RF25109HL Series 20 BB Orbit Block™

Lashing Head User Instructions (cont.)

USER INFORMATION - RF25109HL Series 20 BB Orbit Block™ Lashing Head User Instructions Page 4.

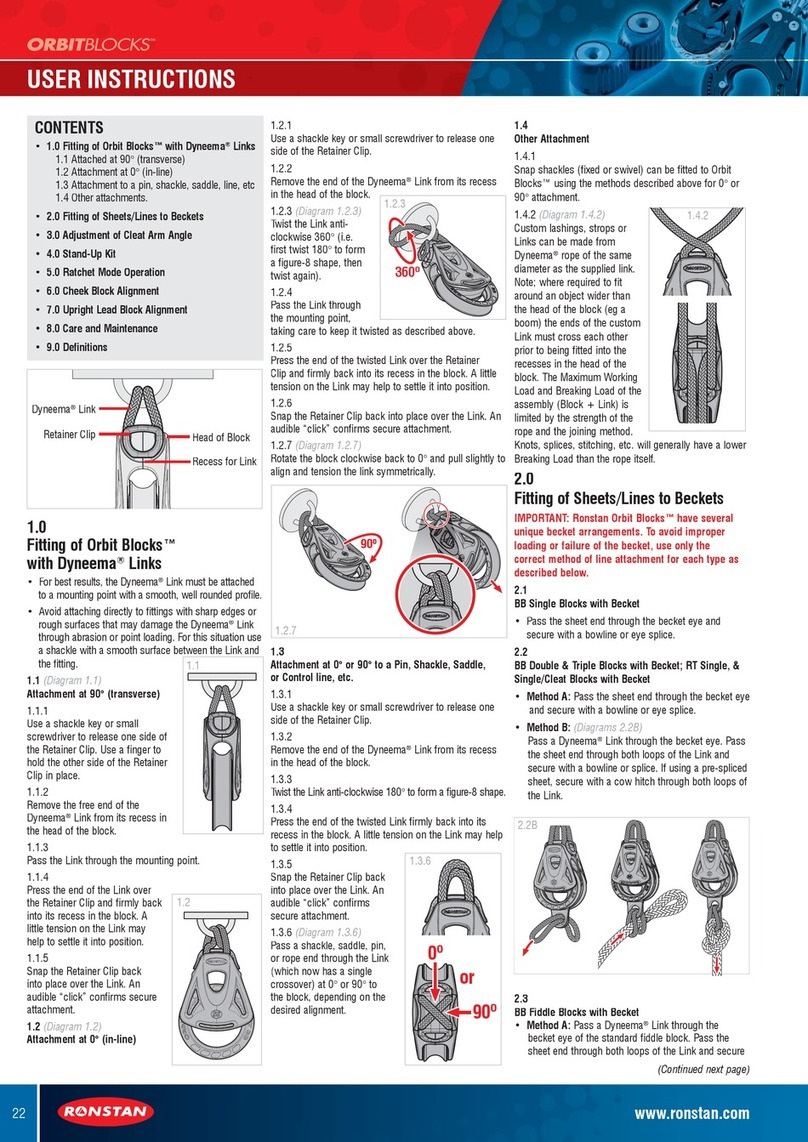

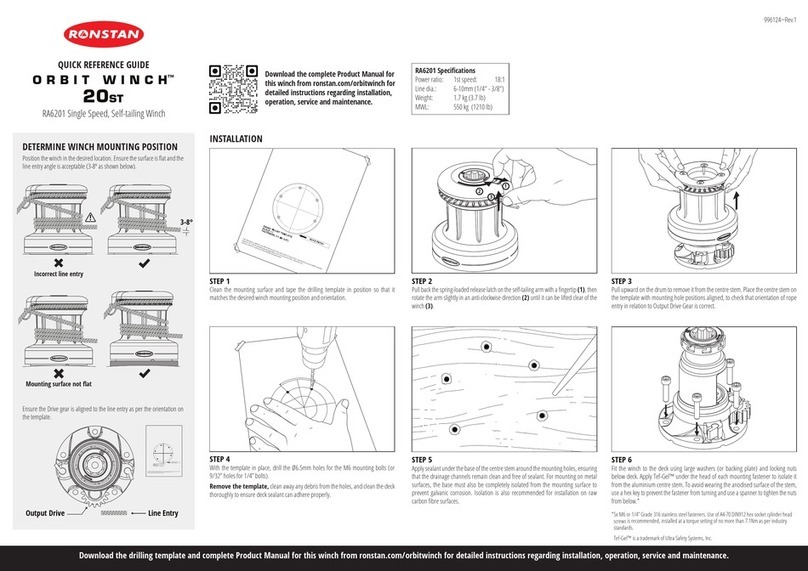

2.3 SINGLE LINE USED AS BECKET & SHEETS - FOR SHEETS UP TO 3MM (1/8”)

2.3.1 Pass the line in

through a cheek, up

through the head,

around the xing

point, back down

through the head

and out through the

opposite cheek.

