any other cause.

ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED ARE HEREBYEX-

CLUDED.

IN CONSIDERATION OF THE HEREIN-STATED PURCHASE PRICE OF THE

GOODS, THE SELLER GRANTS ONLY THE ABOVE-STATED EXPRESS WAR-

RANTY. NO OTHER WARRANTIES ARE GRANTED INCLUDING, BUT NOT LIM-

ITED TO,EXPRESS AND IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESSFOR A PARTICULAR PURPOSE.

THIS WARRANTY IS THE ONLY WARRANTY MADE BY LDETEK INC. FOR THE

GOODS DELIVERED HEREUNDER, AND NO EMPLOYEE, REPRESENTATIVE OR

OTHER PERSON OR ENTITY IS AUTHORIZED TO ASSUME FOR LDETEK INC

ANY OBLIGATION OR LIABILITY BEYOND OR AT VARIANCE WITH THIS

WARRANTY IN CONNECTION WITH THE SALE OF LDETEK PRODUCTS.

Limitations of Remedy. SELLER SHALL NOT BE LIABLE FOR DAMAGES

CAUSED BY DELAY IN PERFORMANCE. THE SOLE AND EXCLUSIVE REMEDY

FOR BREACH OF WARRANTY SHALL BE LIMITED TO REPAIR OR REPLACE-

MENT UNDER THE STANDARD WARRANTY CLAUSE. IN NO CASE, REGARD-

LESS OF THE FORM OF THE CAUSE OF ACTION, SHALL THE SELLER'S LIABIL-

ITY EXCEEDS THE PRICE TO THE BUYER OF THE SPECIFIC GOODS

MULTIDETEK3

User’s manual

10

MANUFACTURED BY SELLER GIVING RISE TO THE CAUSE OF ACTION. BUY-

ER AGREES THAT IN NO EVENT SHALL SELLER'S LIABILITY EXTEND TOIN-

CLUDE INCIDENTAL OR CONSEQUENTIAL DAMAGES. CONSEQUENTIAL

DAMAGES SHALL INCLUDE BUT ARE NOT LIMITED TO, LOSS OF ANTICIPAT-

ED PROFITS, LOSS OF USE, LOSS OF REVENUE, COST OF CAPITALAND DAM-

AGE OR LOSS OF OTHER PROPERTY OR EQUIPMENT. IN NO EVENT SHALL

THE SELLER BE LIABLE FOR PROPERTY DAMAGE AND/OR THIRD-PARTY

CLAIMS COVERED BY UMBRELLA INSURANCE AND/OR INDEMNITY COVER-

AGE PROVIDED TO THE BUYER, ITS ASSIGNS, AND EACH SUCCESSORINTER-

EST TO THE GOODS PROVIDED HEREUNDER.

Major force. The seller is not liable for failure to perform due to labour strikes or actsbe-

yond the seller’s direct control.

SERVICE POLICY

1. If a product should fail during the warranty period, it will be repaired free of

charge. Forout-of-warranty repairs, the customer will be invoiced for repair charges at

current standard labour and materials rates.

2. Customers who return products for repairs, within the warranty period, and the

productis found to be free of defect, may be liable for the minimum current repair

charge.

3. For parts replacement, the original part must be returned with the serial and mod-

el numbersof the analyzer. NO PART WILL BE SHIPPED IF THE ORIGINAL IS NOT SENT

BACK TO LDETEK INC.

MULTIDETEK3

User’s manual

11

RETURNING A PRODUCT FOR REPAIR

Upon determining that repair services are required, the customer must:

•Obtain an RMA (Return Material Authorization) number.

•Supply a purchase order number or other acceptable information.

•Include a list of problems encountered along with the name, address, telephone, and

RMAnumber.

•Ship the analyzer in its original crating or equivalent. Failure to properly package thean-

alyzer will automatically void the warranty.

•Every gas connection must be capped with appropriate metal caps. Failure to do so will

automatically void the warranty.

•Write the RMA number on the outside of the box.

•Use an LDetek-approved carrier. Also, the delivery must be sent to LDetek facilities.

