Pulley-man CSW-3060 User manual

www.pulleyman.co.kr

PULLEY-MAN CO.,Ltd

CSW-3060

Single Line Use

Double Line Use

PULLEY-MAN

USER’S MANUAL

MULTIPURPOSE

& PORTABLE

WINCH

PULLEY-MAN

MODEL

CSW-3060

www.pulleyman.co.kr

2

INTRODUCTION

Thank you very much for purchasing PULLEY-MAN.

Please read this manual carefully for safe use, improved

productivity and proper maintenance. Specifications may

change without prior notice for product improvement. For

updated information, please contact your dealer or

manufacturer.

A single unit of PULLEY-MAN CSW-3060 alone can perform

all the functions of conventional hoist, winch and chain block.

Unlike such conventional products, which wind wire on a

drum and thus can work load only within length of the wound

wire rope, CSW-SERIES is designed to perform its functions

quickly, easily and efficiently under any working conditions

regardless of length or direction, whether it is vertical,

horizontal or slant environment, as long as there is an anchor

to hook the equipment.

Please consult the governing laws, rules or directives before

use for standards of manufacture, safery and inspection.

3

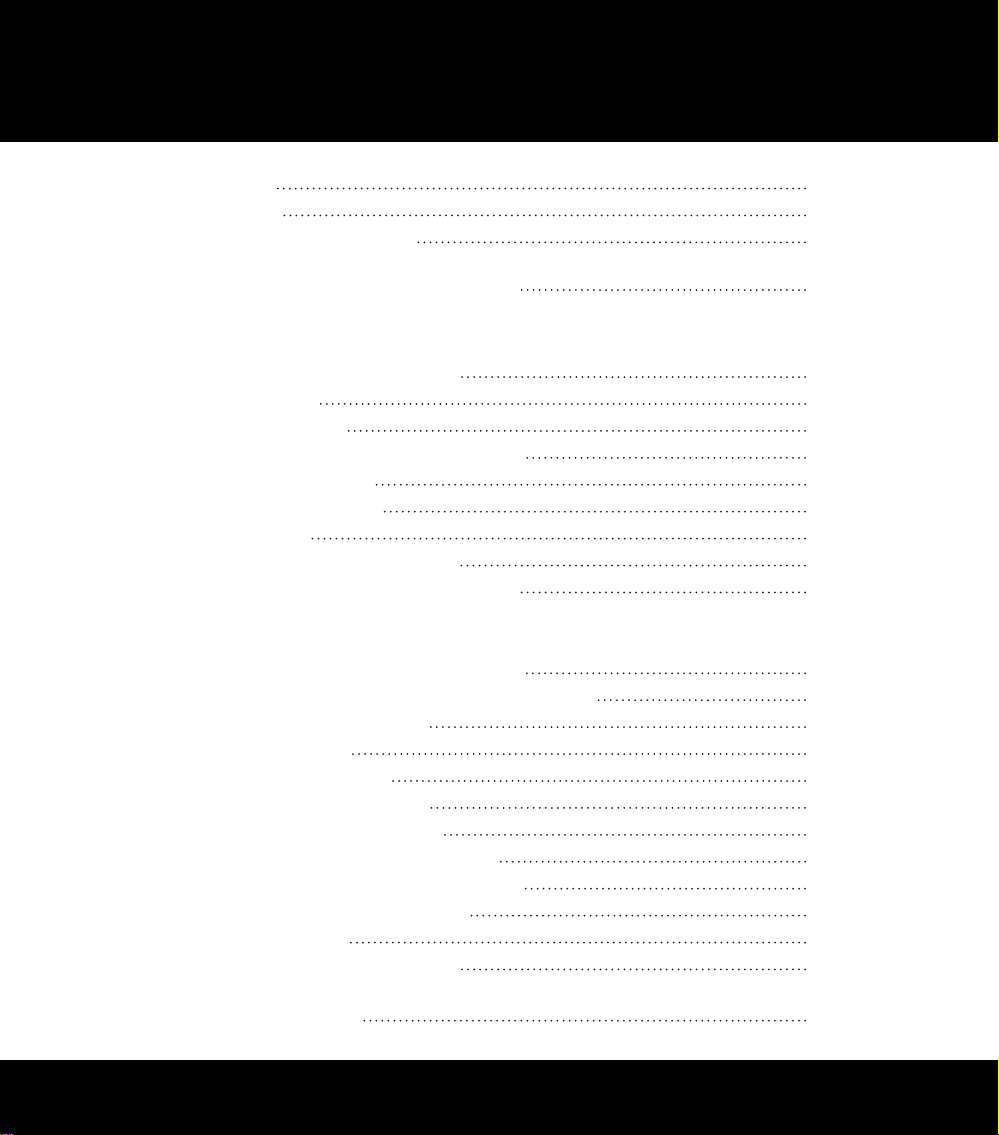

TABLE OF CONTENTS

Ⅰ. Safety Instructions

Ⅱ. A description for a speed reducer

Ⅲ. Uses & Operations

Ⅳ. Maintenance

Ⅴ. Limited Warranty

1. Symbols

2. Definitions

3. Precautions against Danger

1. Standard Offerings and Options

2. Specifications

3. Parts and Names

4. Incorporation and Removal of Wire Rope

5. Treatment of Wire Tip

6. In-Put Power Sources

7. Applications

8. PULLEY-MAN used as a Winch

9. Precautions for Non-Professional Users

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Appointment of Maintenance Personnel

Safety Rules for Maintenance & Trouble-Shooting

Warning Labels for Danger

Labels and Details

Grease Replenishment

Assembly and Disassembly

Precautions for Re-Assembly

Check-Up Points after Re-Assembly

Replacement of Parts and Components

Daily and Periodical Maintenance

Trouble-Shooting

Education and Training for User

4

4

5

9

10

11

12

14

16

17

18

22

22

23

23

23

24

24

24

27

27

27

29

31

31

32

4

Ⅰ. Safety Instructions

1. Symbols

2. Definitions

1) Entrepreneur(person in charge) :

Owner of PULLEY-MAN who uses PULLEY-MAN for his applications, or one who authorizes

someone else to use PULLEY-MAN.

2) Authorized Personnel :

Qualified personnel who are authorized by entrepreneur to install, use and keep maintenance of