LASHING ATTACHMENT

• To receive the maximum performance benet from the Lashings, they must be used correctly installed, inspected regularly and replaced

when required.

• Lashings must be attached to a mounting point with a smooth, well rounded prole without sharp edges or burrs. If in doubt, use a

shackle with a smooth surface between the Lashing and the mounting point.

• Lashings will eventually suer degradation from fatigue, wear and UV exposure. Like all running and standing rigging, Lashings should be

inspected as a part of your regular boat maintenance program and replaced if they show signicant wear or bre damage.

ORBIT BLOCKS™

• Grit and sand will damage bearing systems. Ronstan Orbit Blocks™ have a precisely engineered bearing system that should be kept clean

and free of sand and grit to ensure optimum performance and service life. Blocks, in particular the bearing areas, should be ushed with

fresh water regularly and periodically cleaned with a mild detergent and water.

• Dry lubricants such as Ronstan Sailfast™ silicon spray may be used to lubricate the bearing system. Oil/petrochemical based lubricants

must not be used.

• Ronstan Orbit Blocks™ are designed and manufactured for applications on sailboats.

• See the INFO section of the Ronstan web site and our catalogue for important customer considerations and warranty information.

BB = Ball Bearing

MWL = Maximum Working Load

BL = Breaking Load

Dyneema® is a trademark of Royal DSM NV.

DSM is the inventor and manufacturer of Dyneema®, the world’s strongest bre™. “Dyneema®”, and “Dyneema®, the world’s

strongest bre™” are trademark(s) (applications) owned by Royal DSM NV.

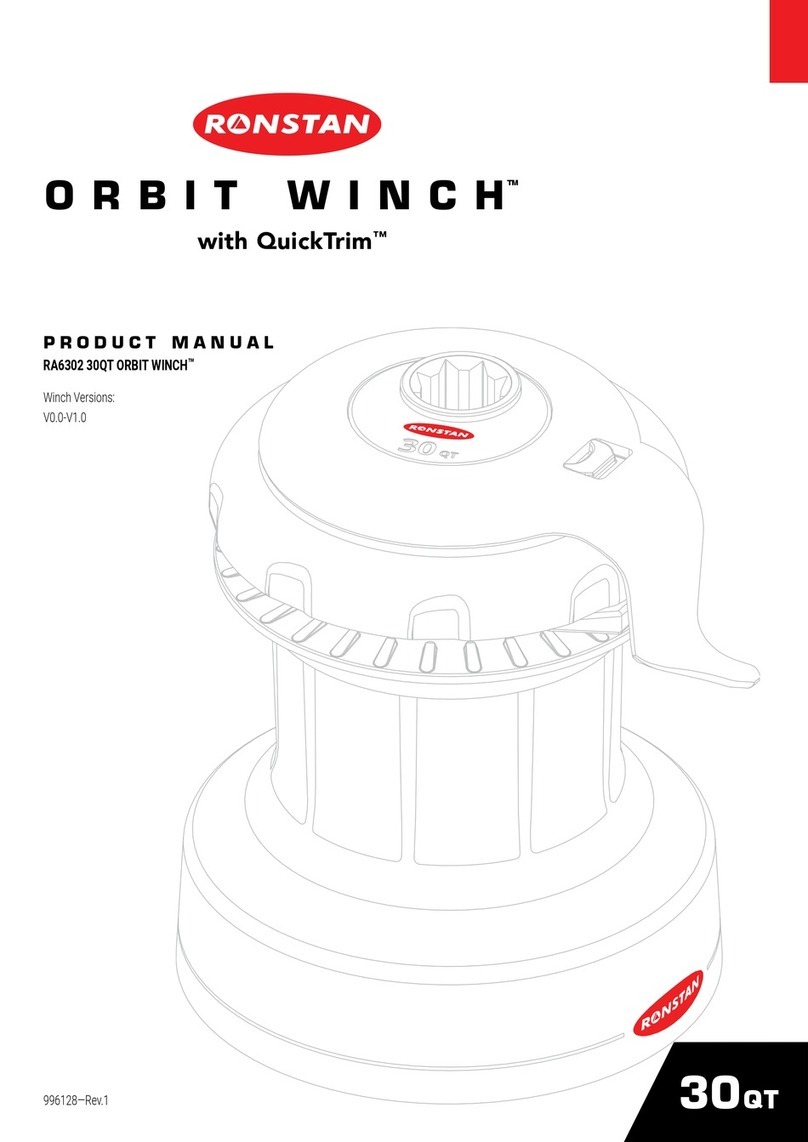

2.3.2 Pass both ends

through the hub in

opposite directions.

2.3.3 Finish lashing with appropriate knot, splice or whipping. If a knot is

used it must not be a ‘slip’ knot, and the knot must be such that it pulls

equally on each line leading up to the hub. A bowline is ideal. Note: the

breaking load of the installed block is dependent on the breaking load of

the line; up to a maximum B.L. of 900kg (1980lb). Knots, splices, stitching,

etc. will generally have a lower breaking load than the rope itself.

3.0 CARE AND MAINTENANCE

4.0 DEFINITIONS