PVI Industries 800-N-Z5DA-PV User manual

Other PVI Industries Water Heater manuals

PVI Industries

PVI Industries 1100N300A-E User manual

PVI Industries

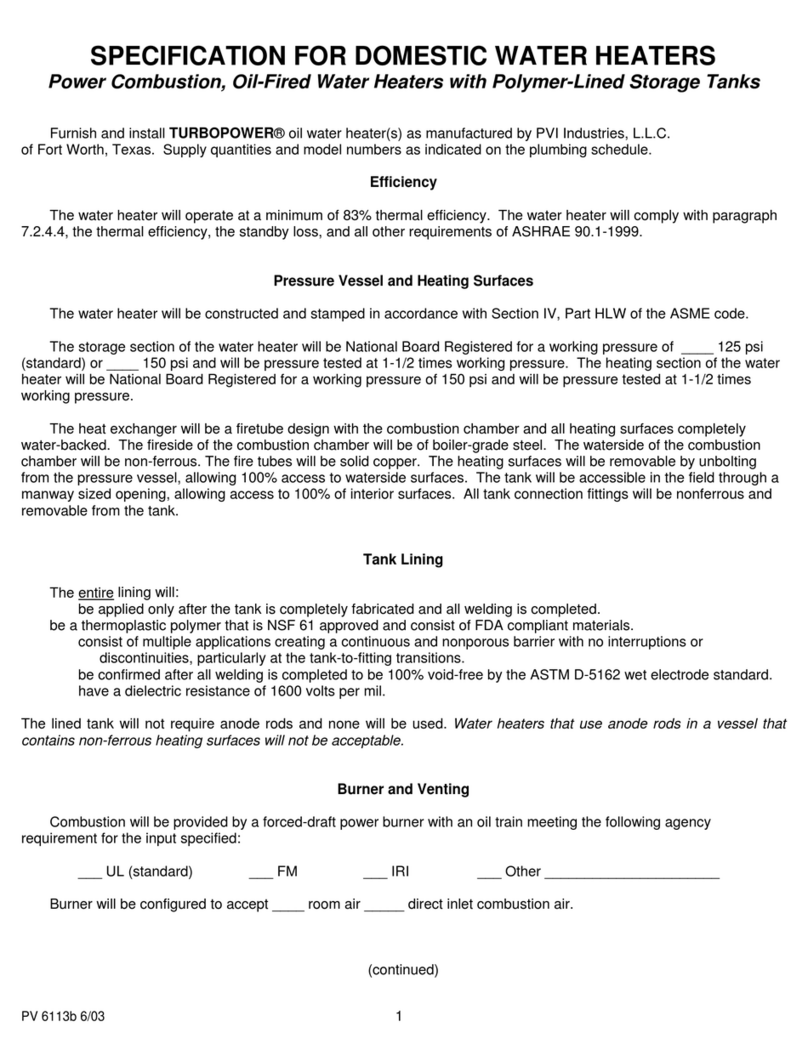

PVI Industries PV 6113b User manual

PVI Industries

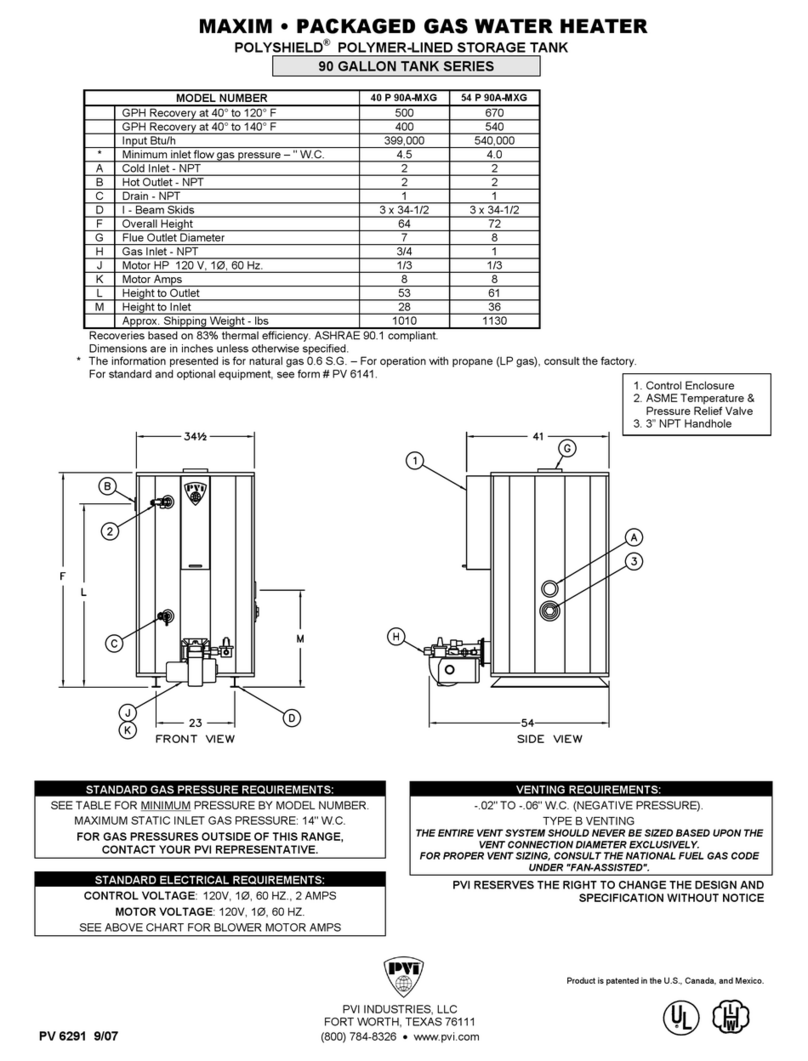