LDetek will not accept airport-to-airport delivery.

•LDetek will not cover the transportation fees.

Other conditions and limitations may apply to international shipments.

PROPRIETARY RIGHTS

Buyer agrees that any LDetek’s software, firmware and hardware products ordered or in-

cluded in the goods ordered are proprietary of LDetek. No change, modification,deface-

ment, alteration, reverse engineering, neither software de-compilations norreproductions of

such software or hardware products, or disclosures of programming contentto other parties

are authorized without the express written consent of LDetek.

To maintain LDetek’s trade secret and other proprietary protection of such software and

firmware, such items are not sold hereunder but are licensed to the buyer.

LDetek Inc. reserves the right to interrupt all business relationships and warranty or service

if there is any tentative from any customers to reverse engineering any of LDetek products

or to tamper with any sealed module.

Trademarks and product identification as MULTIDETEK3 are the property of

LDetek Inc. and shall be used only in connection with LDetek's products. No third party

could remove or deface any model number or marks.

MULTIDETEK3

User’s manual

12

3.Declaration of conformity

E

U

Declaration of Conformity

1.

Product model:

M

ulti

D

etek

3

Compact gas chromatpgraph

2.

Name and address of the manufacturer:

LDetek Inc.

Monfette E.

990

Thetford Mines, QC G6G 7K6

(418)

+1

755

-

1319

This

product is in conformity with the following EU Directives ,Standard(s) or Normative Document(s):

3.

Directives

.

Low Voltage Directive (LVD) 2014/35/EU,

Electromagnetic Compatibility Directive (EMC) 2014/30/EU,

Restriction of Hazardous

Substances (RoHS) Directive 2011/65/EU2014/68/EU

Pressure Equipment Directive

This product does not bear CE marking for the Pressure Equipment Directive, but are supplied in accordance

with Article 4, paragraph 3 of 2014/68/EU by using SEP (sound engineer

ing practice) in the design and

manufacturer and are provided with adequate instructions for use.

4.

Standards

:

CISPR

32:

2015

A

1:

2019

, Class A : Electromagnetic compatibility of multimedia equipment

-

Emission

requirements

EN61010

-

1:2010

Safety Requirements for Electrical Equipment for Measurement, Control, and

Laboratory Use

-

Part 1: General Requirements

5.

On behalf of the

above

-

named company, I declare that under our sole responsibility, on the date that

the equipment accompanied by this declaration is placed on the market, it conforms with all technical

and regulatory requirements of the above listed EU Directives.

MULTIDETEK3

User’s manual

13

MULTIDETEK3

User’s manual

14

4.Specifications

Gas Chromatography Detector:

•PED / TCD / FID

Online Detectors:

•Quartz Crystal Microbalance / Ceramic Metal-Oxide / Electro-

chemical / Zirconia

Standard features:

•Temperature-controlled process GC

•15,6’’ wide touchscreen with 1366 x 768 HD resolution (IP65)

•Windows 10 IoT

•Ethernet ports available for remote control and Modbus

•Self-diagnostic system with maintenance planning

•Isothermal and/or programmable ramping ovens

•Electronic flow control regulators for carrier & sample gases

•4-20 mA isolated outputs

•Alarm Historic

•Digital system output for remote monitoring (dry relay contact)

•2 alarms contact

•High-resolution Chromatogram output

Options:

•Serial communication (RS232/485) / Profibus / Modbus /

Ethernet

•Compact purifier attached to the chassis for generating high-

purity carrier gas

•Integrated stream selector system

•Digital inputs for remote starting

•Analog inputs for connecting external instruments

•Remote control for stream selector (LDGSS)

•Split/splitless injector (can be heated)

•Dual sample inlets with simultaneous analysis

•Built-in online sensor module for trace moisture: Quartz Crystal

(ppb/ppm) or Ceramic (ppm)

•Built-in online sensor module for trace oxygen: Electrochemical

(ppm) or Zirconia (ppm)

Gas connections:

•1/8’’ or 1/4’’ face seal or compression fittings

Carrier pressure:

•100 PSIG (other carrier pressure available on request)

Ambient temperature range:

