SECTION 1

FEATURES AND APPLICATIONS

HIGH RESOLUTION, INTERLINE TRANSFER CCD

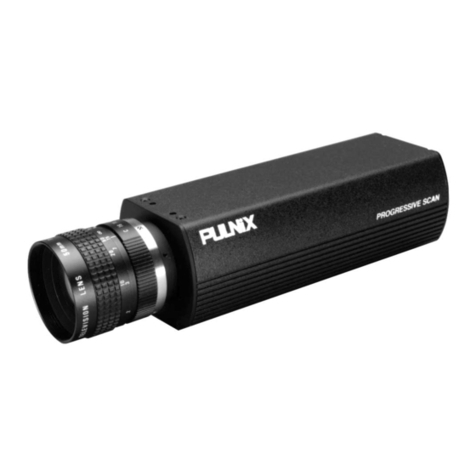

The TM-7/TM-6 series are state-of-the-art CCD cam-

eras which use a 1/2 inch high resolution imager.

These units offer outstanding compactness high per-

formance long life high stability as well as a number of

technical innovations such as variable electronic shut-

ter and asynchronous reset. They are designed to be

simple yet high quality cameras for versatile applica-

tions such as machine vision and image processing

robotics medical and surveillance applications. The

uniqueness of the TM-7 series is the size and resolu-

tion which is essential for the latest artificial intelli-

gence. For applications requiring external sync the

TM-7EX is used.

VARIABLE ELECTRONIC SHUTTER AND RANDOM

CCD INTEGRATION

The TM-7 / TM-6 series cameras have a substrate

drain-type shutter mechanism which provides a superb

picture at various speeds without smearing. The "CN"

and "EX" model cameras have the capability to exter-

nally vary the electronic shutter rate via a manually

controlled BCD switch from 1/60 to 1/10 000 sec. in

discrete steps.

MINIATURIZED AND LIGHTWEIGHT

All PULNiX cameras are built with the same design prin-

ciples: solid state technology; miniaturization (including

lenses housings and cables); specialization (such as

remote imager and image intensified camera versions).

The use of a CCD image sensor in the video camera

module and the development of special mini C-mount

lenses makes it possible to produce a very compact

lightweight and robust series of cameras. The TM-7

series is the extension of this principle and makes the

entire camera just like a remoted head.

LONG LIFE: A THREE YEAR WARRANTY

The CCD solid state image sensor allows the camera

to maintain a superior performance level indefinitely

while requiring virtually no maintenance. PULNiX

backs all of the TM series cameras with a three year

warranty.

WARNING: Unscrewing the camera cover or opening the

camera in any way will void this warranty

HIGH SENSITIVITY

The TM-7 series is one of the most low light sensitive

1/2 " CCD cameras available today. This is especially

important when using the faster shutter speeds. The

CCD detects images into the near infrared. It requires

only 1.0 lux of minimum illumination and 0.5 lux mini-

mum illumination at maximum gain. In general such a

low light camera allows use of a higher lens F-value

and provides greater depth of field and sharper

images.

PRECISE IMAGE GEOMETRY

On the CCD image sensor the photosensor elements

form exact rows both horizontally and vertically so that

a very precise image geometry may be obtained.

LOW LAG/HIGH RESISTANCE TO IMAGE BURNING

Compared to the lag of conventional cameras which

use a pickup tube the lag of a CCD camera is consider-

ably reduced so that a clear picture may be obtained

when shooting a rapid moving object or when shooting

in a low illumination environment. Since the CCD is

highly resistant to image burning the camera may be

exposed to bright objects for a long period of time. It

must be noted that a “smear” phenomenon may occur

when shooting a very bright object. An infrared cutoff fil-

ter is recommended to obtain a clear picture.

HIGH RESISTANCE TO MAGNETIC FIELD AND

VIBRATION/MECHANICAL SHOCK

Due to its ruggedized design the CCD imager can

withstand strong vibration and shock and little or no

noise will appear in the picture. Since the TM-7 series

camera is not influenced by a magnetic field it will pro-

duce stable images even when placed next to objects

such as electric furnaces welding machines or NMR

scanners.

QUICK START-UP AND LOW POWER CONSUMP-

TION

No more than 2 seconds are needed for the TM-7

series to warm up and shooting may begin within a

second after turning on the camera. The power con-

sumption is only 3.0W. This makes the cameras excel-

lent for use with battery operated systems.

GENLOCK CIRCUIT

A genlock circuit is not built into the TM-7 series to

accept external sync. The design principle of this type

of camera is intended for numerous usages in simple

but demanding applications which require compact

high resolution and high quality but most importantly

low cost cameras. External sync is built into the TM-

7EX series for applications where external sync is

required.

AGC SELECTION, MANUAL GAIN CONTROL AND

GAMMA ADJUSTMENT

The AGC (automatic gain control) may be externally

switched from automatic to fixed gain on the TM-7CN

back plate. The manual gain is externally adjustable.

Gamma may also be externally set either to 1 or 0.45.

These adjustments are particularly important in vision

system applications.

4