OPERATION AND MAINTENANCE MANUAL

PAGE # 9

PF-63 Series Separator (ver. 7_10)

OPERATION AND MAINTENANCE MANUAL

3a. (Closed circuit or pressurized system) Run an effluent line from the separator return

labeled "OUTLET" back to the system piping (low pressure side).

NOTE:

The effluent line should be piped to the suction side of the process system pump. A flow

control or throttling device is recommended in the effluent line (separator return) to regulate

flow through the separator. A service valve and flange/union should be installed in this line

near the separator.

3b. (Open system or sump) Run an effluent line from the separator return labeled "OUTLET"

back to the system sump on the opposing side of the suction (influent) line.

NOTE:

If the system dynamics dictate a lower or higher discharge pressure, the pump & motor may

require a change to match the actual system dynamics. A flow control or throttling device

could also be installed in the effluent line to regulate flow through the separator.

A service valve and flange/union should be installed in this line near the separator.

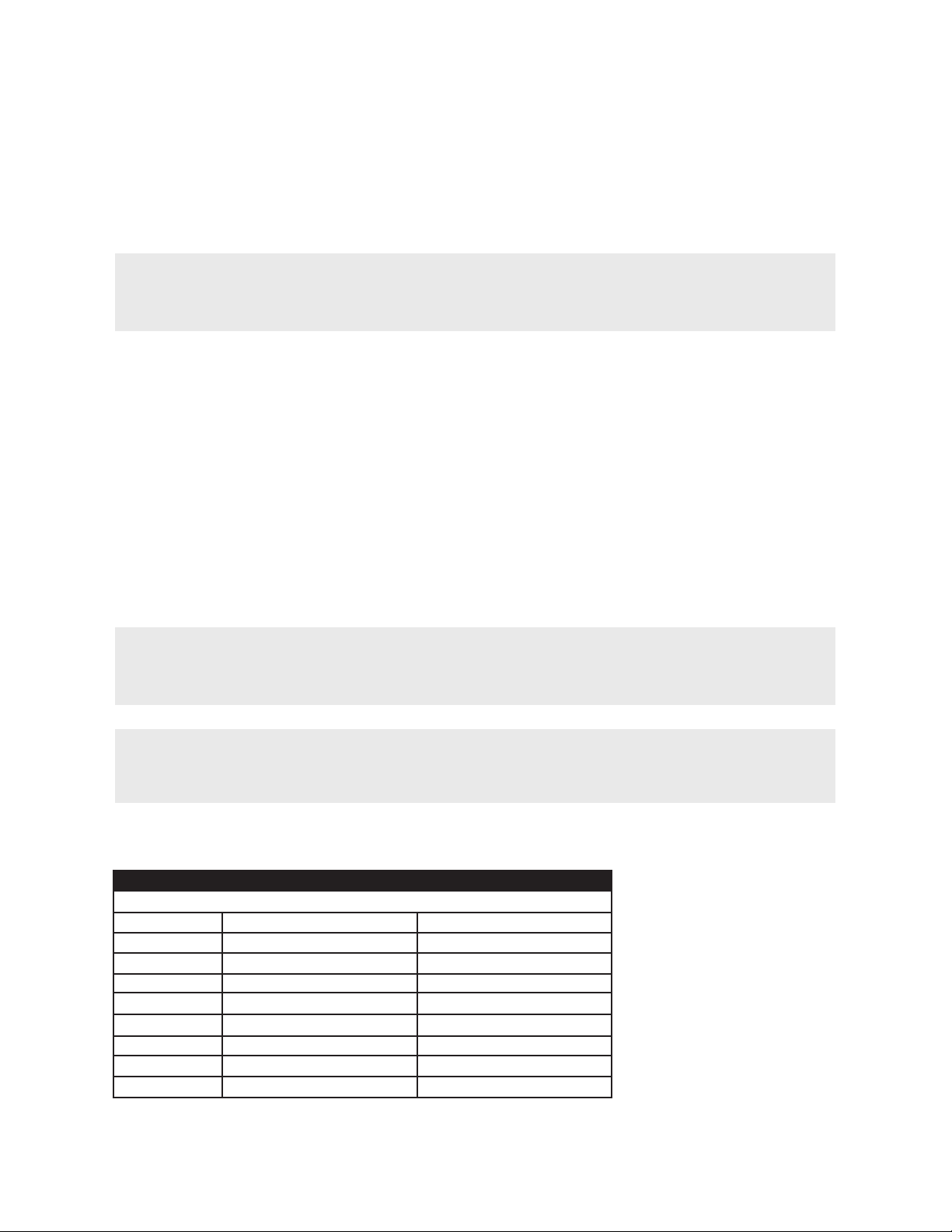

TABLE III - SIZE & CONNECTION

MODEL PF-63 INLET(INCHES) OUTLET (INCHES)

PF-63-012 2 (FLNG) 1-1/4 (MPT)

PF-63-015 2 (FLNG) 1-1/2 (MPT)

PF-63-020 3 (FLNG) 2 (MPT)

PF-63-025 3 (FLNG) 2-1/2 (MPT)

PF-63-030 3 (FLNG) 3 (FLNG)

PF-63-040A 4 (FLNG) 4 (FLNG)

PF-63-040B 4 (FLNG) 4 (FLNG)

PF-63-050 6 (FLNG) 5 (FLNG)

PF-63-060A 6 (FLNG) 6 (FLNG)

PF-63-060B 8 (FLNG) 6 (FLNG)

NOTE:

It is important that all piping and components associated with the filter system installation

must be supported to eliminate stress on the filter and piping.

Always follow local, county, state or other government agency requirements for piping

hook-ups.