QBD COOLING SYSTEMS INC.

QBD.COM

3

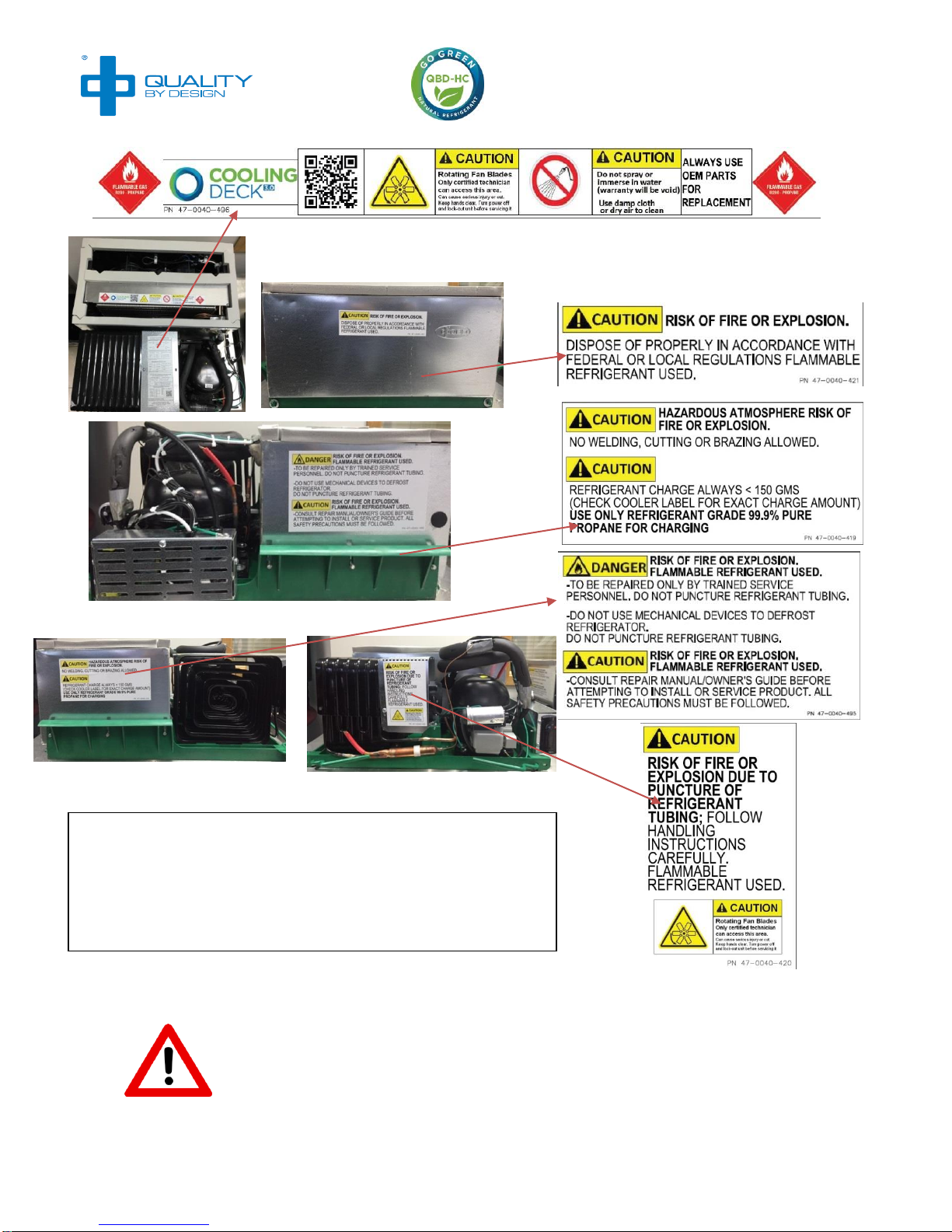

-Always use QBD supplied OEM parts only. Use of non-OEM

parts will not only void the warranty but may also lead to a fire,

explosion, serious injury or death.

------------------------------------------------------------------------------------------

-Only trained and certified technician, for Hydrocarbon

systems, should service these coolers.

------------------------------------------------------------------------------------------

-Use extreme caution and follow all local/regional codes for

transportation or relocation of Hydrocarbon coolers.

1. DISCLAIMER

Please read this manual carefully before

installing, operating and servicing this QBD

R-290 Hydrocarbon cooler. Improper

installation, operation and maintenance of

cooler can cause damage to the cooler, fire,

explosion, severe injuries or death.

This manual must be kept in an accessible

location for easy reference during

installation, operation, maintenance and

service.

QBD neither assumes nor authorizes any

representative or other person to assume

for it any obligation or liability in connection

with the QBD product, its sale, operation or

use other than such as is expressly set forth

herein.

Exclusions from Warranty Coverage

QBD warranty does not cover:

a) Spoilage of products, loss of sales,

incidental, indirect, consequential or

special damages, or any injury, loss,

cost or expense directly or indirectly

sustained in connection with the

Product, its sale, operation or use.

b) without limiting the generality of the

foregoing, spoilage of products, loss of

sales, incidental, indirect, consequential

or special damages, or any injury, loss,

cost or expense arising directly or

indirectly from fungi or fungal

derivatives sustained in connection with

the Product, its sale, operation or use.

c) glass (Door & Side Window) or light

bulb breakage (Fluorescent Tubes or

Light Bulbs), castors, hinges, magnetic

gasket, sliding door wheels, (Header &

Header Lens),door tracks, decals,

(Power Cord, Starters) and parts of

normal wear and tear.

d) any product that has been subject to

misuse, neglect, alteration, tampering,

accident, or to any damage to any

product caused during transportation,

improper installation (except when the

Product is installed by employees of

QBD), flood, fire, water damage,

burglary, terrorism or acts of God.

Limited Warranty

QBD warrants to the original purchaser at

the location of original installation of the

Product that the Product is free from defects

in material or workmanship under normal

use and service for a period as defined in

warranty terms from the date of shipment.

QBD’s obligation under this warranty shall

be limited to repairing or replacing at QBD’s

option, any part of such product, which

proves thus defective and which upon

examination by QBD and to its satisfaction

to be defective shall be determined to be

defective. Notwithstanding this assumption