- 2 -

7.1 Preparation data .....................................................................................................................................- 66 -

7.2 Fault diagnosis.......................................................................................................................................- 66 -

7.3 Front wheel ............................................................................................................................................- 67 -

7.4 Direction handle.....................................................................................................................................- 69 -

7.5 Front fork...............................................................................................................................................- 69 -

7.6 Radiator/expansion kettle components ..................................................................................................- 70 -

8 Rear wheel/rear suspension ..............................................................................................................................- 73 -

8.1 Preparation data .....................................................................................................................................- 73 -

8.2 Fault diagnosis.......................................................................................................................................- 73 -

8.3 Rear wheel .............................................................................................................................................- 74 -

8.4 Rear shock absorber/rear rocker ............................................................................................................- 75 -

9 Lubrication system ...........................................................................................................................................- 78 -

9.1 Preparation data .....................................................................................................................................- 78 -

9.2 Fault diagnosis.......................................................................................................................................- 78 -

9.3 Oil pump ................................................................................................................................................- 79 -

10 Carburetor.......................................................................................................................................................- 82 -

10.1 Preparation data ...................................................................................................................................- 82 -

10.2 Fault diagnosis.....................................................................................................................................- 82 -

10.3 Disassembly of carburetor ...................................................................................................................- 83 -

10.4 Installation of carburetor......................................................................................................................- 85 -

10.5Adjustment of carburetor......................................................................................................................- 85 -

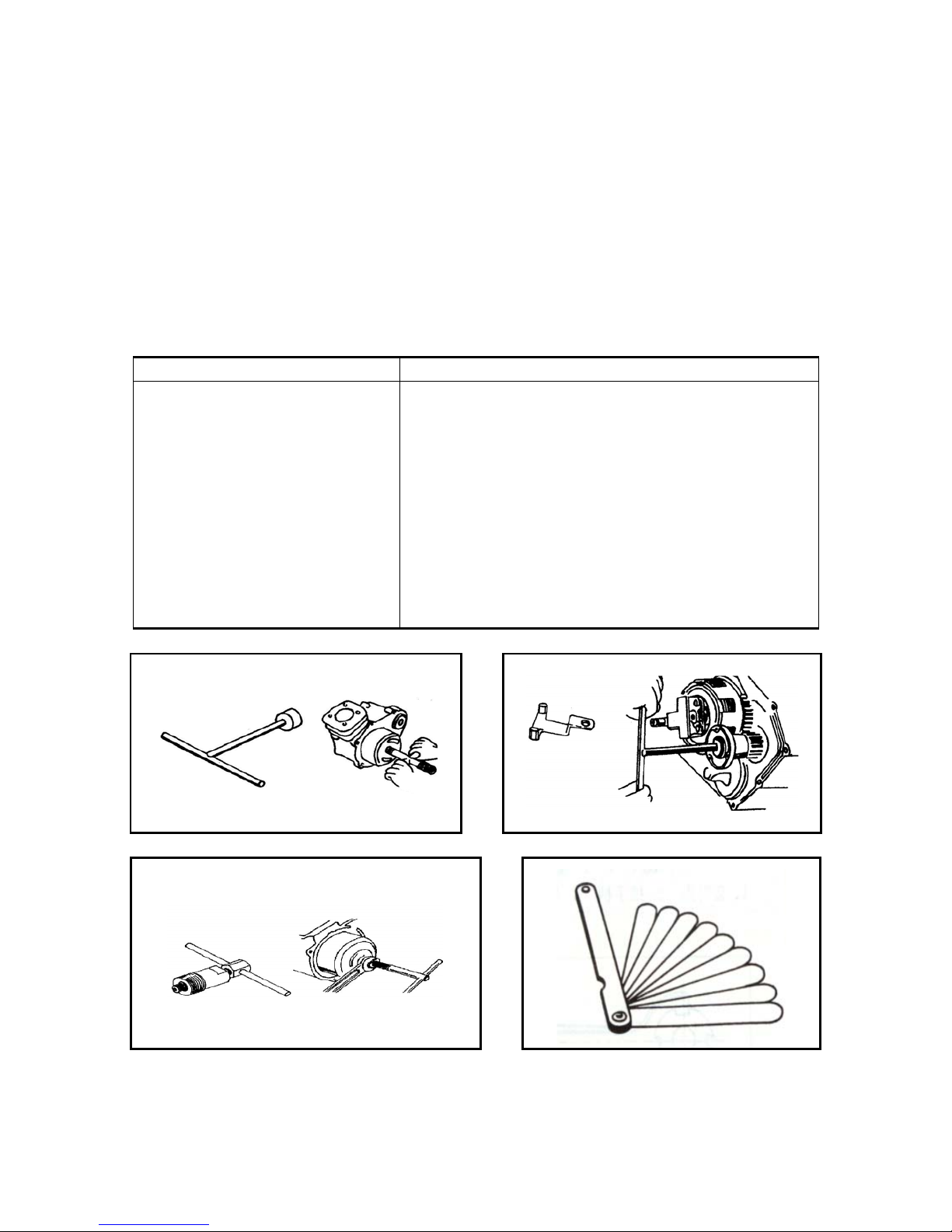

11 Cylinder cover/air cylinder/piston ..................................................................................................................- 87 -

