MD 5850 Installation Manual

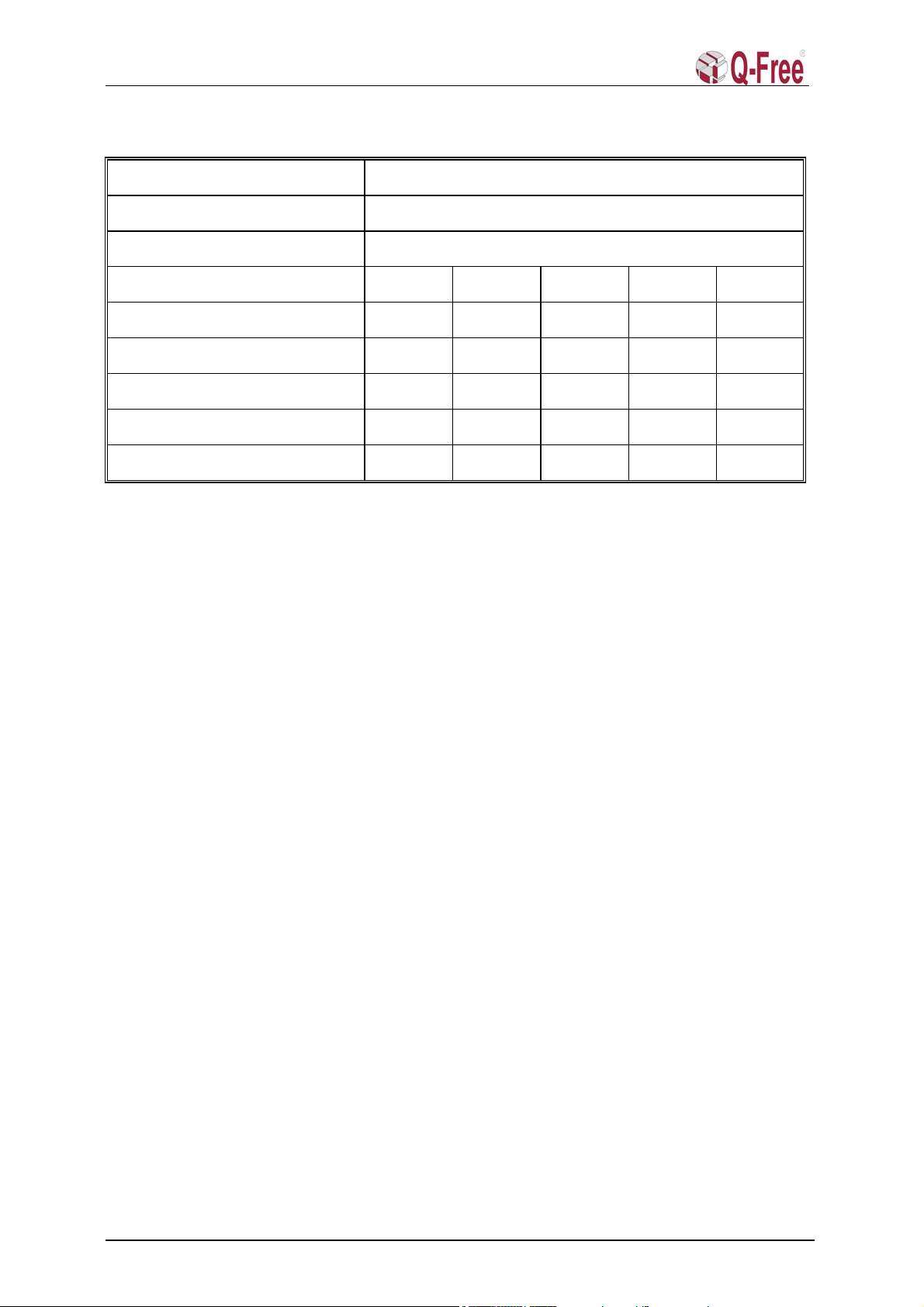

Table of Content

1INTRODUCTION ..............................................................................................................4

1.1 Abbreviations..........................................................................................................................4

2MULTIREADER HARDWARE INSTALLATION..........................................................4

2.1 MultiReader Cabinet Installation .........................................................................................4

2.2 Installation site .....................................................................................................................5

2.2.1 Toll plaza superstructure................................................................................................................. 5