PVI Industries MAXIM 40 P 90A-MXG User manual

PVI Industries

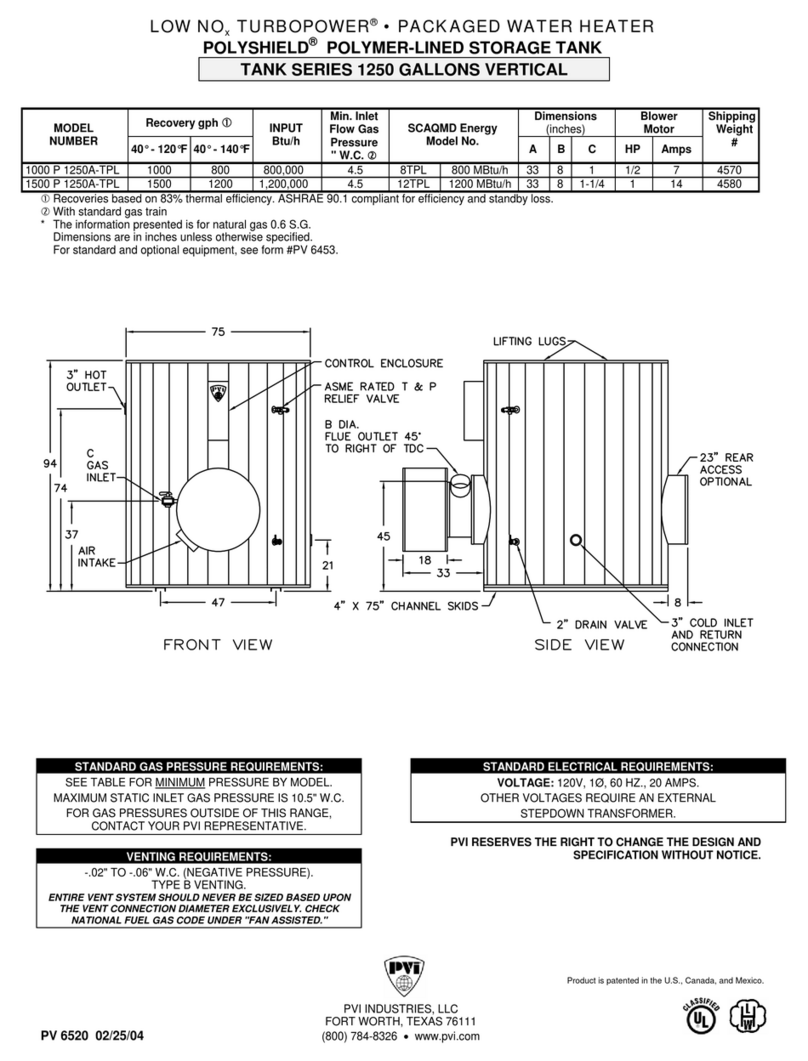

PVI Industries 1000P1250A-TPGO User manual

PVI Industries

PVI Industries TURBOPOWER 99 User manual

PVI Industries

PVI Industries CONQUEST 20 L 100 A-GCL Instruction Manual

PVI Industries

