9

PM-940M 10-2016 v1.indd

POWER-UP PROCEDURE

Depending on the available 220V wall outlet, install a

6-15 or 6-20 plug on the mill power cord. Be sure the

green/yellow ground wire is attached (it may be tagged

PE = Protective Earth).

Before connecting power be sure that:

The spindle (main) motor switch, lower right of the

control panel, is set to S.

The Z-axis crank handle is removed.

There are no clamps or locks on moving parts.

The gearbox contains oil – check the sight glass at

right of the headstock.

The gear levers are set for the lowest speed: Hi-Lo

to L, 1-2-3 to 1.

The gears are fully engaged – hand rotate the spin-

dle forward and back while applying light pressure

on each lever, listening for the click as gears en-

gage.

Referring to Section 3, test the mill as follows:

Connect power.

Be sure the E-stop (Emergency) button is not pushed

in (it pops out when twisted clockwise), Figure 3-1.

Press the green Power button. Expect to hear a click

from the control box – this is a contactor energizing.

The power lamp should light.

Check the emergency function by pressing the E-

stop button. The power lamp should go out, de-en-

ergizing the contactor, disabling all electrics.

If this doesn’t happen, the E-stop function is defec-

tive, and needs attention

Restore power by twisting the E-stop button firmly

clockwise until it pops out.

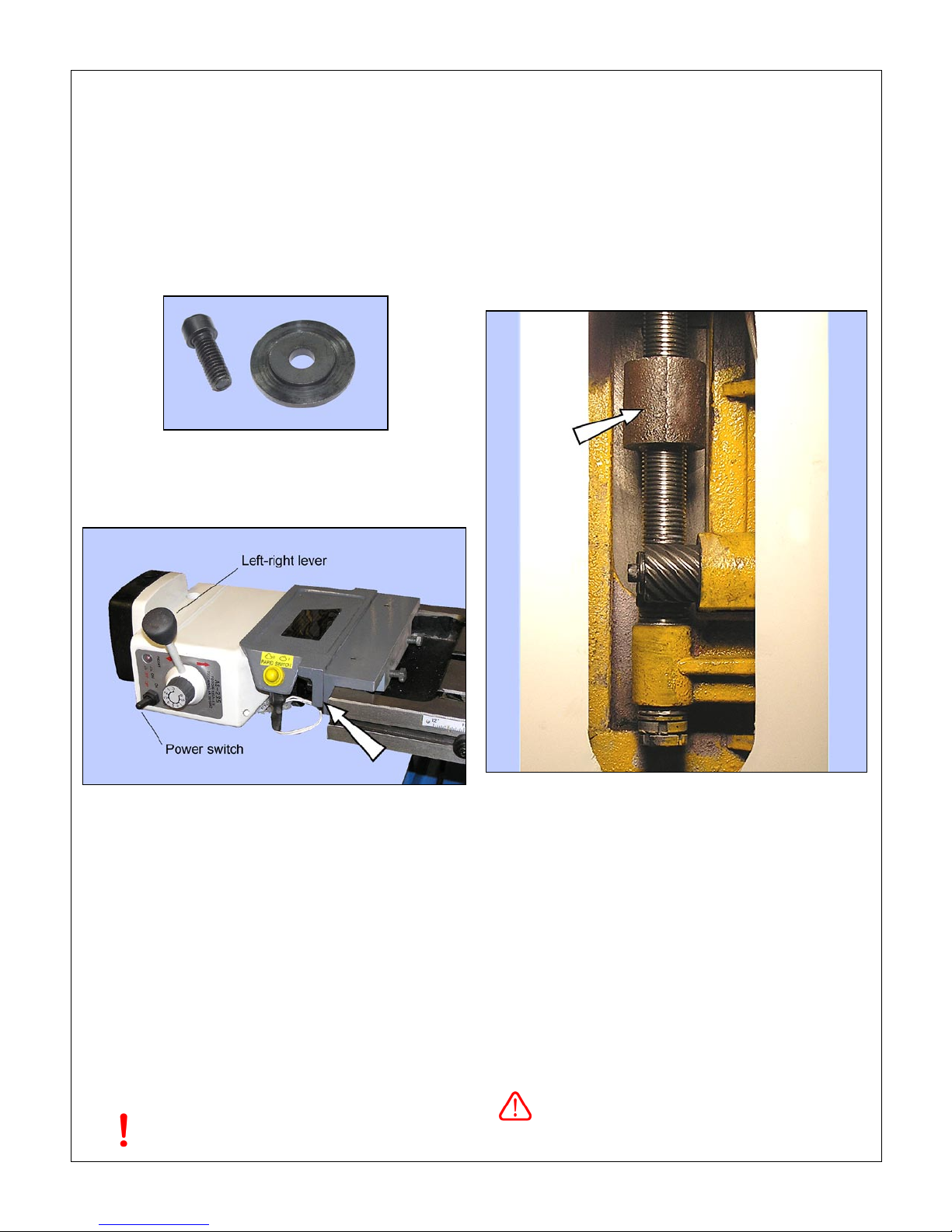

Center the Left-Right lever on the table power feed.

Rotate the speed control knob fully counter-clock-

wise, then clockwise about 45 degrees.

Switch on the table motor. Test the power traverse

function by selecting Left traverse, followed by stop

(center), then Right.

Check that the limit switch assembly stops motion

correctly when actuated by the left and right stop

blocks, Figure 3-4.

Crank handle removed? Headstock locking levers

loose? Run the headstock up the column, Z-axis

motor switch (bottom left) set to Up. Check that the

motor stops as the upper limit switch is actuated,

Figure 2-11.

Check for no obstructions, then run the headstock

down to the lower limit.

Expect to hear a click from the control box when

Up is selected. This is one of the two Z-axis motor

1.

2.

3.

4.

5.

6.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

contactors energizing. A similar click from the other

contactor should be heard when Down is selected.

Figure 2-11 Z-axis (elevation) limit switches

These are actuated by the block attached to the headstock

TEST RUN PROCEDURE

Do not leave the machine unattended during this

procedure

Gear levers set to L and 1 (90 rpm)? Gears fully

engaged?

Test the spindle motor by setting the motor switch,

upper right on control box panel, to F (forward) and

R (reverse) in turn.

Run the spindle at 90 rpm for a few minutes, then

stop.

Select each of the available speeds in turn (L-2, L-3,

H-1, etc.). Check gear engagement each time, then

run for a few minutes.

Optional

After a few hours of run time you may wish to drain the

oil to flush out any residue from the manufacturing pro-

cess. This may result in smoother, quieter running, to-

gether with longer service life.

Refill the gearbox with the recommended oil, see

Section 4

The machine should now be ready for normal opera-

tions.

1.

2.

3.

4.