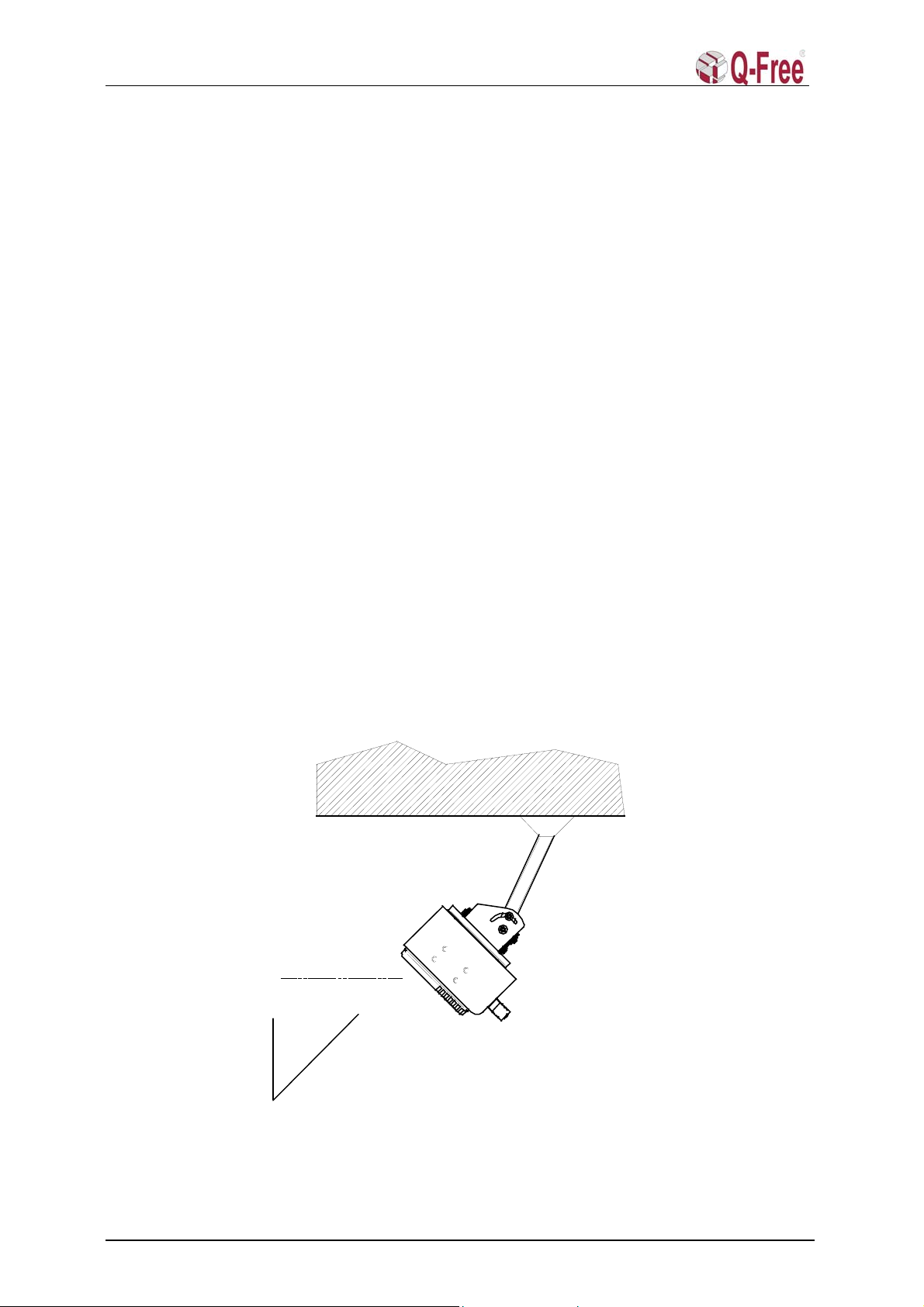

2.3 Basic installation ..................................................................................................................5

2.3.1 Mounting height and angle ............................................................................................................. 5