PVI Industries POWER VT PLUS Instruction Manual

PVI Industries

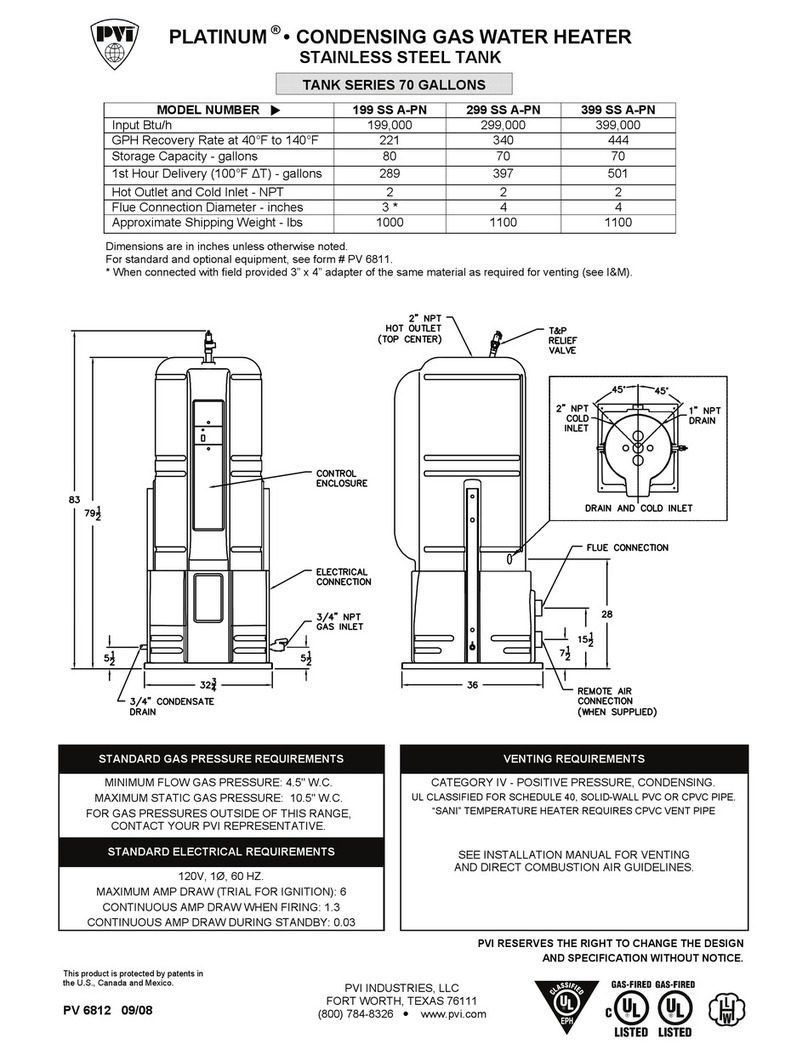

PVI Industries PLATINUM 199 SS A-PN User manual

PVI Industries

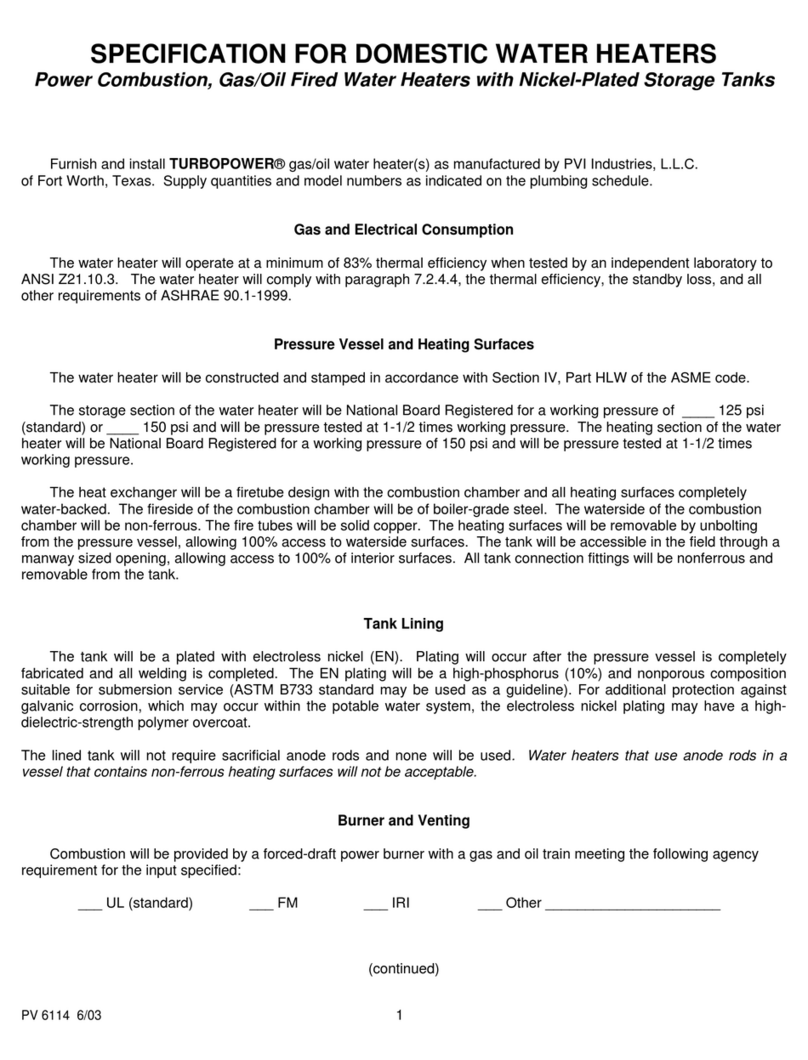

PVI Industries PV 6114 6/03 1 User manual

PVI Industries

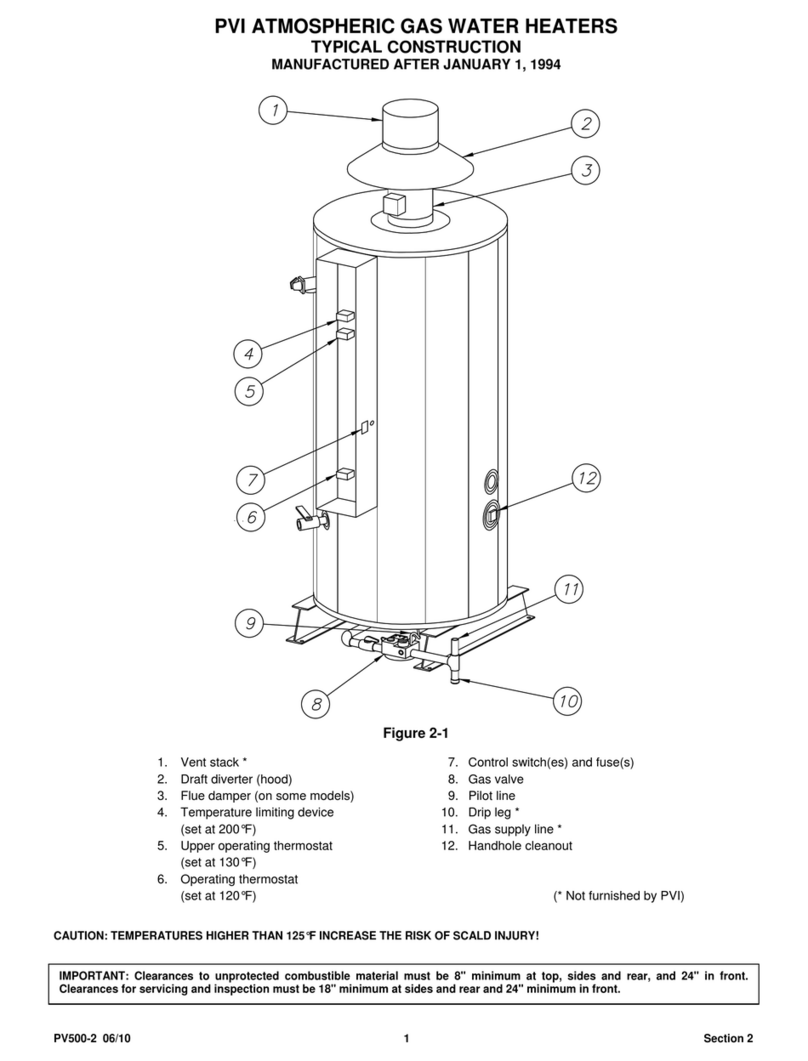

