1 Introducon

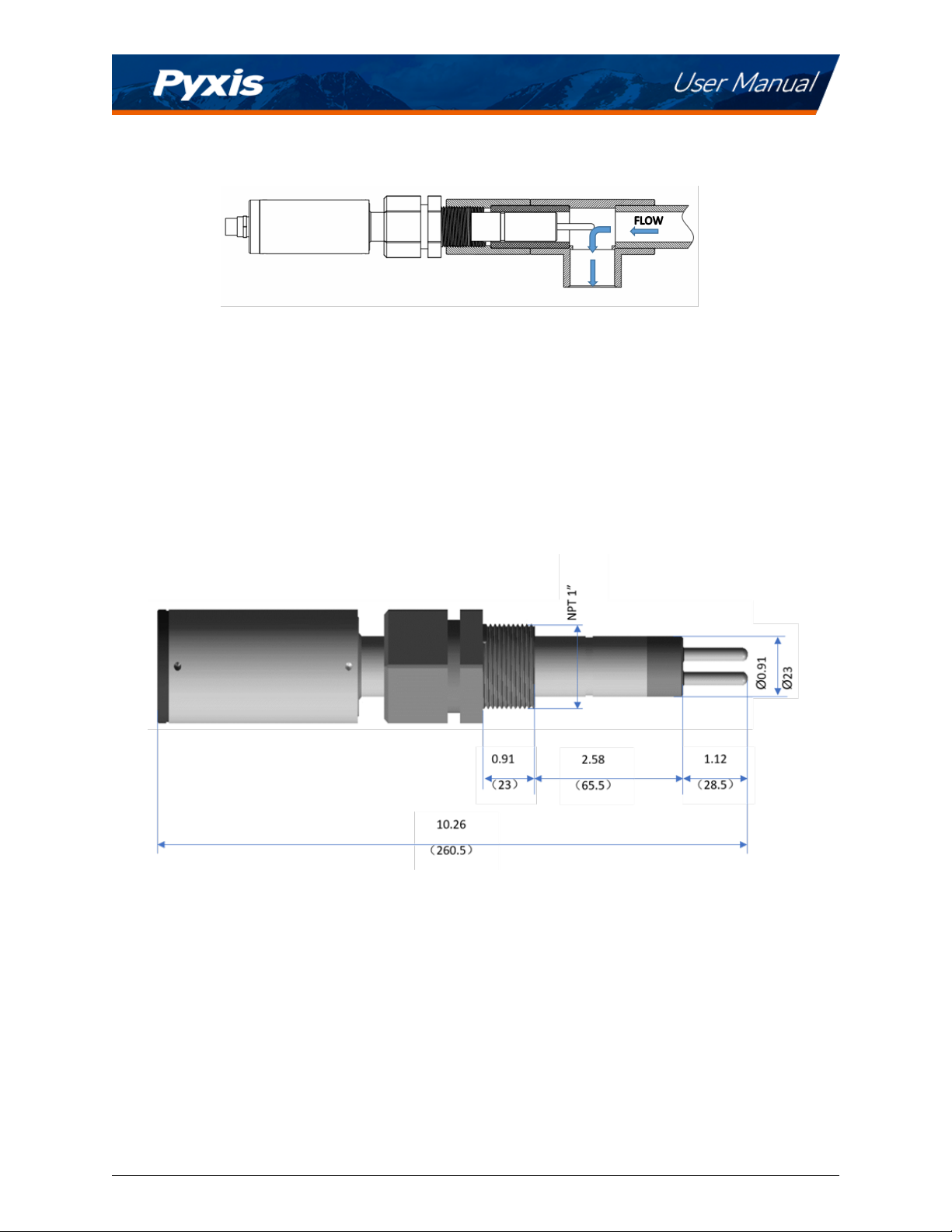

The Pyxis CR-200/300 corrosion sensor measures the metal corrosion rate in an aqueous environment based

on the principle of linear polarizaon resistance (LPR). A small polarizaon DC voltage is applied to two test

metal electrodes and the resulng current is measured by the sensor. The polarizaon resistance value is

calculated from the measured current and the applied polarizaon voltage. The metal corrosion rate in the

unit of thousandths of inch per year (or mils per year, MPY) is then determined as:

MP Y =B/Rp (1)

where Rp is the polarizaon resistance (LPR) and B the proporonal constant.

To calculate Rp originated from the electrochemical reacon at the metal water interface, the Pyxis CR-

200/300 sensor subtracts the soluon resistance Rs due to the test soluon conducvity from the total

resistance measured between the two test electrodes. The Pyxis CR-200/300 sensor accurately measures

the test soluon conducvity using the two test electrodes and the bipolar pulse technique, which has been

successfully used in other Pyxis conducvity sensors and handheld meters.

A challenge of using the LPR method to measure corrosion rate below 0.01 MPY is to measure electric

current in the range of pico and nano-amperes. The Pyxis CR-200/300 sensor adapts a range of techniques

that are pracced in our uorometers where low pico ampere current is measured. These techniques in-

clude electromagnec interference shielding, special analog circuit designs, and digital signal processing.

The proporonal constant B has a theorecal value for a given metal type and size. The Pyxis CR-200/300

assumes B equal to 1.24 MPY∙Ω for a 5 cm2mild steel electrode, which is a typical value that has been used

in many LPR corrosion researches. This proporonal constant may be also referred as to the alloy factor of

the test metal and normalized to 1.0 for the steel electrode for convivence. It can be adjusted by the user

to account for variaons in a real applicaon environment.

To determine the corrosion situaon of real process equipment is not a simple maer. The corrosion rates

for various metal surfaces contacng aqueous uids in a process depends on many parameters, including

the corrosivity pertaining to the chemistry of the aqueous uid, physical parameters such as temperature

and the velocity of the uid, and the metallurgical composion of the process equipment itself. Because

of this, the corrosion rate measured by the Pyxis CR-200/300 should not be used alone to predict or assess

the real corrosion rate of the process equipment. Nevertheless, the science of using the LPR technique to

quanfy the corrosion rate has been well established. The corrosion rate measured by the Pyxis CR-200/300

sensor can be used to understand the corrosivity trend of the aqueous uid over a period and its correlaon

to changes in the process parameters.

Measuring corrosion rate using a weight loss corrosion coupon is sll widely pracced in many industry

applicaons. LPR is an instantaneous method compared with the corrosion coupon method. It can indi-

cate a change in corrosion rate in a me scale of a few minutes. In theory, a me averaged corrosion rate

measured by the Pyxis LPR sensor should agree with that from the weight loss coupon method if both are

pracced according to the common pracces known in the industry. For monitoring mild steel corrosion

rate in an industrial cooling water system, one could also treat the LPR metal electrode itself as the weight

loss corrosion coupon and compare the corrosion rate calculated from the weight loss of the electrode to

the averaged LPR corrosion rate in order to calibrate the LPR corrosion rate by adjusng the alloy factor.

The electrochemical noise measurement has long been used to quanfy the localized corrosion or ping

corrosion rate. The Pyxis CR-200/300 sensor measures the short circuit electric current owing through the