4

IMPORTANT SAFEGUARDS AND WARNINGS

SAFETY FIRST!

Proper safety precauons such as safety shoes, eyeglasses, gloves, earplugs, etc. must be used when installing, servicing, or using the QLK® Wheelchair

Docking System.

READ AND UNDERSTAND THE MANUALS!

Do not install, operate, or use this product unl you read and fully understand all the instrucons in the installaon manual, user and care manual, and

in-vehicle placard. Place or ax the provided installaon manual, use and care manual, and in-vehicle placard in an accessible and visible locaon for the

end user.

TRAINED PERSONNEL ONLY!

The QLK® Wheelchair Docking System and its components must be installed and serviced by an experienced and trained technician and operated by a

trained person who fully understand the operaon and use of the system and when the system is, or is not, operang as required. Improper use of the

QLK® Wheelchair Docking System may result in personal injury.

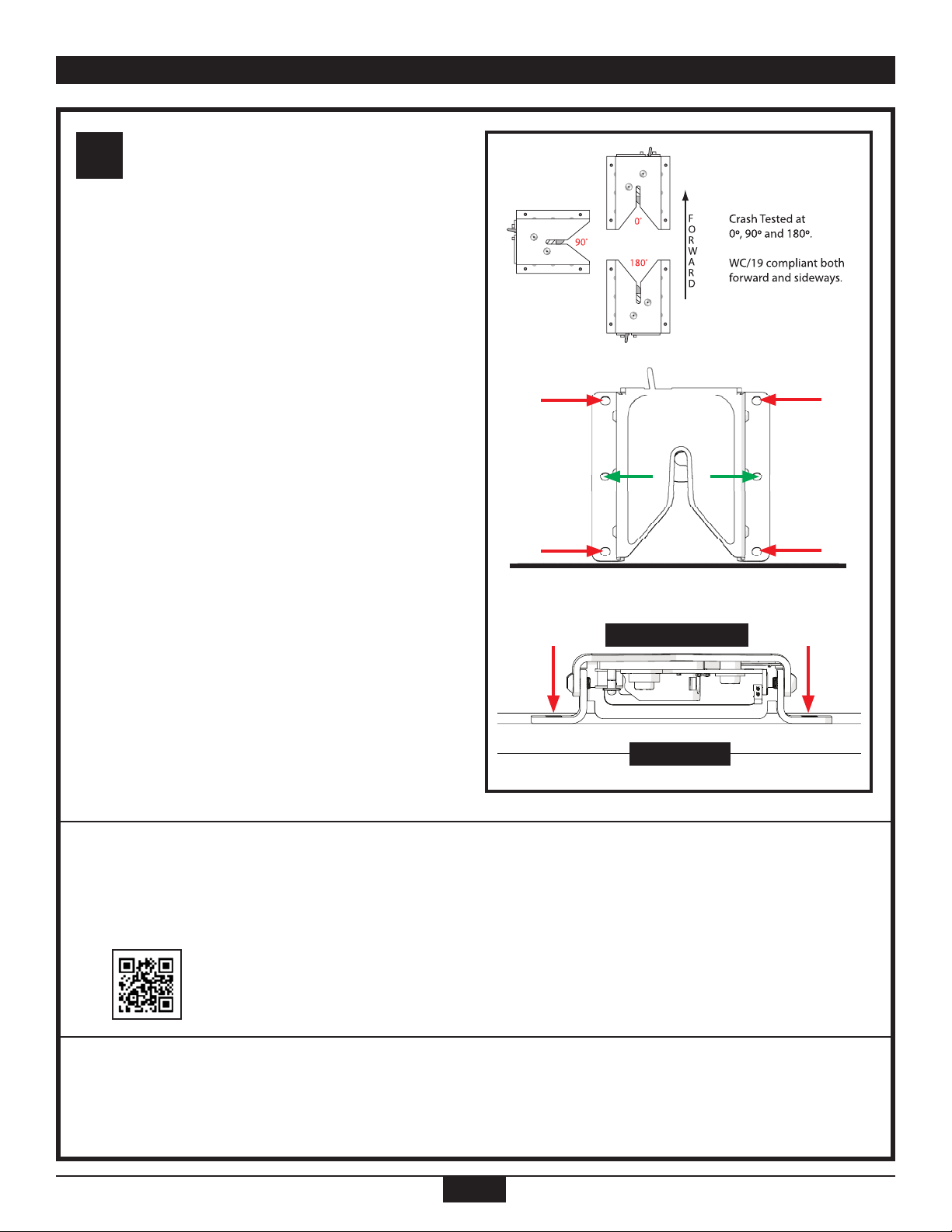

VERIFY SUITABILITY OF VEHICLE STRUCTURE!

Inspect and verify the underside locaon of the vehicle oor, ulies, frames, cross-members, fuel tanks and other possible obstrucons that may

aect the proper installaon of the QLK® Wheelchair Docking System. Do NOT relocate any vehicle equipment without consulng with the vehicle

manufacturer and do NOT install anchorages or any other system components into faulty or non-durable materials such as corroded metal, wood, plasc,

or berglass panels.

VERIFY WHEELCHAIR ANCHORAGE POINT STRENGTH!

The QLK® Wheelchair Docking System plaorm anchorages and hardware must be installed with a minimum torque requirement of 30 FT-LBS directly

into the vehicle oor structure with reinforcement, as required. The installer must ensure that the wheelchair anchor installaon points do not, as

individual anchors or as a complete system, damage or weaken the vehicle structure.