PVI Industries PV500-2 User manual

PVI Industries

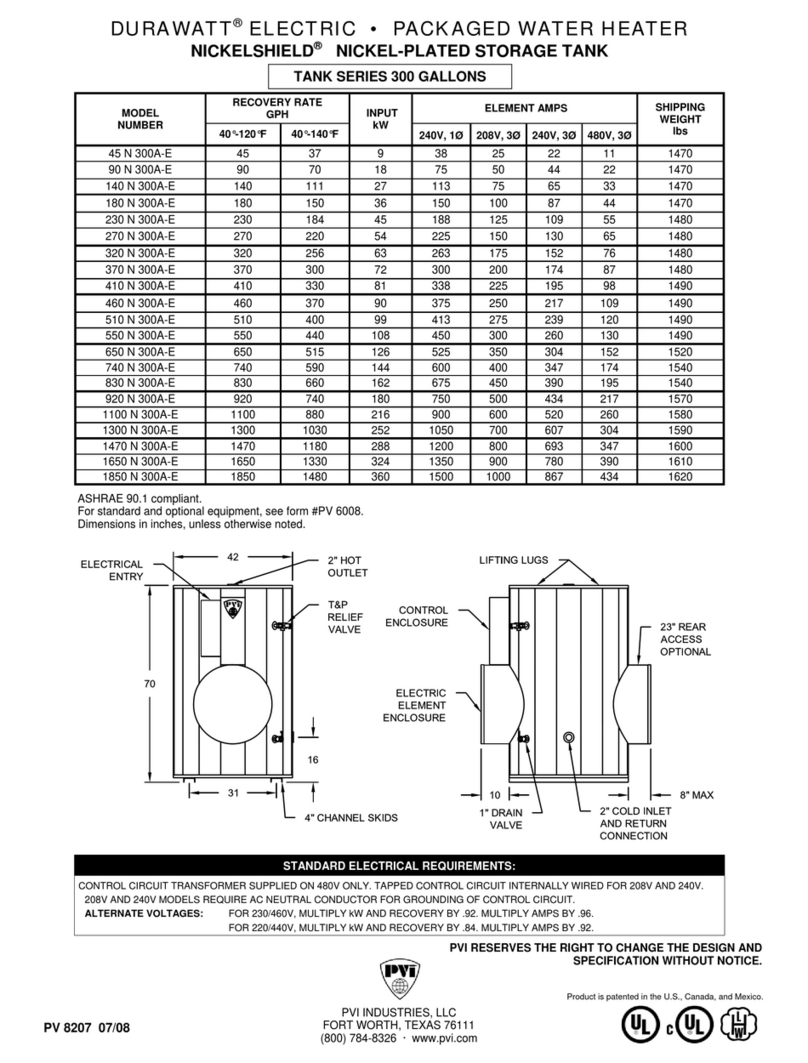

PVI Industries 45N300A-E User manual

PVI Industries

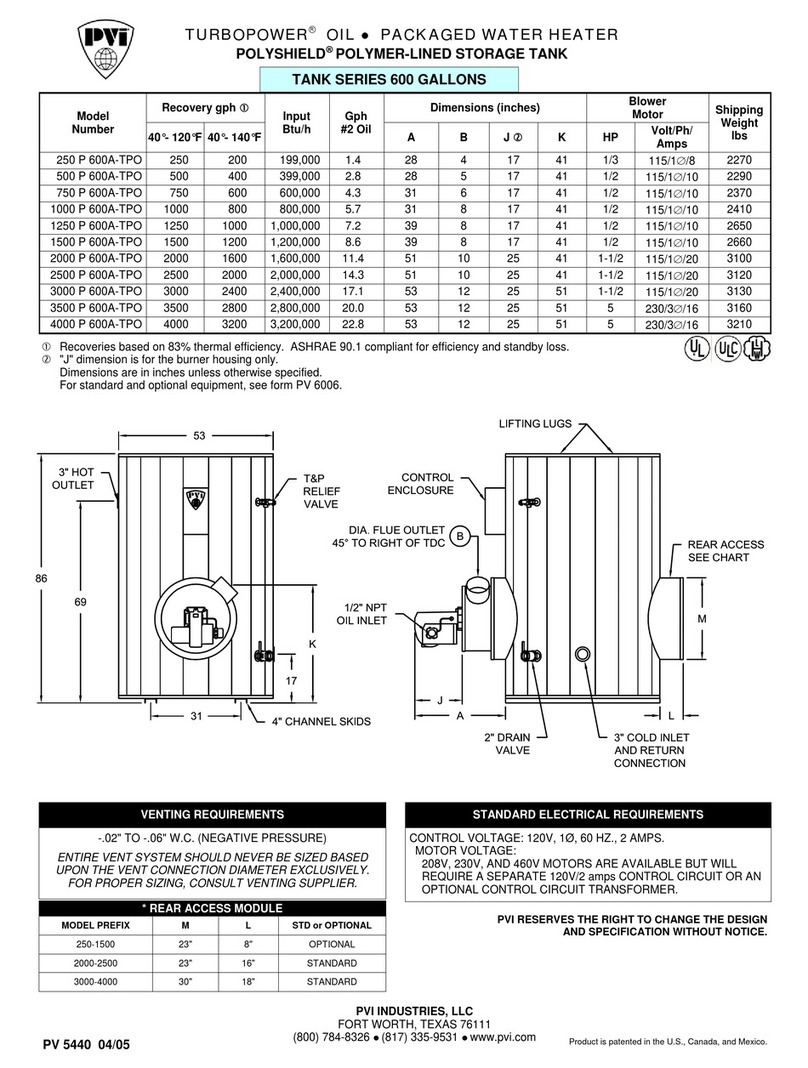

PVI Industries Btu/h GPH User manual

PVI Industries

PVI Industries 40L125A-MXIF Instruction Manual

PVI Industries