•10 °C - 45 °C

Ambient temperature control range

feature:

•20°C - 40°C (out of this range, surrounding ambient tempera-

ture must be stabilized)

Calibration gas:

•50% to 90% of the full scale

Sample pressure:

•5 to 30 PSIG (other pressures available on request)

Supply:

•115 VAC, 50 –60 Hz or 220 VAC, 50 –60 Hz

Power consumption:

•Maximum 500 Watts

Repeatability:

•Three times the percentage of deviation (3*CV %) of each

component has to be smaller than 5% on ten consecutive cycles

Accuracy:

•Better than +/- 1% error or LDL whichever is higher

LDL:

•3 times the noise level

LOQ:

•3 times LDL value

Long-term stability & drift:

•Three times the percentage of deviation (3*CV %) of each

component has to be smaller than 10% for 8 hours

Linearity:

•For 5 points within the measuring range, the linear curve must

have its R2 at a value between 0.998 and 1.00

MULTIDETEK3

User’s manual

15

5.Installation

5.1. Detector cautions

The MultiDetek3 utilizes multiple detection techniques that have been well-established in

the industry for many years, including Plasma Emission Detector (PED), Flame Ionization

Detector (FID), Thermal Conductivity Detector (TCD), and others upon request.

PED

The PED operates on the principle of spectroscopic emission. A pure quartz cell is placed

in an electromagnetic field generated by a specific high-intensity generator. This electro-

magnetic field creates plasma, which emits light at different wavelengths. By using appro-

priate optical filters, the detector can detect the desired impurities. One of the key benefits

of the PED is its ability to offer a selective mode based on the spectral line used to measure

specific impurities, providing both selectivity and sensitivity.

To prevent the quartz cell from cracking, it is important to maintain atmospheric pressure

in the analyzer vent. Any back pressure on the detector vent connection can cause dam-

age and require the replacement of the plasma detector module. However, the PED is a

low-maintenance device that does not require regular upkeep.

FID

The FID is a commonly used gas chromatography detector for the analysis of organic

compounds. It operates on the principle that when organic molecules pass through a hy-

drogen flame, they are ionized, creating a current that is measured. The magnitude of the

current is proportional to the concentration of the organic compound. The FID requires a

fuel gas (usually hydrogen) and an oxidant gas (usually air) to sustain the flame. The FID

is highly sensitive to most organic compounds, making it a popular choice for a wide range

of applications.

TCD

A TCD is a type of detector commonly used in gas chromatography. It operates by measur-

ing changes in the thermal conductivity of the carrier gas flowing through the detector

caused by the presence of analytes. The TCD consists of a sensing element and two refer-

ence elements, all of which are housed in an oven. When the carrier gas passes through the

sensing element, it transfers heat away from a filament that is heated to a constant tempera-

ture. As the analytes pass through the sensing element, they displace the carrier gas, caus-

ing a decrease in thermal conductivity and a corresponding increase in filament tempera-

ture. This temperature change is detected and measured by the reference elements, allow-

ing for the quantification of the analytes. The TCD is highly selective and sensitive and is

commonly used for the detection of non-volatile or semi-volatile compounds, such as gas-

es, inorganic compounds, and some organic compounds.

MULTIDETEK3

User’s manual

16

5.2. Analyzer application

The MultiDetek3 is specifically designed for analyzing impurities and samples as outlined in the

instrument's specification sheet. Using this instrument with any other gas type may cause damage

to the analyzer. To ensure safe and proper use, refer to the "Operating Parameters" document that

accompanies the unit. It is important to note that the GC is not intended for use in hazardous areas.

5.3. Start-up

To ensure the proper start-up of the MultiDetek3, it is important to follow the steps below.

All LDetek products are carefully packaged in a sturdy cardboard box, and each instrument

is accompanied by a USB drive containing relevant documentation. If you require any as-

1. Carefully unpack the instrument from the box and inspect it to ensure that it is in good

condition and has not been damaged during shipping.

2. Locate the documents, USB drive, fuse kit and power cables.

3. Choose whether to install the unit on a table or mount it on a rack. If mounting on a

rack, refer to section 10 for panel cutout drawings and to determine the required space.

