QuickDrawStorage and Semi-instantaneous

Steam Heater

10 PV500-25 05/13

5.4 Electronic Low Water Cut-off (optional)

When the water level is above the electrode position in the tank, the reset pushbutton will energize the control (LED

will be lit). The control remains energized until the water level recedes below the electrode position (LED will not be

lit). Unless otherwise specified, there is a three-second time delay on decreasing level. Water level must be below

tank probe location for full three seconds before control de-energizes.

5.5 Sequence of Operation

1. When power is supplied through the unit’s On-Off switch, if the stored water temperature is below the operating

thermostat set point, the limit operating circuit closes creating a call-for-heat-demand, which energizes the

actuator on the control valve.

2. On a call-for heat, the actuator motor runs and the actuator shaft extends causing the valve to allow steam

through the heat exchanger.

3. When the demand is satisfied, the operating thermostat opens and the valve actuator is de-energized. The

actuator motor stops running and the actuator shaft spring returns to the retracted position, which stops steam

flowing through the heat exchanger.

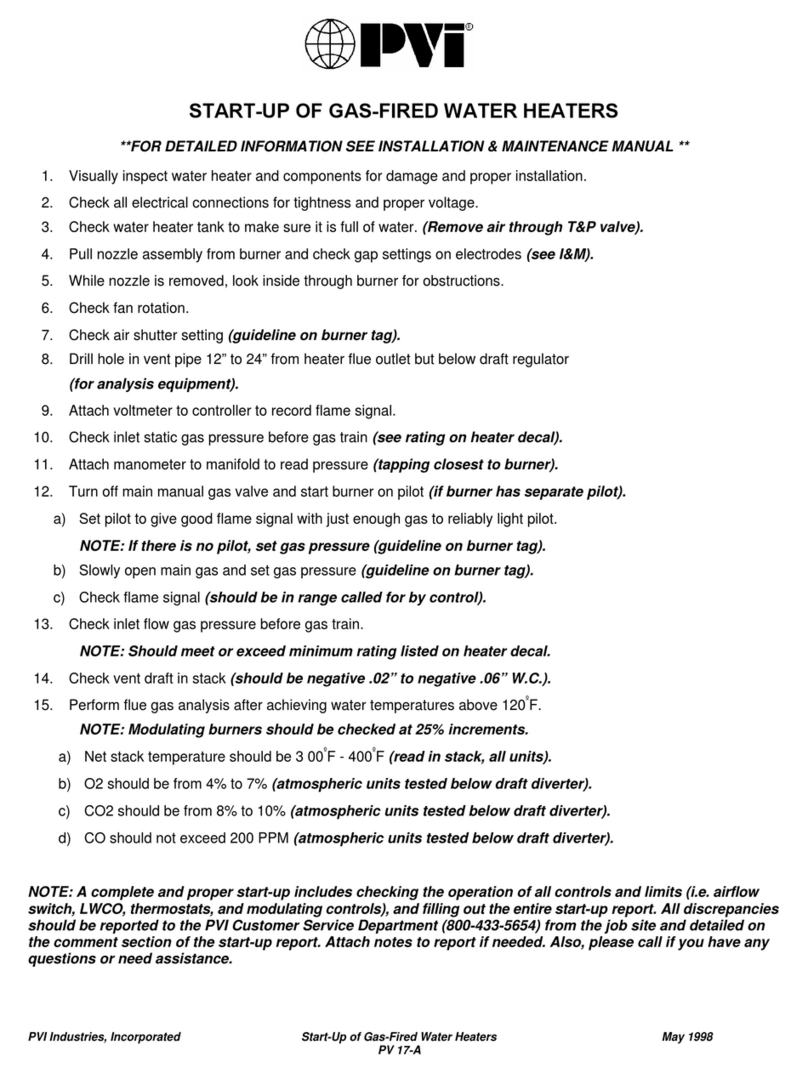

6 START-UP PROCEDURE

1. After all the steam, condensate and water lines are installed and inspected, the steam supply source and the

condensate receiver should be checked for correct operation. Steam supply pressure to the heater must be equal

to or less than the supply pressure on the heater decal. A pressure reducing valve can be installed in the supply

line to meet this requirement.

2. Steam is directed to the heat exchanger through a header and steam control valves. The steam control valves are

normally closed, on-off, electric valves and solenoid-operated. Should an electrical power failure occur, steam

valves will close and stop steam flow to the unit.