PULLEY-MAN.

3) Maintenance Personnel :

Qualified personnel who are authorized by entrepreneur to install, adjust, keep maintenance, and

remove defects of PULLEY-MAN.

May lead to fatal or serious danger when handled improperly.

May lead to physical or property damage when handled improperly.

Caution against electric danger

Physical contacts during operation may immediately lead to bodily injury. Parts with

this symbol must be handled only by qualified technicians. Power must be turned off

while handling such parts.

Caution against hanging load.

Operation under hanging load may lead to a serious accident. Donʼt come under a

hanging load.

Caution for handling during installation.

Thes symbol in this manual indicates warning of all kinds. Disregard of this symbol

may cause damage to PULLEY-MAN or load.

5

Ⅰ. Safety Instructions

3. Precautions against Danger

4) Electrician :

Those who have knowledge and experience in the field along with relevant qualification and can

identify potential factors of danger in electrical and related equipment and take appropriate measures.

5) Knowledgeable Personnel :

Those who have extensive knowledge, technical training and experience with regard to PULLEY-MAN

and can make general decisions regarding safety rules, accident-preventive tips, methods of operation

and conditions of safe operation.

6) Operator :

Person authorized by entrepreneur to operate or to move place of PULLEY-MAN

7) Non-Professional User :

Person not authorized by entrepreneur to operate PULLEY-MAN and needs education and training. He

has to be informed of relevant rules and safety measures along with accident-preventive tips.

8) PULLEY-MAN :

Product having function of lifting and conveying load like crane, hoist, winch and cable car.

1) Check below after purchasing PULLEY-MAN.

❶ Type

❷ Lifting Capacity

❸ Diameter and Length of Wire Rope

❹ Standard parts, Components and Accessories

❺ Options (in-put power source)

6

Ⅰ. Safety Instructions

4) Safe Usage

❶ Do not overload.

❷ Do not operate right beneath hanging load or PULLEY-MAN.

-When operating with hand drill as power source, maintain at least 24in.(60cm) from load.

-When operating with motor as power source, maintain at least 3.3~4.9ft. (1~1.5m).

❸ Fix PULLEY-MAN or wire hook before hooking load.

❹ Do not hold or lay hands on the load while lifting.

❺ Keep workplace in order and maintain at least 300 lux.

❻ Make sure no person or object is in front or rear of moving load.