4. Carefully install the instrument in its designated location and inspect it to ensure that it

is in good condition and undamaged. Before connecting the carrier gas lines to the Mul-

tiDetek3, it is necessary to install and purge the lines. Please consult the "Operating Pa-

rameters" document included on the USB drive for information on the appropriate carri-

er gas type, pressure and gas line connections.

5. The carrier gas purifier (LDP1000) must be started first and to install it, follow the steps

in the LDP1000 user’s manual.

6. After the LDP1000 has been purged, connect its outlet to the back panel connection of

the MultiDetek3 named “Carrier Inlet”. Before connecting the carrier, it is very im-

portant to remove all the caps installed on the MultiDetek3 back panel. Any back pres-

sure on the detector vent connection can cause damage and require the replace-

ment of the plasma detector module.

7. Once the gas lines have been purged and the carrier gas is connected, connect the power

source. Check the "Operating Parameters" document to verify that the voltage is correct

(either 120VAC or 240VAC), and make sure that the voltage indicated on the red indi-

cator of the power inlet module on the back panel matches the voltage of the power

source. Using the wrong voltage source can cause severe damage to the instrument.

8. Turn ON the unit by switching on the back panel switch and wait for the unit to boot.

TheMultiDetek3 works within a Windows-based environment. LDChroma+ will start

automatically after the start-up. After each boot-up, the chromatogram screen shown be-

low will appear.

MULTIDETEK3

User’s manual

17

Figure 1: Boot up screen

9. Before proceeding, it is essential to resolve all active alerts, except for "Flow deviation

on Sample" and "Low flow on Sample". To view the list of active alerts, double-click

on the red alert bar to open the alert menu.

Figure 2: Boot-up alerts

MULTIDETEK3

User’s manual

18

Below are the principal alerts that you may encounter:

Temperature deviation: This type of alert is normal during initial start-up and will typically

resolve itself after a few minutes as the ovens, HCD or heated zone warm up. However, if

the alert persists and no temperature change occurs, it may indicate a problem that requires

further attention. To check the set points for each module, refer to the "Operating Parame-

ters" document or go to the settings menu (Settings>>Settings>>Oven or Set-

tings>>Settings>>HCD) and click on the "+" beside the module you want to check. Then,

click on "Time Table" and check the first value in the timetable (besides "at start"). If the

alert remains active after a few minutes, please contact LDetek support for further assistance

Figure 3: Oven setpoint

Flow deviation on LDepc #: Flow deviation on LDepc#: This alert may appear after the in-

itial start-up, and can take a few minutes to disappear as the LDEPC must stabilize to their

setpoint. The setpoints for each LDEPC are listed in the document "Operating Parameters,"

or can also be seen from the settings menu (Settings>>Settings>>Flow). Check the first

value in the timetable (besides "at start") to confirm the setpoints. If the alert persists after

a few minutes, ensure that the inlet pressure is set to the value specified in the "Operating

Parameters" document (typically 100 psig) and that there are no restrictions in the carrier

gas line between the source and the analyzer's carrier inlet. If the above checks do not re-

solve the alert, please contact LDetek support for further instructions.

MULTIDETEK3

User’s manual

19

Figure 4: Flow setpoint

Low flow on sample: This alert will typically resolve automatically within a few minutes.

During initial start-up, the sample proportional valve needs some time to stabilize. The set-

point for the sample flow can be found in the document “Operating Parameters”. You can

also check the sample setpoint in the settings menu (Settings>>Settings>>Flow). Select the

sample flow and look at the first value in the timetable (besides “at start”). If the alert per-

sists and no flow change is detected after a few minutes, please verify that the sample pres-

sure is set to the value specified in the document “Operating Parameters” (typically 5-30

psig). Additionally, make sure that the right stream is selected, and finally, ensure that

there are no obstructions between the sample source and the analyzer's sample inlet. If the

alert remains active after these checks, please contact LDetek support for further assis-

tance.

