3

This instruction manual is intended for your benefit. Please read and follow the safety, installation, maintenance and troubleshooting

steps described within to ensure your safety and satisfaction. The contents of this instruction manual are based upon the latest

product information available at the time of publication. The manufacturer reserves the right to make product changes at any time

without notice.

SAFETY GUIDELINES / DEFINITIONS

UNPACKING AND INSPECTION

WARNING: Read and understand this entire instruction manual before attempting to assemble, install, operate or maintain

this product. Failure to comply with the instructions may result in serious personal injury and/or property damage!

The following signal words are used to emphasize safety warnings that must be followed when using this product:

DANGER:

Indicates an imminently hazardous situation

that, if not avoided, WILL result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation that,

if not avoided, COULD result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation that,

if not avoided, MAY result in minor or moderate injury.

NOTE: Indicates important information, which if not

followed, MAY cause damage to equipment.

After opening the carton, unpack your new product and related parts and accessories. Please

inspect it carefully for any damage that may have occurred during transit. Please check it against

the package contents on page 4. If any parts are missing, please call customer service at 1-800-

426-1262 between 6 a.m. and 5 p.m. Pacific time.

WARNING: DO NOT operate this product if damaged during shipment, handling or misuse.

Do not operate the product until the parts have been replaced or the fault rectified. Failure to do

so may result in serious personal injury or property damage. All damaged parts must be repaired

or replaced as needed prior to operating this product. Check to see that all nuts, bolts and fittings

are secure before putting this product into service.

If you have any questions, or require assistance with damaged or missing parts, please contact

our customer service department at 1-800-426-1262. Please have the serial number, model

number, and date of purchase available for reference when calling.

PRODUCT WARNINGS

• Failure to heed these warnings may result in loss of load, damage to lift, and/or lift failure

resulting in personal injury or property damage.

• This is a lifting device only. Load must be supported immediately by Safety Bar and other

appropriate device.

•

Do not overload lift beyond rated capacity. Overloading can cause damage to or failure of the lift.

•

Refer to LIFTING PROCEDURES IN THE owners manual FOR THE ITEM YOU ARE

LIFTING. Lift only on areas as specified by the manufacturer.

• This lift is designed for use only on hard level surfaces capable of sustaining the load. Use of

lift on other than hard level surfaces can result in lift instability and possible loss of load.

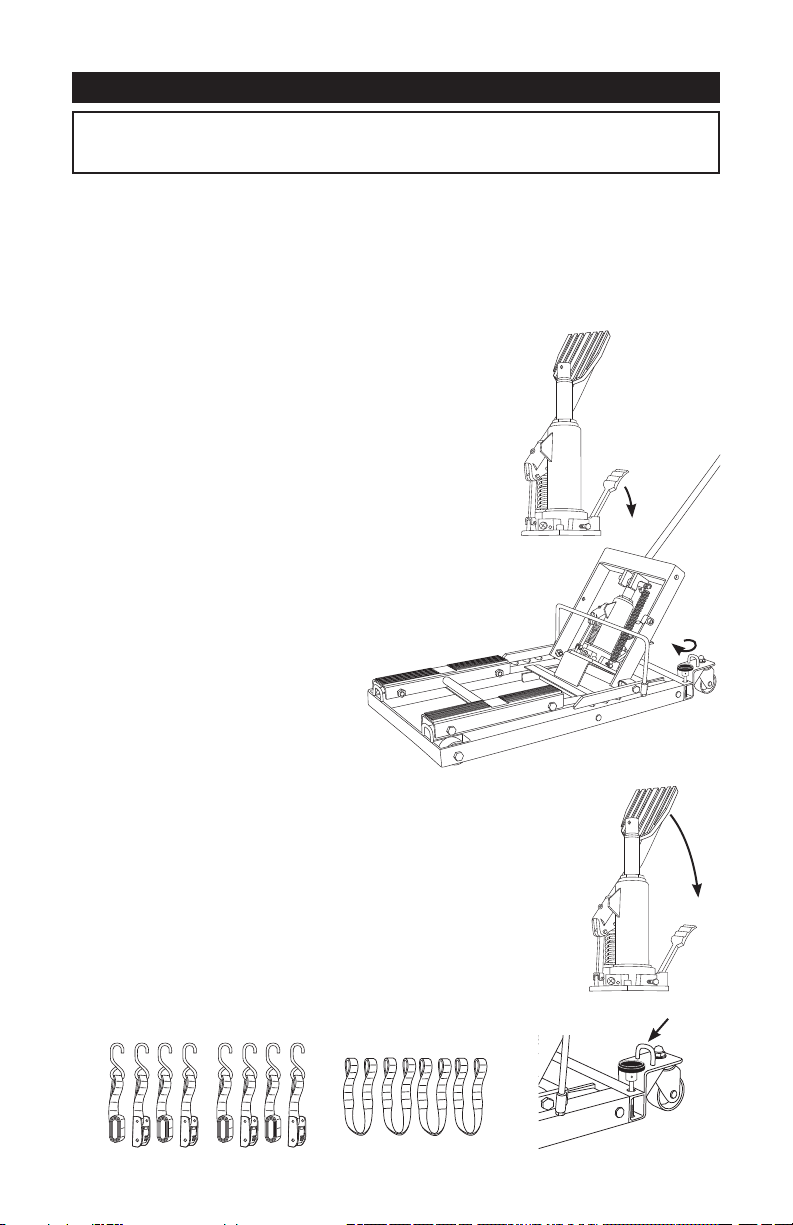

WARNING: NEVER ATTEMPT TO RAISE THE LIFT WHILE THE TIE DOWNS ARE

ATTACHED TO THE LOAD.

• Leveling bolts are intended to fix the unit to the ground and avoid movement while lifting a

load. DO NOT use them as stabilizers.

• USE included straps to secure the load to the lift.

• ENSURE the safety levers are engaged when load is raised to prevent accidental lowering.

• DO NOT make any alterations to this product.

• LOWER LIFT as much as possible before moving lift while supporting a load.

• KEEP FINGERS, HANDS AND FEET AWAY from the lift arms and other moving parts.

• NEVER lift the load without first assuring that it is properly balanced and secure on the lift.