PVI Industries QuickDraw Instruction Manual

PVI Industries

PVI Industries 250N600A-TPO User manual

PVI Industries

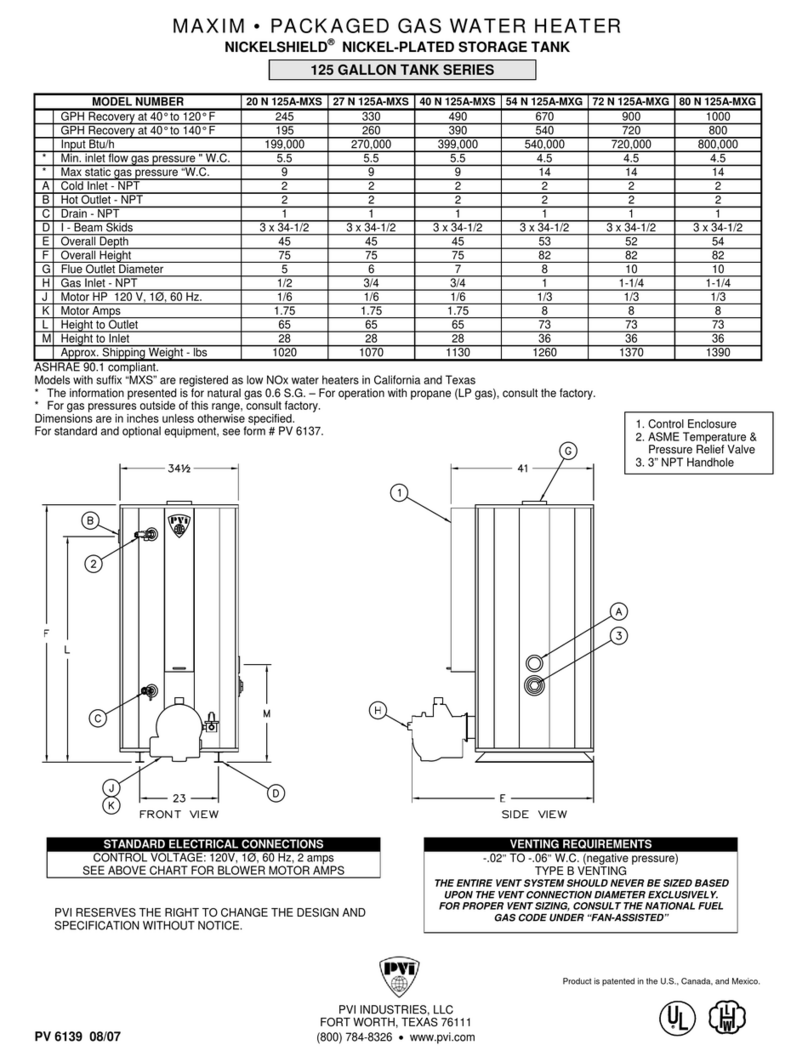

PVI Industries MAXIM 20 N 125A-MXS User manual

PVI Industries

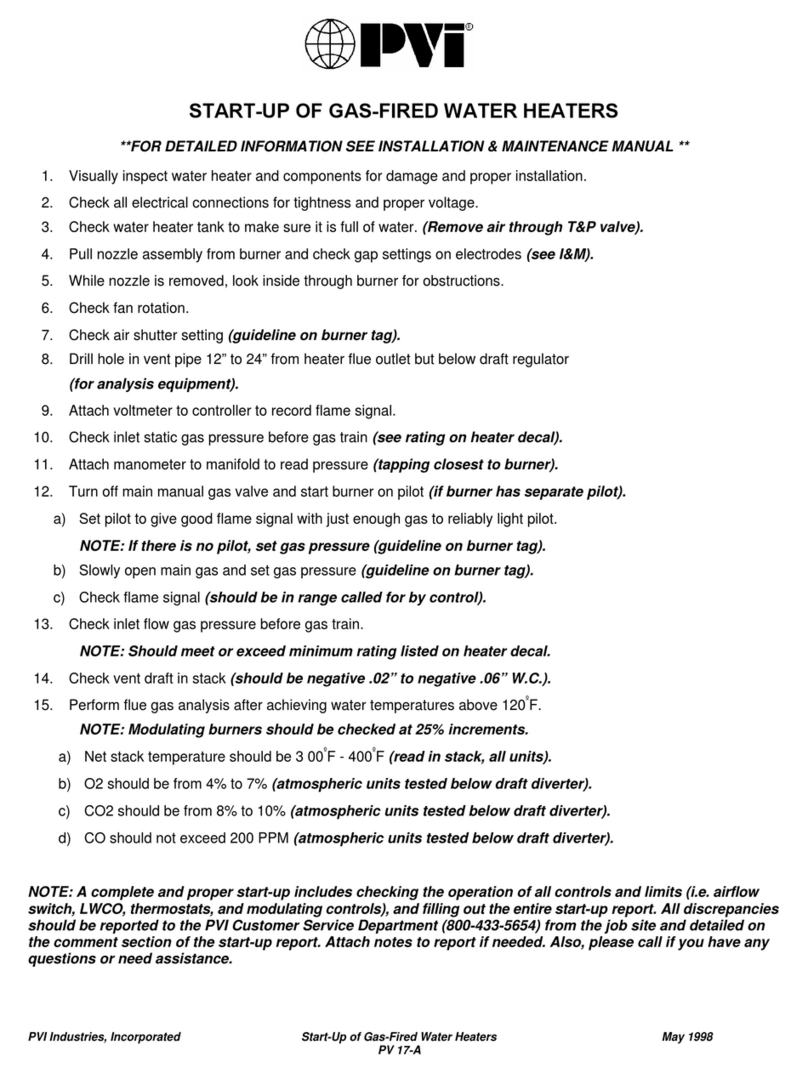

PVI Industries PV 17-A User guide

PVI Industries