Detector # off: This alert may be resolved automatically after a few minutes. It is the time

required for the detectors to stabilize and purge after the initial start-up. Once the LDEPC

reaches their setpoints and a partial purge is achieved, the detectors will turn on automati-

cally. To confirm the setpoints for each sensor, refer to the document "Operating Parame-

ters". If the alert persists after a few minutes, please ensure that the LDEPC is functioning

properly and the carrier inlet pressure is set to the value indicated in the document "Operat-

ing Parameters". Additionally, make sure that there are no obstructions in the carrier gas

flow path. If you still have an active "Detector # off" alert after confirming the above steps,

please contact LDetek support for further instructions.

MULTIDETEK3

User’s manual

20

10. After resolving all active alerts, except for "Flow deviation on Sample" and "Low

flow on Sample", the system must purge. A partial purge will take about 2-3 hours and a

good purge will take 12-24 hours depending on the system configuration. Note that for ppb

systems with ranges of measurements below 1000 ppb, the purge may take 2-3 days.

To ensure that the system is well purged, you can compare the sensor voltages with the

values specified in the "Operating Parameters" document. To access the voltage chart on

the MultiDetek3, click on Tools >> Diagnostics >> Analog Input >> Page 3. The rule of

thumb is to have signals between +/-25% of the values specified in the "Operating Parame-

ters". The number of sensors depends on the MultiDetek3's configuration. The figure be-

low shows an example of a voltage chart found in the "Operating Parameters" document.

Figure 5: Operating Parameters

11. Once the sensor voltages are within +/- 25% of the values shown in the "Operating

Parameters" document, you can connect the calibration gas cylinder (span) to the system.

When selecting a span gas cylinder, ensure that the concentration range for each impurity

is within 50% to 90% of the full-scale range. Additionally, the balance gas of the cylinder

should match the carrier gas or sample gas.

For example, if the MultiDetek3 is configured to measure 0-10ppm Ar and 0-50ppm N2 in

Oxygen using Helium as the carrier gas, a certified span gas with a concentration range be-

tween 5-9ppm Ar and 25-45ppm N2 in Helium or Oxygen can be used. It is recommended

to use the same balance gas as the carrier gas, as it simplifies troubleshooting.

Depending on the system configuration, the span gas cylinder must be connected to the ap-

propriate inlet to calibrate the system. If the system has an integrated stream selector, the

span gas must be connected to the span inlet. Otherwise, it should be connected to the sam-

ple inlet. For systems with a dilution system (LDGDSA), refer to the user manual for spe-

cific instructions. Make sure to set the span gas pressure according to the values indicated in

the "Operating Parameters" document. Once the span gas is connected, the "Sample Low

Flow" alert should disappear. It might be required to select the span stream from the chro-

matogram menu (Figure 22). When the alerts are all resolved, the red alert bar on the bot-

tom will automatically disappear.

Once the sample lines are properly purged, simply start a cycle from the chromatogram

menu. At the end of the analysis, it is important to look at the chromatogramto make sure all

This manual suits for next models

1

Table of contents

Popular Laboratory Equipment manuals by other brands

Labnet

Labnet Spectrafuge 24D instruction manual

Hach

Hach HQ440d user manual

Hamamatsu Photonics

Hamamatsu Photonics C12666MA manual

STERILUX

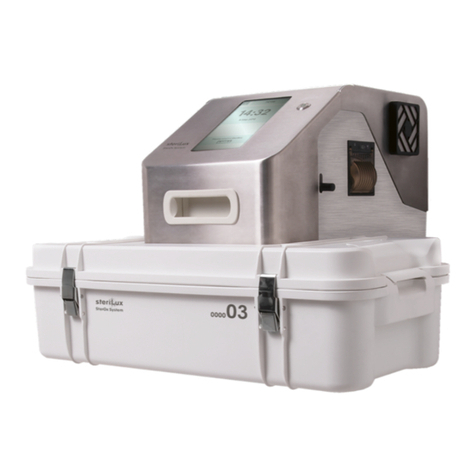

STERILUX SterOx System V Series Instructions for use

3M

3M Ranger 245 Service manual

Agilent Technologies

Agilent Technologies 1260 Infinity II Quaternary System manual