3. When placing the unit into operation, open relief valve to purge air from top of tank and begin to fill the tank with

cold water. Check for plumbing leaks. Be sure to fill the tank completely before closing the relief valve.

CAUTION: Do not energize the heater or circulating pump until the tank is full of water. Serious damage may result.

4. Push control switch, located on the control box, to activate the steam valve and thermostats. Check steam valve

for operation; the valve solenoid should “click” “ON” to open valve(s) when operating switch is pushed “ON”. The

tank-circulating pump should also operate. Check thermostat settings.

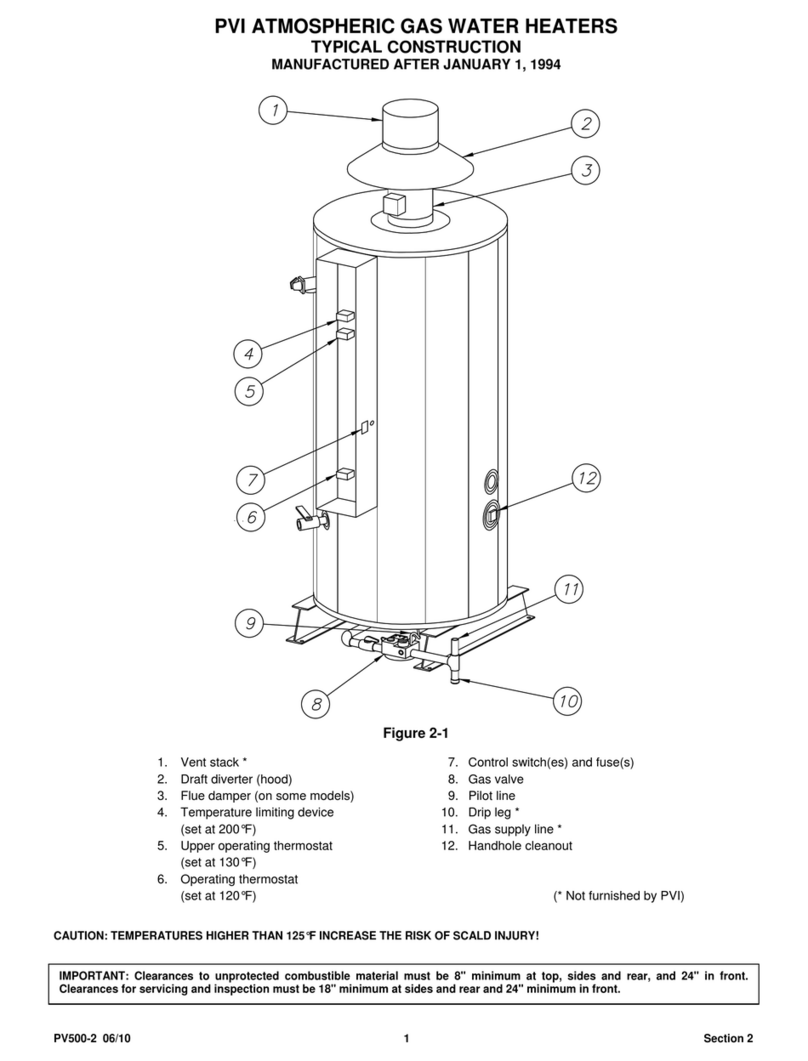

Temperature Setting: The operating thermostat is set at the factory at approximately 120°F and the upper

operating thermostat is set at approximately 130°F. Make adjustments by turning the thermostat dial to the

desired temperature. The temperature limited device is factory set at 200°F.

CAUTION: Gradually introduce fluids to the unit. Failure to do so can cause damage to the heat exchanger.

5. Push the operating switch, located on the control box, to “OFF” before opening manual main steam supply valve.

This will allow condensate that has collected in the supply line to drain through the trap installed in front of the

steam valve. When the steam supply line is free of condensate, push operating switch to “ON”, opening the

electric on-off steam valves allowing steam to flow through the heat exchanger.

WARNING: Do not operate unit under conditions in excess of those specified on nameplate and ASME

data plate. Failure to operate the heat exchanger within the specified design pressure and temperature

may result in damage to the heat exchanger, property damage, personal injury or loss of life.

6. Open nearby hot water tap to maintain a flow of water through the tank when starting up units. Regulate flow of

water through the tank to allow the steam valve(s) to cycle off and on. Observe condensate flow at the receiver or

other collection sight to verify satisfactory flow. Check operation of all safety and operating controls.

7. In all installations, there should be no pulsation or water hammer since this causes vibration and strain with

resulting leaks.