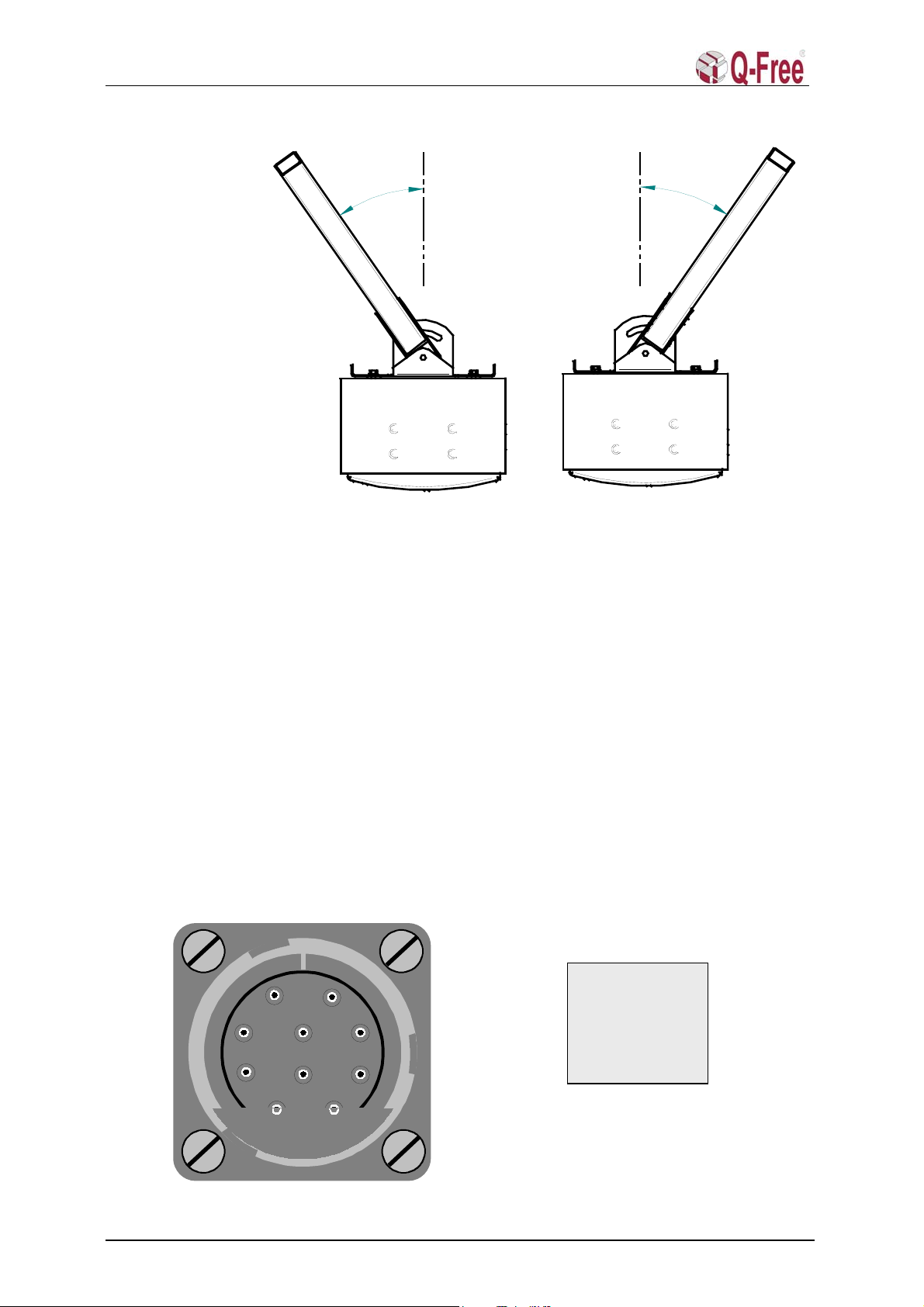

2.4 Square tube from customers construction........................................................ 6

2.4.1 Requirements for using the Uni-bracket ......................................................................................... 6

2.4.2 Fixing the square tube..................................................................................................................... 6

2.4.3 Square tube angles .......................................................................................................................... 6

2.5 Square tube sideways angles.................................................................................................. 6