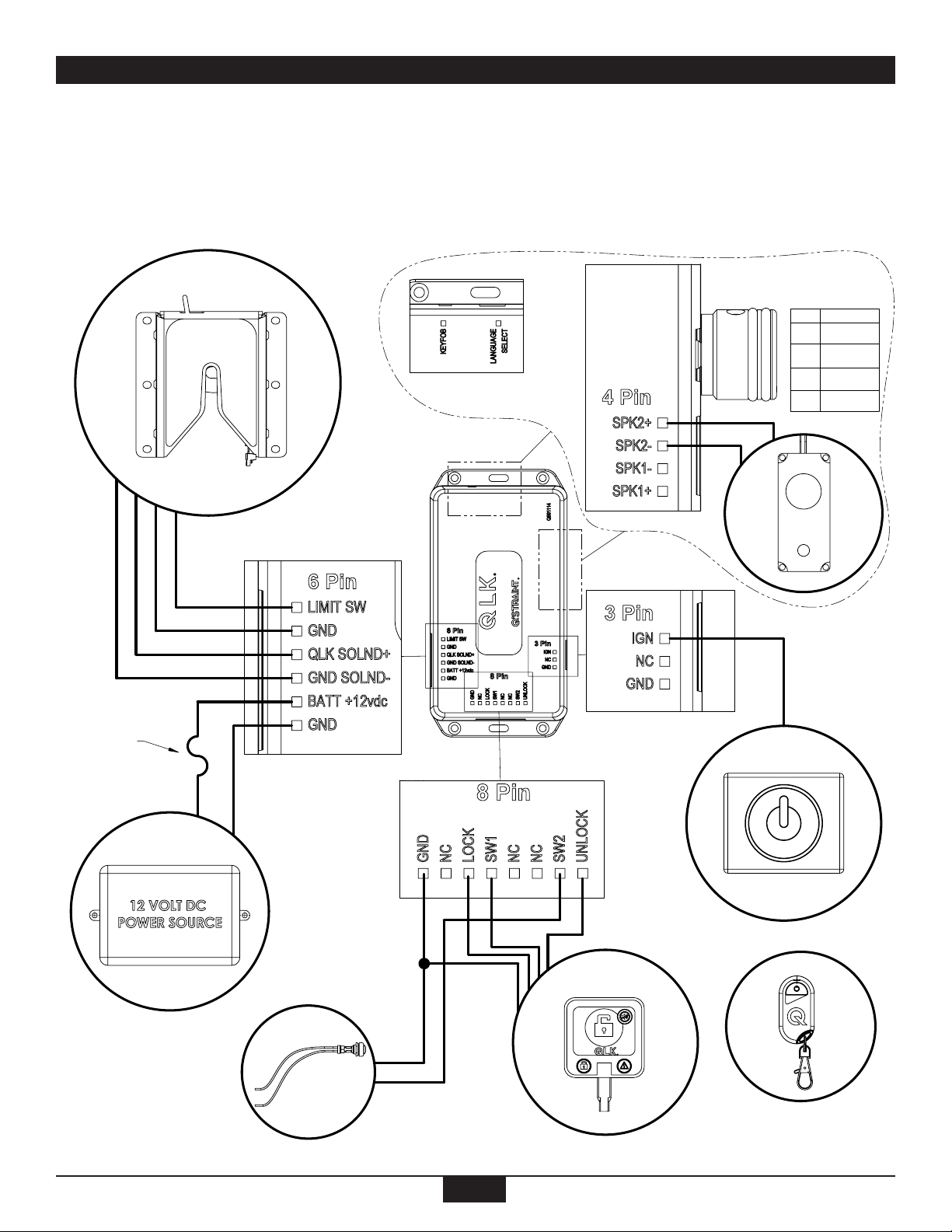

VERIFY ELECTRICAL WIRE ROUTING!

Determine the most eecve and protecve roung methods for the electrical wires so to prevent pinch points, wire chang, sharp edges, or corroded or

exposed metals since any of these condions could damage the wires and cause a malfuncon of the QLK® Wheelchair Docking System.