11.1 Preparation data ...................................................................................................................................- 87 -

11.2 Fault diagnosis .....................................................................................................................................- 88 -

11.3 Cylinder head.......................................................................................................................................- 88 -

11.4 Examination on cylinder head .............................................................................................................- 90 -

11.5 Valve ....................................................................................................................................................- 91 -

11.6 Examination on valve ..........................................................................................................................- 91 -

11.7 Replace the valve guide .......................................................................................................................- 92 -

11.8 Shaping of Valve Seat ..........................................................................................................................- 93 -

11.9 Installation ...........................................................................................................................................- 95 -

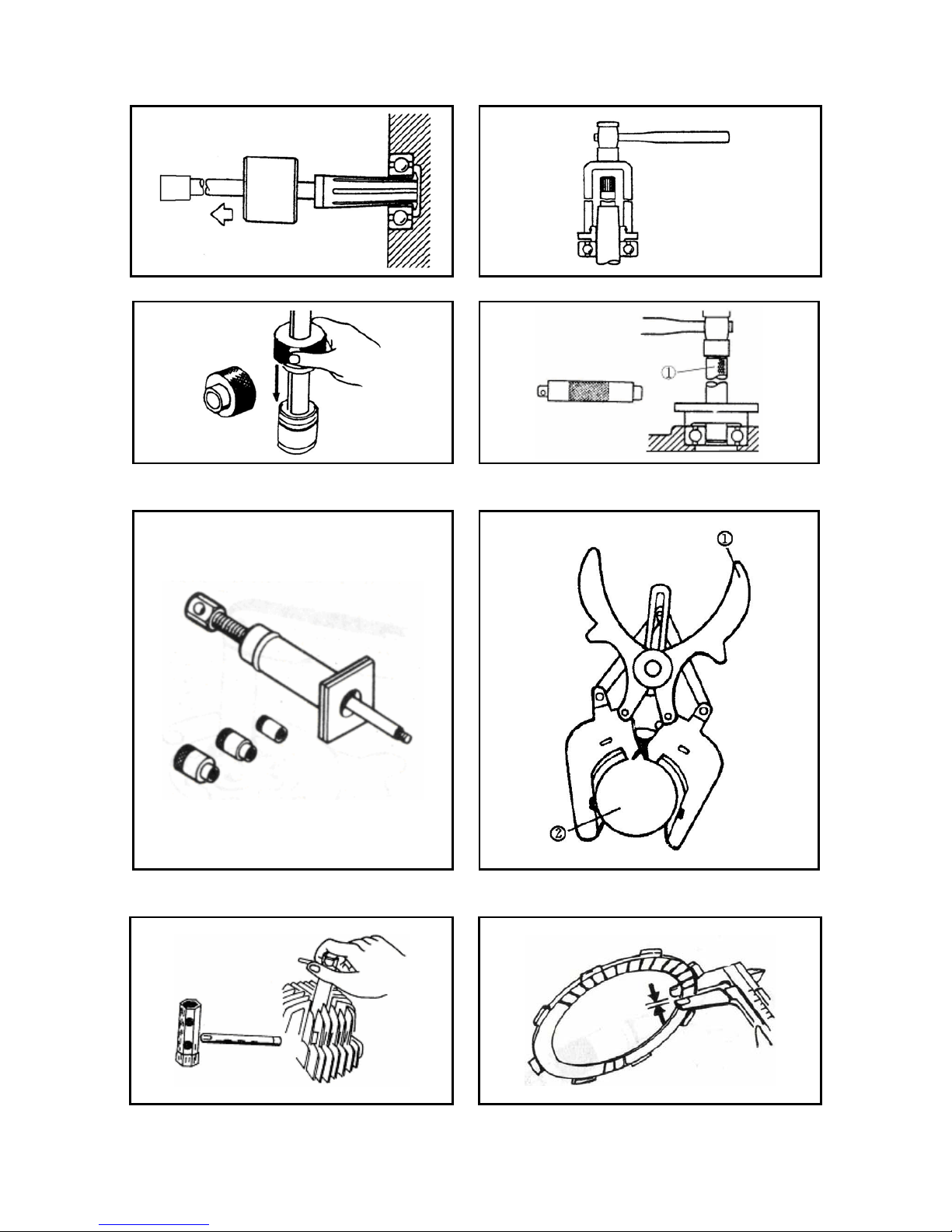

12 Crankcase/clutch/actuating lever ....................................................................................................................- 97 -

12.1 Preparation data ...................................................................................................................................- 97 -

12.2 Fault diagnosis.....................................................................................................................................- 98 -

12.3 Cylinder body ......................................................................................................................................- 98 -

12.4 Piston ...................................................................................................................................................- 99 -

12.5 Installation of piston ..........................................................................................................................- 101 -

12.6 Installation of the air cylinder............................................................................................................- 102 -

13 Drive disk/Clutch/Driven Wheel ..................................................................................................................- 104 -

13.1 Preparation data .................................................................................................................................- 104 -

13.2 Fault diagnosis...................................................................................................................................- 104 -

13.3 Left crankcase cover ..........................................................................................................................- 105 -

13.4 Drive disk ..........................................................................................................................................- 105 -