3MULTIREADER CABLE INTERFACE..........................................................................7

3.1 MultiReader Power Supply and Data Interface ..................................................................7

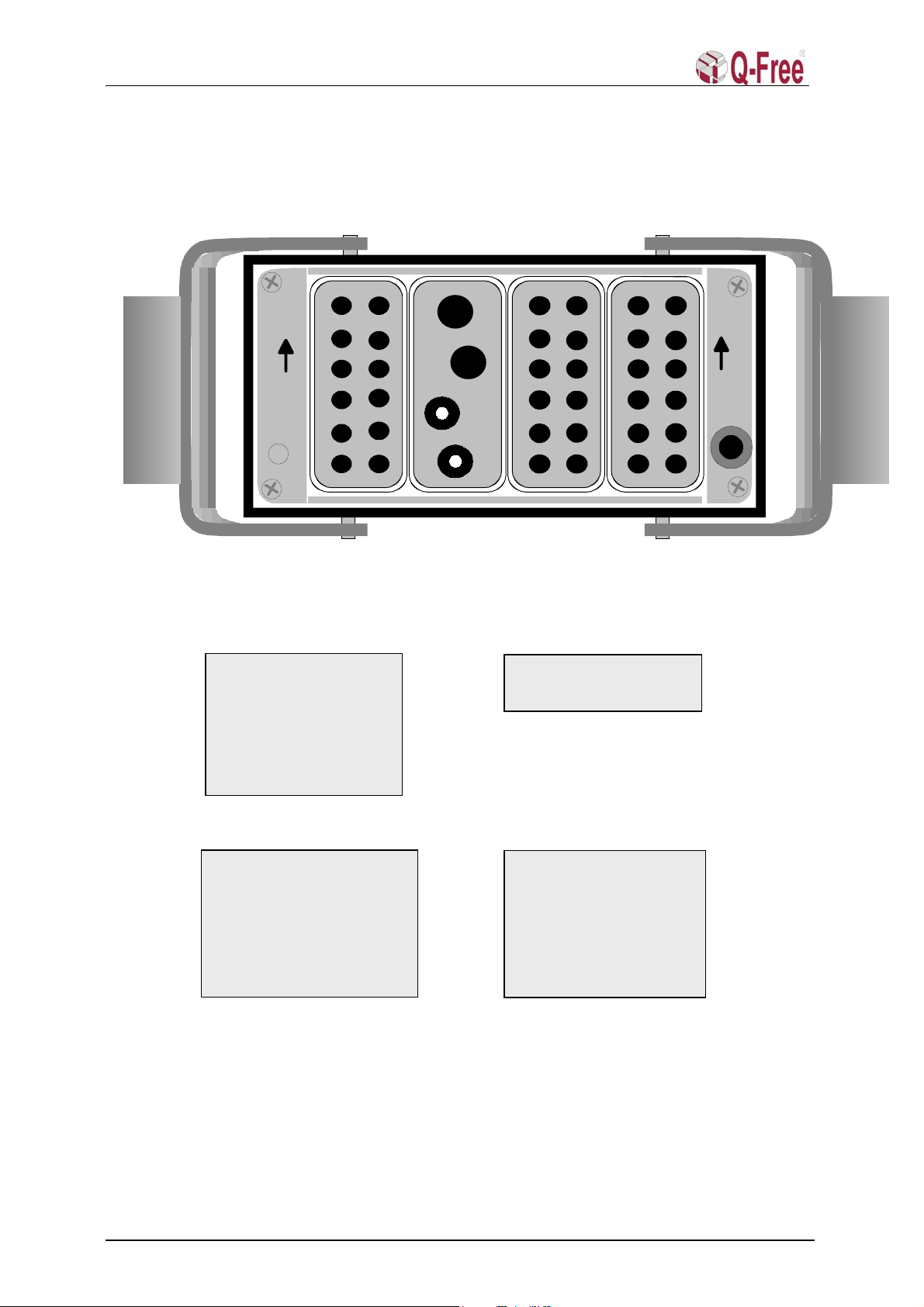

3.2 Circular Chassis Connector................................................................................................... 7