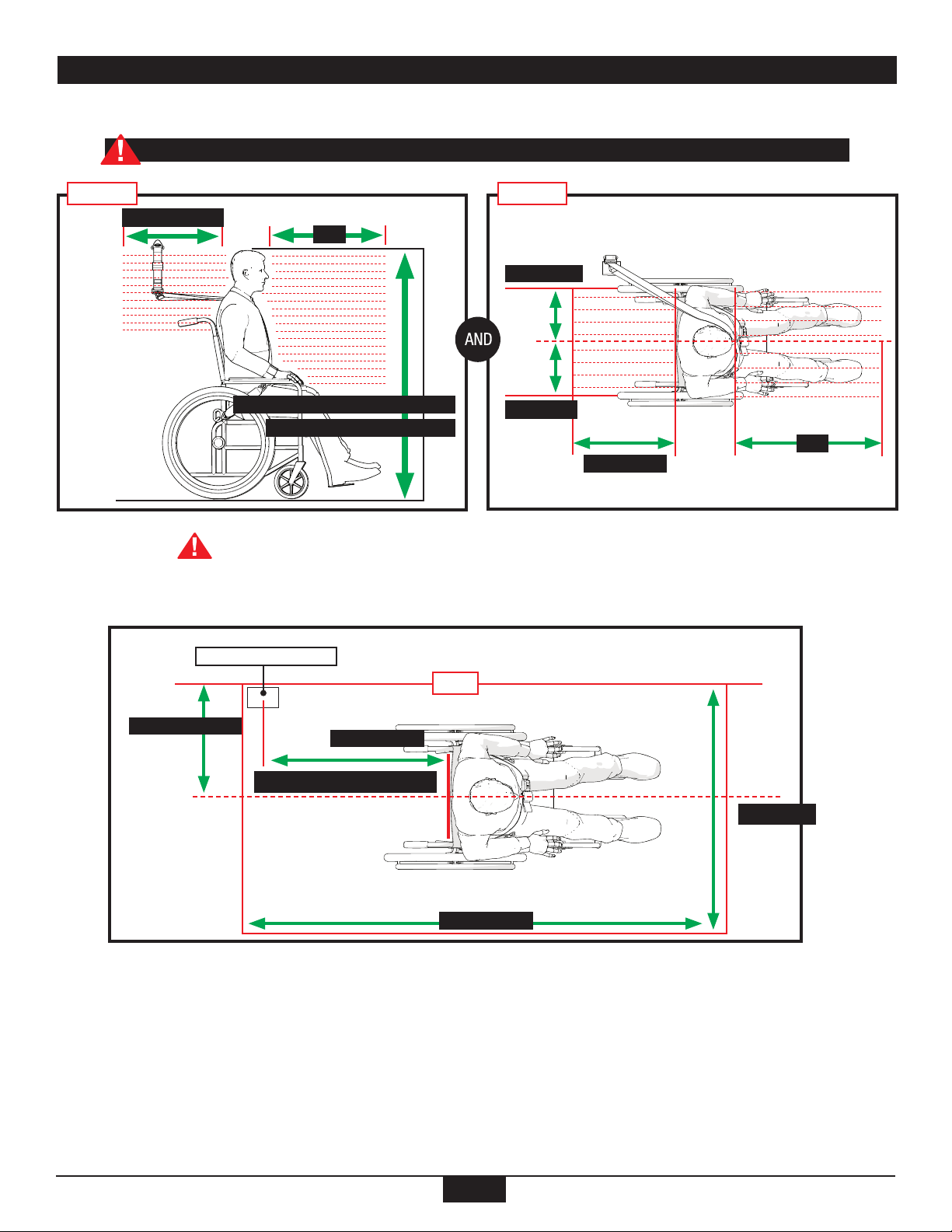

SUPPORT WHEELCHAIR SPACE!

The QLK® Wheelchair Docking System wheelchair space, dened as the surface where the wheelchair rests, must include ooring frames, or cross-

members, capable of supporng the expected weight of the wheelchair, occupant, and any addional equipment that may be transported. The installer

is responsible for ensuring that the wheelchair space structure, or any cross bracing, complies with applicable regulaons, standards, and performance

requirements for the vehicle.

OPTIMIZE WHEELCHAIR LOCATION!

The QLK® Wheelchair Docking System must be posioned to allow for proper wheelchair access and space. Remove any obstrucons from the rear,

front, le and right of the wheelchair area that prevents proper securement of the wheelchair and occupant. Do not allow elevaon or an incline of the

wheelchair as it will interfere with proper securement and may create risk for wheelchair p-over.

FORWARD FACING ONLY!

This QLK® Wheelchair Docking System must only be installed for use with forward-facing wheelchairs and occupants.

VERIFY SAFE AIRBAG LOCATION!

Airbags should only be used as an added safety device in conjuncon with the QLK® Wheelchair Docking System. Airbags can cause serious injury if the

wheelchair occupant sits too close to the airbag module. Do not disable the airbag without rst contacng the vehicle manufacture.

VERIFY OCCUPANT RESTRAINT INTEGRITY!

The occupant restraint (lap and shoulder belt) must be installed into a vehicle frame structure using the provided hardware. The belts must be protected

from contacng any sharp edges of any vehicle components. Improper installaon or posioning of the occupant restraint (lap and shoulder belt) may

place the passenger at a greater risk of serious injury or death during normal vehicle travel, emergency maneuvers, or a crash.

DO NOT MODIFY!

The QLK® Wheelchair Docking System is a completely integrated system. Do NOT alter or modify any poron of the system and do not interchange or

substute any components or subassemblies from dierent manufacturers as they are not compable and such changes may compromise the funconality

of the unit, occupant safety, or load distribuon. Any deviaon from these requirements is the sole responsibility of the installer or user.

USE Q’STRAINT PRODUCTS ONLY!

Only use Q’STRAINT approved replacement components and subassemblies for the QLK® Wheelchair Docking System.