❼ If fixation of PULLEY-MAN or hooking of load is unstable, take immediate measure.

❽ Do not operate near hazardous gas such as acid and alkali or in surroundings subject to

inflammation.

❾ Make sure no uncovered flame, excessive heat or sparks are near PULLEY-MAN.

❿ Install PULLEY-MAN at least 3.3~4.9ft. (1~1.5m) from the wall or obstacle(s).

Do not operate at humid or wet places on rainy days (except manual usage). It may lead to electric

shock. When operating PULLEY-MAN outdoors or at humid places, take protective measures that

meet IP54 requirements.

3) Safeguards against Danger

❶ Protection over Pulley

- Press Roller Casing is designed with protective cover closed over pulley, which transports wire rope

back and forth

❷ Hook: Must have a latch to prevent load-binding material from slipping off the hook.

❸ End-Stopper: Fixed at the other end of wire rope to prevent wire rope, and load in consequence,

from slipping off the pulley due to excessive load weight.

2) Working Environment and Operational Conditions

Continuous operation time: within 25 minutes

7

Ⅰ. Safety Instructions

When using hand drill as in-put power source, use voltage and frequency only u specified in labels.

When standing on a conductive object during operation, make sure to ground it.

When PULLEY-MAN is not in use, or when repairing, cleaning or examining, make sure in-put

power is off.

When assembling, disassembling or replacing parts, follow instructions in this manual.

Use only the parts provided or certified by manufacturer.

Improper usage or usage without proper maintenance is prohibited.

Do not allow children, or anyone unaware of precautions or incapable of proper operation, to

operate PULLEY-MAN.

Be sure to grip a hand drill with both hands when using it.

5) Check-Up Points before Operation

❶ Check PULLEY-MAN if there is a loose connection.

❷ Check wire rope for abrasion or damage.

❸ Check if wire hook is inserted in right direction.

❹ Check if wire rope is properly fitted into the pulley groove and press rollers are pressing wire rope.

❺ Check if nuts are fastened and nut-holding pins are positioned.

❻ Check if gateway latch of wire hook is functioning.

❼ Check if labels and danger signs are attached properly.

6) Preparations before Operation

❶ Wear safety helmet that meets safety standards to protect your head.

❷ Wear safety shoes to protect your feet.

❸ Wear safety gloves that are convenient to wear.

❹ Be careful about loose tip of your costume during operation, such as hanging necktie or sleeves.

8

Ⅰ. Safety Instructions

7) Storage after Usage

❶ Separate in-put power source (e.g. hand drill) from main body before storage.

❷ Separate wire rope from main body in order to prevent warping or bending and keep it properly

rolled.

❸ When keeping for long time unused, clean it properly and keep it oiled.

❹ When main body is damaged, repair it before storage. If replacement part(s) is required, use one(s)

supplied or recommended by manufacturer.

❺ Keep PULLEY-MAN safe from humidity and dust.

8) Exemptions from Liability

❶ Accidents from improper handling.

❷ Accidents occurring from disregard of instructions in this manual.

❸ Accidents in result of improper repair, arbitrary modifications or revisions.

❹ Accidents due to use of parts or components unapproved of by manufacturer

❺ Accident caused due to lifting a person.

❻ If used in lifting a high-priced equipment whose the price is more than twenty thousand US dollars.

men using PULLEY-MAN as a hoist consult relevant laws and rules enacted by your government for

manufacturing, safety and inspection standards.

It is not allowed to we PULLEY-MAN for transportation of people. When that is inevitable, please

contact manufacturer for relevant safety rules or laws to consult.