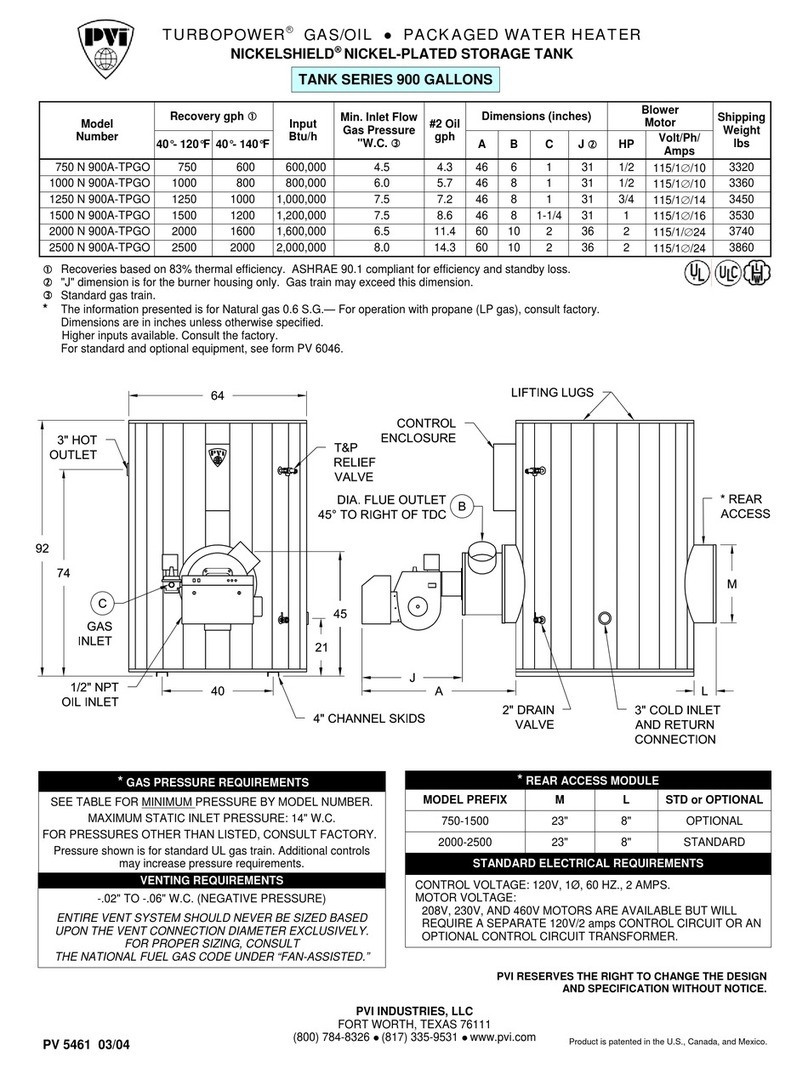

PVI Industries 750P900A-TPGO User manual

PVI Industries

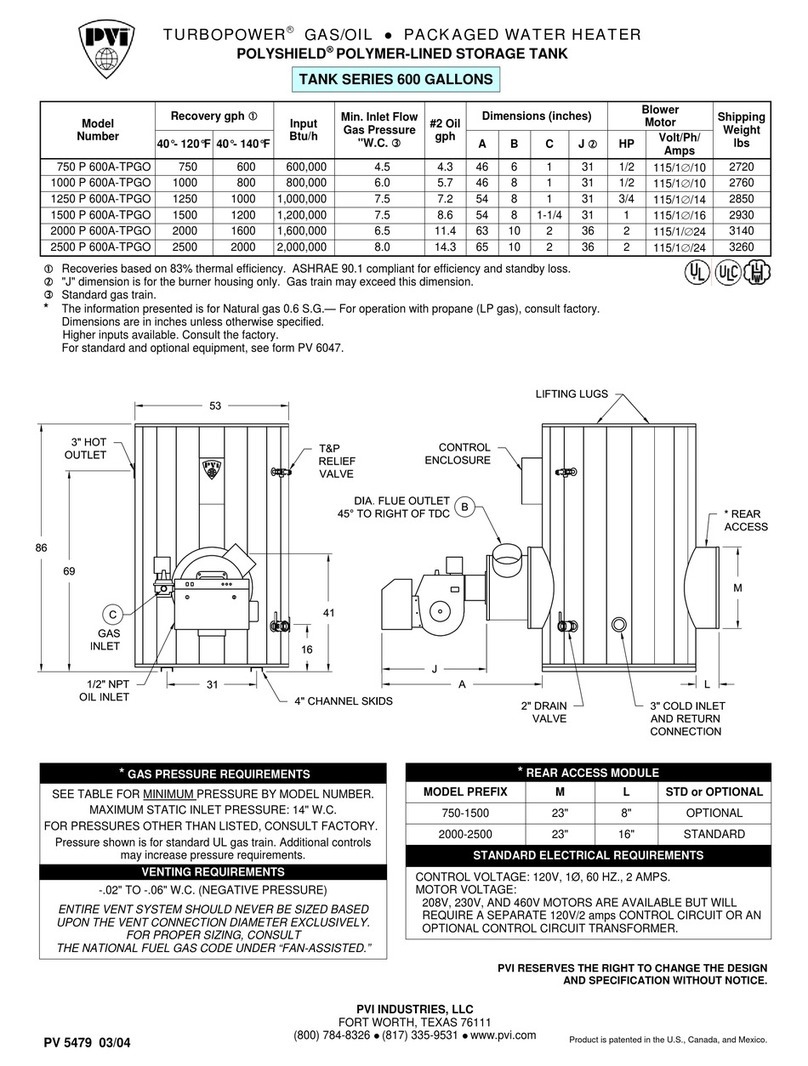

PVI Industries 1000P600A-TPGO User manual

PVI Industries

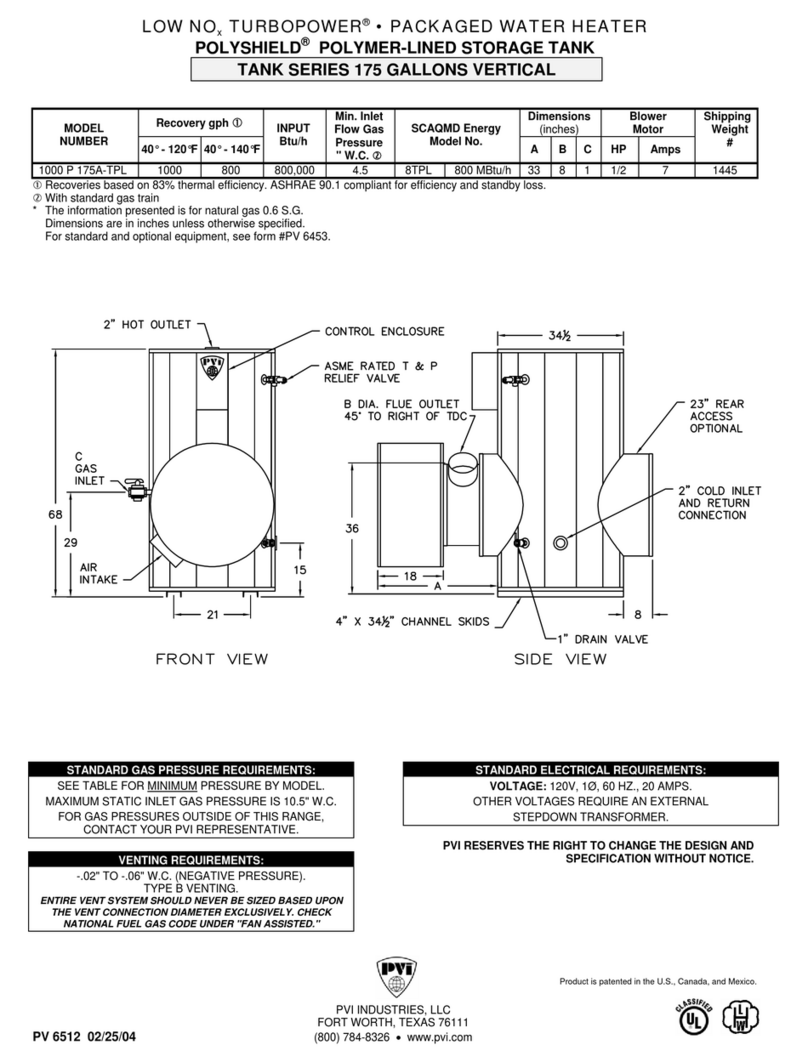

PVI Industries TURBOPOWER 1000 P 175A-TPL User manual

Popular Water Heater manuals by other brands

Kenmore

Kenmore 153.582400 Use & care guide

STIEBEL ELTRON

STIEBEL ELTRON Eltronom SHU 5 S Operating and installation instructions

clage

clage E-Mini Series Operating and installation instructions

Toyotomi

Toyotomi Oil Miser OM-180 installation manual

Bradford White

Bradford White EF Series Service manual

Eccotemp

Eccotemp 40-H Use & care manual

Dimplex

Dimplex ECSd125-580 Installation and user instructions

Dux

Dux 32FCR6N installation manual

Noritz

Noritz N-132M Owner's guide and installation manual

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions