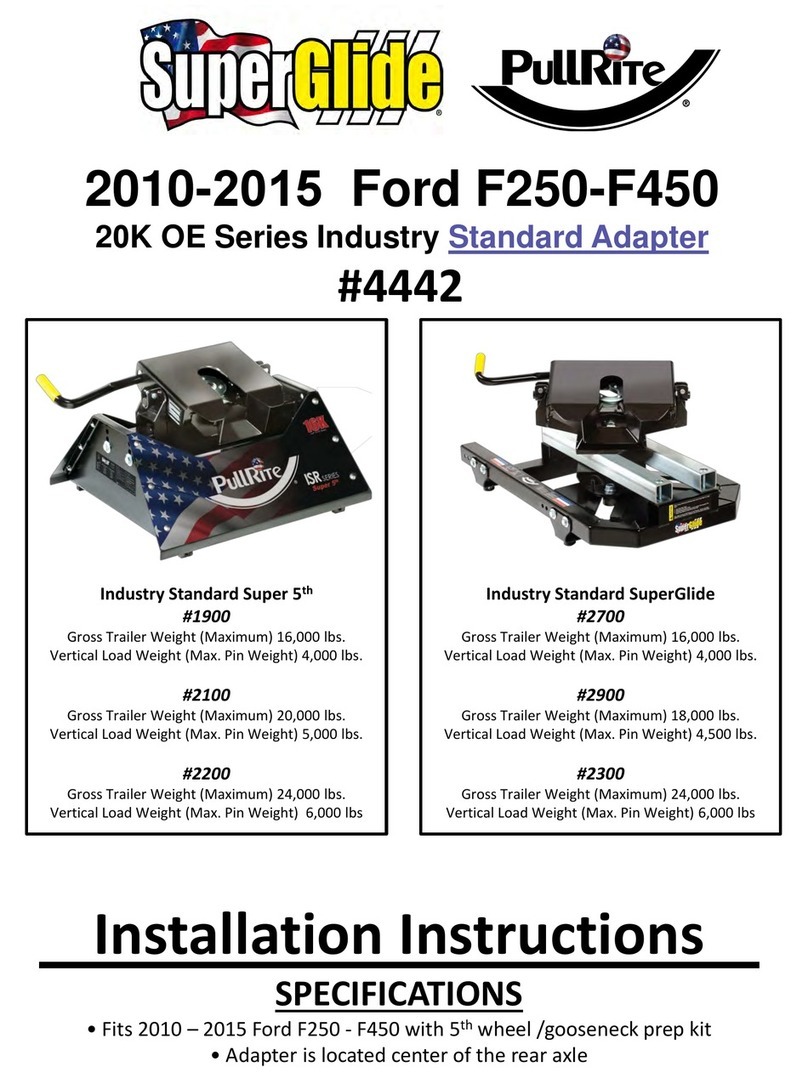

PullRite SuperLite 2400 User manual

The following instructions provide valuable information regarding the function and proper use of the Super 5th Fifth Wheel Towing System.

YOU MUST COMPLETELY READ THE INSTRUCTIONS WITHIN THIS MANUAL, PRIOR TO OPERATING THE HITCH TO PREVENT UNNECESSARY DAMAGE

TO THE HITCH, VEHICLE, OR TRAILER.

For more information, please call PullRite at (800) 443-2307.

OWNER’S MANUAL

#2400 (20K) Industry Standard Super 5th

Gross Trailer Weight (Maximum) 20,000 lbs.

Vertical Load Weight (Max. Pin Weight) 4,000 lbs.

12.14.15:revA

TABLE OF CONTENTS

SYSTEM WEIGHT RATING vs. COMPONENT WEIGHT RATING .....................................................................................3

LUBRICATION........................................................................................................................................................................3

KING PIN ADAPTER BALL & COUPLER TUBE............................................................................................................3

ANNUAL MAINTENANCE..............................................................................................................................................3

HEIGHT ADJUSTMENT .........................................................................................................................................................4

KING PIN ADAPTER INSTALLATION....................................................................................................................................5

HITCHING ..............................................................................................................................................................................6

SAFETY CHECKS PRIOR TO TOWING................................................................................................................................6

UNHITCHING.........................................................................................................................................................................7

CHALLENGE VS. SOLUTION................................................................................................................................................7

#2400 EXPLODED VIEW.......................................................................................................................................................8

#2400 PARTS LIST ................................................................................................................................................................9

5 YEAR LIMITED WARRANTY ...............................................................................................................................................I

PRODUCT REGISTRATION ..................................................................................................................................................II

Page 3

SYSTEM WEIGHT RATING vs. COMPONENT WEIGHT RATING

A towing system includes each vehicle and component involved in towing. Each item in your towing system has a capacity

or weight rating. You trailer has a Gross Vehicle Weight Rating, or GVWR. Your truck has a tow capacity, payload

capacity, and possibly more. In addition, your fth wheel hitch has a weight rating. This weight rating must be at, or

above, the GVWR of your trailer for you to tow safely. In addition, if your truck can tow larger loads (has a larger capacity)

than the rating of your hitch, your system is only safe to tow loads at the lower rating, that of the hitch.

Your mounting kit also has a weight rating, just like your fth wheel hitch. Many times, these rating are designed to match.

But, this is not always the case. Your mounting kit may be higher rated than your fth wheel hitch, but it also could be

lower depending on the components involved. The lowest rating of any one component in the system becomes the

rating of the entire system. If your mounting kit is rated to 18,000 lbs., and your hitch is rated at 24,000 lbs., the weight

rating of the entire system will not be above 18,000 lbs. Other components in the system could lower the actual system

rating further.

It is the end users responsibility to ensure a safe towing experience. To this end, it is your responsibility to ensure that

the truck, trailer, hitching components, and all other items involved are rated or have a capacity sufcient for the loads

involved.

LUBRICATION

DO NOT OPERATE HITCH UNTIL YOU READ THIS SECTION!

KING PIN ADAPTER BALL & COUPLER TUBE

The King Pin Adapter Ball and Remote Latch System must be

lubricated before each trip or as needed. PullRite recommends

using a dry graphite spray to prevent the attraction of dust and

debris. A light wet lubricant such as WD-40 can also be used,

but the two types of lubricants should not be used together.

Be sure the Coupler Tube is free of any obstructions prior to

lubrication and before each use. Spray both the Tube and

Funnel areas to aid in hitching up.

When lubricating the Remote Latch System using a dry graphite

spray, place the latch system in both closed and open positions

to cover the spring and pin effectively. If using a wet lube, pull

the Release Handle repeatedly between the open and closed

positions, so the lubricant is evenly spread among the moving

parts.

Be sure the King Pin Adapter Ball is clean and free from rust. A

light coating of lubricant should be used before each trip or as

needed.

Inspect all mounting brackets and hitch hardware to verify that it is securely fastened. Inspect all mounting bolts for

tightness and general condition.

When storing your SuperLite hitch, you should be sure that the coupler and hitch parts are lubricated with WD-40,

dry lube, or a combination of both—wet lube for other wear areas such as the contact area between the Hitch Base

and the Base Rails where the paint may rub off—to retard the formation of rust. Cover the entire assembly to prevent

accumulation of dirt, grime, or rust.

ANNUAL MAINTENANCE

Page 4

The #2400 SuperLite is height adjustable and can be set at three positions. Refer to the illustration below and the “#2400

Exploded View” drawing on page 8, following each step below to adjust your hitch’s height:

1. Loosen the three coupler jam nuts (7/8” socket) as well as the three coupler bolts (3/4” socket). It is not necessary to

remove the bolts - just back out about two complete turns or until the coupler is loose in the base.

2. Remove the clevis pin and clip and adjust to the desired height.

3. Re-pin and clip

4. Torque the three bolts rst to 45 ft. lbs., then tighten the jam nuts to 45 ft. lbs. as well. Over-tightening these bolts

could cause damage to the base. Always torque properly.

HEIGHT ADJUSTMENT

18.7”

17.2”

15.7”

NOTE: Heights shown here

are installed heights. To

obtain the correct height

needed for towing, choose

the corresponding hole in the

Coupler Tube.

The installed heights listed

here are measured from the

base of the hitch to the top

of the Coupler Tube once

properly installed.

Different base rails have

different heights above

the truck bed, such as

SuperRails, so be

certain to add that

height value to the

measurements

provided here.

coupler bolts and jam nuts

Page 5

1. Verify that the king pin is clean and free

of burrs before installing the King Pin

Adapter {A}. Remove any burrs with a

at le. If you are having t issues, see

“Challenge vs. Solution” on page 7.

2. Slide the King Pin Adapter over the king

pin and install one Adapter Plate Bolt

{A1} and Flat Washer {A3} horizontally

through the smaller cross hole nearest

the hitch ball (right). Install 1/2” Flange

Nut {A4} and hand tighten only.

3. Install the Adapter Bolt Reinforcement

Tube {A2} through the larger cross hole

in the Adapter Plate, then the remaining

Adapter Plate Bolt and Flat Washer

through this tube. Install nut and snug

by hand.

4. The adapter can be installed with the hitch ball offset in two positions—either ahead or behind the king pin. Determine

the position you would like installed; placing the hitch ball ahead of the king pin will add additional cab clearance

during tight turns, but does not guarantee total cab clearance for short bed trucks. Likewise, placing the ball behind

the king pin will reduce the trailer-to-cab clearance. Orient the King Pin Adapter appropriately and make sure it’s

aligned parallel with the king pin box.

5. Tighten the four Adapter Plate Set Screws {A6} evenly with a 9/16” socket, and torque to 20 ft. lbs. The gap between

the King Pin Adapter and the king pin box’s skid plate may be uneven due to several conditions, e.g., concave or

convex skid plate or skewed king pins.

6. Tighten the four 3/8” Flange Nuts {A5} until tight, approximately 20 ft. lbs.

7. Torque both Adapter Plate Bolts installed in Steps 2 & 3 to 75 ft. lbs.

8. Should you want to change the orientation of the adapter, it should only be necessary to loosen the Flange Nuts

{A5} and Adapter Plate Set Screws, and rotate the Adapter Plate on the king pin. Loosening the remaining hardware

should not be necessary most of the time.

KING PIN ADAPTER INSTALLATION

A1

A2 A3

A4

A5

A6

Page 6

SAFETY CHECKS PRIOR TO TOWING

1. Prior to towing, it is imperative to know if are

hooked up and the lock pin is engaged:

• First, check the height of the King Pin

Adapter; if seated properly below the Latch

Pin, it will sit at the correct height (top left). If

it’s sitting higher than it should, you’ve either

not lowered your trailer enough, or it’s sitting

on top of the Latch Pin inside the Coupler

Tube.

• Second, check the Latch Handle. If it is pulled outward in the open position, you’ve not secured the Lock Pin over

the ball of the King Pin Adapter (top right).

2. Raise the trailer jack base plates just above the ground, lock your trailer brakes, then pull the tow vehicle slowly

forward putting a strain on the trailer.

3. When you are assured that the trailer is safely hooked up, raise your trailer jacks into their full retracted position.

FAILURE TO PERFORM THESE SAFETY CHECKS MAY RESULT IN DAMAGES TO TRUCK AND TRAILER.

correct incorrect

WARNING: Never perform any of the following actions while any part of a

person is between the vehicle and trailer.

1. Verify that the Latch Handle {B1} is pulled outward and rotated (left

or right) into the latched open position (right). Damage could result

should you attempt to hook up with the latch pin in the closed position.

2. Lower the trailer landing gear high enough to raise the ball above the

top of the coupler funnel.

3. After lowering your truck tail gate, back the truck under the kingpin

adapter to orient the ball above the funnel coupler (make sure there

is space to completely back your truck into hitching position with the

tail gate down). It is not necessary to be completely centered over

the coupler, as long as the center of the ball is inside the diameter of

the “funnel”. The ball should slide toward the coupler tube when the

trailer jacks are retracted.

4. Lower the trailer landing gear so the ball drops into the hitch coupler.

The ball must be fully seated in the coupler to allow the latch

mechanism to close properly.

5. Once the weight of the trailer is supported by the tow vehicle, use the

latch handle to rotate the latch pin so that it retracts into the locked position. Do not forget this step.

HITCHING

latch handle rotated, pin

turned into slot opening

latch handle pulled

outward, pin centered to

slot opening

B1

pin

Page 7

CHALLENGE VS. SOLUTION

WARNING: Never perform any of the following actions while any part of a person is between the vehicle and the trailer.

1. Once you have the trailer located and are ready to unhitch, block the trailer wheels so it will not roll back or forward.

2. Pull the Latch Handle {B1} towards the rear of the vehicle and rotate either clockwise or counter clockwise into the

slotted opening as you did in the “Hitching” section. The latch pin must be retained in the open position to release the

adapter ball from the tube.

3. Extend the trailer jacks until the ball is fully removed from the Coupler Tube {B} and above the top of the coupler

funnel.

4. After lowering the truck’s tailgate, disconnect the trailer’s electrical cord and break-away switch cable, then pull

forward.

CAUTION: If you nd it necessary to reposition your trailer, you must follow the hitching procedures to ensure the hitch

is latched before moving the trailer.

UNHITCHING

CHALLENGE SOLUTION

Cannot open the Latch Pin. Should only be restricted if trailer is applying pressure to the pin.

Raise trailer jacks to relieve ball pressure against pin.

My King Pin Adapter isn’t tting well over the king

pin.

Paint or “crud” build up on the upper ange of the king pin

(particularly near the junction of the king pin and skid plate),

bent, skewed, or king pins that are too long or too short can

cause a poor t. Contact PullRite’s Customer Service Dept. at

(800) 443-2307 and we’ll give you suggestions on how to correct

it.

Trailer overhang is hitting the truck bed rails when

the trailer and truck are at sharp angles.

Raise or lower the hitch coupler height and/or lower the king pin

box. There should be at least 6” between the top of the bed rails

and bottom of the trailer.

The latch handle mechanism seems too stiff to

operate.

Spray the locking mechanism with WD-40. Work the handle until

it slides freely. If the problem persists, you may need to degrease

and re-lube all working parts.

I need to have a professional evaluate my

SuperLite.

Contact PullRite’s Customer Service Dept. at (800) 443-2307.

Your needs will be assessed and resolved by PullRite or you will

be directed to an authorized PullRite Service Center.

Page 8

#2400 EXPLODED VIEW

B

A

A1

A2

A3 A4

A5

A6

C

FE

C3

C1

C4

D

C2

B1 B3B2

Page 9

#2400 PARTS LIST

Item Description Part No. Qty. Description

AKING PIN ADAPTER 2403 1

BCOUPLER TUBE ASSEMBLY 2402 1

C HITCH BASE 2401 1

D RELEASE HANDLE 2405 1

ADAPTER PLATE HARDWARE KIT -- 240302

A1 ADAPTER PLATE BOLT 98010203 2 1/2”-13 X 5-1/2” HHCS GRD 5

A2 ADAPTER BOLT REINFORCEMENT TUBE 24030201 1 0.75 X 0.531 TUBE

A3 FLAT WASHER 98250147 2 1/2” FLAT WASHER

A4 1/2” FLANGE NUT 98150201 2 1/2”-13 SERRATED FLANGE NUT

A5 3/8” FLANGE NUT 98150168 4 3/8”-16 FLANGE NUT

A6 ADAPTER PLATE SET SCREWS 98010222 4 3/8”-16 X 1.25” BOLT

LATCH PIN ASSEMBLY

B1 LATCH HANDLE 240205 1 HANDLE AND SPRING

B2 LATCH PIN HOUSING COVER 24020601 1

B3 LATCH PIN HOUSING SET SCREWS 98410236 2 1/4”-20 X 2.75” SHCS ZINC

BASE HARDWARE KIT -- 240105

C1 COUPLER TUBE PIN 010019 1 5/8” PIN, .625 DIA.

C2 COUPLER PIN CLIP 98410143 1

C3 COUPLER TUBE SET BOLT 98010167 3 1/2”-13 X 1 1/2” BOLT

C4 COUPLER TUBE SET NUT 98150214 3 1/2”-13 HEAVY HEX NUT (7/8” HEX)

PINS AND CLIPS MOUNTING KIT -- 080601

E MOUNTING PIN 08060001 4

F MOUNTING PIN CLIP 98410127 4

BASE RAIL KIT

PULLRITE INDUSTRY STANDARD BASE RAILS ARE SOLD SEPARATELY. CALL (800) 443-2307 FOR MORE INFORMATION.

TORQUE TABLE

Hardware Size Torque Specs

Latch Pin Housing Set Screws 1/4” 5 ft. lbs.; factory assembled

Adapter Plate Set Screws 3/8” 20 ft. lbs.; both bolt and set nut,

must be torqued after

installing Adapter Plate

Bolts

Coupler Tube Set Bolts 1/2” 45 ft. lbs.; both bolt and set nut

Adapter Plate Bolts 1/2” 75 ft. lbs.; torque before Adapter

Plate Set Screws

Page i

5 YEAR LIMITED WARRANTY

PULLIAM ENTERPRISES, INC. hereinafter referred to as “PULLIAM”, warrants to the rst retail owner only, this PullRite towing system

to be free from defects in materials and workmanship for a period of ve (5) years or 31,068 miles (50,000 km) after the installation

on purchaser’s vehicle, whichever occurs rst.

To validate this warranty, the rst retail owner must mail the provided warranty card to PULLIAM, or register online at www.

pullrite.com, within ten (10) days after installation of said towing system on his vehicle.

The owner is responsible for all normal and preventative maintenance described in the Owner’s Manual.

If any defect occurs which the owner believes is covered by this warranty within said ve (5) year period, the owner shall contact

PULLIAM immediately, either in writing or by telephone call, Attention Customer Service Department. The owner will be

instructed to return the hitch at his expense either to an authorized PullRite dealer or to PULLIAM to repair or replace any parts

necessary to correct defects in material or workmanship.

Repair or replacement shall be at the sole option of PULLIAM and shall be completed by or on behalf of PULLIAM free of charge

for materials and labor.

This warranty gives you specic legal rights, and you may also have other right’s which vary from state to state.

THIS WARRANTY SPECIFICALLY EXCLUDES EACH OF THE FOLLOWING:

1. Defects in the product resulting from misuse, neglect, accident, loading beyond the vehicle’s

capacity, failure to comply with instructions contained in the Owner’s Manual or unauthorized

repairs, replacements, alterations or modications. “Unauthorized repair, replacements,

alterations” are those made without PULLIAM’S prior knowledge and consent.

2. Any incidental or consequential damage including, but not limited to, loss of use of the vehicle,

towing charges, vehicle rental, loss of time, inconvenience, travel, gasoline, lodging and telephone

expenses, loss of revenue and damages on account of personal injury and property damage.

(Some states do not allow the exclusion or limitation of incidental or consequential damages, so

these limitations may not apply to you).

3. Repairs or replacements of defects in any PullRite towing system, or part thereof, installed on any

vehicle which has been rented, leased or used for any commercial purpose.

4. Any representation, warranty of undertaking made by any dealer or third party beyond the scope

of the warranty herein expressed.

5. Any problem resulting in normal deterioration due to wear or exposure.

TO THE EXTENT PERMITTED BY LAW, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

LIMITED IN DURATION TO FIVEYEARS FROM THE DATE OF INSTALLATION ON THE FIRST OWNER’SVEHICLE. (SOME STATES, HOWEVER,

DO NOT ALLOW LIMITATIONS AS TO DURATION OF IMPLIED WARRANTY, SO THOSE LIMITATIONS MAY NOT APPLY TO YOU)

5 YEAR LIMITED WARRANTY

Page ii

PRODUCT REGISTRATION

Product Warranty Registration

Name: ________________________________________________________________________________

Address: ________________________________________________________________________________

City: ____________________________ State: ______________ Zip: _________________

Email Address: ____________________________________________________________

Phone (op onal): ____________________________

Purchase Price: ____________________________ Date of Purchase: __________________________________

As an owner of a PullRite product, you must register your product to be considered for

warranty coverage. See Owners Manual for further details.

Please note, that you can also register online at www.pullrite.com/warranty.htm.

Dealer’s Name: ____________________________________________

Dealer’s Address: ____________________________________________

Dealer’s City: ____________________________ Dealer’s State: ______________ Dealer’s Zip: _________________

Dealer’s Phone: ____________________________

Model Purchased: ____________________________________________

Vehicle Make: ____________________________ Vehicle Model: ______________ Vehicle Year: _________________

Vehicle Year: ____________________________ Vehicle Cab Style: ______________ Vehicle Bed Length: _________________

Did you receive an Owners Manual from the Dealer? Yes / No

What infl uenced you to buy your hitch? _____________________________________________________________________

Comments:

MANUFACTURED BY:

PULLIAM ENTERPRISES, INC.

13790 East Jefferson Blvd.

Mishawaka, IN 46545

(574) 259-1520 • (800) 443-2307

Table of contents

Other PullRite Automobile Accessories manuals