9

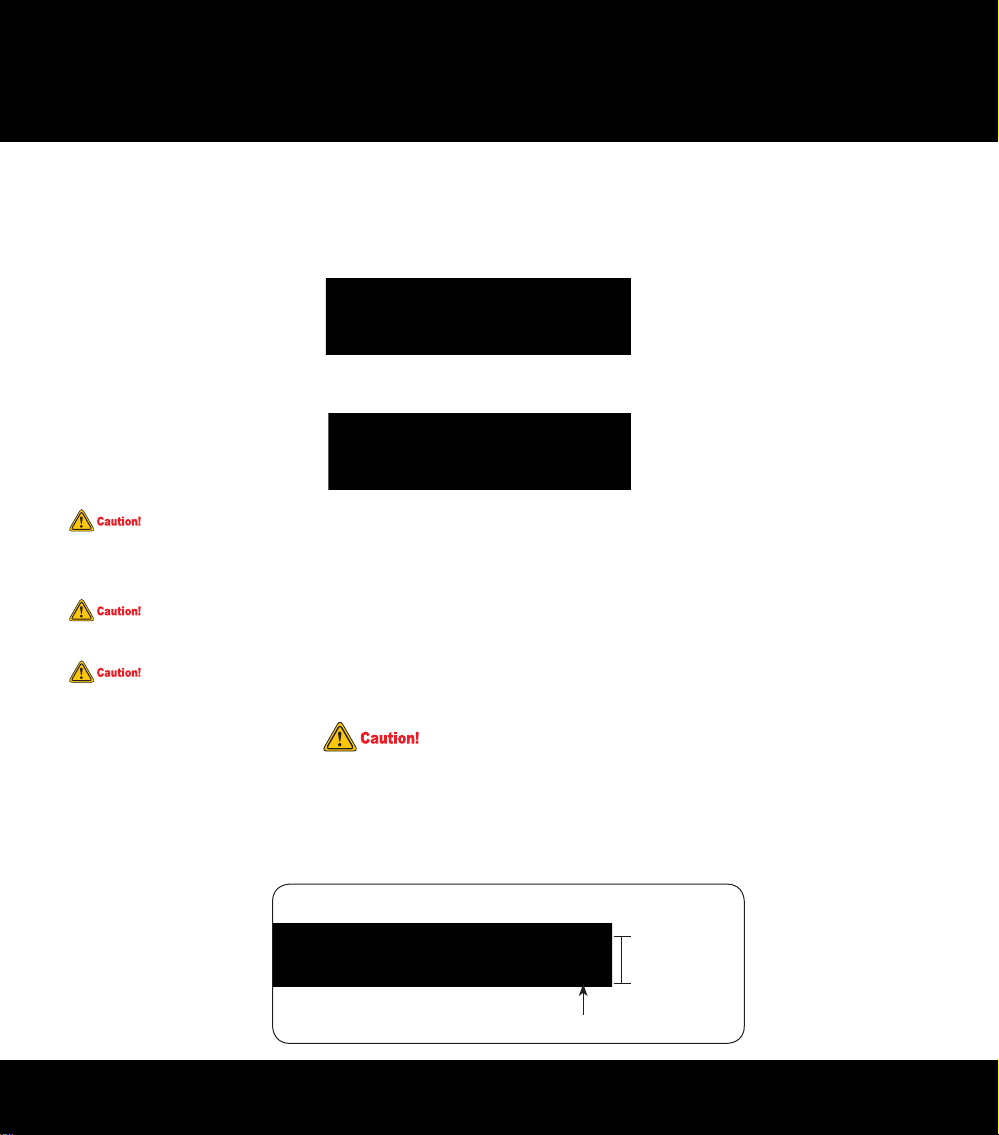

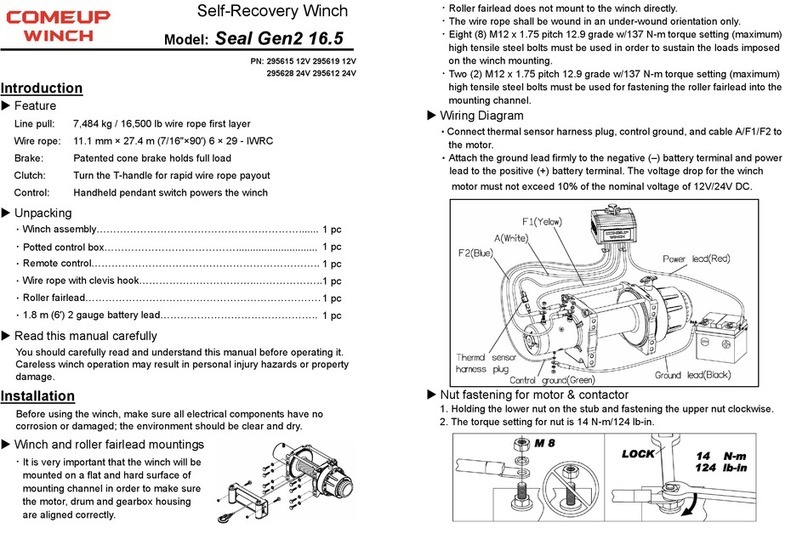

Ⅱ. A description for a speed redueer

The speed reducer is torque-up with 102.5:1 speed ratio of input speed.

