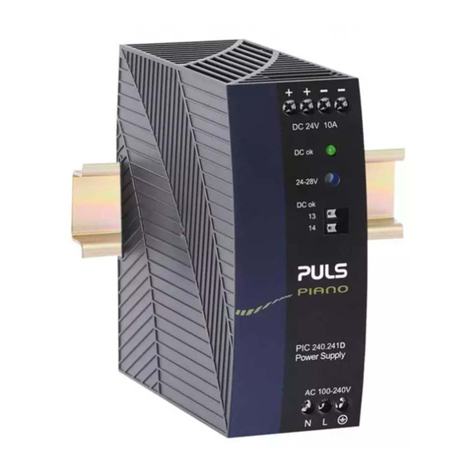

Product Description

The XT40.241 is a DIN-rail mountable power supply for three-phase mains systems, which provides a

floating, semi-stabilized and galvanically separated SELV/PELV output voltage.

The power supply utilizes a resonant converter topology which regulates a stable output voltage in the

core range of the input voltage. The core range is defined as ±10% of the nominal voltage. Outside of

this window, the output voltage follows proportionally the input voltage, similar to a transformer.

Intended Use

This device is designed for installation in an enclosure and is intended for commercial use such as in

industrial control, process control, monitoring and measurement equipment or the like. The principal

use are applications such as motors, valves and other load circuits with high power consumption,

where an accurate output voltage regulation and low amount of ripple voltage (standard on switch

mode power supplies) is not required.

Do not use this device in equipment, where malfunctioning may cause severe personal injury or

threaten human life without additional appropriate safety devices, that are suited for the end-

application.

If this device is used in a manner outside of its specification, the protection provided by the device may

be impaired.

Installation Instructions

Install device in an enclosure providing protection against electrical, mechanical and fire hazards.

Install the device onto a DIN-rail according to EN 60715 with the input terminals on the bottom of the

device. Other mounting orientations require a reduction in output current.

Make sure that the wiring is correct by following all local and national codes. Use appropriate copper

cables that are designed for a minimum operating temperature of 60°C for ambient temperatures up to

+45°C, 75°C for ambient temperatures up to +60°C and 90°C for ambient temperatures up to +70°C.

Ensure that all strands of a stranded wire enter the terminal connection. Use ferrules for wires on the

input terminals. Unused screw terminals should be securely tightened.

The device is designed for pollution degree 2 areas in controlled environments. No condensation or

frost is allowed.

The housing of the device provides a degree of protection of IP20. The housing does not provide

protection against spilled liquids.

The isolation of the device is designed to withstand impulse voltages of overvoltage category III

according to IEC 60664-1.

The device is designed as “Class of Protection I” equipment according to IEC 61140.

Do not use without a proper PE (Protective Earth) connection.

The device is suitable to be supplied from TN, TT or IT mains networks. The continuous voltage

between the input terminal and the PE potential must not exceed 400Vac. The device is not designed

to be used on corner grounded delta systems.

A disconnecting means shall be provided for the input of the device.

The device is designed for convection cooling and does not require an external fan. Do not obstruct

airflow and do not cover ventilation grid!

The device is designed for altitudes up to 5000m (16400ft). Above 2000m (6560ft) a reduction in

output current and over voltage category is required.

Keep the following minimum installation clearances: 40mm on top, 20mm on the bottom, 5mm left and

right side. Increase the 5mm to 15mm in case the adjacent device is a heat source. When the device

is permanently loaded with less than 50%, the 5mm can be reduced to zero.

The device is designed, tested and approved for branch circuits up to 16A (IEC) and 15A (UL) without

additional protection device. If an external fuse is utilized, do not use circuit breakers smaller than 6A

B- or 3A C-Characteristic to avoid a nuisance tripping of the circuit breaker.

The maximum surrounding air temperature is +70°C (+158°F). The operational temperature is the

same as the ambient or surrounding air temperature and is defined 2cm below the device.

The device is designed to operate in areas between 5% and 95% relative humidity.

Functional Description

The output is electronically protected against no-load, overload and short circuit and can supply any

kind of loads, including inductive and capacitive loads. If capacitors with a capacitance >160mF are

connected, the device might not be able to start or switch off.

Do not apply returnvoltages fromthe loadtothe output terminals higher than28.9V.

Green DC OK LED

This LED when on, reports an output voltage above 21.6V of a running device.

Yellow Diagnoses LED

This LED is on solid, when the output current is higher than the nominal current. A double flash

indicates a phase loss or a too high or too low input voltage. A fast flashing warns of an impending

temperature shut down. A shut down can be expected within 10 minutes, if the ambient temperature or

the load current stays constant.

Red Shut Down LED

This LED flashes when the device has shut down. Pressing the reset button or cycling the input power

(10s required) initiates an attempt to start. If the fault has been cleared, the device will operate

normally.

The device is designed to deliver 50A output current for up to 15s with nominal output voltage after an

automatic shut-down occurs. An increased current up to 80A with reduced output voltage is available

for up to 5s before an automatic shut-down occurs. At higher currents the device will shut-down after

0.1s. Pressing the reset button or cycling the input power (10s required) initiates an attempt to start. If

the fault has been cleared, the device will operate normally.

Do not parallel devices for higher output currents.

Same devices can be connected in series for higher output voltages. It is allowed to connect as many

devices in series as needed, providing the sum of the output voltage does not exceed 150Vdc.

In case of an internal defect or too high input voltage, a redundant circuit limits the maximum output

voltage to 29.9V. After 2s the output shuts down and requires a manual reset.