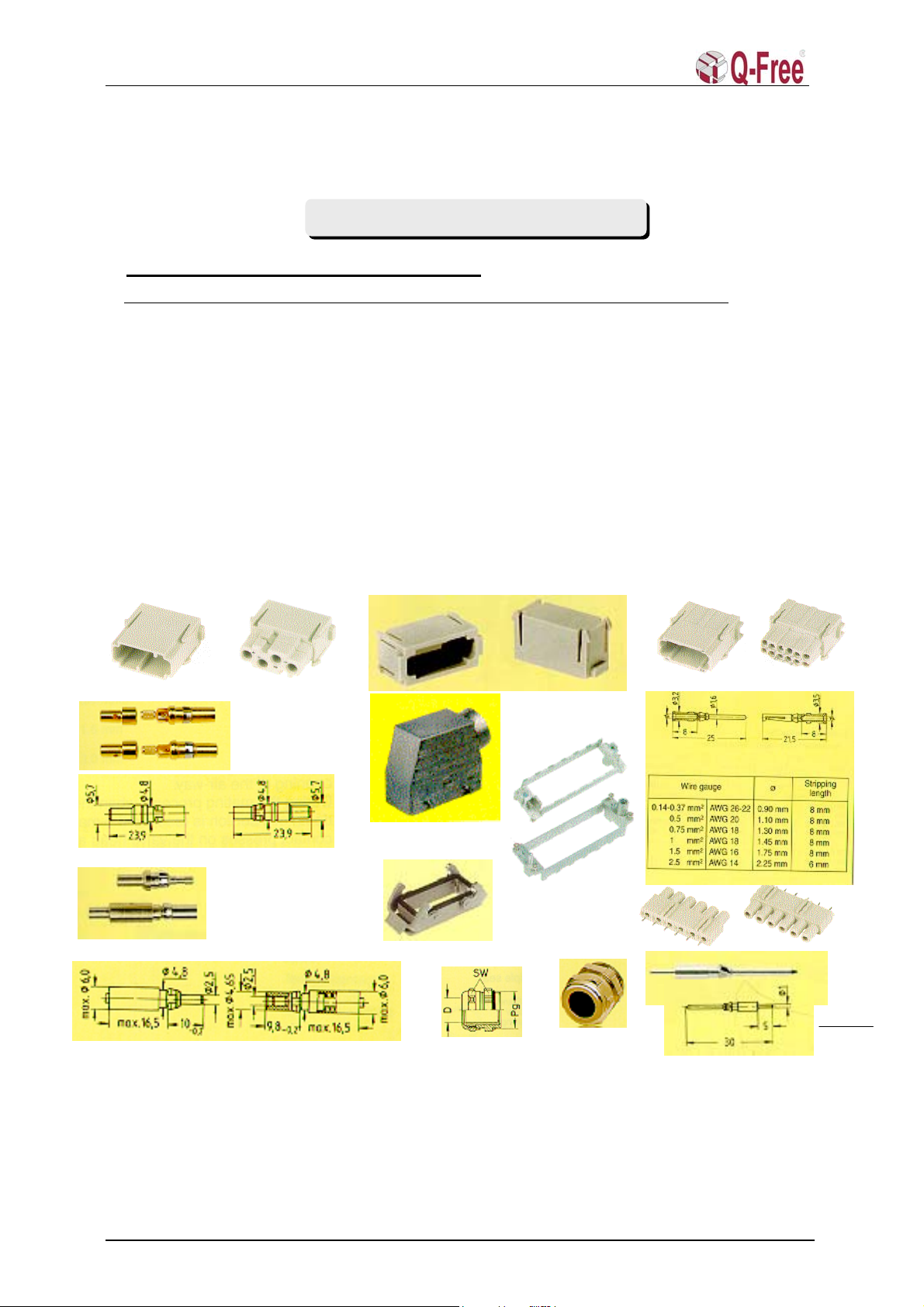

3.3 Han-Modular Connector .......................................................................................................8

3.4 Han-Modular connector assembly parts ..............................................................................9

3.5 Installation tools (preferred) ...............................................................................................10

4EXTERNAL CABLE INTERFACE................................................................................11

4.1 Cable dimensions.................................................................................................................. 11

4.2 Circular connector ...............................................................................................................11

4.3 Han-Modular connector ...................................................................................................... 12

5MULTIREADER SOFTWARE INSTALLATION.........................................................12

5.1 How to flash the MV162-12 and MVME162P CPU-card through the serial port

(console)............................................................................................................................................12

5.1.1 Loading the software and flashing................................................................................................ 13

5.1.2 Closing up..................................................................................................................................... 14

5.1.3 Make new startup file ................................................................................................................... 15

5.1.4 bootChange................................................................................................................................... 15

5.2 How to flash the MultiReader via Ethernet. ......................................................................15

6TEST WITH APPLICATION SW ...................................................................................16

6.1 PC/ Terminal Connection to MultiReader......................................................................... 16

6.2 PC/ Terminal connection to MultiReader through a TPC ............................................... 16

6.3 Testmode ...............................................................................................................................17

6.4 Format ...................................................................................................................................17

7TEST WITH TEST TAGS AND INSTRUMENTS.........................................................18

7.1 Downlink signal test .............................................................................................................18

7.1.1 Test Tag measurements. ............................................................................................................... 18

7.1.2 Measuring the MultiReader footprint with a test tag. ................................................................... 18

7.1.3 Spectrum Analyser measurement. ................................................................................................ 19

Q-Free®ASA 645-054-1999 rev.4 2 of 20