So, It can lift up or pull the heavy object without heavy energy.

It consists of wire, speed reducer, wedge-shaped pulley system.

The 9 gears in speed reducer have brake power that multply the blocking frition from output speed.

1. It is safe if there is no movement of an

input axis in state of lifted up a object.

When you take down a heavy object,

the brake function can be minimize or

lost because of increasing energy of

inertia & potential.

2. Every power source must has own

brake system.

It is safe using in speed 3m/min

3. Do not apply the object heavier than

the proof load.

Wedge - shaped Pulley

In - Put Axis

Out - Put

Wire rope

Speed reducer part

10

Ⅲ. Uses and Operations

1. Standard Offerings and Options

AC Motor Double Line Options

CSW-3060

11

Ⅲ. Uses and Operations

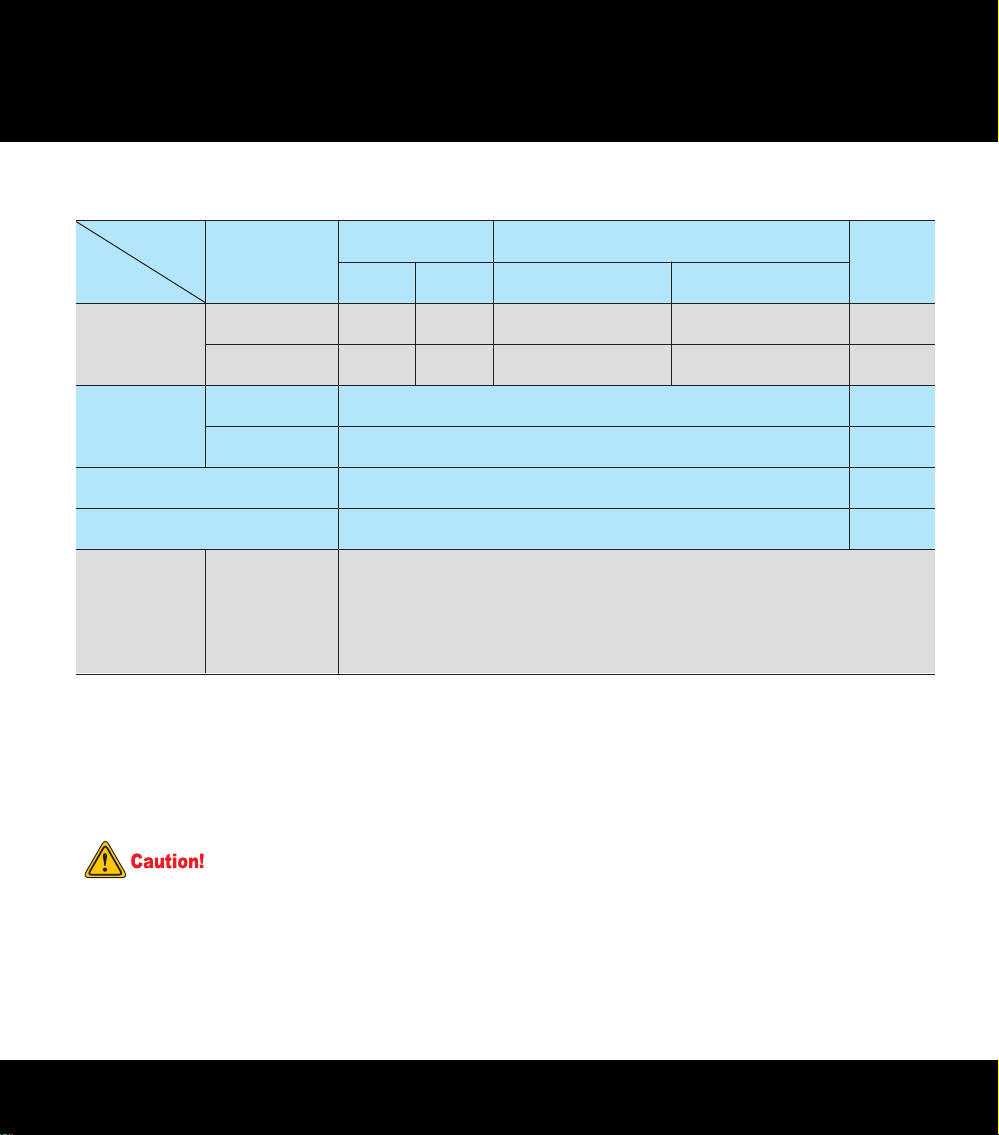

2. Specifications

Standard Specifications

▶The above instructions should be observed for safety

▶Use indoors only for safety on a rainy, snowy, windy or dark day.

▶Do never lift a person.

Working

Distance

∞

∞

Number of

Falls

Hand Drill

Load capacity

Wire Rope

Options

Single Line

Doulle Line

Diameter

Standard Spec.

Hand Drill

Cordless Drive Drill

AC Motor

single phase 220V, min. 550W, 3000rpm, reversible

3/8˝ (10mm), 18V DC, max. torque 230in./lbs. or above, reversible

single phase 220V, min 1500W, Hz60/50, 5200rpm. reversible.

Weight : CSW-3060 of Main Body(kgs/lbs.)

Weight : CSW-3060 of Wire Hook(kgs/lbs.)

4.76mm(3/16in.) Steel Wire Rope (7×19)

Wire Rope 12M(40ft.) with Hook and Wire-Rope Reel, Hook Socket & End-Stopper

3.8/8.4

1.9/4.2

300

600

600

1,200

6.0/19.8

3.0/9.9

3.75/12

1.85/6

Lifting capacity Line Speed

kgs lbs. No Load(MPM/FPM) Full Load(MPM/FPM)

✽MPM : meter per minute

✽FPM : feet per minute

12

Ⅲ. Uses and Operations

3. Parts and Names

CSW-3060

Single-Line Use

Main Frames

Frame Cover

In-Put Axis

Gear Box

In-let Lock Pin

Latch

Wire-Rope Reel

Wire Rope

End-Stopper

Wire-Hook

13

Ⅲ. Uses and Operations

Press Roller Casing

Hook

Hook Cover

Double-Line

Hook Cover

Wire Rope

Socket

Wire Rope

Hook Block

Out-let

Roller

Hand Drill

Press Roller Casing

Lock Pin

Double-Line Use

14

Ⅲ. Uses and Operations

4. Incorporation and Removal of Wire Rope

Wire rope of PULLEY-MAN is separate from main body unless it is incorporated.

Before installation, assemble main body with wire rope. Incorporate wire rope into main body in following

procedures. (Follow the procedures backwards when removing wire rope from main body).

❶

Pull off In-Let Lock Pin.

Remove split pin and pull loop

of in-let lock pin.

❷

Pull off two press Roller Casing

Lock Pins.

Remove split pins and pull loops of

press roller casing lock pins.

❸

Remove Hook of main body

(Single-Line Use).

Remove nut-holding pin and nut and

pull off hexagon bolt.

❸

Remove Double-Line Hook

Cover (Double-Line Use).

Remove nut-holding pin and nut and

pull off hexagon bolt.

❹

Incorporate Wire Rope into pulley

groove.

Inserting direction is from in-let

lock pin toward press roller casing.

Pull out Wire Rope long enough

for operation before fitting onto pulley

groove.

❺

Push in In-Let Lock Pin.

Push in the pin from gear-side frame

and insert split pin.

❻

Re-assemble main body Hook

(Single-Line Use).

Screw in hexagon bolt, lock nut,

and insert nut-holding pin.

1) Procedures of Incorporation: CSW-3060

15

Ⅲ. Uses and Operations

❻

Re-assemble double-line Hook

Cover (Double-Line Use).

Screw in hexagon bolt, lock nut, and

insert nut-holding pin.

❼

Press Wire Rope with Press Roller

Casing.

Lift press roller casing about 90° and

pass wire rope between out-let roller

and press roller casing. Pull wire

rope in end-stopper direction so that

it fits to bottom of pulley groove.

Close press roller casing toward

frame so as to press wire rope.

Check if press rollers are

pressing wire rope.

Insert wire rope between sheave and

side plates, and re-assemble hook

with wire rope socket. Before

re-assembling hook, check if wire

rope is properly laid in the middle of

sheave groove. Screw in bolt and nut

and insert nut-holding pin.

Assemble wire rope socket to double-

line hook cover. Screw in nut and insert

nut-holding pin.

Incorporation of Wire Rope comploted.

When holes for lock pins on frames and

press roller casing are in line, insert lock

pins from speed-reducer-side frame and

insert split pins.

(Single-Line User : END)

(Double-Line User : END)

❽

Push in Press Roller Casing Lock

Pin.

❾

Separate Hook from Wire Rope

Socket.

Remove nut-holding pin, bolt and

nut from wire rope socket, which is

connecting wirerope hook and wire

rope at tip of wire rope.

❿

Insert wire rope over Hook Black

and re-assemble Hook.

Connect wire rope socket to double-

line hook cover.

16

Ⅲ. Uses and Operations

5. Treatment of Wire Tip

3) Fixation of End-Stopper

Fix the other tip of wire rope with steel cube by press fixation method. Thickness of the steel should be

more than 10㎜ after press. Grind remnant wire rope off the end-stopper.

▶When using a wire rope longer than the one provided by manufacturer(40ft. (12m)), use one

recommended by manufacturer, and fix wire tip by either method shown above and connect wire

rope socket (wire rope provided by manufacturer is fixed by press fixation method).

▶When fixing wire tip, its safety factor must be at least 5 times and a safety test must be

conducted before using it.

▶Contact manufacturer when employing wire rope longer than 40ft. (12m)

10㎜

End-stopper

1) Clip Fixation

For wire ropes whose diameters are less than 5/8in. (16mm), use 4 clips and give spacing

between clips wider than 6 times diameter of Wire Rope.

2) Press Fixation

Use cold-pressed steel.

17

Ⅲ. Uses and Operations

6. In-Put Power Sources

1) Hand Drill

❶

Specifications: single phase 110/220V, min. 550W, 3000rpm, reversible

❶

Precautions

●

Install anti-leakage insulator at main power and make sure to ground it.

●

Use voltage of main power as specified in label.

●

When using as in-put power source, check if its chuck is properly connected to hexagonal tip

of in-put axis.

●

Do not touch spinning chuck.

2) Cordless Drive-Drill

❶

Specifications: 3/8˝ (10mm), 18V DC, max. torque 230in./lbs. or above, reversible

❶

Precautions :

●

Use when it is fully charged.

●When using as in-put power source, check if its chuck is properly connected to hexagonal tip of

in-put axis.

●Do not touch spinning chuck.

3) Motor

❶

Specifications: single phase 220V, 50/60Hz, 5,200rpm (max.), remote control switch.

❶

Precautions:

●

Apply voltage as specified in the label.

●

After attaching motor, check joints and attachment to main body.

▶For products not supplied by manufacturer, check accordingly.

▶When using PULLEY-MAN as a hoist, ground and discharge the in-put power source in

order to protect from thunderbolt.

18

Ⅲ. Uses and Operations

7. Applications (CSW-3060) Caution!

PULLEY-MAN CSW-3060 is designed to be multifunctional and adaptable to perform functions of

conventional hoist, winch and chain block altogether. CSW-3060 can work load quickly and easily

regardless of working length, direction and condition, whether it is vertical, horizontal or slant, as

long as there is an anchor to hook.

Before using PULLEY-MAN for whatever application, consult the governing law.

How to Use & Install CSW-3060

600lbs

300kgs 1200lbs

600kgs

◈

Fixed Pulley-Man

600lbs

300kgs 1200lbs

600kgs

◈

Fixed Wire Hook

600lbs

300kgs

1200lbs

600kgs

◈

Fixed Pulley-Man on the Bottom

19

Ⅲ. Uses and Operations

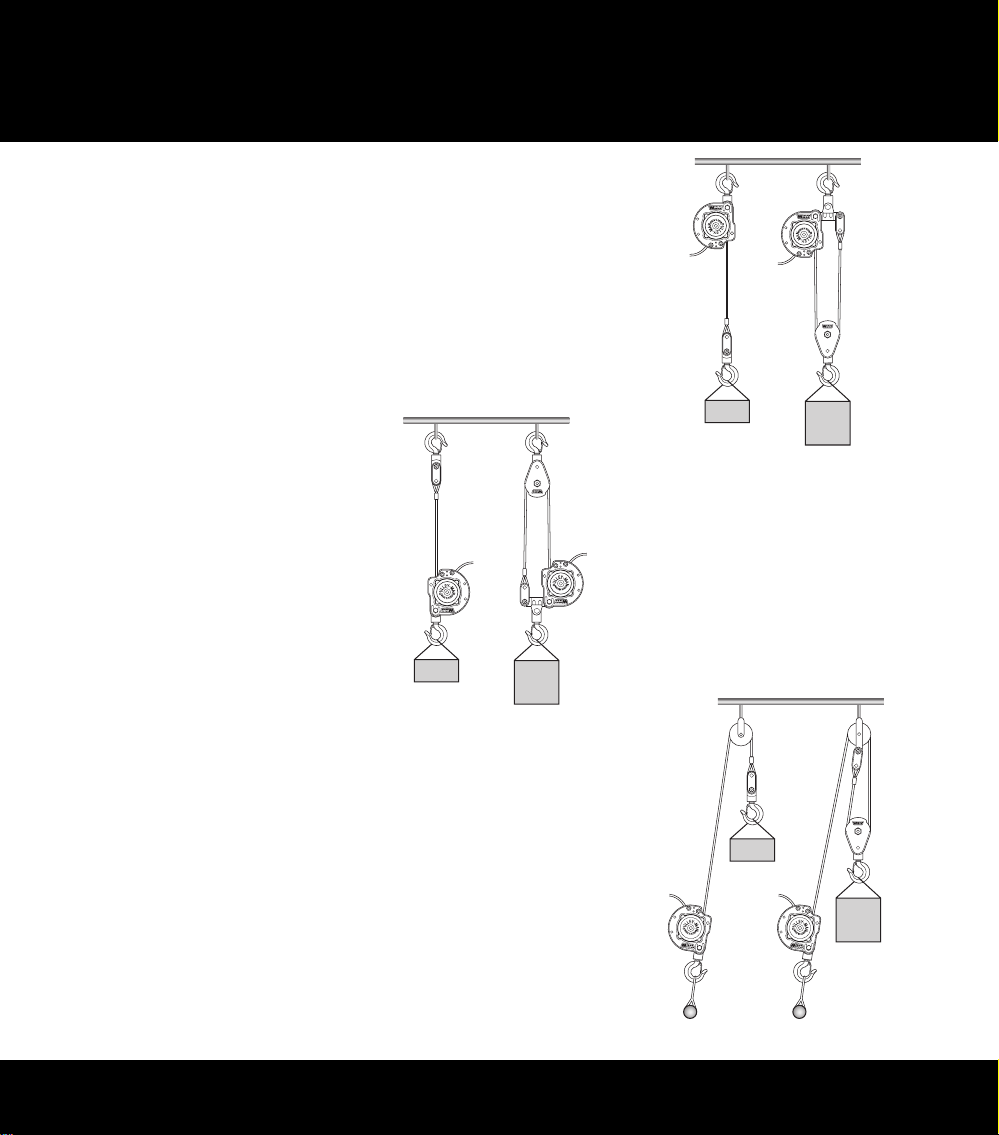

2) Set-Up Modes of PULLEY-MAN

❶

Fixed PULLEY-MAN

Fix main body at an I-beam, round beam or other stable overhead

structure and hook load with wire rope to move load vertically.

❷

Fixed Wire-Hook

Fix wire-hook at an I-beam,

round beam or other stable

overhead structure and hook

load with main body hook to

move load vertically.

Fix main body at a stable anchor on the ground, pass wire

rope through block fixed at an I-beam, round beam or other

stable overhead structure, and hook load with wire rope to

move load vertically.

❸

Fixed PULLEY-MAN on Ground

Table of contents

Popular Winch manuals by other brands

Come.up Winch

Come.up Winch 295750 12V manual

Come.up Winch

Come.up Winch Seal Gen2 16.5 quick start guide

Warrior Winches

Warrior Winches 95SPS12 Assembly & operating instructions

Cycle Country

Cycle Country 25-5193 Assembly & owners manual

Comeup

Comeup CWS-230 manual

Farmi Forest

Farmi Forest W30F OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Ronstan

Ronstan BB Orbit Block 20 Series User instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR 150 RLP Operating and maintenance manual

Mile Marker

Mile Marker SEC18 Installation & operator's manual

SVERO

SVERO 16 User instructions

Kong

Kong RAIZER manual

Warrior Winches

Warrior Winches 80RVSHY owner's manual